Abstract

The journey in the packaging of microelectronics with intense heat transfer rate and miniaturization are continuing. To satisfy the above criteria, the thermal interface materials (TIMs) classified into two categories. One should have high thermal conductivity, high dielectric constant or low electrical conductivity, and high mechanical strength inclusive of processability. Other is high thermal conductivity along with electrical conductivity properties. In this review, we have reported the idea and concept behind TIMs including varieties of TIMs and their significance. We also referred to a few progressive techniques of thermally conductive filler synthesis and preparation of epoxy-based thermal conductive TIMs. Some basic thermal conductivity models have been adopted to conceptualize the thermal conductivity mechanism along with various types of thermal conductivity measurement principle. We also explore how the morphological characteristics of different filler system affect the thermal conductivity of the epoxy matrix. In addition to thermal performance and efficiency, the reliability testing of TIM during package development stage is analyzed in which the design iteration has been considered for long-term packages and feasibility study. The specified utility of TIMs in different electronics application has been described according to properties of fabricated composite with the high-performance interface. The future perspectives of electronics packaging in advanced and miniaturized application for epoxy-based TIMs are briefly elaborated.

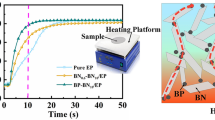

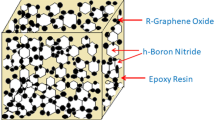

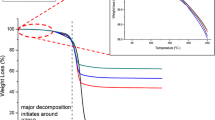

Graphic abstract

Similar content being viewed by others

References

Agari Y, Ueda A (1997) Thermal diffusivity and conductivity of PMMA/PC blends. Polymer 38:801–807

Agari Y, Uno T (1986) Estimation on thermal conductivities of filled polymers. J Appl Polym Sci 32:5705–5712

Ahn K, Kim K, Kim J (2015) Thermal conductivity and electric properties of epoxy composites filled with TiO2-coated copper nanowire. Polymer 76:313–320

An F, Li X, Min P, Li H, Dai Z, Yu ZZ (2018a) Highly anisotropic graphene/boron nitride hybrid aerogels with long-range ordered architecture and moderate density for highly thermally conductive composites. Carbon 126:119–127

An F, Li X, Min P, Liu P, Jiang ZG, Yu ZZ (2018b) Vertically aligned high-quality graphene foams for anisotropically conductive polymer composites with ultrahigh through-plane thermal conductivities. ACS Appl Mater Interfaces 10(20):17383–17392

ASTM E1530-11 (2011) Standard test method for evaluating the resistance to thermal transmission of materials by the guarded heat flow meter technique

ASTM C714 (2003) Standard test method for thermal diffusivity of carbon and graphite by a thermal pulse method, 2003 annual book of ASTM standards, vol 15

Astm, ASTM (2006) D5470-06: standard test method for thermal transmission properties of thermally conductive electrical insulation materials. In: Book of Standards, 10

ASTM Committee E37 on Thermal Measurements (2007) Standard test method for determining thermal diffusivity by the flash method. ASTM International, West Conshohocken

ASTM Standard E2585-09 (2009) ASTM Standard E2585-09: standard practice for thermal diffusivity by the flash method. ASTM Int

Barako MT, Gao Y, Won Y et al (2014) Reactive metal bonding of carbon nanotube arrays for thermal interface applications. IEEE Trans Compon Packag Manuf 4:1906–1913

Bharatham L, Fong WS, Torresola J, Koang CC (2005) Qualification of phase change thermal interface material for wave solder heat sink on FCBGA package. In: Proceedings of 7th electronic packaging technology conference, 2005. EPTC 2005, vol 2. IEEE, pp 6-pp

Bischak G, Vogdes C (1998) Thermal management design criteria and solutions. In: Wescon/98. IEEE, pp 188–193

Blazej D (2003) Thermal interface materials. Available from: http://www.electronics-cooling.com/2003/11/thermal-interface-materials

Bolon DA (1995) Epoxy chemistry for electrical insulation. IEEE Electr Insul Mag 11:10–18

Burg BR, Kolly M, Blasakis N et al (2015a) Steady-state low thermal resistance characterization apparatus: the bulk thermal tester. Rev Sci Instrum 86:124903

Burg BR, Kolly M, Blasakis N et al (2015b) Steady-state low thermal resistance characterization apparatus: the bulk thermal tester. Rev Sci Instrum 86:124903

Chen CI, Ni CY, Pan HY, Chang CM, Liu DS (2009) Practical evaluation for long-term stability of thermal interface material. Exp Tech 33(1):28–32

Chen H, Ginzburg VV, Yang J et al (2016a) Thermal conductivity of polymer-based composites: fundamentals and applications. Prog Polym Sci 59:41–85

Chen L, Zhao P, Xie H, Yu W (2016b) Thermal properties of epoxy resin based thermal interfacial materials by filling Ag nanoparticle-decorated graphene nanosheets. Compos Sci Technol 125:17–21

Chen W, Wang Z, Zhi C, Zhang W (2016c) High thermal conductivity and temperature probing of copper nanowire/upconversion nanoparticles/epoxy composite. Compos Sci Technol 130:63–69

Chen L, Xiao C, Tang Y, Zhang X, Zheng K, Tian X (2019) Preparation and characterization of epoxy-based composite with multilayered structure and high thermal conductivity. Mater Res Express 6(7):075314

Cheng SC, Vachon RI (1969) The prediction of the thermal conductivity of two and three phase solid heterogeneous mixtures. Int J Heat Mass Transf 12:249–264

Chiu CP, Chandran B, Mello K, Kelley K (2001) An accelerated reliability test method to predict thermal grease pump-out in flip-chip applications. In: 2001 proceedings. 51st electronic components and technology conference (Cat. No. 01CH37220). IEEE, pp 91–97

Culham JR, Teertstra P, Savija I, Yovanovich MM (2002) Design, assembly and commissioning of a test apparatus for characterizing thermal interface materials. In: The eighth intersociety conference on thermal and thermomechanical phenomena in electronic systems, 2002. ITHERM 2002. IEEE, pp 128–135

de Sorgo M (2002) Understanding phase change materials. Available from: http://www.electronics-cooling.com/2002/05/understanding-phase-change-materials/

Due J, Robinson AJ (2013) Reliability of thermal interface materials: a review. Appl Therm Eng 50(1):455–463

E1952 Method for Thermal Conductivity and Thermal Diffusivity by Modulated Temperature Differential Scanning Calorimetr, ASTM International, West Conshohocken, PA

Ekpu M, Bhatti R, Ekere N, et al. (2012) Effects of thermal interface materials (solders) on thermal performance of a microelectronic package. Dtip

Eucken A (1932) Forsch gebiete ingenieurw. B3 Forschungsheft 353:16

Every AG, Tzou Y, Hassleman DPH, Raj R (1992) The effect of particle size on the thermal conductivity of ZnS/diamond composites. Acta Mater 40:123–129

Fukushima K, Takahashi H, Takezawa Y et al (2006) High thermal conductive resin composites with controlled nanostructures for electric devices. IEEJ Trans Fundam Mater 126:1167–1172

Emerson J, Rightley M, Galloway J, Huber D, Rae D, Cotts E (2006) Minimizing the bondline thermal resistance in thermal interface materials without affecting reliability (googlescholar). http://documents.irevues.inist.fr/bitstream/handle/2042/6438/1033-2.pdf

Gao Z, Zhao L (2015) Effect of nano-fillers on the thermal conductivity of epoxy composites with micro-Al2O3 particles. Mater Des 1980–2015(66):176–182

Gap Pad Products (2016) Available from: http://www.bergquistcompany.com/thermal_materials/gap-pad.Htm

Goel N, Anoop TK, Bhattacharya A, Cervantes JA, Mongia RK, Machiroutu SV, Liu CH (2008) Technical review of characterization methods for thermal interface materials (TIM). In: 11th intersociety conference on thermal and thermomechanical phenomena in electronic systems, 2008. ITHERM 2008. IEEE, pp 248–258

Gowda A, Zhong A, Esler D, David J, Sandeep T, Srihari K, Schattenmann F (2003) Design of a high reliability and low thermal resistance interface material for microelectronics. In: Electronics packaging technology, 2003 5th conference (EPTC 2003). IEEE, pp 557–562

Gowda A, Esler D, Paisner SN, Tonapi S, Nagarkar K, Srihari K (2005) Reliability testing of silicone-based thermal greases [IC cooling applications]. In: Semiconductor thermal measurement and management symposium, 2005 IEEE twenty first annual IEEE. IEEE, pp 64–71

Gu J, Zhang Q, Dang J, Xie C (2012) Thermal conductivity epoxy resin composites filled with boron nitride. Polym Adv Technol 23(6):1025–1028

Gupta A, Liu Y, Zamora N, Paddock T (2006) Thermal imaging for detecting thermal interface issues in assembly and reliability stressing. In: The tenth intersociety conference on thermal and thermomechanical phenomena in electronics systems, 2006. ITHERM’06. IEEE, pp 4-pp

Han Z, Fina A (2011) Thermal conductivity of carbon nanotubes and their polymer nanocomposites: a review. Prog Polym Sci 36:914–944

Han J, Du G, Gao W, Bai H (2019) An anisotropically high thermal conductive boron nitride/epoxy composite based on nacre- mimetic 3D network. Adv Func Mater 29(13):1900412

Hansson J, Nilsson TM, Ye L, Liu J (2018) Novel nanostructured thermal interface materials: a review. Int Mater Rev 63(1):22–45

Harada M, Hamaura N, Ochi M et al (2013) Thermal conductivity of liquid crystalline epoxy/BN filler composites having ordered network structure. Compos B Eng 55:306–313

Hou H, Dai W, Yan Q, Lv L, Alam FE, Yang M, Jiang N (2018) Graphene size-dependent modulation of graphene frameworks contributing to the superior thermal conductivity of epoxy composites. J Mater Chem A 6(25):12091–12097

Huang XY, Jiang PK, Tanaka T (2011) A review of dielectric polymer composites with high thermal conductivity. IEEE Electr Insul Mag 27:8–16

Huang T, Zeng X, Yao Y, Sun R, Meng F, Xu J, Wong C (2016) Boron nitride@ graphene oxide hybrids for epoxy composites with enhanced thermal conductivity. RSC Adv 6(42):35847–35854

Huang T, Zeng X, Yao Y, Sun R, Meng F, Xu J, Wong C (2017) Novel h-BN–RGO hybrids for epoxy resin composites achieving enhanced high thermal conductivity and energy density. RSC Adv 7(38):23355–23362

Islam N, Lee S, Jimarez M, Lee J, Galloway J (2008) TIM degradation in flip chip packages. In: 11th intersociety conference on thermal and thermomechanical phenomena in electronic systems, 2008. ITHERM 2008. IEEE, pp 259–265

ITRS (2013) International technology roadmap for semiconductors emerging research materials summary. https://www.semiconductors.org/resources/2013-international-technology-roadmap-for-semiconductors-itrs/. Accessed 16 Feb 2019

JEDEC Standard JESD51-2a “Integrated circuits thermal test method environmental conditions—natural convection (still air)”. http://www.jedec.org/standards-documents/docs/jesd-51-2a

Kang R, Zhang Z, Guo L, Cui J, Chen Y, Hou X, Yu J (2019) Enhanced thermal conductivity of epoxy composites filled with 2D transition metal carbides (MXenes) with ultralow loading. Sci Rep 9(1):9135

Kearns D (2003) Improving accuracy and flexibility of ASTM D 5470 for high performance thermal interface materials. In: Semiconductor thermal measurement and management symposium, 2003. Ninteenth Annual IEEE, p 129–133

Kempers R, Kolodner P, Lyons A et al (2009a) A high-precision apparatus for the characterization of thermal interface materials. Rev Sci Instrum 80:95111

Kempers R, Kolodner P, Lyons A et al (2009b) A high-precision apparatus for the characterization of thermal interface materials. Rev Sci Instrum 80:95111

Kempers R, Kolodner P, Lyons A, Robinson AJ (2009c) A high-precision apparatus for the characterization of thermal interface materials. Rev Sci Instrum 80(9):095111

Khuu V, Osterman M, Bar-Cohen A, Pecht M (2009) Effects of temperature cycling and elevated temperature/humidity on the thermal performance of thermal interface materials. IEEE Trans Device Mater Reliab 9(3):379–391

Kim HS, Kim JH, Kim WY, Lee HS, Kim SY, Khil MS (2017) Volume control of expanded graphite based on inductively coupled plasma and enhanced thermal conductivity of epoxy composite by formation of the filler network. Carbon 119:40–46

Kittel C, Kroemer H (1980) Thermal physics, 2nd edn. WH Freeman, San Francisco (the discussion on p. 199–217 is highly recommended)

Kumar R, Nayak SK, Sahoo S, Panda BP, Mohanty S, Nayak SK (2018) Study on thermal conductive epoxy adhesive based on adopting hexagonal boron nitride/graphite hybrids. J Mater Sci Mater Electron 29(19):16932–16938

Kundan KV, Katti P, Kumar S, Bose S (2017) Assessing the interfacial properties in carbon fiber/epoxy nanocomposites: from ‘interlayers’ to ‘interconnects’. Nano-Struct Nano-Objects 12:194–209

Lee YT, Shanmugan S, Mutharasu D (2014) Thermal resistance of CNTs-based thermal interface material for high power solid state device packages. Appl Phys A 114(4):1145–1152

Lewis TB, Nielsen LE (1970) Dynamic mechanical properties of particulate-filled composites. J Appl Polym Sci 14:1449–1471

Li Q, Guo Y, Li W, Qiu S, Zhu C, Wei X, Mishra AK (2014) Ultrahigh thermal conductivity of assembled aligned multilayer graphene/epoxy composite. Chem Mater 26(15):4459–4465

Lian G, Tuan CC, Li L, Jiao S, Wang Q, Moon KS, Wong CP (2016) Vertically aligned and interconnected graphene networks for high thermal conductivity of epoxy composites with ultralow loading. Chem Mater 28(17):6096–6104

Lin F, Bhatia GS, Ford JD (1993) Thermal conductivities of powder-filled epoxy resins. J Appl Polym Sci 49:1901–1908

Liu Z, Shen D, Yu J, Dai W, Li C, Du S, Lin CT (2016) Exceptionally high thermal and electrical conductivity of three-dimensional graphene-foam-based polymer composites. RSC Adv 6(27):22364–22369

Lorenz CD, Ziff RM (1998a) Precise determination of the bond percolation thresholds and finite-size scaling corrections for the sc, fcc, and bcc lattices. Phys Rev E 57(1):230

Lorenz CD, Ziff RM (1998b) Universality of the excess number of clusters and the crossing probability function in three-dimensional percolation. J Phys A Math Gen 31(40):8147

Lorenz CD, Ziff RM (2001) Precise determination of the critical percolation threshold for the three-dimensional “Swiss cheese” model using a growth algorithm. J Chem Phys 114(8):3659–3661

Lorenz CD, May R, Ziff RM (2000) Similarity of percolation thresholds on the HCP and FCC lattices. J Stat Phys 98(3–4):961–970

Luo F, Wu K, Guo H, Zhao Q, Lu M (2016) Anisotropic thermal conductivity and flame retardancy of nanocomposite based on mesogenic epoxy and reduced graphene oxide bulk. Compos Sci Technol 132:1–8

Lv L, Dai W, Li A, Lin CT (2018) Graphene-based thermal interface materials: an application-oriented perspective on architecture design. Polymers 10(11):1201

Mahanta NK, Loos MR, Zlocozower IM, Abramson AR (2015) Graphite-graphene hybrid filler system for high thermal conductivity of epoxy composites. J Mater Res 30(7):959–966

Marconnet AM, Yamamoto N, Panzer MA et al (2011a) Thermal conduction in aligned carbon nanotube- polymer nanocomposites with high packing density. ACS Nano 5:4818–4825

Marconnet AM, Yamamoto N, Panzer MA et al (2011b) Thermal conduction in aligned carbon nanotube- polymer nanocomposites with high packing density. ACS Nano 5:4818–4825

Marcus SM, Blaine RL (1994) Thermal conductivity of polymers, glasses and ceramics by modulated DSC. Thermochim Acta 243:231–239

McNamara AJ, Joshi Y, Zhang Z et al (2015) Double-sided transferred carbon nanotube arrays for improved thermal interface materials. J Electron Packag 137:31014

Messina E, Leone N, Foti A, Di Marco G, Riccucci C, Di Carlo G, Fazio B (2016) Double-wall nanotubes and graphene nanoplatelets for hybrid conductive adhesives with enhanced thermal and electrical conductivity. ACS Appl Mater Interfaces 8(35):23244–23259

Moore AL, Shi L (2014) Emerging challenges and materials for thermal management of electronics. Mater Today 17:163–174

Mu M, Wan C, McNally T (2017) Thermal conductivity of 2D nano-structured graphitic materials and their composites with epoxy resins. 2D Mater 4(4):042001

Mun SY, Lim HM, Lee SH (2018) Thermal and electrical properties of epoxy composite with expanded graphite-ceramic core-shell hybrids. Mater Res Bull 97:19–23

Na N, Hasegawa K, Zhou X et al (2015) Denser and taller carbon nanotube arrays on Cu foils useable as thermal interface materials. Jpn J Appl Phys 54(9):95102

Narumanchi S, Mihalic M, Kelly K, Eesley G (2008) Thermal interface materials for power electronics applications. In: 11th intersociety conference on thermal and thermomechanical phenomena in electronic systems, 2008. ITHERM 2008. IEEE, pp 395–404

Nayak SK, Mohanty S, Nayak SK (2019) Mechanical properties and thermal conductivity of epoxy composites enhanced by h-BN/RGO and mh-BN/GO hybrid filler for microelectronics packaging application. SN Appl Sci 1(4):337

Nielsen LE (1973) Thermal conductivity of particulate-filled polymers. J Appl Polym Sci 17:3819–3820

Paisner SN, Touzelbaev M, Refai-Ahmed G, Yang Y (2010) New developments for a no-pump-out high-performance thermal grease. In: 2010 12th IEEE intersociety conference on thermal and thermomechanical phenomena in electronic systems (ITherm). IEEE, pp 1–4

Parameswaranpillai J, George A, Pionteck J, Thomas S (2013) Investigation of cure reaction, rheology, volume shrinkage and thermomechanical properties of nano-TiO2 filled epoxy/DDS composites. J Polym. https://doi.org/10.1155/2013/183463

Parker WJ, Jenkins RJ, Butler CP et al (1961) Flash method of determining thermal diffusivity, heat capacity, and thermal conductivity. J Appl Phys 32(9):1679–1684

Parrott JE, Stuckes AD (1975) Thermal conductivity of solids. Pion, London, p 131

Poornima V, Thomas S, Huczko A (2010) Epoxy resin/SiC nanocomposites. Synthesis and characterization. Kompozyty 10(1):11–14

Prasher RS (2001) Surface chemistry and characteristics based model for the thermal contact resistance of fluidic interstitial thermal interface materials. J Heat Trans-T ASME 123:969–975

Prasher R (2006) Thermal interface materials: historical perspective, status, and future directions. Proc IEEE 94(8):1571–1586

Prasher RS, Matayabas JC (2004) Thermal contact resistance of cured gel polymeric thermal interface material. IEEE Trans Compon Packag Technol 27(4):702–709

Prasher RS, Shipley J, Prstic S, Koning P and Wang JL (2003) Thermal resistance of particle laden polymeric thermal interface materials. In: ASME 2003 international mechanical engineering congress and exposition. American Society of Mechanical Engineers, pp 431–439

Ramaswamy C, Shinde S, Pompeo F, Sablinski W, Bradley S (2004) Phase change materials as a viable thermal interface material for high-power electronic applications. In: The ninth intersociety conference on thermal and thermomechanical phenomena in electronic systems, 2004. ITHERM’04, vol 2. IEEE, pp 687–691

Sagalianov I, Vovchenko L, Matzui L, Lazarenko O (2017) Synergistic enhancement of the percolation threshold in hybrid polymeric nanocomposites based on carbon nanotubes and graphite nanoplatelets. Nanoscale Res Lett 12(1):140

Shen X, Wang Z, Wu Y, Liu X, He YB, Zheng Q, Kim JK (2018) A three-dimensional multilayer graphene web for polymer nanocomposites with exceptional transport properties and fracture resistance. Mater Horizons 5(2):275–284

Singh AK, Panda BP, Mohanty S, Nayak SK, Gupta MK (2017) Study on metal decorated oxidized multiwalled carbon nanotube (MWCNT)-epoxy adhesive for thermal conductivity applications. J Mater Sci Mater Electron 28(12):8908–8920

Singh AK, Panda BP, Mohanty S, Nayak SK, Gupta MK (2018) Recent developments on epoxy-based thermally conductive adhesives (TCA): a review. Polym-Plast Technol Eng 57(9):903–934

Smith AN, Jankowski NR, Boteler LM (2016) Measurement of high-performance thermal interfaces using a reduced scale steady-state tester and infrared microscopy. J Heat Transf 138:41301

Sponagle B, Groulx D (2016) Measurement of thermal interface conductance at variable clamping pressures using a steady state method. Appl Therm Eng 96:671–681

Srinivas K, Bhagyashekar MS (2015) Thermal conductivity enhancement of epoxy by hybrid particulate fillers of graphite and silicon carbide. J Miner Mater Charact Eng 3(02):76

Standard Test Method for Thermal Transmission Properties of Thermally Conductive Electrical Insulating Materials (2012) In: D5470-12, ed. ASTM International, West Conshohocken, Pennsylvania

Struzziero G, Remy B, Skordos AA (2019) Measurement of thermal conductivity of epoxy resins during cure. J Appl Polym Sci 136(5):47015

Su Z, Wang H, Tian K, Huang W, Xiao C, Guo Y, Tian X (2018) The combination of π–π interaction and covalent bonding can synergistically strengthen the flexible electrical insulating nanocomposites with well adhesive properties and thermal conductivity. Compos Sci Technol 155:1–10

Sun Y, Tang B, Huang W, Wang S, Wang Z, Wang X, Tao C (2016) Preparation of graphene modified epoxy resin with high thermal conductivity by optimizing the morphology of filler. Appl Therm Eng 103:892–900

Sun J, Wang D, Yao Y, Zeng X, Pan G, Huang Y, Hu J, Sun R, Xu JB, Wong CP (2017) Boron nitride microsphere/epoxy composites with enhanced thermal conductivity. High Volt. https://doi.org/10.1049/hve.2017.0040

Sundstrom DW, Lee YD (1972) Thermal conductivity of polymers filled with particulate solids. J Appl Polym Sci 16:3159–3167

Taylor SH, Garimella SV (2016) Capacitive sensing of local bond layer thickness and coverage in thermal interface materials. Int J Heat Mass Transf 97:26–31

Thermally Conductive Adhesives (2016) Available from: Available from: http://www.epoxies.com/products/thermallyconductive

Thompson DR, Rao SR, Cola BA (2013) A stepped-bar apparatus for thermal resistance measurements. J Electron Packag 135:041002

Tian W, Yang R (2008) Phonon transport and thermal conductivity percolation in random nanoparticle composites. Comput Model Eng Sci 24(2/3):123

Toberer ES, Baranowski LL, Dames C (2012) Advances in thermal conductivity. Ann Rev Mater Res 42:179–209

Tonapi S, Nagarkar K, Elser D, Gowda A (2007) Reliability testing of thermal greaes. Electronics Cooling, November (google scholar)

Tong XC (2011) Advanced materials for thermal management of electronic packaging, vol 30. Springer, Berlin

Tsao GTN (1961) Thermal conductivity of two-phase materials. Ind Eng Chem Res 53:395–397

Vass-Varnai A, Sarkany Z, Rencz M (2009) Method for in situ reliability testing of TIM samples. In: 15th international workshop on thermal investigations of ICs and systems, 2009. THERMINIC 2009. IEEE, pp 219–223

Verdonck E, Dreezen G (2003) Thermal conductivity measurements of conductive epoxy adhesives by MDSC. Thermal Library Application Brief TA312, TA Instruments New Castle, Delaware

Viswanath R, Group M, Corp I (2000) Thermal performance challenges from silicon to systems. Intel Technol J Q3:1–16

Wang TH, Chen HY, Lee CC, Lai YS (2011) High-powered thermal gel degradation evaluation on board-level HFCBGA subjected to reliability tests. Microelectron Eng 88(10):3101–3107

Wang Z, Fu Y, Meng W, Zhi C (2014a) Solvent-free fabrication of thermally conductive insulating epoxy composites with boron nitride nanoplatelets as fillers. Nanoscale Res Lett 9(1):643

Wang Y, Yu J, Dai W, Wang D, Song Y, Bai H, Jiang N (2014b) Epoxy composites filled with one-dimensional SiC nanowires-two-dimensional graphene nanoplatelets hybrid nanofillers. RSC Adv 4(103):59409–59417

Wang Z, Qi R, Wang J, Qi S (2015a) Thermal conductivity improvement of epoxy composite filled with expanded graphite. Ceram Int 41(10):13541–13546

Wang R, Zhuo D, Weng Z, Wu L, Cheng X, Zhou Y, Xuan B (2015b) A novel nanosilica/graphene oxide hybrid and its flame retarding epoxy resin with simultaneously improved mechanical, thermal conductivity, and dielectric properties. J Mater Chem A 3(18):9826–9836

Wang F, Zeng X, Yao Y, Sun R, Xu J, Wong CP (2016) Silver nanoparticle-deposited boron nitride nanosheets as fillers for polymeric composites with high thermal conductivity. Sci Rep 6:19394

Wilson J (2006) Thermal conductivity of solders. Available from: http://www.electronics-cooling.com/2006/08/thermal-conductivity-of-solders/

Woodside WMJH, Messmer JH (1961) Thermal conductivity of porous media. I. Unconsolidated sands. J Appl Phys 32:1688–1699

Yan H, Wang R, Li Y, Long W (2015) Thermal conductivity of magnetically aligned graphene-polymer composites with Fe3O4-decorated graphene nanosheets. J Electron Mater 44(2):658–666

Yu JH, Duan JK, Peng WY, Wang LC, Peng P, Jiang PK (2011) Influence of nano-AlN particles on thermal conductivity, thermal stability and cure behavior of cycloaliphatic epoxy/trimethacrylate system. eXPRESS Polym Lett 5(2):132–141. https://doi.org/10.3144/expresspolymlett.2011.14

Yu L, Park JS, Lim YS, Lee CS, Shin K, Moon HJ, Han JH (2013) Carbon hybrid fillers composed of carbon nanotubes directly grown on graphene nanoplatelets for effective thermal conductivity in epoxy composites. Nanotechnology 24(15):155604

Yuan W, Xiao Q, Li L, Xu T (2016) Thermal conductivity of epoxy adhesive enhanced by hybrid graphene oxide/AlN particles. Appl Therm Eng 106:1067–1074

Zeng C, Lu S, Song L, Xiao X, Gao J, Pan L, Yu J (2015) Enhanced thermal properties in a hybrid graphene-alumina filler for epoxy composites. RSC Adv 5(45):35773–35782

Zha JW, Zhu TX, Wu YH, Wang SJ, Li RK, Dang ZM (2015) Tuning of thermal and dielectric properties for epoxy composites filled with electrospun alumina fibers and graphene nanoplatelets through hybridization. J Mater Chem C 3(27):7195–7202

Zhang P, Xuan Y, Li Q (2014) A high-precision instrumentation of measuring thermal contact resistance using reversible heat flux. Exp Therm Fluid Sci 54:204–211

Zhang L, Deng H, Fu Q (2018) Recent progress on thermal conductive and electrical insulating polymer composites. Compos Commun 8:74–82

Zhao S, Chang H, Chen S, Cui J, Yan Y (2016) High-performance and multifunctional epoxy composites filled with epoxide-functionalized graphene. Eur Polym J 84:300–312

Zhou T, Wang X, Liu X, Xiong D (2010) Improved thermal conductivity of epoxy composites using a hybrid multi-walled carbon nanotube/micro-SiC filler. Carbon 48(4):1171–1176

Acknowledgements

This work is supported by the Board of Research Board in Nuclear Science (BRNS), Department of Atomic Energy (DAE), Govt. of India (Project No. 39/14/01/2018-BRNS/39001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nayak, S.K., Mohanty, S. & Nayak, S.K. Fundamental and innovative approaches for filler design of thermal interface materials based on epoxy resin for high power density electronics application: a retrospective. Multiscale and Multidiscip. Model. Exp. and Des. 3, 103–129 (2020). https://doi.org/10.1007/s41939-019-00064-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41939-019-00064-z