Abstract

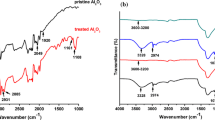

The improvement of heat conduction in any electronic devices has become a predominant issue in which effective heat dissipation is crucial to enhance the performance of packaged devices. This paper elucidates the application of thermally conductive particles filled composites as thermal interface material for LEDs. Present work aims on reducing the junction temperature and thermal resistance of the device under test with heavily filled ceramic-epoxy composite as the interface material between the device and metal substrate. Silane treated aluminium nitride (AlN) powder was studied for its feasibility as the filler material. The thermal conductivity values obtained by hot disc method (ISO/DIS 22007-2.2) were 0.66, 0.54 and 0.44 W/mK for 60, 50 and 40 wt% AlN filled epoxy composites respectively which were described well by thermal transient measurement of LEDs. The junction temperature and total thermal resistance of the thermal set up was reduced significantly with increased filler loading. The least junction to ambient thermal resistance (RthJ-A) was achieved for 60 wt% followed by 50 and 40 wt% AlN filled TIM with the values of 24.8, 31.98 and 34.64 K/W respectively. Characteristics of the AlN filled composites for LED applications are discussed extensively in terms of thermogravimetric and thermo-mechanical analysis.

Similar content being viewed by others

References

C.H. Chao Chen, L.J. Yu, C.H. Yi, Opt. Express. 21, 3 (2013)

LED Professional Review, 2 (June 2007) Luger Research & LED professional

A. Poppe, G. Farkas, G. Molnár, B. Katona, T. Temesvölgyi, W.K. Jimmy, Proc. SPIE, 7784 (2010)

A. Poppe, G. Farkas, V. Székely, G. Horváth, M. Rencz, 22nd IEEE Meas. Power SEMI-THERM Symp. (2006)

A. Boudennea, L. Ibosa, M. Foisa, J.C. Majeste, E. Ge´hina, Compos. Part A. 36 (2005)

J. Xu, K.S. Moon, C. Tison, C.P. Wong, IEEE Trans. Adv. Packag. 29, 2 (2006)

H.J. Kim, D.H. Jung, I.H. Jung, J.I. Cifuentes, K.Y. Rhee, D. Hui, Compos. Part B. 43, 1743 (2012)

S.Y. Pak, H.M. Kim, S.Y. Kim b, J.R. Youn, Carbon. 50, 4830 (2012)

C.C. Teng, C.C.M. Ma, K.C. Chiou, T.M. Lee, Compos. Part B. 43, 265 (2012)

E.S. Lee, S.M. Lee, J. Am. Ceram. Soc. 91, 4 (2008)

K. Kim, J. Kim, Ceram. Int. 40, 5181 (2014)

J.D. Bolt, D.D. Button, B.A. Yost, Mater. Sci. Eng. A. 109, 207 (1989)

Y. Zhou, H. Wang, L. Wang, K. Yu, Z. Lin, L. He, Y. Bai, Mater. Sci. Eng. B. 177, 892 (2012)

S. Chooi, J. Kim, Compos. Part B. 51, 140 (2013)

F.Y. Yuan, H.B. Zhang, X. Li, X.Z. Li, Z.Z. Yu, Compos. Part A. 53, 137 (2013)

J.A. Molefi, A.S. Luyt, I. Krupa, Express Polym. Lett. 3, 10 (2009)

G.W. Lee, M. Park, J. Kim, J.I Lee, H.G. Yoon, Compos. Part A. 37, 727 (2006)

J. Jiao, S. Rak, A. Polak, Thermochim. Acta. 357–358, 313 (2006)

M.A. Raza, A.V.K. Westwood, A.P. Brown, C. Stirling, J. Mater. Sci-Mater. Electron. 23, 1855 (2012)

S.A. Shokralla, N.S. Al-Muaikel. Arab. J. Sci. Eng. 35, 7 (2010)

Y.S. Xu, D.D.L. Chung, Compos. Interfaces 7, 4 (2000)

S. Li, S. Qi, N. Liu, P. Cao, Thermochim. Acta. 523, 111 (2011)

J.P. Hong, W.Y Sung, T. Hwang, S.O. Joon, C.H Seung, Y. Lee, D.N Jae, Thermochim. Acta. 537, 70 (2012)

LT W5SM Golden Dragon. http://catalog.osram-os.com/catalogue/catalogue.do?favOid=0000000000032440001d0023&act=showBookmark

L.C. Sim, S.R. Ramanan, H. Ismail, K.N. Seetharamu, T.J. Gohc, Thermochim. Acta. 430, 155 (2005)

R.M. Overney, C. Buenviaje, R. luginbuhl. F. Dinelli, J. Therm. Anal. Calorim. 59, 205 (2000)

MasterBond Tech spotlight, How to Relieve Thermally Induced Stress with Epoxies, Master Bond Inc. 154 Hobart Street, Hackensack, NJ 07601 USA, WhitePaper@masterbond.com

W.C. Lim, L.H. Huong, W.S. Chow, J. Phys. Sci. 21, 1 (2010)

P. Dittanet, R.A. Pearson, Polymer 54, 7 (2013)

V. Szekely, V.B. Tran, Solid-State Electron. 31, 9 (1988)

M. Rencz, Microelectron. J. 34, 3 (2003)

M. Rencz, A. Poppe, E. Kollar, S. Ress, V. Szekely, B.Courtois, IEEE Trans. Thermal and Thermomechanical Phenomena in Electronic Systems, ITHERM 04, 1 (2004)

Acknowledgments

The authors would like to thank USM for the Post Graduate Research Grant Scheme (PRGS) funding, OSRAM Optosemiconductors (Malaysia) Sdn. Bhd. and OSRAM Optosemiconductors GmbH, Regensburg, Germany for characterization facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anithambigai, P., Mutharasu, D., Huong, L.H. et al. Synthesis and thermal analysis of aluminium nitride filled epoxy composites and its effective application as thermal interface material for LED applications. J Mater Sci: Mater Electron 25, 4814–4821 (2014). https://doi.org/10.1007/s10854-014-2238-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2238-y