Abstract

Rechargeable all-solid-state batteries (ASSBs) are considered to be the next generation of devices for electrochemical energy storage. The development of solid-state electrolytes (SSEs) is one of the most crucial subjects in the field of energy storage chemistry. The newly emerging halide SSEs have recently been intensively studied for application in ASSBs due to their favorable combination of high ionic conductivity, exceptional chemical and electrochemical stability, and superior mechanical deformability. In this review, a critical overview of the development, synthesis, chemical stability and remaining challenges of halide SSEs is given. The design strategies for optimizing the ionic conductivity of halide SSEs, such as element substitution and crystal structure design, are summarized in detail. Moreover, the associated chemical stability issues in terms of solvent compatibility, humid air stability and corresponding degradation mechanisms are discussed. In particular, advanced in situ/operando characterization techniques applied to halide-based ASSBs are highlighted. In addition, a comprehensive understanding of the interface issues, cost issues, and scalable processing challenges faced by halide-based ASSBs for practical application is provided. Finally, future perspectives on how to design high-performance electrode/electrolyte materials are given, which are instructive for guiding the development of halide-based ASSBs for energy conversion and storage.

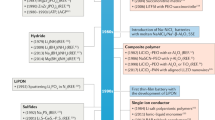

Graphical Abstract

In this review, a critical overview is given on the development, synthesis, chemical stability and remaining challenges facing for halide SSEs. The design strategies for optimizing ionic conductivity of halide SSEs like elements substitution, crystal structures design are summarized in detail. Future perspectives are given on how to design high-performance electrode/electrolyte materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Driven by the ongoing advancement of the new energy revolution worldwide, the development of high-energy and high-power energy storage devices simultaneously exhibiting enhanced safety features is urgently required to satisfy the stringent demands of grid-scale and utility-scale stationary storage [1,2,3]. Conventional lithium-ion batteries with organic liquid electrolytes have been typically applied as the dominant energy storage devices for the mobile electronics industry and electric vehicles [4,5,6]. However, the thermal runaway risks caused by flammable organic electrolytes as well as the low energy densities (up to 300 Wh kg−1) profoundly limited by the nature of the material chemistry have seriously impeded the further development of traditional lithium-ion batteries with liquid electrolytes [7,8,9,10]. All-solid-state batteries (ASSBs) are prevailingly acknowledged as the most promising candidate for next-generation energy storage, primarily benefiting from their high energy density and high safety through the incorporation of nonflammable solid-state electrolytes (SSEs) and high-voltage cathode materials (e.g., LiCoO2 and Li[Ni,Co,Mn]O2) or high-capacity electrodes (e.g., a lithium metal anode and a S cathode) [11,12,13,14,15]. Notably, the appreciable merits of ASSBs originate from the nature of SSEs in terms of high single-ion conductivity, outstanding thermal stability and simplified packaging design [16,17,18].

To date, several promising SSEs involving oxide, sulfide, and halide electrolytes with high ionic conductivity over 1 mS cm−1 at room temperature (RT) have received extensive attention for energy storage in ASSBs [19,20,21,22]. A comparison of various properties among the three families of ceramic solid electrolytes is shown in Fig. 1. The oxides exhibit acceptable chemical stability and good electrochemical oxidation stability; however, their mechanical rigidity results in poor interfacial contact with electrode materials, requiring high-temperature processes or infiltration of liquid electrolytes for battery assembly [23,24,25,26]. In contrast, sulfides deliver enhanced properties in terms of higher ionic conductivity and excellent mechanical deformability, whereas they are vulnerable to moisture in the ambient atmosphere, suffering from detrimental hydrolysis reactions along with severe reduction of the ionic conductivity [27,28,29,30]. Furthermore, the intrinsic poor oxidation stability of sulfides critically restricts the direct utilization of high-voltage cathode active materials (CAMs) [31, 32]. Currently, emerging halide SSEs are a research hotspot since their superior properties integrate the merits of oxides and sulfides to some extent, and thus, they possess high ionic conductivity (> 10−3 mS cm−1), reliable deformability and superior electrochemical oxidation stability (up to 6 V vs. Li+/Li) and can even be realized through soluble water-medium synthetic routes [21, 33,34,35].

A schematic timeline of the development of halide SSEs from 1930 to the present with the representative key milestones is shown in Fig. 2. Halide-related materials can be dated back to 1930 [36], when lithium halides (LiX, X = F, Cl, Br, I) with Li+ conducting behavior were first studied. After that, LiI SSEs were further developed and applied in thin-film-type ASSBs at the end of the 1960s [37], and subsequently, ternary halides such as Li1.52Mn1.24Cl4 and Li2TiCl4 were reported in 1984 and 1988 [38, 39]. Unfortunately, both of their ionic conductivities at RT were relatively low at ~ 10−5 S cm−1, and as a result, the development of halide SSEs was severely delayed for a long time [40,41,42,43]. In 2018, Asano et al. [44] achieved a momentous breakthrough in the field of halide SSEs; specifically, Li3YCl6 and Li3YBr6 with high ionic conductivities of (0.03–1.7) × 10−3 S cm−1 at RT were successfully synthesized through a high-energy ball milling and annealing process, which are several orders of magnitude higher than those of previously reported halide electrolytes. Shortly afterward, a series of halide superionic conductors, such as Li3ErCl6 [45], Li3−xM1−xZrxCl6 (M = Y, Er, In, Yb) [46,47,48] and Li3HoBr6 [49], were gradually developed by similar approaches. In particular, Sun’s group synthesized Li3InCl6 by employing a facile water-mediated strategy in 2019 [33] and then dexterously developed a universal ammonium-assisted methodology to synthesize various halide SSEs in 2021 [50], which enabled manufacture of halide SSEs on a large scale for commercial implementation.

To date, the reported halide SSEs with the formula of Li–M–X (M = metal element, X = F, Cl, Br, I) can be classified into four categories according to the different types of central metal element [21, 51] as follows. (1) Halide SSEs with group 3 elements (Sc, Y, La–Lu) commonly exhibit exceptional electrochemical oxidation stability and decent ionic conductivity, especially chloride-based halides, whereas the high cost of rare-earth materials makes scalable manufacturing challenging. (2) Halide SSEs with group 13 elements (Al, In, Ga) possess reliable air stability and good ionic conductivity, for example, Li3InCl6 delivers high ionic conductivity (1.49 mS cm−1) at RT and desirable humidity tolerance originating from the generation of a stable hydrate phase [52]. (3) Halide SSEs with divalent metal elements (e.g., Ti, V, Cr) are mostly demonstrated to show undesirable ionic conductivity at RT, several orders of magnitude lower than the other SSEs, and consequently have received less attention. (4) Halide SSEs with tetravalent metal elements (Zr, Hf) have been developed in recent years, especially Li2ZrCl6, which has a high ionic conductivity of 0.81 mS cm−1 at RT and a remarkable cost effectiveness as well as an exceptional humidity tolerance [53]. Radar plots comparing the (electro)chemical properties of the four types of halide SSEs with various central metal elements are shown in Fig. 3. Consequently, compared with oxide and sulfide solid electrolytes, emerging halide SSEs offer a wider range of options in terms of composition, structure and chemistry for designing and synthesizing prospective electrolytes with enhanced comprehensive properties.

In this review, we comprehensively summarize the recent developments in halide SSEs for ASSBs. Various synthesis routes of halide SSEs, including the recently developed universal ammonium-assisted method, are systematically reviewed. Furthermore, the design strategies for optimizing the ionic conductivity of halide SSEs, such as element substitution and crystal structure design, are summarized in detail. Simultaneously, the associated chemical stability issues in terms of solvent compatibility, humid air stability and corresponding degradation mechanisms are discussed. The advanced in situ/operando techniques employed to investigate the structural evolution of halide electrolytes and the underlying redox mechanisms of halide-based ASSBs under realistic operating conditions are thoroughly introduced. In addition, a comprehensive understanding of the interface, cost, and scalable processing issues of halide-based ASSBs for practical application is provided. Finally, we offer future perspectives on pursuing high-performance electrode/electrolyte materials to address the challenges in the practical application of halide-based ASSBs.

2 Synthesis

A simple and cost-effective synthesis route for manufacturing halide SSEs with high ionic conductivity plays a decisive role in realizing practical application of halide-based ASSBs. In general, synthesis methods for halide SSEs can be classified into three categories: solid-state reaction routes, liquid-phase routes and chemical vapor routes. A schematic diagram of various synthesis routes for halide SSEs is shown in Fig. 4. The ionic conductivities of various types of halide SSEs obtained from different synthesis methods are summarized in Table 1.

2.1 Solid-State Reaction Synthesis

Solid-state reaction routes are the earliest and most popular methods for synthesizing halide solid electrolytes. According to the various operating conditions, solid-state reaction routes can be further divided into three methods: mechanochemical milling, mechanical milling with postannealing and solid-state sintering. Note that the operating conditions and the processing parameters in solid-state reactions exert a great effect on halide SSEs in terms of their lattice structure, crystallinity and ionic conductivity.

2.1.1 Mechanochemical Milling

Mechanochemical milling methods commonly employ high-energy mechanical milling technology with appropriate ball milling speed and reaction time for synthesizing halide SSEs (Fig. 5a), in which the stoichiometric precursors can undergo intense shearing, friction and collision between the grinding ball and jar wall to achieve effective reactions at the atomic level [69]. Mechanochemical synthesis enables the preparation of unique amorphous variants or strong amorphization of compounds with low coherence that cannot be obtained by classical high-temperature solid-state synthesis, while rapid crystallization with subsequent quenching can significantly reduce the amorphous structure, giving rise to augmentation of long-range coherent structures in crystalline compounds (Fig. 5b) [70]. Prevalent site disorder and defect structure of halide SSEs can be obtained by mechanochemical milling, which is favorable for enhancing their ionic conductivity, and consequently, the corresponding halide SSEs could be directly applied to battery assembly without post pulverization or heat treatment [54]. In 2018, Asano et al. [44] successfully synthesized Li3YCl6 and Li3YBr6 with high RT ionic conductivities of 0.51 and 0.72 mS cm−1, respectively, through mechanochemical milling for the first time and found that the remarkably high conductivity of the as-synthesized halide SSEs benefits from the partially disordered cation arrangement and the abundant defect structures induced by mechanical milling techniques. Sebti et al. [71] reported that coexistence of a high concentration of stacking faults and Li-only defect layers in Li3YCl6 can be achieved by mechanochemical synthesis, which allows the formation of extra site linkages with lower migration barriers and dramatically promotes Li+ mobility in the microcrystalline structure of Li3YCl6. Notably, the planar defects induced by mechanochemical synthesis are metastable, which is responsible for the highly tunable ionic conductivity of Li3YCl6. Under such circumstances, heat treatment even as low as 60 °C is demonstrated to be capable of reducing the ionic conductivity of Li3YCl6 due to the gradual elimination of metastable defect structures. Schlem et al. [72] demonstrated that prevalent cation site disorder between Er/Y sites and a disordered structure, such as LiCl65− octahedral distortion, could be generated in Li3YCl6 and Li3ErCl6 by employing mechanochemical synthesis, which exhibited markedly intensified ion transport through expansion of lithium diffusion bottlenecks. The microcrystalline structure of Li3MCl6 (space group: P\(\overline{3}\)m1) can be described as a trigonal lattice formed by three types of MCl63− octahedra (Fig. 5c–e), in which Wyckoff positions 1a and 2d are occupied by M1 and M2, respectively, and M3 occupying the M2-equivalent position in the (001) plane enables the formation of M2–M3 site disorder. The authors found that the M3/M2 ratio was high in the halide Li3ErCl6 synthesized by mechanical ball milling (Fig. 5f), yielding abundant M2–M3 disorder, which could effectively reduce the Li+ migration energy barrier along the c-axis, while the corresponding site disorder significantly decreased after heat treatment even for a short time of 1 min, which accounted for the reduced ionic conductivity of Li3ErCl6 prepared by subsequent annealing and ampoule synthesis (Fig. 5g). For the synthesis of a 1 g batch of halide samples through the mechanochemical milling approach, an excess amount of rare-earth chlorides of approximately 10 wt% (wt% means the weight percentage) was applied to compensate for the loss during the pregrinding process due to the strong adhesion between the rare-earth chloride precursors and the agate mortar.

Reproduced with permission from Ref. [70]. Copyright 2021, Wiley–VCH. c Li3ErCl6 unit cell with construction units of ErCl63− octahedra that form a trigonal unit cell and face-sharing ErCl63− octahedra chains perpendicular to the (002) plane, with three possible erbium sites (Er1, Wyckoff 1a; Er2 and Er3, Wyckoff 2d). d The vacant octahedral sites in Li3ErCl6 were occupied by lithium (Wyckoff 6g, 100% occupied; Wyckoff 6h, 50% occupied). e The possible lithium pathways in Li3ErCl6 involve face-sharing LiCl65− octahedra along the c-direction and tetrahedral voids in the a–b plane. f Evolution of the Er2–Er3 site disorder determined by G(r) fits (open circles) and Rietveld refinements (open squares). g Ionic conductivity and corresponding activation energy of Li3ErCl6 as a function of annealing time. Reproduced with permission from Ref. [72]. Copyright 2019, Wiley–VCH

Mechanochemical synthesis enhances the disordered structure of halides for fast lithium-ion transport. a Schematic diagram of the mechanochemical synthesis of solid electrolytes, in which the precursors (cyan, purple) react to form the final products (red) under the impact of the ball milling medium (black spheres). b Comparison of the mechanochemical synthesis and classic high-temperature preparation for solid electrolytes with different degrees of coherence.

Regarding sodium-conducting halide solid electrolytes, the mechanochemically synthesized samples also exhibit higher ionic conductivity than the samples with a subsequent crystallization route, which deliver similar behavior to the lithium-conducting halide counterparts. Kwak et al. [67] reported that mechanochemically prepared Na2ZrCl6 possessed an ionic conductivity of 0.018 mS cm−1 at RT, which was nearly three orders of magnitude higher than that of the sample (6.9 × 10−8 S cm−1) synthesized with subsequent annealing at 400 °C, although both types of electrolytes had the same trigonal lattice (space group P\(\overline{3}\)m1). Site disorder in terms of Zr and Na can be observed in the microcrystalline structure of Na2ZrCl6 obtained from mechanochemical milling syntheses, which could induce partial occupation of sodium interstitial sites to form additional transport pathways, thus leading to a substantially improved ionic conductivity. In contrast, sodium ions 100% occupy the crystallographic Wyckoff site (6g) without undergoing any disordering for the subsequently annealed Na2ZrCl6, and simultaneously, the Na–Cl interatomic distance is considerably shortened by heat treatment, promoting strong bonding between the Na+ and Cl− ions, which could be responsible for the significantly decreased ionic conductivity of Na2ZrCl6 obtained from the subsequent crystallization route. A similar phenomenon was also found for the sodium halide Na3YCl6 and its derivatives. Wu et al. [66] demonstrated that the mechanochemical milling approach enables remarkable improvement of the ionic conductivity for annealed Na3YCl6 by nearly three orders of magnitude, and for its derivative Na2.25Y0.25Zr0.75Cl6, the corresponding ionic conductivity can also be dramatically improved from 1.3 × 10−5 to 6.1 × 10−5 S cm−1 at RT after subjecting the material to a similar processing procedure. The major disadvantage of mechanochemical synthesis lies in its high energy and time consumption, and the partial precursors may be contaminated by the grinding balls, which is not conducive to synthesizing high-purity halide SSEs.

2.1.2 Mechanical Milling with Postannealing

Typically, in the mechanical milling with postannealing route, stoichiometric raw materials are first subjected to a high-energy mechanical milling process to achieve fully mixed and low-crystallinity halide precursors with a smaller size, then pressed into pellets and sealed in a quartz tube, followed by annealing to obtain halide SSEs. Through this method, a certain amount of a halide, such as Li3MCl6 (M = In, Yb) and Li3YBr6, can deliver higher Li+ ionic conductivity than the corresponding halide electrolytes obtained from the mechanochemical milling route [52, 55, 73], primarily ascribed to the enhanced crystallinity along with evolution of the crystal structure of halide electrolytes that may effectively facilitate Li+ diffusion.

Li et al. [52] investigated the effects of heat treatment conditions in terms of various temperatures and durations on the ionic conductivity of the halide Li3InCl6 synthesized by mechanical milling with postannealing and found that annealing ball-milled Li3InCl6 in the range of 260–400 °C could effectively improve the ionic conductivity, accompanied by distinctly enhanced crystallinity. Increasing the heat treatment time in the range of 260–400 °C had little influence on the ionic conductivity of Li3InCl6, and the highest ionic conductivity of 1.49 mS cm−1 at RT could be achieved by annealing at 260 °C for 2 h, which was significantly higher than that of ball-milled samples (0.83 mS cm−1). Park et al. [55] successfully synthesized Li3YbCl6 SSEs through the mechanical milling with postannealing route and demonstrated the dynamic structural evolution of Li3YbCl6, which varied with the annealing temperature. The trigonal (P\(\overline{3}\)m1) structure exhibited slightly higher RT ionic conductivity (0.19 mS cm−1) than the orthorhombic (Pnma) structure sample (0.14 mS cm−1), which were prepared by annealing ball-milled Li3YbCl6 at 400 and 500 °C, respectively. Yu et al. [73] investigated various annealing parameters, including the heat treatment temperature (250–550 °C) and duration (3–15 h), in terms of the influence on the ionic conductivity of Li3YBr6 prepared by the mechanical milling with the postannealing method (Fig. 6a–c). The halide Li3YBr6 annealed at 500 °C for 5 h exhibited the highest ionic conductivity of 3.31 mS cm−1 at RT, which is an order of magnitude higher than that of mechanical milling products (0.39 mS cm−1). The high-temperature annealing process after mechanical milling can enhance the anharmonic vibration in the lattice structure of Li3YBr6, which is favorable for appreciably enhancing the hopping rate of lithium ions between adjacent sites, thereby achieving high mobility of lithium ions in the microcrystalline structure to improve the ionic conductivity of Li3YBr6.

Reproduced with permission from Ref. [73]. Copyright 2020, Elsevier. d (d1–d4) Anisotropic thermal displacement parameters of ampoule and mechanochemically synthesized Li3YBr6 compounds. e Convolution of the effects of the disordered structures in halide compounds on the observed changes in the ionic transport. Reproduced with permission from Ref. [74]. Copyright 2021, American Chemical Society. f Illustration of the water-mediated synthesis route for Li3InCl6. Reproduced with permission from Ref. [33]. Copyright 2019, Wiley–VCH. g Schematic of solution infiltration synthesis for a Li3InCl6/glass-fiber solid-composite electrolyte film, and corresponding electrochemical test curves. Reproduced with permission from Ref. [75]. Copyright 2022, Elsevier

a XRD patterns of Li3YBr6 samples obtained from mechanical milling with postannealing at various temperatures. b Changes in the ionic conductivity of the annealed Li3YBr6 samples with the annealing temperature. c Arrhenius plots of the ionic conductivity of Li3YBr6 pellets obtained from a precursor mixture milled at 550 rpm for 32 h followed by annealing at 500 °C for various durations.

Although the additional heat treatment increases the costs and time for synthesizing halide SSEs by the mechanical milling with the postannealing route, the improved ionic conductivity endows the SSEs with application potential in ASSBs, which suggests that this method could be regarded as a potential option to manufacture halide SSEs.

2.1.3 Solid-State Sintering

The solid-state sintering route is generally regarded as a simple approach for synthesizing halide SSEs through direct thermal sintering of the stoichiometric precursors in a high-vacuum ampoule. The starting materials could be cold-pressed into pellets after manual grinding or mechanical milling at a low rotational speed for further heat treatment. Notably, the precursor ratio, sintering temperature and duration are crucial factors for successfully obtaining high-purity halide SSEs.

Liang et al. [60] optimized the composition ratio of initial precursors for synthesizing a series of Li–M–Cl (M = Tb, Dy, Ho, Y, Er, Tm) halide SSEs through direct annealing at 650 °C for 24 h, and different ratios of the starting materials could significantly affect the ionic conductivity of the halides by changing the crystal phase structure. For example, Li2.73Ho1.09Cl6 with the orthorhombic phase exhibited a fourfold increase in the ionic conductivity up to 1.3 mS cm−1 at RT compared to Li3HoCl6 with the trigonal phase. Through this method, Li3HoBr6 halide with a high RT ionic conductivity of 1.1 mS cm−1 could also be successfully synthesized through annealing at 450 °C for 12 h [64]. Kim et al. [47] investigated the effects of various annealing temperatures (350–650 °C) and durations (36–100 h) on the crystal structure and ionic conductivity of Li3YbCl6. The Li3YbCl6 with the trigonal phase annealed at 350 °C showed a markedly higher ionic conductivity (0.1 mS cm−1 at 30 ℃) than that of the orthorhombic phase (0.06 mS cm−1 at 30 °C) annealed at 650 ℃, and the metastable trigonal phase could be converted to the thermodynamically stable orthorhombic phase by increasing the annealing time from 36 to 100 h. Schlem et al. [74] demonstrated that Li3YBr6 prepared by the solid-state sintering method exhibited higher ionic conductivity than Li3YBr6 prepared by the mechanochemical milling route or mechanical milling with postannealing route, which is closely associated with the directional thermal amplitude and partial occupancies of additional sites. The structure of Li3YBr6 (space group C2/m) can be described as a monoclinic unit cell. For the ampoule-synthesized (solid-state sintering method) compound, the authors found that the larger yttrium occupancy of the lithium 4g site produced an increased electrostatic repulsion, which could promote rotation of the anisotropic thermal displacement ellipsoids away from yttrium octahedra, accompanied by a larger displacement of lithium in the a-direction (Fig. 6d1, d3), thus being pushed to the tetrahedral position. This phenomenon is highly favorable for lithium-ion transport, leading to a higher ionic conductivity. In contrast, the lower occupancy of the lithium 4g site in the mechanochemically synthesized Li3YBr6 caused displacement of lithium to octahedral sites rather than tetrahedral sites, resulting in a larger displacement of the anisotropic thermal displacement ellipsoids in the b-direction (Fig. 6 d2, d4), thereby increasing the diffusion barrier for lithium ions in the microcrystalline structure of Li3YBr6. The abundant yttrium disorder in ampoule-synthesized Li3YBr6 can effectively affect lithium polyhedral volumes and the thermal displacement amplitudes of lithium, which further facilitates the formation of optimized transport pathways for lithium ions to improve the ionic conductivity (Fig. 6e).

Although the simple solid-state sintering method is favorable for easily achieving large-scale production of halide SSEs, the underlying issues of the harsh high-vacuum environment and poor homogeneity as well as impure phases generated by elemental volatilization at high temperatures impede its widespread application for manufacturing halide electrolytes.

2.2 Liquid-Phase Synthesis

Recently, wet-chemical synthesis routes employing liquid solvents as reaction media have received a strong upsurge of interest for fabricating halide solid electrolytes, which offer numerous advantages in terms of easily scalable production, effective size/morphology control and time-saving processes. Wet-chemical synthesis approaches have been successfully applied to synthesizing halides and can be classified into two strategies, water-mediated synthesis and ammonium-assisted synthesis, based on the different reaction mechanisms.

2.2.1 Water-Mediated Synthesis

Employing an ecofriendly and cost-effective water-medium approach for synthesizing halide electrolytes with high ionic conductivity and humidity tolerance is regarded as the most promising strategy for achieving commercial application of halide SSEs.

In 2019, Li et al. [33] successfully synthesized high-purity Li3InCl6 through a water-medium approach for the first time; in detail, the hydrate intermediate (Li3InCl6·nH2O) was first generated by reacting LiCl and InCl3 in an aqueous solution, followed by heat treatment in vacuum to remove water molecules (Fig. 6f). Li3InCl6 prepared at 200 ℃ in vacuum exhibited the highest ionic conductivity of 2.04 mS cm−1 at RT compared with Li3InCl6 prepared at the heat treatment temperatures of 100 and 130 ℃, and the production of high-purity Li3InCl6 can be easily scaled up to 110 g by using the water-mediated route. The authors found that the dehydrated form of Li3InCl6 could also be acquired by applying a dehydration process in an air or argon atmosphere, but the appearance of the impurity phase InOCl accompanied this process; thus, the dehydration process should be carried out under vacuum to ensure high purity. In addition, high-purity Na3InCl6 can also be successfully synthesized under similar synthetic conditions by reacting NaCl and InCl3 in an aqueous solution, followed by heat treatment at 200 ℃ in vacuum. Furthermore, Zhao et al. [75] proposed an infiltration method for preparing Li3InCl6 thin films that is compatible with the roll-to-roll manufacturing technique (Fig. 6g). Glass fibers were immersed into the precursor solution of stoichiometric LiCl and InCl3·4H2O, followed by vacuum drying at 60 and 200 °C for 4 h, and the prepared composite electrolytes were further roll pressed to obtain a free-standing and compact Li3InCl6 film with an ionic conductivity of 5.4 × 10−4 S cm−1 at RT.

However, employing the water-mediated synthesis method for halide SSEs is limited to In-based electrolytes, which is primarily ascribed to the reversible interconversion between the hydrated intermediate and dehydrated phase. Consequently, developing a general wet-chemical method for synthesizing various kinds of halide electrolytes is of great importance.

2.2.2 Ammonium-Assisted Synthesis

Recently, the universal ammonium-assisted wet-chemistry route for preparing various halide SSEs with nanoscale particles was successfully developed, which is a crucial breakthrough for realizing large-scale halide production.

Inspired by the industrial preparation of high-purity anhydrous rare-earth chlorides, Wang et al. [50] first introduced NH4Cl into an aqueous solution of YCl3 and LiCl as a coordination agent to preferentially generate the (NH4)3[YCl6] intermediate, and after the moisture was removed in vacuum at 80 °C, the acquired powders were pressed into pellets, followed by annealing at 500 °C, in which the intermediate could react with LiCl to synthesize Li3YCl6 with a high ionic conductivity of 0.345 mS cm−1 at RT. Through this method, a series of halide SSEs, such as Li3ScCl6, Li3ErCl6 and Li3YBr6 with ionic conductivities of 1.25, 0.41 and 1.09 mS cm−1 at RT, were successfully synthesized, proving that the ammonium-assisted route is a universal method to prepare various halide SSEs with decent ionic conductivity. Shi et al. [49] developed a vacuum evaporation-assisted (VEA) method for successfully synthesizing the halide Li3HoBr6 by employing a cost-effective rare-earth raw material (Ho2O3). Specifically, the mixed precursor powders of Li2CO3 and Ho2O3 were introduced to a HBr solution, followed by adding NH4Br as a coordinator, and after removing the moisture, the resulting powders were heat treated under vacuum and inert gas protection to synthesize high-quality Li3HoBr6 with a high ionic conductivity of 1.25 mS cm−1 at RT. By employing the VEA method, approximately 10 g of Li3HoBr6 with well-dispersed and nanosized particles can be prepared each time. This synthesis approach provides an important breakthrough for large-scale manufacturing of rare-earth halide SSEs with cost-effective raw materials and thus offers a critical economically viable foundation for realizing practical application of rare-earth halide-based ASSBs.

In summary, wet-chemical synthesis methods can be successfully employed to synthesize various types of high-purity halide SSEs and have shown extensive development prospects for practical applications because of the easy large-scale production, time-saving processes and homogeneity of the resulting electrolytes. However, there are still some challenging issues to be solved when synthesizing halide SSEs through liquid-phase synthesis routes. First, the synthesis process and operating conditions are generally demanding since halide SSEs are sensitive to the ambient atmosphere. Moreover, the introduction of ammonium salts induces the generation of corrosive gases, such as HCl and HBr, and thus, a special apparatus with corrosion resistance should be utilized, especially in large-scale production processes. In addition, halide SSEs synthesized by wet-chemical methods exhibit decreased ionic conductivity compared with halide SSEs synthesized by solid-state reaction routes, so an in-depth understanding of the chemical reactions involved in liquid synthesis methods is indispensable for revealing the complete reaction mechanism.

2.3 Chemical Vapor Synthesis

Chemical vapor synthesis routes are mainly employed for synthesizing thin-film halides, especially fluoride-based halides, and they can usually be categorized into thermal evaporation methods and vapor deposition methods.

In 1981, Qi et al. [76] successfully prepared mLiF–nAlF3 films with different stoichiometric ratios (1/3 \(\leqslant\) m/n \(\leqslant\) 3) and a thickness of 0.8 μm by using a thermal evaporation method in a high-vacuum environment, and the ionic conductivity of the amorphous films could exceed 10−6 S cm−1 at RT. Only 3LiF–1AlF3 or Li3AlF6 can exhibit a stable state, which is primarily ascribed to the existence of the structure of vertex-sharing [AlF6]3− octahedra. Subsequently, the authors synthesized a series of mLiF–nMF3 (M = Al, Cr, Sc, Ti, V, Cr, Ga, Y and Ce) and mLiF–nMF2 (M = Mg, Ca, Ni, Cu, Zn, and Sr) thin films by thermally evaporating the precursor materials in a high-vacuum environment for 10 min [21, 77]. Notably, F-based halides with wider electrochemical windows can be used as ionic interface layers for metal oxide cathode materials to enhance the stability and energy density of full cells. For example, Xie et al. [78] successfully coated LiAlF4 on the surface of LiNi0.8Mn0.1Co0.1O2 by an atomic deposition method and found that a battery based on LiAlF4-coated cathode materials can exhibit stable cycling performance over a wide electrochemical window of 2.75–4.5 V vs. Li+/Li. In summary, chemical vapor synthesis routes are limited to preparing fluorine-based halide films and have underlying scalable production and high cost of equipment issues; thus, they may preferentially be used to meet the special requirement of fluorine-based halide films for assembling high-performance full cells.

3 Strategies for Improving the Ionic Conductivity

To date, only a few halide SSEs can experimentally show an intrinsic ionic conductivity over 1 mS cm−1 at RT, and the majority of halide SSEs deliver far less satisfactory lithium diffusion properties compared to traditional liquid electrolytes, requiring valid strategies to further improve the ionic conductivity to facilitate the application of halide SSEs in ASSBs. Substitution of elements with different valences and ionic radii is acknowledged to be a feasible strategy to improve the ionic conductivity of halide solid electrolytes by tuning the disorder in cation/anion sublattices and vacancy concentrations [55, 62, 63, 79]. Furthermore, regulating the composition of halide compounds also offers an available methodology to achieve distinct ionic conductivity by optimizing the metal/vacancy site occupations and the carrier concentrations in the microcrystal structure [57, 60, 80]. The effective strategies for improving the ionic conductivity of halide solid electrolytes are summarized in Fig. 7.

3.1 Aliovalent Cation Substitution

The substitution of central metals in halide SSEs with aliovalent cations can be used to tune the distribution and concentration of Li+ or change the local structure framework to improve the ionic conductivity. Notably, the preferential utilization of elements with high abundance in the Earth’s crust for central metal substitution in halide electrolytes offers a promising option to realize commercial application of halides in ASSBs.

Recent studies have demonstrated that the ionic conductivity of Li3MCl6 (M = Y, In, Yb, Er) [46,47,48] and Na3MCl6 (M = Y, Er) [66, 68] can be effectively improved through central metal substitution with tetravalent Zr4+ in the structural framework of halide electrolytes. Park et al. [46] successfully synthesized new mixed-metal halides Li3−xM1−xZrxCl6 (M = Y, Er; x = 0–0.6) by substituting Y3+ (r = 90 pm) and Er3+ (r = 89 pm) with Zr4+ (r = 72 pm), reaching the corresponding highest RT ionic conductivity of 1.4 mS cm−1 for Li2.5Y0.5Zr0.5Cl6 and 1.1 mS cm−1 for Li2.5Er0.63Zr0.37Cl6. The authors reported that the gradual substitution of Zr4+ for Y3+ and Er3+ is accompanied by a structural evolution from the trigonal to orthorhombic phase through the reduction of the average transition metal ion radius (Fig. 8a–c), which is beneficial for increasing the number of additional lithium vacancies to improve the ionic conductivity. Bond valence site energy (BVSE) analysis revealed the emergence of one metastable octahedral interstitial site (“Oct.”, Fig. 8d) in the microcrystalline structure, which shares a trigonal face with the (Er1/Zr1) octahedron and yields the most favorable 1D ion transport path of a [Li3 − Oct. − Li3 − Li2] zigzag chain running along the [010] direction (Fig. 8d1, red portion). As a result, a 3D transport network for lithium ions in Li2.5Er0.5Zr0.5Cl6 can be formed by the intersection between this pathway in the ab plane and other chains of [Li2–Li3–Li1] running in the ac plane (Fig. 8d1, green and blue portions). The corresponding ion migration pathway is depicted in the bond valence energy map (Fig. 8e), viewed as the yellow isosurface of constant EBVSE(Li) for lithium in the model. In contrast, the BVSE calculations for Li3ErCl6 (Fig. 8d2) indicated that the migration energy barrier for lithium ions is approximately 1.5 times higher than that of Zr-substituted Li3ErCl6. Consequently, the additional Li sites induced by Zr substitution are a decisive factor for enhancing the ionic conductivity of halide electrolytes. Helm et al. [48] demonstrated that substitution of Zr for a central metal in Li3InCl6 can provide a series of Li3−xIn1−xZrxCl6 (0 \(\leqslant\) x \(\leqslant\) 0.5) solid solutions, which allows an increase in the RT ionic conductivity from the initial 0.47 to 1.25 mS cm−1 for Li2.4In0.6Zr0.4Cl6. This increase is primarily attributed to the incorporation of an optimal Li+/vacancy density and the induced cation site disorder capable of forming a three-dimensional Li+ diffusion pathway. Park et al. [55] synthesized a suite of Li3−xYb1−xMxCl6 (M = Hf, Zr; 0 < x < 1) materials by substituting Hf4+ and Zr4+ for Yb3+ (Fig. 8f), and the highest ionic conductivity of 1.5 mS cm−1 was achieved for Li2.6Yb0.6Hf0.4Cl6 synthesized at 400 ℃ (Fig. 8g), benefiting from the newly generated cubic close-packed (ccp) monoclinic structure with substituted halides being more favorable for Li+ diffusion than the hexagonal close-packed (hcp) orthorhombic structure of Li3YbCl6.

Reproduced with permission from Ref. [46]. Copyright 2020, American Chemical Society. f Schematic diagram of the phase evolution of Hf4+-substituted Li3YbCl6 synthesized by annealing at 400 or 500 °C. g Ionic conductivity and corresponding activation energies for Li3−xYb1−xHfxCl6. Reproduced with permission from Ref. [55]. Copyright 2021, Elsevier

Structural evolution and corresponding Li+ conductivity of heterovalently substituted halide SSEs. a XRD patterns of Li3−xEr1−xZrxCl6. b, c Ionic conductivity and corresponding activation energy of Li3−xEr1−xZrxCl6 and Li3−xY1−xZrxCl6. d (d1, d2) BVSE analysis of migration barriers for Li-ion migration within the Li2.5Er0.5Zr0.5Cl6 and Li3ErCl6 structures. e Li-ion migration pathway of Li2.5Er0.5Zr0.5Cl6 in the ab plane.

The newly discovered Li2ZrCl6 free of rare-earth metals has received extensive attention due to its cost-effective starting materials and good ionic conductivity as well as its high humidity tolerance. By employing the more inexpensive and earth-abundant Fe element, Kwak et al. [56] reported that the aliovalent substitution of Li2ZrCl6 with Fe3+ dramatically improved the ionic conductivity from 0.4 mS cm−1 to the maximum of 1 mS cm−1 for Li2.25Zr0.75Fe0.25Cl6, and the substitution of Zr4+ with trivalent Cr3+ and V3+ also exhibited beneficial effects, as shown in Fig. 9a, b. The Fe3+ substitution induced shrinkage of ZrCl62− octahedra and augmentation of the bond covalency, which could enlarge Li+ channels and reduce the energy landscape for favorable Li+ migration. Subsequently, the authors found that aliovalent substitution with the trivalent metals In3+ and Sc3+ was also feasible for improving the Li+ conductivity of Li2ZrCl6, and a more than two orders of magnitude improvement could be easily achieved for Li2+xZr1−xMxCl6 (M = In, Sc; 0 \(\leqslant\) x \(\leqslant\) 1.0), with a maximum of 2.1 mS cm−1 (M = In, x = 0.7) at 30 ℃ (Fig. 9c, d). This improvement is primarily attributed to the expanded anisotropic lattice volume and the increased concentration of Li+ in the (002) plane, making Li+ migration more favorable in the microcrystalline structure.

Reproduced with permission from Ref. [56]. Copyright 2021, Wiley–VCH. c, d XRD patterns and ionic conductivities with the corresponding activation energies of Li2+xZr1−xMxCl6 (M = In, Sc). Reproduced with permission from Ref. [62]. Copyright 2022, Wiley–VCH. e (e1–e4) Plots of the probability density of Na+ and Cl− in Na3YCl6 and Na2.25Y0.25Zr0.75Cl6 from AIMD simulations. f, g Ionic conductivities and XRD patterns of Na3−xY1−xZrxCl6. Reproduced with permission from Ref. [66]. Copyright 2021, Nature Publishing Group

Effect of central metal substitution on the structural evolution and ionic conductivity of representative halide SSEs. a, b XRD patterns and ionic conductivities with the corresponding activation energies of Li2+xZr1−xMxCl6 (M = Fe, V, Cr).

Regarding Na-based halide SSEs, aliovalent substitution of the central metals of Na3MCl6 (M = Y, Er) with tetravalent Zr4+ also proved to be an effective approach for improving the ionic conductivity. Wu et al. [66] reported aliovalent substitution of Y3+ in the sodium-based halide Na3YCl6 with tetravalent Zr4+, and a series of Na3–xY1–xZrxCl6 (0 < x < 0.875) materials were successfully synthesized. They demonstrated that the impurity phase appeared in the X-ray diffraction (XRD) pattern at 9.6° and 10.5° when the Zr value was increased to 0.875 (Fig. 9e), and the highest ionic conductivity of 6.6 × 10−5 S cm−1 at RT was achieved for Na2.125Y0.125Zr0.875Cl6 (Fig. 9g). Ab initio molecular dynamics (AIMD) trajectory simulations indicated that the Na+ trajectories exhibited mostly local Na+ motion with little long-range transport (Fig. 9f1) and that Cl− remained relatively static (Fig. 9f3) in Na3YCl6, while macroscopic 3D Na+ diffusion (Fig. 9f2) and substantial Cl− motion corresponding to YCl63−/ZrCl62− octahedra rotations (Fig. 9f4) were observed in Na2.125Y0.125Zr0.875Cl6. The synergistic effect between the increased carrier concentration and the polyanionic rotation was concluded to result in remarkably improved Na+ conductivity upon Zr incorporation. Similarly, Schlem et al. [68] found that Zr4+-substituted Na2.4Er0.4Zr0.6Cl6 exhibits an appreciably improved ionic conductivity of ~ 0.04 mS cm−1 compared with the value of 10−9 S cm−1 for Na3ErCl6. Accordingly, heterovalent substitution of Zr for the expensive central metal element of sodium-based halides is highly desirable not only for appreciable enhancement of the ionic conductivity but also for clear cost effectiveness to further realize practical manufacture of sodium-based halide electrolytes.

3.2 Isovalent Cation Substitution

Because the various isovalent cations have different ionic radii and chemical bonding properties, isovalent cation substitution of central metals in halide compounds can effectively optimize the parameters of the unit cell structure and carrier concentration to achieve enhancement of the ionic conductivity.

Li et al. [81] investigated the effect of substituting In3+ for the central metal in Li3YCl6 on its structural evolution and ionic conductivity, and a series of Li3Y1−xInxCl6 (0 \(\leqslant\) x < 1) materials were synthesized by mechanical milling with postannealing at 260 °C. Li3YCl6 has an orthorhombic structure without the introduction of In3+, and the corresponding crystal structure can transform to a trigonal structure when the substitution ratio of In3+ increases to 0.1, whereas both microcrystalline structures are based on hcp anion arrangements. The gradual structural conversion from the hcp anion arrangement to the ccp anion arrangement can be traced when the substitution ratio of In3+ is over 0.2, which allows a dramatic improvement in the ionic conductivity, with a maximum of 1.42 mS cm−1 for Li3Y0.5In0.5Cl6. The In3+ substitution can be interpreted to induce conspicuous changes in the lithium substructure and the metal-Cl covalency along with the generation of the ccp anion arrangement, which are responsible for the appreciably facilitated fast Li+ transport in the microcrystalline structure of In-substituted Li3YCl6. Zhou et al. [59] reported a family of lithium mixed-metal chlorospinels Li2InxSc0.666−xCl4 (0 < x < 0.666) with a relatively low activation energy of ~ 0.33 eV as well as a high Li+ conductivity of 1.80–2.03 mS cm−1, which is much higher than that of spinel-type superionic Li2Sc2/3Cl4 (1.5 mS cm−1). Li2InxSc0.666−xCl4 exhibits a pure cubic spinel microcrystalline structure within the corresponding solid solution range of 0 \(\leqslant\) x < 0.444, whereas the impurity phases Li3InCl6 and LiCl appear in high In3+ content (x > 0.555) compounds, as determined by XRD. The highest ionic conductivity of 2.03 mS cm−1 at RT can be achieved for Li2In1/3Sc1/3Cl4 with four Li sites per unit cell, similar to the crystallite structure of Li2Sc2/3Cl4 but with different occupation, which primarily benefits from the three-dimensional Li-ion diffusion pathway induced by the highly disordered Li-ion distribution in the spinel structure. More importantly, Li2In1/3Sc1/3Cl4 with an ultralow electronic conductivity of 4.7 × 10−10 S cm−1 could be successfully applied in high-output-voltage (4.8 V vs. Li+/Li) ASSBs with the LiNi0.85Co0.1Mn0.05O2 CAM and simultaneously deliver stable cycling with very slow capacity degradation during the charge‒discharge process. Consequently, isovalent cation substitution of central metals in halide compounds can be regarded as a promising option to further enhance the ionic conductivity and stability of halide SSEs.

3.3 Anion Substitution

The central metal of halide SSEs can be incorporated with various halogen anions to crystallize different types of lattice structures, such as Li3ErCl6 (trigonal, P\(\overline{3}\)m1) and Li3ErBr6 (monoclinic, C2/m), which thus offers an efficient approach to enhance the ionic conductivity through the design of halide structures based on halogen anion substitution. Liu et al. [63] successfully synthesized a new family of halide electrolytes Li3MBr3Cl3 (M = Y, Er) by substituting Br− for halogen anions in Li3MCl6 (M = Y, Er), and the Li3YBr3Cl3 obtained by mechanochemical milling exhibited a high ionic conductivity of 1.6 mS cm−1 at RT, which is threefold higher than that of Li3YCl6. Notably, interesting coexistence of Li tetrahedral occupation (1/3 in total) and octahedral occupation (2/3 in total) in the layered structure of Li3YBr3Cl3 is achieved through substitution of Br−, along with corresponding changes in the lattice parameters, which is rarely reported in other halide electrolytes but reasonable in thermodynamics. The presence of tetrahedral Li can induce more vacancies at the octahedral sites as well as change the energy landscape by making it flat, consequently giving rise to the appreciably enhanced Li+ diffusion pathway in the microcrystalline structure of Li3YBr3Cl3. Moreover, the ionic conductivity of the Li3YBr3Cl3 compound could be further improved to 7.2 mS cm−1 at RT after a hot-pressing process at 170 °C, mainly ascribed to the Br− substitution inducing rapid 3D diffusion pathways, resulting from a mass of Li at the tetrahedral sites as well as enhancement of grain boundary contact through hot-pressing. Due to the higher ionic conductivity of Li3YBr3Cl3, a primarily improved specific capacity of the full cell fabricated with Li3Ybr3Cl3 was achieved compared to the cell with Li3YCl6. Through this method, a noteworthy enhancement of the ionic conductivity could also be obtained for Li3ErBr3Cl3, indicating that this anion substitution strategy appears to be general in terms of improving the ionic conductivity for mixed anionic halide electrolytes. Tomita et al. [43] investigated the effect of Cl− substitution of Br− in Li3InBr6 on its ionic conductivity and thermal stability, and a series of Li3InBr6−xClx (0 < x < 6) solid solutions were prepared by mechanical ball milling and subsequent annealing. They reported that Li3InBr3Cl3 exhibited the highest ionic conductivity of 1.2 × 10−4 S cm−1 at 300 K, and the phase transition temperature was lowered to approximately 295 K. The substitution of bromine with chlorine was demonstrated to allow reduction of the lattice volume and induction of partial diffusion of lithium ions, which was confirmed by 7Li NMR analysis that showed faster diffusion of lithium ions in Li3InBr3Cl3.

3.4 Heterogeneous Compositing

A heterogeneous compositing strategy can be used to enhance the ionic conductivity of halide SSEs by introducing uniformly dispersed heterogeneous materials, and it is preferentially applied to the case of halide compounds with halogen fluoride anions. Typically, the introduced heterogeneous phase could exhibit chemical affinity for the mobile ions on the surface of halide compounds and absorb the mobile cations, resulting in defect concentration and consequently enhancement of the ionic conductivity of halide solid electrolytes [82, 83].

Feinauer et al. [84] investigated the effect of introducing nanocrystalline alumina (γ-Al2O3) on the ionic conductivity of the halide β-Li3AlF6, and a series of β-Li3AlF6 + Al2O3 (2–20 wt%) composites were prepared through mechanical milling. The ionic conductivity of the halide β-Li3AlF6 can be increased up to 10 times through compositing with 2 wt% γ-Al2O3, whereas a higher content will not further enhance the ionic conductivity because of the blocking effect. Notably, for the corresponding assembled ASSBs, the first charge capacity of the cell with Li//β-Li3AlF6 + γ-Al2O3//LiMn2O4 can reach 108 mAh g−1, which is 33 mAh g−1 higher than that of the cell based on β-Li3AlF6 under the same test conditions. This difference is primarily attributed to the substantially enhanced ionic conductivity of β-Li3AlF6 induced by heterogeneous compositing with nanocrystalline alumina. In addition, Miyazakiz et al. [85] reported that the ionic conductivity of nanocrystalline β-Li3AlF6 at RT can be dramatically increased from 7 × 10−7 to 2 × 10−6 S cm−1 through compositing with LiCl, mainly ascribed to the mixing anion effect and the dispersion effect related to the space charge region. The heterogeneous compositing strategy exhibits an easily operated advantage by coupling uniformly dispersed materials to enhance the ionic conductivity of the prepared halide compounds, which also offers a potential way to optimize the performance of fluorine-based halide electrolytes for realizing their application in ASSBs.

3.5 Regulating the Composition

Regulating the composition of halide compounds enables optimization of metal/vacancy site occupations, which is conducive to achieving a balance between the Li+ carrier concentration and total vacancy content for enhancing the ionic conductivity of halide SSEs. Variation of the halide composition within a certain range can simultaneously induce a gradual transformation of the crystallite structure, which presents an opportunity for obtaining optimally uninterrupted Li+ diffusion channels in halide compounds. Liang et al. [57] discovered a series of LixScCl3+x (x = 2.5, 3, 3.5 and 4) superionic halide electrolytes with RT ionic conductivities over 1 mS cm−1 based on the ccp anion sublattice and increasing the x value in LixScCl3+x gave rise to augmentation of the Li+ carrier, while the opposite trend was observed for the total vacancy content. The optimal balance was obtained for Li3ScCl6 with appropriate Li+ carrier and vacancy concentrations, and consequently, Li3ScCl6 achieved the highest ionic conductivity of 3.02 mS cm−1 at RT among the as-synthesized Li–Sc–Cl halide compounds. Wang et al. [53] investigated the effect of composition variation on the ionic conductivity of Li–Zr–Cl-type halide SSEs and reported that Li2ZrCl6 delivered the highest ionic conductivity of 0.81 mS cm−1 at RT compared to LiZrCl5 (0.15 mS cm−1) and Li3ZrCl7 (0.27 mS cm−1), although these halide compounds could remain phase-pure. Xu et al. [80] synthesized a series of Li3−xYb1+xCl6 (x = 0.017, 0.034, 0.053, 0.071) materials with various degrees of Li deficiency to improve the ionic conductivity of Li–Yb–Cl-type halide electrolytes by increasing the Li vacancies in the lattice structure. Although all prepared samples exhibited an orthogonal crystal structure, Li2.966Yb1.034Cl6 showed the highest ionic conductivity of 0.5 mS cm−1 at RT, benefiting from the optimal balance between the carrier and vacancy concentrations.

Optimizing the composition of halide compounds can be simultaneously employed to regulate their initial crystal structure to enhance the ionic conductivity. Liang et al. [60] reported a series of Li3−3xHo1+xCl6 (− 0.14 < x \(\leqslant\) 0.5) halide superionic conductors with a transition from the trigonal to orthorhombic structure when x was gradually increased. The halide Li2.73Ho1.09Cl6 with the orthogonal structure can exhibit the highest ionic conductivity of 1.3 mS cm−1 at RT, which is four times higher than that of Li3HoCl6 with the trigonal structure, mainly because of the facile diffusion in the z-direction in the orthorhombic structure for Li2.73Ho1.09Cl6. Moreover, the trigonal-to-orthorhombic phase transition has been proven to be universal in Li3−3xM1+xCl6 (− 0.14 < x \(\leqslant\) 0.5, M = Dy, Y, Er, Tm). Specifically, the orthorhombic phase of Li2.73M1.09Cl6 containing Dy, Y, Er, and Tm delivers superior ionic conductivities of 0.9, 0.7, 0.64 and 0.89 mS cm−1 at RT, respectively, which are an order of magnitude higher than the conductivities of the corresponding trigonal phases of Li3MCl6. This trigonal-to-orthogonal structural transition may be a prevailing phenomenon in many other types of Li3−3xM1+xCl6, and further investigation of it is highly desirable to discover new superionic halide electrolytes. Consequently, precise control of the composition of halide compounds can be considered a feasible strategy for improving the ionic conductivity of halide SSEs by achieving the optimal ion diffusion channel in their corresponding microcrystalline structures.

4 Chemical Stability

The chemical stability of halide SSEs is regarded as a crucial performance indicator that could significantly affect their implementation in their whole life, from synthesis, storage, and transportation to application, and is closely related to the operation of the material and the application cost of manufacturing ASSBs. Chemically unstable electrolyte materials suffer severe mechanical and chemical degradation as a result of the destruction of the crystalline structure, which can occur even prior to electrochemical cycling, resulting in unsatisfactory ionic conductivity, high interfacial resistance, and degraded cell performance [24]. Consequently, rational optimization of the chemical stability enables effective regulation of production processes and battery configurations, which in turn offers a favorable guarantee for reducing production costs to maintain performance standards and large-scale commercial applications.

4.1 Air/Humidity Stability

4.1.1 Degradation Mechanisms under Humid Air

An in-depth and comprehensive understanding of the influencing factors of humid air on various halide SSEs and the corresponding degradation mechanisms is highly beneficial for facilitating efficient application of different halide compounds and obtaining feasible strategies against degradation. Halide solid electrolytes exhibit better air stability than sulfide electrolytes and can avoid the generation of toxic H2S, which is favorable for safe operation [21, 28]. Moreover, halide solid electrolytes that can maintain decent stability in dry oxygen environments, such as Li3YCl6 and Li3YBr6 [44], will not undergo degradation in terms of decomposition, phase transition and oxidation reactions. Nevertheless, recent studies have indicated that the majority of halide electrolytes are unstable when exposed to ambient atmosphere and can react with moisture to form different hydrated products, including MCl3·xH2O and LiCl·xH2O [86, 87]. As a consequence, an irreversible degradation reaction occurs, and MCl3·xH2O is transformed into M2O3 and HCl during the thermal dehydration process. In the case of Li3YCl6, the corresponding degradation reactions can be described by Eqs. (1) and (2) [21, 87, 88].

The halide Li3InCl6 exhibits superior tolerance to ambient air compared to other halide compounds, which is mainly attributable to the preferential formation of hydrated intermediates (Li3InCl6·xH2O) that can effectively resist the constant occurrence of harmful hydrolysis reactions (Fig. 10a) [87]. Notably, the conversion from Li3InCl6 to Li3InCl6·xH2O is reversible, which means that the initial structure and ionic conductivity of Li3InCl6 can be recovered after removing the crystal water through a simple dehydration process [52, 81].

Reproduced with permission from Ref. [87]. Copyright 2022, Wiley–VCH. c Hydrolysis reaction energy for binary chlorides M–Cl, ternary lithium chlorides Li–M–Cl, and ternary sodium chlorides Na–M–Cl. Reproduced with permission from Ref. [89]. Copyright 2020, Wiley–VCH. d Illustration of the humidity stabilities of Li3Y1−xInxCl6 and Li3YCl6. e Arrhenius plots of Li3Y0.2In0.8Cl6 before and after air exposure. Reproduced with permission from Ref. [81]. Copyright 2020, American Chemical Society. f Schematic illustration of coating Li3InCl6 with Al2O3 by powder atomic layer deposition. g Digital photos of powder and pellet samples for Li3InCl6 over time in ambient air with (35 ± 5)% relative humidity. Reproduced with permission from Ref. [87]. Copyright 2022, Wiley–VCH

Moisture stability of halide SSEs. a Schematic diagram of the Li3InCl6 degradation mechanism under humid air, and b XRD pattern and digital photo of Li3InCl6 reacted with Al foil for 12 h.

However, Li3InCl6 will inevitably undergo decomposition to form InCl3 and LiCl with long-term exposure, and InCl3 further hydrolyzes to produce In2O3 and HCl through the formation of the unstable intermediate phase In(OH)3; the related reactions are shown in Eqs. (3) and (4) [87, 88]. The formation of the acidic product HCl can corrode aluminum foil (Fig. 10b) [87], which is commonly used as a current collector for battery assembly, and thus possibly cause a safety hazard in application. In addition, Wang et al. [53] demonstrated that Li2ZrCl6 exhibits better stability than Li3InCl6 in an atmosphere with 5% relative humidity. However, the degradation mechanism of Li2ZrCl6 with high humidity tolerance is still unclear and conducting in-depth and comprehensive research in the future is highly desirable.

4.1.2 Strategies to Improve Humid Air Stability

The air/humidity tolerance of halide SSEs is closely associated with the type of central metals in the halide compounds with various valences and ionic radii [89]. In addition, the water absorption rate of the halide electrolytes can be changed by adjusting the contact area of the solid/gas interface and the particle size of halide compounds to effectively regulate the degradation rate of the halide in practical applications.

Zhu et al. [89] investigated the moisture stability of Li- and Na-containing halide compounds A3MCl6 (A = Li/Na, M = cation) by quantifying the hydrolysis reaction energy, and corresponding thermodynamic analyses based on a first-principles computational database were performed, as shown in Fig. 10c. Their results demonstrated that sodium ternary chlorides with lanthanide cations (Tm3+, Er3+, Ho3+, Tb3+, etc.) exhibit better moisture stability, among which the best humidity tolerance is achieved for Na3TmCl6. Lithium ternary chlorides with trivalent metal ions (In3+, Ga3+) and transition metal ions (Cd2+, Zn2+) deliver excellent moisture stability, and halide Li3InCl6 possesses the best moisture resistance, which is also in accordance with the superior humidity tolerance of Li3InCl6 reported experimentally. The results also imply that several of these identified cations with decent moisture stability are viable elements for doping/substitution to enhance the humidity tolerance of halide SSEs.

Li et al. [81] investigated the effect of isovalent In3+ substitution of the central metal in Li3YCl6 on the humidity tolerance of Li3YCl6 and demonstrated that Li3Y1–xInxCl6 (x > 0.5) with a high In3+ content exhibited significantly improved moisture stability. For instance, pristine Li3Y0.2In0.8Cl6 delivered an ionic conductivity of 1.23 mS cm−1 at RT, and the reheated Li3Y0.2In0.8Cl6 after 3%–5% humidity exposure still exhibited a relatively high ionic conductivity of 1.05 mS cm−1 at RT (Fig. 10f), making the corresponding conductivity retention appreciably increase to 85.37% compared to the poor conductivity retention of 0.8% for Li3YCl6. The hydrated intermediate Li3(Y1−xInx)Cl6−xH2O is preferentially formed because of the generation of (Y/In)Cl63− octahedra in the crystallite structure after In-substituted halide compounds are exposed to a humid atmosphere, which is beneficial for the efficient recovery of the initial halide structure after removing crystal water (Fig. 10d); thus, a dramatically improved conductivity retention is achieved. In contrast, the unsubstituted Li3YCl6 is thoroughly hydrolyzed into separated products involving LiCl·H2O and YCl3·6H2O after exposure to moist air under the same conditions, which cannot be converted back by heat treatment (Fig. 10e).

Wang et al. [87] proposed enhancing the moisture stability of Li3InCl6 by coating a layer of Al2O3 on the surface of Li3InCl6 via powder atomic layer deposition (Fig. 10g). They reported that the water absorption rate of Li3InCl6@Al2O3 (5.16 mg h−1) could be decreased to 1/4 of that of the as-synthesized Li3InCl6 (20.83 mg h−1), and the corresponding liquefaction time was significantly improved by seven times. Consequently, coating Li3InCl6 with an Al2O3 protective layer can be regarded as a valuable methodology to hinder hydrolysis degradation of pure Li3InCl6, although the corresponding ionic conductivity slightly decreased after introducing the Al2O3 protective layer. The authors simultaneously reported that the Li3InCl6 pellet samples obtained from cold pressing over 300 MPa could maintain a round shape after exposure to humid air for 8 h, whereas for the Li3InCl6 powder, more than half of the sample turned into a solution after only 1 h of exposure (Fig. 10h) under the same conditions. The relative density of Li3InCl6 is significantly improved from powder to pellet samples, which can greatly reduce the contact area of the solid/gas interface, and thus, the pellet samples exhibited much better moisture stability than the powder samples for Li3InCl6 halide electrolytes.

In summary, the spontaneous degradation of halide SSEs in a humid atmosphere is a crucial challenge hindering large-scale manufacturing and application of halide-based ASSBs. In the future, effective strategies for enhancing the humidity tolerance of halide SSEs to further develop, through optimization of the design, novel moisture-stable halide electrolytes and for exploiting valuable protection approaches are highly desirable.

4.2 Solvent Compatibility

Emerging halide electrolytes are considered promising candidates for facile processing of ASSBs due to the advantages of reliable deformability and high ionic conductivity. Despite this, the solid electrolyte pellets prepared by cold pressing exhibit weak mechanical properties, such as cracks generated during the pressing process [90, 91], that need to be compensated for, which severely limits the large-scale processing of solid electrolytes for the production of commercial ASSBs. Solvent-based processes have received extensive attention for fabricating high-energy–density composite cathodes and ultrathin composite electrolyte membranes with outstanding electrochemical performance [28, 92], which are capable of achieving tight contact between materials and effectively avoiding the occurrence of mechanical failures during the pressing process. Consequently, solvent-based processes can be regarded as a highly reliable strategy for realizing commercial application of halide-based ASSBs.

Generally, maintaining good stability of halide SSEs in solvents is of great importance, and the requirements for an acceptable solvent are that it should not cause chemical or structural detrimental effects or loss of the ionic conductivity of halide SSEs. Unfortunately, the severe reactivity of halide SSEs with polar solvents greatly restricts the widespread application of common solvents [51]. As shown in Fig. 11a, halide SSEs usually exhibit relatively weak interactions with nonpolar or weakly polar solvents. However, because of the strong interaction between halide compounds and polar solvents, halide SSEs can easily react with polar solvents, accompanied by dissolution through the loss of the original microcrystal structures, resulting in reduction of the ionic conductivity to some degree. The possible nucleophilic attacks of solvents on halide solid electrolytes are illustrated in Fig. 11b. Highly polar solvents are considered strong Lewis bases, which contain lone-pair electrons of electronegative elements such as N and O and can react with electrophilic central metals with high valence in halide solid electrolytes according to the hard and soft acids and bases (HSAB) principle [93], giving rise to challenging issues in terms of the poor compatibility of halide compounds with polar solvents.

Reproduced with permission from Ref. [51]. Copyright 2022, American Chemical Society

Solvent compatibility of halide SSEs. a Schematic illustration of the compatibility between halide SSEs and organic solvents with various degrees of polarity. b Possible nucleophilic attacks by different solvents on halide SSEs. c, d Ionic conductivities and dissolved amounts of Zr for Li2ZrCl6 after exposure to various solvents, and corresponding XRD patterns.

Kwak et al. [51] investigated the compatibility of Li2ZrCl6 with different organic solvents by measuring the ionic conductivities and detecting the amount of Zr4+ dissolved in organic solvents. They found that nonpolar dibromoethane (DBM) could only dissolve a very small amount of Li2ZrCl6, corresponding to only 9.9 ppm (1 ppm = 1 μmol mol−1) Zr4+ detected in the mixed suspension with DBM (Fig. 11c), which is also in accordance with the retention of relatively complete XRD peaks and the high ionic conductivity retention achieved after removing the solvent (Fig. 11d). The halide Li2ZrCl6 exhibited severe dissolution in both the strongly polar solvent N-methyl-2-pyrrolidinone and the intermediate-polarity solvent hexyl butyrate. Unexpectedly, even when Li2ZrCl6 was exposed to nonpolar (o-xylene) or weakly polar (toluene) solvents, the main XRD peaks of Li2ZrCl6 disappeared after removing the solvent, accompanied by the appearance of the impurity phase of LiCl (Fig. 11d), indicating that the microcrystal structure of Li2ZrCl6 severely collapsed, leading to a remarkable loss of the ionic conductivity (3 × 10−10 S cm−1 at 30 °C). This work implied that halide electrolytes may have stringent requirements for compatible solvents. To date, reports on acceptable solvents for halide SSEs are rare; considering the relatively high reactivity between common polar solvents and halide compounds, the selection of compatible solvents requires great efforts.

Consequently, to obtain acceptable solvents for realizing application of solvent-based scalable processes for halide SSEs, revealing the degradation mechanisms of halide electrolytes when they are exposed to incompatible solvents and further understanding the stability of halide electrolytes in various types of organic solvents are of great significance.

5 In Situ/Operando Characterization Techniques Applied to Halide-Based ASSBs

The development of high-performance halide-based ASSBs requires an in-depth understanding of the electrochemical reaction processes, degradation mechanisms and dynamic evolution of the electrolyte under realistic operating conditions. This understanding could be achieved through in situ/operando characterization techniques, which offer information on the structural evolution of electrolytes, redox mechanisms and solid-electrolyte interphase (SEI) formation under continuous operation. Compared with traditional ex situ characterization techniques, which are restricted to the understanding of the starting and ending states of materials and batteries and have the characteristics of data uncertainty and hysteresis, in situ/operando characterization techniques are beneficial for gaining deeper insight into the working principle of devices and the underlying reaction mechanisms of materials and are consequently capable of providing a theoretical basis for the design of ASSBs with high energy density and long cycle life.

5.1 In Situ/Operando Characterization of Electrolyte Materials

Recently, computational simulations and experimental results have indicated the existence of metastable state materials during the synthesis of halide electrolytes by the solid-state reaction route, and metastable halides can deliver appreciably enhanced ionic conductivity because of the formation of faster Li+ diffusion pathways in the microcrystalline structure [45, 55, 94]. An in-depth understanding of the synthesis conditions and dynamically stable mechanisms of metastable halides plays an important role in further developing novel halide electrolytes. More importantly, limited by the data hysteresis of ex situ characterization techniques, the underlying degradation mechanisms of halide electrolytes upon humid air exposure are still not completely understood. In situ/operando characterization methods can provide the evolution of the electrolyte microstructure, surface morphology and local chemical state during the dynamic reaction by obtaining continuous monitoring data, which offers an effective strategy to deeply investigate the dynamic structural evolution of halide electrolytes during solid-state synthesis and the degradation mechanisms in continuous operation environments.

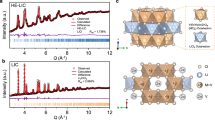

Ito et al. [95] employed in situ synchrotron XRD to investigate the solid-phase reaction of LiCl and YCl3 during the continuous heating process for synthesizing Li3YCl6 and reported that the novel metastable phase β-Li3YCl6 with smaller lattice parameters was formed in the temperature range of 450–600 K, which gradually transformed into α-Li3YCl6 in the process of heating over 600 K (Fig. 12a). The related reactions can be described by Eq. (5) and (6), and the corresponding mass fractions of various phases during the solid-state reaction are shown in Fig. 12b, calculated from the corresponding Rietveld refinement results. Furthermore, the authors found that the synthesis by heating precursor materials to 823 K followed by annealing at 595 K did not yield β-Li3YCl6, suggesting that the phase transition from β- to α-Li3YCl6 was irreversible and that β-Li3YCl6 was a metastable halide electrolyte. β-Li3YCl6 could be assigned to a cell with a 1/3 a-axis and a c-axis similar to that of α-Li3YCl6, leading to electronic repulsion between Y3+ accompanied by a broadened Li+ diffusion channel, and consequently, the ionic conductivity of β-Li3YCl6 with a disordered Y site was appreciably improved by an order of magnitude compared with α-Li3YCl6. Consequently, in situ investigation of solid-state reactions could promote detection of new cation arrangements in the microcrystalline structure of solid electrolytes, which is conducive to the discovery of novel metastable halide electrolytes with high ionic conductivity.

Reproduced with permission from Ref. [95]. Copyright 2021, Wiley–VCH. c Two-dimensional intensity color map of NPD patterns for mechanochemically synthesized α-Li2ZrCl6. d Nyquist plots of α-Li3YCl6 and β-Li3YCl6. Reproduced with permission from Ref. [53]. Copyright 2021, Springer Nature. e Schematic diagram of the operando optical microscopy and Raman spectroscopy device (middle), operando optical microscopy photos obtained with various exposure times (left), and Raman spectra evolution of Li3InCl6 exposed to moist air (right). f, g Illustration of operando SXRD for Li3InCl6, and corresponding patterns of Li3InCl6 during exposure to air with 30% humidity for 120 min. Reproduced with permission from Ref. [88]. Copyright 2020, American Chemical Society

In situ/operando characterization of halide solid electrolytes. a, b In situ synchrotron XRD patterns upon heating the mixture of LiCl and YCl3 to synthesize Li3YCl6, and corresponding mass fractions obtained from Rietveld refinement.

Wang et al. [56] applied in situ neutron powder diffraction (NPD) to study the phase evolution of mechanochemically synthesized α-Li2ZrCl6 in the temperature range from 27 to 427 °C, as shown in Fig. 12c. When the temperature is higher than 275 °C, β-Li2ZrCl6 with a structure similar to that of Li3InCl6 emerges, along with the gradual reduction of the α-Li2ZrCl6 reflection intensities, and β-Li2ZrCl6 is the only phase identified in the NPD pattern at temperatures above 350 °C. The β-Li2ZrCl6 obtained at high temperatures loses the nonperiodic features in terms of the defect structure, strain and amorphous phase, resulting in the ionic conductivity decreasing from a value of 8.08 × 10–4 S cm−1 for the initial α-Li2ZrCl6 to 5.81 × 10–6 S cm−1 (Fig. 12d).

Li et al. [88] revealed the degradation mechanism of halide Li3InCl6 when it was exposed to moist air through various in situ/operando characterization techniques. The optical images obtained from operando optical microscopy suggested that Li3InCl6 particles underwent rapid morphological changes within several minutes of exposure to 30% humidity, which confirmed the hydrophilic characteristic of Li3InCl6 (Fig. 12e). Furthermore, a new peak at 131.5 cm−1 assigned to In2O3 appeared in the operando Raman spectrum, which could be one of the products formed during the degradation of Li3InCl6, and the intensity of the O–H peak significantly increased over time, which provided evidence of hydrated halide formation. Operando synchrotron-based X-ray powder diffraction (SXRD) was employed to detect other hydrolysis products of Li3InCl6, in which a Pilatus pixel area sensitive detector was used to record the scattered X-ray beams (Fig. 12f). A new set of peaks assigned to Li3InCl6·xH2O appeared after exposure to moist air for 10 min, and a mixture of peaks at ~ 19.9° and ~ 23.2° belonging to Li3InCl6·xH2O and LiCl was detected in the SXRD pattern when the exposure time reached 120 min (Fig. 12g), indicating that both were products of the hydrolysis reaction. In addition, in situ X-ray absorption near-edge structure (XANES) results also confirmed the formation of LiCl and Li3InCl6·xH2O when Li3InCl6 was exposed to a humid environment. Based on this, the authors concluded that hydrophilic Li3InCl6 can react with moisture and finally decompose to nonionically conductive In2O3 and LiCl, while part of Li3InCl6 would absorb moisture to form Li3InCl6·xH2O when it was exposed to ambient air.

5.2 In Situ/Operando Characterization of Electrodes and Interfaces

Bulk-type halide-based ASSBs can be directly fabricated through stepwise cold pressing of materials, including solid electrolytes, CAMs and anodes, benefiting from the outstanding mechanical deformability of halide electrolytes, but the related challenging issues of the interfacial stability of the electrolyte and CAMs and the reversible redox reaction in the composite cathode require a thorough understanding [26, 96]. Specifically, the degradation mechanisms of halide electrolytes against lithium anodes during realistic electrochemical reactions require further clarification. Without disassembling batteries and extracting samples for testing, in situ characterization techniques can offer effective information on heterogeneous reactions in high-energy-density cathodes, SEI formation and degradation mechanisms during battery charge and discharge, which in turn can provide crucial strategies for optimization and design of high-performance halide-based ASSBs.

For the first time, Asano et al. [44] performed in situ XRD characterization of a bulk-type cell based on Li3YCl6 to investigate the redox reaction of composite cathodes under realistic operating conditions. A schematic diagram of the in situ XRD measurement geometry and the corresponding cell structure are shown in Fig. 13a. They reported that the (003), (006) and (104) peaks of LiCoO2 shifted to a low angle while the (101) peak slightly shifted to a higher angle during the initial charging cycle (Fig. 13b), indicating that the c-axis of LiCoO2 was elongated and the a-axis was shortened, in accordance with the LiCoO2 evolution behavior detected in situ with liquid electrolytes. However, the in situ XRD peaks of halide Li3YCl6 were not shifted during the charge process, confirming that the charging current is solely produced through Li+ extraction from LiCoO2 cathode materials. Consequently, they concluded that Li3YCl6 with outstanding electrochemical stability can be directly used for ASSBs based on uncoated high-voltage CAMs.

Reproduced with permission from Ref. [44]. Copyright 2018, Wiley–VCH. c, d In situ/operando Raman spectra of the Li3InCl6@LiCoO2 electrode during the charge and discharge processes. e Contour plots of Li3InCl6@LiCoO2 during the charge process. Reproduced with permission from Ref. [97]. Copyright 2020, Elsevier. f Schematic of Li deposition with an argon sputter gun and subsequent in situ XPS measurement. g–i X-ray photoelectron In-3d and Li-1s and Auger In-MNN spectra during/after Li deposition on Li3InCl6. Reproduced with permission from Ref. [98]. Copyright 2021, Wiley–VCH

In situ/operando characterization of electrodes and interfaces for halide-based ASSBs. a Schematic illustration of the in situ XRD measurement geometry and the corresponding cell construction. b In situ XRD patterns of the Li3YCl6-based cell during initial charging.