Abstract

As the world works to move away from traditional energy sources, effective efficient energy storage devices have become a key factor for success. The emergence of unconventional electrochemical energy storage devices, including hybrid batteries, hybrid redox flow cells and bacterial batteries, is part of the solution. These alternative electrochemical cell configurations provide materials and operating condition flexibility while offering high-energy conversion efficiency and modularity of design-to-design devices. The power of these diverse devices ranges from a few milliwatts to several megawatts. Manufacturing durable electronic and point-of-care devices is possible due to the development of all-solid-state batteries with efficient electrodes for long cycling and high energy density. New batteries made of earth-abundant metal ions are approaching the capacity of lithium-ion batteries. Costs are being reduced with the advent of flow batteries with engineered redox molecules for high energy density and membrane-free power generating electrochemical cells, which utilize liquid dynamics and interfaces (solid, liquid, and gaseous) for electrolyte separation. These batteries support electrode regeneration strategies for chemical and bio-batteries reducing battery energy costs. Other batteries have different benefits, e.g., carbon-neutral Li-CO2 batteries consume CO2 and generate power, offering dual-purpose energy storage and carbon sequestration. This work considers the recent technological advances of energy storage devices. Their transition from conventional to unconventional battery designs is examined to identify operational flexibilities, overall energy storage/conversion efficiency and application compatibility. Finally, a list of facilities for large-scale deployment of major electrochemical energy storage routes is provided.

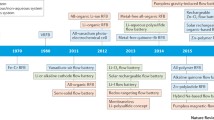

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 World Energy Consumption Scenarios and Emissions

Energy from different sources, non-renewable and renewable, in various forms, including electricity, heat and motion/position is used to deliver goods and services in modern society. Carbon-based non-renewable oil, gas and coal are the dominant global energy sources [1]. As these extractable resources are depleted, and the detrimental environmental consequences from burning fossil fuels accelerate, a global search for un-depletable energy sources is taking place. There is a tremendous interest in primary, inexhaustible energy resources derived from biomass, hydropower, geothermal, solar, wind, marine, wave and/or tidal energy. Nuclear fission energy is considered nearly inexhaustible and capable of replacing fossil fuels [2]. The coupling of renewable and electrification is an enticing path to simultaneously combat deleterious\anthropogenic greenhouse gas (GHG) emissions on climate change and particulate emissions on urban air quality. Renewable energy sources and advanced electricity storage/conversion systems are gaining popularity, as evidenced by significant investments and policies that favor renewable and clean energy technologies.

Clean power sources are the most sought-after alternative to reduce GHG emissions, as evident in the dramatic increase in the global renewable energy capacity over the last decade. It is estimated that the total amount of energy consumed globally in 2018 was about 151 PW h (1 peta (P) = 1 × 1015) with significant contributions from coal, crude oil, and natural gas [3]. The major portion of utilized energy comes from fossil fuels, and the remaining contribution comes from nuclear and renewable energy. Although natural gas is a fossil fuel, its combustion produces significantly lower emissions than the combustion of coal or oil [4]. The combustion of fossil fuels contributes to 65% of the total global GHG emissions, of which coal accounts for 45%, oil for 35%, and natural gas for 20% [1]. The largest energy consumption sectors are industry (~ 50%) followed by residential and commercial buildings (~ 29%) and the transportation sector (21%). Multiple energy resources with low carbon emission potential are in huge demand in all these sectors [5]. A dramatic shift in the electrification of the transportation sector and an increasing interest to adopt solar-derived power in residential and commercial buildings contribute to the increased adoption of diverse renewable energy sources despite these efforts; the global carbon emission has risen to 36.8 Gt (1 giga (G) = 109) per year based on 2019 data [6]. Energy demand is expected to continue to grow driven by the fast-growing economies of India and China, and a global population is expected to reach 9.2 billion by 2040 [7, 8]. The adoption of renewable energy in different sectors is a plausible solution to balance the energy demand and supply equation.

1.2 The Critical Role of Electrochemical Energy Storage in Transition to Renewable Energy

Global renewable energy usage reached 2.3 TW h (1 tera (T) = 1 × 1012) in 2018 with 61% of new installed capacity in the Asia region. The International Renewable Energy Agency (IRENA) has stated that the present energy related-CO2 emissions must be reduced to 70% of the 2020 level (~ 35 Gt per year), and 2/3 of the energy consumption must come from renewable energy sources to achieve the 2050 targets set by the Paris agreement on climate change [9]. An irreversible global momentum of clean energy adoption has facilitated efforts to decarbonize energy systems, store carbon and reduce CO2 and non-CO2 emissions [10]. Wind, solar, tidal, geothermal, and biomass energy are globally pervasive renewable energy resources. The tools used to harvest these diverse energy sources are not optimized. They possess high capital costs and suffer from intermittency requiring efficient energy conversion and at-scale energy storage systems. Adoption of renewable energy technology on a large scale will contribute to a predicted decrease in the cost of new power generation for local and global markets. These changes will provide the backbone of de-carbonization [11].

IRENA predicted that renewable energy is expected to provide more than 50% of the energy demands of developing nations by 2040 [3]. This prediction is supported by the trending cost reductions for solar and wind power. The evidence for the decline in current renewable energy prices per kW h is presented in Fig. 1. The intermittency challenges that come with the adoption of solar and wind renewable energy can be addressed by coupling it with suitable energy storage and conversion technologies. Energy can be stored in many ways: mechanical, electrical, chemical and electrochemical with various characteristic storage times and capacities (Fig. 2). Conversion of stored energy into an accessible form is often part of the energy storage paradigm. Some applications require short bursts of energy for only a short period, while others require sustained low amounts of energy over an extended period. The energy utilized through the grid-scale application is stored commonly via a mechanical form such as pumped hydro and/or compressed air [14]. Efficient use of locally distributed energy is possible through microgrids rather than connecting and distributing energy via a centralized grid [15,16,17,18]. Smaller units of energy can be easily stored and used in the form of electrochemical energy storage (EES) devices by end-users. Larger volumes of energy can be stored in mechanical, electromagnetic and/or chemical forms of energy (hydrogen, organic fuels), and these require a significant infrastructure commitment. EES is quickly becoming the most promising energy storage approach due to innovative technology, new materials and an easier end-user approach. Clean energy access routes are more conceivable than ever before due to falling energy prices that have seen $1 per kW h renewables coupled with an energy storage cost of $100 per kW h [19]. By 2023, the world’s cheapest solar power is expected to cost 1.997 ¢ per kW h, and it will be coupled with one of the world’s largest batteries at an electricity cost of 1.3 ¢ per kW h [20].

1.3 Conventional Approaches for Electrochemical Energy Storage

A conventional EES device consists of two electrodes through which electrons are transferred and stored in a chemical form. A membrane/separator is necessary to separate the two electrodes. A common ion is involved in the two different electrochemical reactions at the two electrodes, which couples the two electrode reactions. An electrolyte with selective and facile transport of the common ion is an essential component of the EES device. This common energy storage design in batteries and fuel cells uses solid, liquid, and gaseous forms of reactants. Battery technology has gained attention, due to its modularity and low cost than other electricity storage options [21]. Solid-state devices that use simple anode, membrane and cathode design are restricted by the diffusion-controlled electrode thickness for storing energy at the electrode-electrolyte interface. This problem has been alleviated by using redox materials dissolved in supporting electrolytes accompanied by circulation for better utilization in flow-based batteries. In the flow battery, energy is stored and released in redox states of oxidants and reductants present in the liquid form. Since the circulation of redox liquids from large storage tanks into an energy conversion device is possible, there is a flexibility of decoupling power from energy in these devices. Finally, the gaseous reactants can be used for energy conversion and storage. Hydrogen-based polymer electrolyte fuel cells (PEFCs) operate at lower temperatures (< 120 °C) than other fuel cell types. They generate power from hydrogen and oxygen separated by an ion-exchange membrane with liquid water and heat as byproducts. Hydrogen is the most abundant chemical substance on earth. It is the basic component of water, hydrocarbon, and organic substances. The liquid form of hydrocarbon fuels such as ethanol and methanol can be used in place of hydrogen, providing hybrid liquid and gaseous reactants for energy conversion. These conventional EES devices are not without challenges, as they require components such as electrodes, electrolytes and membranes or separators to be present, which restricts their applicability in a practical situation.

2 The Need for Alternative EES Approaches

Using renewable energy in all sectors should lead to zero-emission and no global warming effects [5]. However, this is yet to be realized. Although fossil fuels will continue to supply the main share of the global energy needs, it is expected that renewable energy could significantly contribute to the total world energy needs by 2050. The target can be achieved sooner by advancing EES technologies to commercial readiness. One such focus is to go beyond classical EES approaches. These are the unconventional EES systems.

Unconventional EES systems are capable of incorporating additional functionalities to gain advantages from a smaller number of components or a hybrid combination of reactants from a decentralized operating environment. They utilize side reactions occurring due to the main chemical reactions, natural processes and excess energy-carrying processes to harvest/convert energy. These side reactions are diverse depending on the unconventional EES system being used: solar radiation, wind energy, geothermal energy, ocean wave energy, subsurface microbial activity near the petroleum reservoir, sedimentary microbial activity in marine environments and biotic interaction of algae. An unconventional approach is a viable alternative to balance increasing energy demand while developing acceptable substitutes for energy harvest/conversion rather than an independent pathway for the energy systems and continuing to keep economics at the forefront. Generally, these alternative approaches have numerous opportunities, but their form factors/designs impose a huge challenge for mass production and commercial success.

2.1 Challenges with Membrane/Separator-Based EES Devices

With the evolution of voltaic cells, a variety of reactants in different states of matter (liquid, gas, and solid) are being considered to achieve high energy storage density. The use of a separator/ion-selective membrane has increased the variety of reactants that can be used by providing a barrier for semi-solid, liquid, gaseous and hybrid reactants. The separator/membrane in an electrochemical device helps increase the system efficiency of the device by separating reactants and products and maximizing reactant utilization. Their downside is that they contribute to performance loss due to ohmic resistance of the transport of ions coupling the reactions at the two electrodes. For high electrical efficiency, membranes must possess high ionic conductivity and a high transference number. They must be durable to reduce the lifetime cost of the energy system. The membrane must be impermeable to gases and liquids to sustain the efficient operation of the electrochemical device. The membrane material itself is inherently capable of having a functional group or chemical composition that is highly selective for the conduction of a specific type of ion. The most commonly used ion-exchange membrane in energy storage/conversion devices is based on a long side-chain perfluorosulfonic acid (PFSA). Here, one of the ionic moieties (SO3–) is covalently attached to the long fluorocarbon backbone, while the counter ion (e.g., H+) is mobile. Ion pairs form an isolated ionic cluster in a less hydrated state and upon hydration, they establish a well-connected network that permits the selective transport of the ions [22]. The ionic conductivity through the membrane depends on the morphology of the membrane and the ability to maintain proper hydration [23, 24]. The dependency of ion conductivity on morphology applies to polymer membranes, polymer composites, ceramic separators, other solid-state membranes and separators.

Solid polymer, copolymer, polymer blend, composite and ceramic membranes combine the advantages of solid polymer electrolytes and filler materials [25]. Their high manufacturing cost makes them an expensive component. A commercial membrane material that possesses the essential characteristics for the polymer electrolyte membrane (PEM) fuel cell is costly (~ $600 m–2 from 1.525 m2 and the thinnest available membrane from Nafion™ store, The Chemours Company). In a redox environment, PFSA ionomer membranes are found to combat electrochemical stresses efficiently due to the chemically stable tetrafluoroethylene backbone and its balanced positioning of polar and non-polar groups in space [22]. The phase-separated geometry makes them stabler at relatively higher temperatures than other polymer electrolytes. The performance and durability of a PEFC that uses a PFSA ionomer membrane are dependent on the morphology of the membrane employed [23]. There is extensive work in the literature on ionomer morphology in thin and thick forms [22], the relationship between structure and morphology, [26] and the effects of morphological changes with ion conduction and durability [27,28,29,30,31,32].

The first vanadium redox flow battery (RFB) using the PFSA variant (Nafion membrane) was invented by Skyllas-Kazacos et al. [33] in the late 1980s. Until recently, the ionomer for redox battery applications had undergone various morphological modifications to suppress ion-crossover and improve cyclability [34, 35]. Problems with crossover and durability have been addressed by using a composite membrane of Nafion. These challenges have been addressed by exposing ionomer to the anode side for oxidative resistance, especially in RFB applications. These membranes suppressed crossover and improved cyclability at higher operating current densities but have reduced specific proton conductivity values [36,37,38]. Oxidizing environmental and physical forces will induce chemical and mechanical stress in unison or individually [39] in these membranes, which results in the loss of ionic conductivity [40], water uptake [24], and change in morphology [23, 41].

During the long-term operation of a conventional EES device with a membrane, the ionomer membrane undergoes degradation due to chemical [42, 43], mechanical [41, 44, 45] or combined forms of stressors [39, 46, 47]. Due to the degradation of the ionomer, the membrane loses its functional properties such as proton conductivity [48], water absorption [24], dimensional stability [46, 49], backbone stability [48] and efficient water management capability [50, 51]. Many variants of the PFSA ionomer, with varying lengths of pendant chains, were investigated [34, 52, 53]. Besides PFSA, other types of membrane chemistries, composites and architectures have been proposed and are documented in the literature for use as flow-based energy conversion devices [25]. Sulfonated polyether-ether ketone (SPEEK)-Nafion [54], SPEEK-lignin composites [55], SPEEK-carbon material [56, 57], and SPEEK-TiO2 have been used to reduce the cost, improve ion-selectivity, reduce crossover, and ensure a good cycle-life. The outcome has been excessive swelling and poor mechanical properties. Vanadium ions were rejected when using a long side-chain polybenzimidazole membrane, and there was a reduction of ion crossover [58]. A specialized polymer blend of SPEEK-polyacrylonitrile (PAN) exhibited high density and reduced permeation by using acid-base interaction [59], and a composite SPEEK/poly(ether-Sulfone) (PES) with a negative charge mitigated the formation of dendrite in a zinc-iron flow battery [60, 61]. Although various membrane architectures have been used in the flow battery setup, they are adopted from other applications, such as fuel cells, and a perfect match that serves multiple applications is elusive. Using membrane in the redox flow battery increases dependency on the mass transport and the nature of the redox species. The costs associated with manufacturing the membrane, their degradation, limited operating temperature and pressure ranges, and permeability of some reactants are long-standing challenges.

When the reactants are solid, the reduction of cathodes and the oxidation of anodes lead to a solid product in a simple case; a porous separator that separates the anode and the cathode is simple to operate. Their weakness is that they allow all types of permeable ions to pass through them and are not ion-selective. The porous structure hosts liquid electrolytes for ions to transport and provides a physical barrier for anode and cathode short-circuiting. Early conventional EES technologies are based on a simple separator that ceased operation when it exceeded the operating parameters such as temperature, operating current density and open-circuit voltage (OCV). There are various types of microporous, modified separators, composite separators and non-woven separators [62]. When the physical integrity of a membrane or a separator is compromised, it leads to self-discharge (the separator) or crossover (the membrane). Either response results in voltage/performance loss. The commonest type of separator is made from wettable non-woven type porous insulating materials, sometimes exfoliated. The host matrix is made mostly from polyolefin, nylon or cellophane. Polymers with low melting points shut the pores for ion transport when the temperature exceeds their melting point, which act as a fuse. Dendrite formation creates a short circuit and leads to battery failure and safety concerns.

One of the biggest challenges in designing membranes for RFBs is to balance electrochemical stability and ionic conductivity in oxidizing and reducing environments without increasing the cost. Since ionic conductivity is intimately related to the internal morphology of operating solid electrolytes, a complete understanding of the distribution of hydrophobic and hydrophilic fractions on the physicochemical properties of the membrane is essential. A similar structure-property relationship exists in ceramic membranes where ion conduction depends on vacancies and interstitials. Anion exchange membranes must compete with the existing cation exchange membrane in terms of ion conductivity, chemical stability and must avoid membrane fouling. High resistance at the electrode/electrolyte interface remains a challenge to solve in ceramic membranes. Separators must provide overcharge protection and withstand significant volume expansion during charge-discharge cycles. Mathematical models that consider the ohmic resistance, thickness, internal morphology, pore size, shrinkage, tortuosity, mechanical strength during the final performance and safety features of batteries must be developed for membranes/separators with tailored electrochemical properties.

2.2 Challenges with Redox-Active Materials

Redox-active materials in solid form have the advantage of high energy density but suffer from diffusion issues associated with electroactive species. Redox liquids have a higher energy density than gaseous form, which flow through intricate cell geometries for better utilization. Redox-active materials dissolved in suitable supporting electrolytes determine the capacity of the storage device. The concentration of redox electrolytes, the number of electrons involved in the redox reaction and the difference between the reduction and oxidation potentials of the electrolyte involved determine the energy density of an RFB. Apart from these, redox electrolytes must exhibit highly reversible cyclability. Redox-active materials used in aqueous and non-aqueous RFBs can be metal-based or metal-free, as depicted in Fig. 3.

2.2.1 Metal-Based Redox Electrolytes

The vanadium-based RFB invented by Skyllas-Kazacos in the 1980s is a classic example of a metal-based redox electrolyte [33]. Vanadium is attractive due to its multivalent nature that exhibits + 2, + 3, + 4, and + 5 oxidation states [63, 64]. Hence, the same type of electrolyte in the anode and cathode chamber mitigates cross-contamination, offers the opportunity for rebalancing if there is any crossover and maintains the energy storage efficiency.

Iron, chromium, nickel and manganese are a few popular metal-based redox materials apart from vanadium used for RFB applications. Although inexpensive and non-toxic, all-iron flow batteries face the challenge of hydrogen evolution due to the presence of FeCl2 in acidic media. They require subsystems to capture hydrogen and rebalance the acidity. Iron-chromium flow batteries use Fe2+ at the cathode and suffer from hydrogen evolution at the chromium anode since Cr2+/Cr3+ redox potential is near the hydrogen evolution potential. A non-aqueous flow battery with cobalt-complex exhibits a cell voltage of 1.45 V [65]. All-nickel-based RFBs exhibited high solubility in ethylene carbonate and propylene carbonate leading to a high working voltage of 2.55 V [66]. All-manganese non-aqueous flow batteries demonstrated an OCV of 1.1 V and 21% energy efficiency attributed to high cell overpotentials [67]. All-polyoxometalate (POM) based on tungsten and vanadium exhibited 95% coulombic efficiency for over 100 cycles at 0.8 V [68]. POMs are formed by linking d0-metal-centered polyhedra with oxygen atoms located at the vertices of multi-electron redox reactions. Mixed-alkoxide clusters can further tune the solubility and electrochemical properties of POMs [69]. A lithium-based POM using different solvents has shown a higher electron transfer number, which increases the energy density of the system [70].

Metal ions such as iron, zinc, cerium, chromium and manganese have the advantage of well-defined redox signals to exhibit a characteristic cell voltage, and their solubility and stability are dictated by the pH of the supporting electrolytes. Redox couples with a large potential window must be selected carefully for high power and energy density. Dissimilar redox metals such as Fe (Metal 1) and Mn (Metal 2) combinations are often used because they are inexpensive, eco-friendly and offer a large redox potential window [71]. A Zn-Fe combination in a specialized cell design delivered a cheaper system capital cost of < $100 per kW h [72]. A Fe-Pb redox combination in methane sulfonic acid (MSA) has demonstrated faster electrochemical kinetics and high coulombic efficiency of 96.2% at 40 mA cm–2 [73].

An asymmetric cell with different POMs has a cell voltage of 1.30 V involving a 4-electron transfer reaction [70]. Often, the corrosion of components by acidic electrolytes is alleviated by using alkaline or neutral pH electrolytes. An all-aqueous iron complex redox pair eliminates hydrogen evolution in alkaline media [74]. Functionalizing alloxazine with carboxylic acid increased the solubility in alkaline media when coupled with ferri/ferrocyanide because the positive electrolyte led to a high energy density flow battery [75]. Similarly, a 2,5-dihydroxy-1,4-benzoquinone-ferri/ferrocyanide alkaline RFB retained a capacity of 96.96% over 400 cycles [76]. Such alkaline quinone-ferri/ferrocyanide RFB was found to offer the longest-lasting high performance at a low cost of $32 per kW h [77]. Alkaline electrolytes not only reduce the problem of corrosion but lead to an unprecedented energy density of 330 W h L–1 when zinc is used with iodine in a hybrid alkaline Zn-I flow battery with a metal-halide redox combination [78]. Similarly, the Zn-Br combination resulted in a high discharge plateau voltage of 2.15 V with a specific energy density of 267.7 W h kg–1. The outcome exhibited high average efficiency of 91% for over 200 charge-discharge cycles [79]. A Sn-Br flow battery demonstrated high performance and long life with 82.6% energy efficiency at 200 mA cm–2 with a potential of a low energy cost of $148 per kW h [80]. The use of halides as redox electrolytes is preferable due to their reversibility, fast kinetics, and high energy densities. There are concerns with environmental hazards, toxicity, electrode and membrane stability, crossover issues and high cost. A related review on thermodynamic and kinetic properties of halogen and polyhalide redox couples and recent advances in electrode and membrane materials for various halogen-based flow batteries and regenerative fuel cells can be found elsewhere [81]. The solubility limit of metal salt, the toxicity of supporting electrolytes, dissimilar species crossover, low electrode potential difference, low dissociation constants of metal complexes in the non-aqueous electrolyte that leads to low electrolyte conductivity, cyclability, and cost are some of the challenges that restrict the realization of metal-based RFBs.

2.2.2 Metal-Free Redox Electrolytes

Some of the challenges associated with metal-based redox electrolytes may be alleviated by using metal-free redox electrolytes in RFBs. Expensive metal-based electrolytes can be replaced by cheaper metal-free electrolytes, less corrosive solvents, and abundant redox-active materials to realize a sustainable energy storage route [82]. The solubility of metal-free redox materials can be improved by attaching metal ligands, whereas the functional groups present in the aromatic ring of the organic molecules tune the redox potential [83, 84]. There are numerous advantages to metal-free electrolytes, such as increased solubility, higher electron transfer numbers and increased stability through molecular engineering strategies [85]. In one study, a materials engineering approach applied to organic molecules led to the synthesis of 2,2,6,6-tetramethylpiperidine-N-oxyl (TEMPO)/phenazine combi-molecule for symmetric aqueous RFBs with a redox potential of 1.2 V [86]. Attaching hydroxyl, sulfonate or carboxylate groups to phenazine derivatives offered a clear separation of electron-dense and electron-deficient regions. This clear separation increased the solubility and widened the window of redox potential by more than 0.4 V [87]. The redox potentials and solubility of organic redox molecules can be engineered by attaching positively charged and negatively charged functional groups to the aromatic rings [88]. The position of side groups determined the redox potential and solubility in organic redox species [89]. The negatively charged redox materials offer reduced crossover due to the repulsion from the negatively charged ion-conducting membrane.

An aqueous methyl viologen (MV) anolyte and 4-hydroxy-TEMPO catholyte in the neutral supporting electrolyte can operate at high current densities (up to 100 mA cm−2) and deliver impressive cycling performance (100 cycles with excellent capacity retention at 60 mA cm−2) with an overall energy cost of ~ $150 per kW h [90]. PEGylation of viologen (conjugation of polyethylene glycol to viologen) enhanced the solubility in acetonitrile and increased the overall molecular size for reduced crossover, which provided an opportunity to use an aramid nanofiber nanoporous separator when paired with ferrocene. The outcome exhibited 99.93% capacity retention for 500 cycles [91]. Though metal-free redox electrolytes can be a sustainable option for conventional and unconventional EES applications, their high molecular weight hinders their rapid solubility and has the disadvantage of low conductivity in non-aqueous electrolytes.

Quinone, a common organic redox electrolyte used in RFB applications, has an excellent specific capacity, redox activity and reversibility. A low-cost quinone-based organic-inorganic RFB has received attention due to its high energy capacity [92]. Diaminoanthraquinone (DAAQ) derivatives can have up to five accessible electrochemical oxidation states, and more recent findings have revealed an increased solubility of 1,4-bis((2-(2-(2-methoxyethoxy)ethoxy)ethyl)amino)anthracene-9,10-dione (Me-TEG-DAAQ) in acetonitrile and 1,2-dimethoxyethane. Various oxidation states and improved solubility enhanced its theoretical energy density [93]. Among different types of quinones for quinone-bromide flow batteries, only anthraquinone-2-sulfonic acid (2 M(1 M = 1 mol L−1)) was found to have high OCV and peak galvanic power density with a reversible reduction reaction [94]. Although the molecular modifications increase solubility and alter the reduction potentials of organic redox species, quinones are a challenging class of redox species in EES applications. Quinones exhibit multi-electron reduction potentials and pH-dependent redox behavior.

Organic and metal-based electrolytes were used as hybrid redox electrolytes. A combination of the mixed redox electrolyte (1:1 in mol L−1), the tungsten-based POM anode and the hydroquinone cathode has enabled a hybrid charge storage cell with an operating voltage of 0.8 V and a specific energy density of 20 W h kg−1 [95]. A mesoporous high surface area carbon electrode enabled high gravimetric energy while possessing supercapacitor-like power handling. Anthraquinonedisulfonic acid (AQDS) was coupled with inexpensive, non-toxic iron sulfate to realize cheaper large-scale energy storage capacity [96]. The cost of redox electrolytes has been reduced further by using organic redox electrolytes. Quinone fractions (\(\leqslant\) $5 kg–1) can be sourced from crude tar to isolate anthracene oil to produce anthracene with more than 95% purity. Anthracene was further oxidized and sulfonated to yield a mixture of anthraquinones [97, 98]. Even with these successes, identifying and extracting enriched quinone derivative and selective oxidation continue to be a prime challenge in this area.

A TEMPO-based catholyte with a zinc-based anolyte demonstrated high-capacity and high current density in an oxygen-insensitive zinc hybrid-flow battery [99]. A highly soluble (NH4)3[Fe(CN)6]/(NH4)4[Fe(CN)6] catholyte paired with a 1,1′-bis(3-sulfonatopropyl)-4,4′-bipyridinium ((SPr)2V) anolyte exhibited an excellent cycling performance of 100% capacity retention for 1 000 cycles with 62.6% energy efficiency at 40 mA cm–2 [100]. Phthalimide-based eutectic mixture with urea and lithium bis(trifluoromethanesulfonyl)imide (LiTFSI) was investigated for anolyte application due to a sixfold increase in solubility and enhanced reversibility [101]. Recent efforts led to novel anolytes with low electrochemical reduction potentials for non-aqueous electrolytes. Non-aqueous electrolytes offer advantages such as wide working temperatures (− 40 °C to + 40 °C) and high cell voltages (~ 4.5 V), which provide faster charging and higher energy density. In contrast, non-aqueous solvents suffer from poor ionic conductivity and low current densities. They require supporting electrolytes such as tetrafluoroborate (BF4─), perchlorate (ClO4─) and hexafluorophosphate (PF6─) to enhance their energy density. Thus, the use of non-aqueous solvents led to an OCV as high as 4.5 V with high energy density in all-organic biphenyl radical anion and octafluoronaphthalene radical cation combinations [102]. N-methylphthalimide anolyte and 2,5-di-tert-butyl-1-methoxy-4-[2′-methoxyethoxy]benzene catholyte redox systems with high theoretical cell voltage (2.3 V) were reported at densities as high as 50 mA cm–2 than other non-aqueous systems tested for 50 cycles [103].

Organic redox species with metal added to the molecular structure lead to improved energy storage and electrochemical properties. Organometallic redox species are created by adding a metal between two cyclopentadienyl (Cp) ligands. Here, the shared π-electrons of two rings and the carbon atoms bonded equally to the central metal atom increased the electron number in the redox reaction. Fe and Co-based metallocenes were used as redox-active cathodes and anodes owing to the two orders' higher reaction rate constant (10–3 cm s–1) than conventional redox-active materials [104]. The potential exists to attach functional groups to CoCp2 to lower the redox potential. The addition of such functional groups to ferrocene derivatives increased solubility [105] and chemical stability during bimolecular decomposition resulting in a high capacity retention neutral pH aqueous flow battery [106]. Flow batteries with the pyridinium salt-based anolyte tend to have a high energy density since they have a lower molecular weight than other organic redox species [107, 108]. Similarly, nitrogen-containing aromatic ring members’ redox potential can be tuned by adding substituents [109].

A novel way to overcome the solubility limit barrier for achieving high energy density is to employ the semi-solid form of redox electrolytes [110]. The use of semi-solid redox-active material in non-aqueous electrolytes creates a high concentration of the anolyte (20 M (1 M = 1 mol L−1)) and the catholyte (22.5 M) and high volumetric capacity. The utilization of Li-ions and semi-solid redox electrolytes results in a high energy density flow battery [111]. The lithium-organic nanocomposite suspension posolyte made of 10-methylphenothiazine provided an eightfold increase in volumetric capacity than its liquid counterpart [112]. In a study by Chen et al. [113], silicon-coated carbon particles as the semi-solid negolyte were employed to reduce the interfacial resistance and volume change upon discharging in lithium metal-free RFBs. Another strategy used a solid/semi-solid form of negative electrode stored within the device, and then, oxygen from atmospheric air was reduced at the positive electrode creating a high specific energy density of the device [114, 115]. Polythiophene, a π-aromatic organic redox molecule, can act as an anolyte and catholyte dispersed as microparticles in a non-aqueous solvent to achieve high energy efficiency of 60.9% [116].

Future RFB technology is anticipated to rely on environmentally sustainable use of the earth’s materials. Owing to the low energy density of liquid electrolytes, the use of semi-solid/solid reactants eventually will be integrated into conventional EES technology that has no membrane. New synthetic organic redox electrolytes and hybrid designs will compete with the existing Li-ion battery’s cell voltage and cost metrics. Low-energy-density remains a challenge to be solved with the help of innovative redox electrolytes, new cell designs, and more efficient electrodes. Advanced redox-active materials must be low-cost to be economical for use in large-scale EES applications and must not suffer from self-discharge issues.

2.3 Limitations on Best-Performing Materials and Methods

Understanding the limitations of existing materials used in EES technologies and processes will help determine the focus of future research. Large-scale adoption of conventional EES technologies requires bridging the present technological gaps. Performance, durability and cost are the benchmark characteristics that will determine the adaptability of conventional EES technologies. Commonly employed electrolytes for EES devices lack several optimal characteristics, such as high electrochemical stability in oxidizing and reducing environments, mechanical stability, high compatibility at the electrode interface, inertness when in contact with various species and safety. The lack of high ionically and poor electronically conducting membrane/separator restricts the development of efficient batteries because high ion-conducting electrolytes allow the use of a thicker cathode for increased battery capacity. Existing battery separators have primary restrictions on temperature fluctuations, low ion-selectivity and the ability to suppress dendrite formation during the use of metallic anodes in dry cells. High-performance electrodes for conventional EES devices must have non-noble electrocatalysts with a high-specific activity, reaction-specific catalysts that avoid unwanted side reactions, the capability to enable multifunctional facile reactions, excellent rechargeability, deep cyclability and a reversible degradation mechanism. The compelling properties are hard to find in existing catalyst systems. Better control of morphology minimizes catalyst loading, which impacts the effective kinetics due to the available high electrochemical surface area (ECSA) and the facile transport of ions or other reactants. A stable support material with the highest achievable current for optimum loading of active mass per cm2 has to be achieved yet, along with morphological, mechanical, and electrical properties of composite electrochemical devices. The capacity of a conventional EES device depends on the effective utilization of its active reactants per charge for extended hours of operation. Though high-capacity secondary batteries are realized with the help of Li-ion batteries so far, there is room to improve the volumetric/gravimetric energy density by incorporating alloy composition owing to the low material density. Other parameters that need enhancements are the limited cell voltage, narrow electrolyte stability windows, solubility limits and the trade-off between particle loading and electrolyte viscosity (in semi-solid reactants).

The challenges presented by EES devices for mobile and stationary applications are different. Reducing the enery cost to ~ $80 per kW h, high-rate charging, increased volumetric and gravimetric energy densities to 400 W h L−1 and 250 W h kg−1, respectively, and extended range (300 miles) per charge are prime factors to adapt EES technology for mobile applications. Innovations and breakthroughs in materials technology, manufacturing engineering and compact pack technology are needed for mobile EES applications. Sustainable mobility requires better EES device characteristics: safe battery components, inflammable electrolytes and infrastructure for refueling/recharging. Insufficient subsidy policies, indeterminate price mechanisms and a robust business model are other challenges that need to be resolved. For stationary application, a high volumetric energy density of 300 Wh L−1, high cycling life of > 5 000 cycles, the durability of > 20 000 h, low levelized energy cost of $0.05 per kW h, and energy cost $145–400 per kW h cost for a 100 MW system still need to be achieved. Developed EES technologies must be cost-competitive with cheap energy storage solutions like pumped and compressed air. A complete understanding of degradation phenomena (due to voltage, thermal, mechanical and charge cycling) and comprehensive analytical techniques to scrutinize failure modes is lacking. A practical lifetime prediction model that considers the full spectrum of mechanistic and functional (hybrid) parameters for a range of conventional EES systems is lacking. Development of efficient and fast charging protocols for batteries, an efficient EES system to manage state-of-charge (SOC), protocols for cooling during charging and preheating in cold conditions, deep, fast, and high-power discharge are yet to be achieved fully [117].

In addition, several environmental considerations could be enhanced as conventional EES technologies are developed, as sustainable production and utilization processes will facilitate a low-carbon footprint. Environmentally benign extraction of electroactive materials from used batteries could provide a closed supply chain management loop. Efficient recycling of electroactive materials from batteries could provide independence from relying on resource-intensive new materials. About 5% of produced batteries are currently being recycled, and the lack of efficient technology for proper recycling has hindered advances in this field. EES devices that use captured carbon for the applications of electrocatalysts, carbon fibers, and carbon substrates would provide additional carbon neutrality.

3 Materials for Energy Storage and Conversion

Several strategies have been undertaken to reduce the cost and optimize the design of conventional EES technologies. Earlier EES devices used liquid, solids and gaseous reactants and provided the advantage of engineered redox materials. Their weaknesses were low energy density, low cyclability and low efficiency. The efficiency of energy storage technology depends on the phase of the electroactive materials and their interaction with the electrode microstructure. Consequently, most new EES designs have focused on the electrode structure, available ECSA, interaction of the electrolyte phase with the electrode to maximize charge transfer and reducing interfacial and ohmic resistances.

3.1 Different States of Matter for EES

The EES device for solid, liquid, gaseous and hybrid reactant types has evolved, but the anode, the cathode and the separator/membrane continue to form the fundamental components. The challenges associated with the solid form of electrodes are higher interfacial resistance, diffusion-controlled mass and charge transport and changes to the ideal electrode morphology over the prolonged/cyclic operation of the device. Liquid electrolytes have a lower capacity to store energy when compared to solid counterparts while providing flexibility for energy storage and safe handling [118]. Faster charge transfer at the surface and the bulk is possible in liquid and gaseous reactants. Gaseous reactants are considered candidates with low volumetric energy density. The following subsections describe the commonly used battery designs for single-phase reactants in conventional battery design and mixed-phase reactants in a hybrid design. Figure 4 provides examples of the best-performing candidate batteries gathered from recent literature.

© 2020, Elsevier B.V. b Aqueous RFB with the ultra-high voltage zinc-cerium RFB with 3.08 V OCV, reprinted with permission from Ref. [120] © 2014, The Royal Society of Chemistry. c Electrochemical behavior of the Li|Fe(CN)63 ─ (aq.) battery tested between 3.0 and 3.75 V, reprinted with permission from Ref. [121] © 2011, American Chemical Society. d A Li-CO2 battery using MoS2 nanoflakes as a cathode catalyst combined with an ionic liquid/dimethyl sulfoxide electrolyte demonstrating 500 mA h g−1 capacity per cycle, reprinted with permission from Ref. [122] © 2019, John Wiley & Sons, Inc.

The highest performing EES system using solid, liquid, and hybrid reactants combinations as follows: a an ASSB with the SSE with the sulfur cathode and the Li anode featuring 32.8 mA h discharge capacity, reprinted with permission from Ref. [119]

3.1.1 Solid and Fluid Reactants in EES

The commonest type of the conventional EES device is a battery, as shown in Fig. 4a. Dendrite formation is a critical problem in batteries with flexible electrolytes/separators. A solid electrolyte in cells with the solid anode and the solid cathode offers a denser pathway for preventing dendrite-based short-circuiting. All-solid-state batteries (ASSBs) are gaining popularity as a solution to mitigate Li-dendrite growth, but this has its inherent challenges—high solid-electrolyte interfacial resistance [123]. Research has shown that solid-state electrolytes have the advantages of good Li-ion conductivity, electrochemical stability and chemical stability toward the cathode and the Li anode [124]. In studies of ASSBs with a sulfide electrolyte, Ag-C composite anodes and high-Ni layered oxide cathodes have shown an all-time high volumetric energy density of 900 W h L–1 [125]. This battery design retains a high specific capacity (> 210 mA h g−1) with stable coulombic efficiency of 99.8% for over 1 000 cycles. ASSBs with high sulfur loaded composite cathodes, super-high ionic conductive Li6PS5Cl electrolytes and Li metal anodes have delivered a discharge capacity of 32.8 mA, as shown in Fig. 4a [119].

High electrode-electrolyte interfacial resistances and short lifetime during cyclic operation are significant problems of current ASSB technology. Electrode interphase engineering alleviated issues related to high interfacial resistances at high-temperature and cyclic operations of ASSBs. ASSBs with the cathode-engineered interphase delivered a large initial capacity for 100 cycles at 25 °C and high-rate performances [126]. A garnet-coated cathode with a garnet electrolyte exhibited discharge capacity retention of 81.3% after 100 cycles at 0.2 C and 55 °C [127]. A similar cathode design demonstrated 80.2% capacity retention at 0.2 C and 60 °C for 400 cycles [128]. The garnet coating suppressed the Mn reactivity of the LiMn2O4 cathode and enhanced ionic conductivity. Interphase layers of various chemistries such as inorganic, organic [129, 130], and inorganic-organic composites [131, 132], alleviated the high interfacial resistance and electrode delamination problems related to the outstanding performance and durability issues. Despite the above technological advancements, high volumetric expansion of the solid electrolyte, cycling performance and high interfacial resistance continue to be prime challenges that must be overcome for ASSBs to be embraced as a reliable battery.

The regular use of Li-ion batteries is increasing, but the rules of supply and demand have seen their price hike. This demand is further exacerbated by the energy-intensive Li-extraction process, as there is a deficit of raw material. Several studies explored the impact of alternative materials to establish a novel energy storage system alternative to Li-ion battery technology. Na-ions [133] and K-ions [134] are studied to replace Li-ion batteries. Rechargeable K-ion-based batteries are emerging as a potential alternative for the Li-ion due to their inexpensive nature and abundance. K+ ions are more active than Li+ ions and possess a higher diffusion coefficient. K-ions and Na-ions are similar in size and exhibit comparable cell voltages, making these batteries suitable for large-scale energy storage applications [135]. The Na-ion battery is less costly to build with inexpensive current collectors, cathodes, and anodes, and the used sodium can be recycled [136]. High-temperature sodium-metal halide batteries with solid electrolytes for Na+ conduction have energy metrics on par with Li-ion batteries. Lowering the operating temperature of the Na-NiCl2 battery has the potential to reduce the costs related to cell fabrication while mitigating heat losses. A planar sodium nickel-chloride battery tested at 190 °C exhibited a high energy density of 350 W h kg–1 over 1 000 cycles [137]. Replacing Ni with Fe increased the rate capability of the device due to the faster kinetics of Fe/Fe+ redox reaction [138].

The zinc-ion battery (ZIB) is gaining popularity in the energy storage world. It has a Zn metal anode, a zinc-containing electrolyte and a Zn hosting cathode. The most commonly studied cathode to host Zn in ZIBs is MnO2 owing to its multivalent states and crystal structure [139]. Modifying the cathode in ZIBs provides excellent energy storage properties such as high-energy capacity and high cyclability. MXene-based materials are endowed with excellent capacitance owing to their layered microporous structures that charge quicker than Li-ion batteries. A hybrid ZIB with the V2CTx MXene cathode possessing phase transition behavior has the highest capacity: up to 18 000 cycles and the highest energy density recorded 386.2 W h kg–1 [140]. A vanadium oxide-modified MXene has been used as a cathode for gel ZIBs producing a high capacity of 358.7 mA h g–1 at 200 mA g–1 after 400 cycles [141]. An innovative cathode based on CaV6O16·3H2O exhibited excellent Zn2+ ion storage performance with chemically self-charging capabilities. The fully discharged CaZn3.6VO recovered to the charged state CaZn3.6−xV6O16·3H2O (CaZn3.6−xVO) without any external power supply [142]. A porous framework of the zinc pyrovanadate cathode had a high energy density of 214 W h kg–1 for up to 300 cycles [143]. A rigid layered superstructure of phenanthrenequinone (PQ) triangles acted as a stable host for Zn2+ ions with water molecules and retained a reversible capacity of 99.9% for over 500 cycles [144]. Distinct from these novel energy storage systems, a “dirt-cheap” unconventional alternative for storing energy has been proposed by using a simple masonry brick. The brick has an open porous microstructure with 8.0 wt.% α-Fe2O3 that acts as a substrate for developing nanofibrillar PEDOT coating, wt.% means the weight fraction. When used with a gel electrolyte, this cheap energy storage system demonstrated 90% capacity retention for ~ 10 000 cycles [145].

The liquid form of redox electrolytes is utilized in RFBs using aqueous and non-aqueous electrolytes, and semi-solid electrolytes. The commonly employed battery design can be a simple membrane to a more complex specialized double ion-exchange membrane (IEM) structure with an acid-base junction for energy storage. In Fig. 4b, the ultrahigh cell voltage of 3.08 V using alkaline zinc-acidic cerium double-IEM cell design is presented. The design provides unprecedented freedom when using redox pairs and supporting electrolytes [120]. This double membrane triple electrolyte design with the Zn-Fe redox pair with the cathode in acidic media and the anode in alkaline media features < $100 per kW system capital cost [72]. A flow battery configuration reduced the toxicity of environmentally hazardous toxic polycyclic aromatic hydrocarbons (PAH), phenanthrene by degrading them, in addition to generating power. [146]

3.1.2 Hybrid Reactants in EES

It is possible to store/convert energy from the solid and liquid reactants without changing the state of reactants at the end of the energy conversion process. Hybrid EES devices can use solid-liquid, solid-gas or liquid-gas combinations. In a typical single-flow design, a liquid catholyte circulates over the solid membrane, which is in contact with the solid anode. In this design, an aqueous ferrocyanide cathode and a solid Li anode demonstrated a high OCV of 3.99 V. The charge-discharge characteristics of Li|Fe(CN)63─ for 20 cycles are shown in Fig. 4c. This design utilizes the high-capacity alkali metals such as Na and Li and the liquid cathode in an alkali-ion battery whose capacity was higher than insertion compounds-based cathodes. One of the significant bottlenecks for a single-flow system is the low power density which may be improved by incorporating 3-D porous flow-through electrodes.

Gaseous reactants in the EES device are accessed by using porous electrodes permeable to air or other gaseous reactants. In metal-air batteries, Fe, Al, Zn, Li act as an anode and oxygen in the air becomes the cathode in the electrochemical redox reaction [114, 115, 147]. In principle, metal-air batteries have a high theoretical energy density since the oxidant used in the cathode is not stored within the system. Zhu et al. [148] reported a novel battery design utilizing a nanostructured lithium manganese oxide cathode and a hydrogen gas anode in an aqueous electrolyte. A vanadium-oxygen RFB used a 3.6 M V2+/3+ ion concentration at the anode and H2O/O2 redox reaction at the cathode generating an overall OCV of 1.49 V [149].

CO2 is one of the prime GHG candidates associated with accelerating global warming. The higher oxidation state of carbon (+ 4) in CO2 requires high energy input for transformations. Hybrid solid-gaseous reactants can be used for generating power while providing carbon neutrality. A Li-CO2 battery that consumes CO2 to form Li-CO3 and irreversible carbon has attracted much attention. This type of battery transforms the CO2 dissolved in a liquid shuttled to carbon through a flow-based system that continuously removes CO2 while generating power [150]. A Li-CO2 battery with the MoS2 nanoflakes cathode combined with the hybrid ionic liquid electrolyte consumes CO2 while maintaining a superior long-life: 500 cycles for 500 mA h g─1 capacity per cycle (Fig. 4d). Further research to develop robust catalysts will improve performance and cyclability [122]. Hybrid redox flow cells (HRFCs) using hydrogen/vanadium (RHVFC), hydrogen/manganese (RHMnFC), and polysulfide/air (S-Air) offer increased efficiency, current density and kinetics [151]. The design for gaseous and liquid reactants is critical to reducing battery costs while increasing energy efficiency when compared to conventional design. The decomposition of electrolytes during charge-cycling and the regeneration requirements of the solid electrode after discharge are significant challenges to be resolved. Figure 5 and Table 1 show the commonest high-performing redox combinations with their OCV and volumetric energy density.

Recent trends in conventional EES technology research suggest that future exploration must focus on developing high-energy (high capacity and voltage) cathodes with improved cyclability. Batteries need to have high-capacity non-graphitic anode materials owing to their limited capacity and sluggish ion-diffusion in layered materials. New electrolytes should lower costs and increase safety. Molecular engineering approaches for electrode design (structure and functionality) will be indispensable for designing energy storage materials. Nanostructuring, nanoporosity, surface coating and compositing may mitigate electrochemomechanical degradation and promote the self-healing/reverse degradation of electrodes. Biomass and petroleum-derived carbon materials and their corresponding composites can deliver high energy capacity, enhanced performance rates and long cycling stabilities. Novel EES technologies may use a combination of favorable pore structures and heteroatom doping possibilities. Electrolytes for batteries have challenges related to lithium safety and electrolyte window dependence on OCV, requiring future research on garnet-type solid electrolytes for ASSBs. Poor stability of solid electrolytes that comes in contact with the Li-metal anode must be improved. Dendrite growth in high current density Li-metal anode batteries and high interfacial resistance in ASSBs may be eliminated by using high Li-conducting ceramic electrolytes. While the structure and ionic conductivity will be a focus of research in solid electrolytes, its dense microstructure will continue to limit realizing high energy density.

3.2 Unconventional Approaches in EES

The high-performing conventional EES devices with solid, liquid, gaseous and hybrid reactants are discussed in the above section. Breakthrough innovations in unconventional EES technologies are urgently needed to reduce the cost of technologies that use large-scale renewables and address many of the challenges identified. A component that continues to contribute to the cost and performance of the conventional EES device is the membrane. The membrane’s selectivity (toward a particular ion type and concentration), crossover issues, membrane fouling and cost remain a significant challenge to adopting chemical and biofuel cells. Unconventional EES devices utilizing (liquid-liquid, solid-liquid and gas-liquid) interface, laminar flow external and in situ electrode regeneration strategies have eliminated the membrane or the counter electrode and the associated issues. The membrane-free cell design strategies improve the adaptability of EES technologies providing increased versatility. A few comprehensive reviews on membrane-less cell design discussing its evolution, key performance metrics, and acceptability of RFBs are found in the literature [168, 169].

3.2.1 Chemical Fuel Cells

Microfluidic channel-based unconventional EES devices have increased energy efficiency due to the smaller electrode separation distance. The small volume of electrolytes means they provide a high power density [170]. Fuel cells and redox flow batteries without a membrane have been proposed for low wattage applications and evolved severally [168, 171]. The separation of electrolytes was achieved by using co-laminar flow through microchannels with aqueous and non-aqueous redox electrolytes at low flow rates [172]. Y, T and/or L-shaped microfluidic channels maintained the co-laminar flow, as shown in Fig. 6a [173]. A specialized design for gaseous and liquid redox electrolytes (Fig. 6b) demonstrated a high power density of 26 mW cm─2 in a co-laminar flow-based air-breathing fuel cell at room temperature and ambient conditions. This design used formic acid oxidation and oxygen reduction with low activation losses [174]. Walsh et al. [175] reviewed developments in parallel flow channel-based devices for electrochemical energy conversion and flow cells for electro-synthesis. Most membrane-less designs that use micron-sized channels relied on the co-laminar flow at low flow rates to minimize intermixing of reactants.

© 2008, American Chemical Society, b Ref. [188] © 2005, American Chemical Society, c Ref. [177] © 2017, Elsevier B.V., d Ref. [189] © 2013, Elsevier B.V., e Ref. [179] © 2020, John Wiley and Sons, f Ref. [185] © 2007, Royal Society of Chemistry and g Ref. [190] © 2019, Royal Society of Chemistry

Unconventional membrane-less designs in electrochemical energy storage/conversion. Schemes adapted with permission from a Ref. [187]

A cell design with a higher flow rate than co-laminar flow-based cells is reported in the literature. In Fig. 6c, a membrane-free design with few millimeter-sized channels between the solid anode and the liquid cathode ensures the electrolyte separation and energy conversion [176, 177]. A similar membrane-less design with a solid nickel/air and solid zinc dual cathode with supporting electrolytes circulating in a narrow channel is shown in Fig. 6d. This design utilizes coulombic efficiency of Ni and oxygen and operated vigorously for more than 1 100 h [178].

The separation of the anode and the cathode is achieved through the immiscibility of electrolytes in a cell design presented in Fig. 6e. This design behaves as a reversible battery system comprised of an acidic aqueous and ionic liquid phase. A design with quinoyl species exhibited an OCV of 1.4 V at a theoretical energy density of 22.5 W h L−1 [179]. A series of aqueous organic electrolytes paired with ionic liquid operated at a voltage > 1.35 V exhibiting high values of coulombic and energy efficiency [180]. Suitable solvents employed with a representative quinone-based anolyte that demonstrated a high cell voltage (~ 2 V) utilizing the electrolyte immiscibility. A 4-hydroxy-2,2,6,6-tetramethylpiperidine1-oxyl (OH-TEMPO)-based catholyte and a polypropylene carbonate-based anolyte retained a high capacity of 85% for over 300 cycles [181]. The Zn-Br membrane-less flow battery utilized the phase separation of polybromine from bromine to prevent electrolyte mixing. This novel battery design exhibited 1 000 charge-discharge cycles with energy efficiency of over 80% [182]. Critical evaluation of membrane-less devices, harnessing key attributes of immiscible electrolytes for RFBs and conversion of solar energy can be found elsewhere [183].

A membrane-less system is known as a bio-battery [184, 185]. It has a pre-acclimated bio-anode, and Prussian blue electrodes are used as the cathode. The cathode can be regenerated in the air after reduction in the single-chamber bio-battery, as shown in Fig. 6f. The system achieves energy recovery efficiency between 18%–33% with stable performance up to 20 cycles [185]. In a similar study by the same group, a silver oxide/silver cathode that required external regeneration at regular intervals was employed. This single-chamber configuration excluded the need for a membrane and oxygen supply fulfilling anaerobic requirements. Chemical oxygen demand (COD) removal efficiency of 84% and the highest OCV of ~ 0.7 V were observed for this device [184]. An enzymatic biofuel cell with glucose dehydrogenase (GDH) enzyme operated in a membrane-less and oxygen-free environment with the NPG/MnO2 cathode. A maximum power density of 2.3 µW cm−2 and an OCV of 0.49 V were recorded. The voltage of the discharged MnO2 was recovered, demonstrating a bio-battery/supercapacitor hybrid device [186].

Figure 6g is a revolutionary membrane-less design based on using a pair of auxiliary electrodes. Unlike ion-conducting membranes in conventional flow batteries, the anode and cathode chambers are connected through a metal wire with redox-active materials at the ends [190, 191]. The auxiliary electrodes are regenerated in situ during the charging reaction eliminating the need for external regeneration for continuous operation. This process eliminates the expensive and problematic ion-exchange membrane in a redox cell, reduces costs and increases the opportunity to use inorganic/organic, aqueous/non-aqueous redox-active liquids. A preliminary proof-of-concept demonstrated by using aqueous vanadium redox electrolytes eliminated the membrane and cut costs by incorporating ion-transfer independent redox electrolytes. A 70% cost reduction capability was demonstrated by eliminating membrane and by a potential choice of dissimilar redox electrolyte media in this design. In conventional membrane-based redox flow cells, the overall redox reaction in conventional RFB design during discharge is presented as follows:

In an auxiliary electrode-mediated membrane-free redox cell (AEM2RC) design, the overall electrode reactions in the anode and cathode compartments in the presence of auxiliary electrodes (AE1 and AE2) are hypothesized as follows:

The overall cell voltage is expressed as follows:

The available advanced membrane-free designs are inferior to conventional EES devices in terms of performance. This is evident in the electrochemical performance, as presented in Table 2, where the alphabets correspond to the design shown in Fig. 6. These designs have a combination of diffusion-controlled and surface-area-controlled conversion and storage mechanisms. This approach is advantageous for practical application by avoiding membrane-related issues and mixed-potential losses. Porous electrodes can be employed for improved mass transport and reduced ohmic losses (for high concentration reactants). The membrane-less unconventional EES technology necessitates the reaction-selective electrodes development to improve electrochemical efficiency.

The utilization of energy from natural processes using microbial catalysts has attracted interest from fuel cell and energy researchers. Figure 6 designs extend to bio-batteries or microbial fuel cells (MFCs). The electrocatalyst in each electrode is replaced with microbes to perform the redox reactions on the supplied fuel. The anode is generally a microbial film grown on a conducting substrate. A novel approach of microbial electrosynthesis captures CO2 providing a value-added product. CO2 is the carbon source for the biocathode, where microorganisms reduce it to longer carbon chain chemicals with commercial value [192]. Acetate is the commonest product of this process, but it is not commercially attractive [193]. Studies on the microbial synthesis of long carbon chain compounds [192], the mixture of C4 and C6 carboxylic acids, and their corresponding alcohols [193] have been reported. Unlike an MFC that generates electricity, the biocatalysts require a specific applied potential to be used in the cathode to attain the desired electro reduction reaction during biosynthesis. The anode and the cathode are simultaneously functional, but the anode biocatalysts oxidize organic matter, and the power generated is used to produce value-added products in the cathode. The process of microbial intervention during electrochemistry is a sustainable technique with numerous applications possible: wastewater treatment, clean energy conversion, synthesis of value-added chemicals and reducing the carbon footprint see Fig. 7a.

© 2012, The Royal Society of Chemistry & Ref. [195], © 2018, Gajda, Stinchcombe, Merino-Jimenez, Pasternak, Sanchez-Herranz, Greenman, and Ieropoulos. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY)

Different approaches of the bioelectrochemical system (BES) toward sustainable power generation using a conventional design, b ceramic cylinder used as a separator in an MFC module, and c a 3-D electrode-based microchannel MFC. Reprinted with permission from Ref. [194],

3.2.2 Biofuel Cells

Membrane-free operation in chemical fuel cells is challenging due to the crossover of reactant gases that lead to mixed potentials. The membrane-free approach is commonly adopted in MFCs due to the use of liquid electrolytes and microbial anode. MFCs containing two chambers (Fig. 7a) are the commonest. These are difficult to scale up due to their complexity, increased cost, and membrane's internal resistance. The operational disadvantages of a single-chamber membrane-less system override the simplicity advantages. The oxygen diffusion into the anode chamber often harms the anaerobic microbial population and lowers the coulombic efficiency of the cell due to alternative fuel substrate utilization. This problem may be circumvented by the formation of the aerobic biofilm on the cathode surface, which will use up the diffused oxygen in the chamber or by introducing a chemical oxygen scavenger like cysteine.

Significant attempts have been taken to construct the membrane-less single-chamber MFC (ML-SCMFC) or alternative separator-based MFCs. The high-power generating MFC devices are often operated in smaller volumes to ensure high power density due to the high surface-to-volume ratio. Most ML-SCMFCs are constructed as cylindrical tubes with varying lengths and diameters [196,197,198,199]. The cell designs were varied to optimize the performance by increasing power density and COD removal and reducing internal resistance. In most vertical cylinder designs, the anode is at the bottom and the cathode on top. Accordingly, ports were drilled at the bottom for influent and the top for effluent. A layer of glass wool and glass beads often separated the anode and cathode chambers [200]. An improved power density is led by varying the distance between the electrodes in such reactors [196]. The use of terracotta and low-cost separators (Fig. 7b) was employed in place of a conventional membrane for system-cost reduction without compromising high volumetric power density values [194, 201].

Although the concept of laminar flow is established in chemical fuel cells, Ye et al. [202]. developed a laminar flow-based MFC to separate electrolytes. The impact was a high volumetric power density of 3 200 W m−3. A previous study by Yang et al. [195] demonstrated a 50 µL MFC with a 3-D nitrogen-doped carbon composite catalyst. Figure 7c produced a power output of about 1 200 W m−3. Membrane-less designs in biofuel cells reduced the costs associated with PEM while providing advantages like simple design, easy scale-up, easy maintenance and lower internal resistance.

4 Scaled-up EES Designs for Field Applications

The commissioning of large-scale EES systems connected to the power grid for sustainable energy management is the expected outcome of laboratory-scale demonstrations. Conventional EES technologies in scaled-up versions have been adopted widely. Large-scale solid-state batteries, flow batteries, and fuel cells are helping to keep several tons of CO2 from entering the atmosphere. The world’s largest Li-ion battery with a capacity of 100 MW is installed in southern Australia, where it has improved renewable energy stability at a nearby solar farm [203].

A new generation of flow batteries supports energy grids because they possess a high-energy capacity higher than Li-ion batteries and are less temperature-sensitive. Na-based high-temperature (~ 300 °C) flow batteries are being used in grid-scale applications owing to their high energy density (140–300 W h L−1) and high cyclability [204]. The world’s largest Na-S battery with an energy capacity of 648 MW h is installed in Abu Dhabi [205]. Flow batteries for grid-scale application using modular 8 MW h units have been installed by the Snohomish Public Utility District, Snohomish, WA. They are housed in 20 connected shipping containers and are the world’s largest containerized flow battery system [206]. Dalian Rongke Power Company is building the world’s largest flow battery in Dalian, China. When complete, it will be capable of producing 200 MW of power. The battery covers an area of more than 20 football fields [207]. This battery uses rare vanadium metal as electroactive redox material. The global vanadium reserve is estimated to be less than 63 Mt. It is found in various forms that are difficult to extract [208], and efforts are underway to find alternative cheaper electrolytes. Hydrogen, the most abundant element in the universe, is used in fuel cells to improve energy metrics. Hydrogen can be obtained through a steam and air injection process from oil fields that leaves the produced CO2 underground making the process carbon neutral [209]. PROTON Technologies has developed a unique membrane-based technology that can separate hydrogen gas from oil fields through in situ combustions. Large-scale fuel cells that provide continuous onsite power production are commercially available with a capacity of 3.8 MW and heat recovery options [210].

A cheaper alternative using wastewater has been applied to MFCs. Several designs have established viability for wastewater treatment while simultaneously generating electricity. Many pilot-scale studies have had low power generation. Despite the many challenges faced by moving MFCs toward commercialization, the new Market Research Report states that the global MFC market is expected to reach $18.6 million by 2025 [211]. The optimism of Market Research Reports may be due to the success of the first reported commercial system based on MFC technology. The EcoVolt reactor by Cambrian Innovation, Inc. (USA) is treating 15 000–40 000 gallons of wastewater per day per reactor with the capacity to produce 30–200 kW net power per installation and significantly lowering BOD [212]. An installation of Eco Volt at the St. Thomas plant, Virgin Islands, USA consumes just 10% of the power of traditional biological treatment facilities using a novel membrane aerated biofilm reactor (MABR). Similar MABRs were installed in places like Caesarea and Moshav Yogev, Israel, and a couple of plants are under construction in Ethiopia [213]. Cascade Clean Energy Inc. developed a sewage-system technology using microbes to clean the wastewater from toilets and reuse it for flushing [214]. With 14 kJ g–1 COD of stored energy in wastewater, this technology could transform energy-demanding wastewater treatment into an energy surplus technology. Grid-scale energy storage has been evolving over the years and is gradually adapting to adopt chemical and bio-based EES technologies.

5 Conclusions and Future Perspective

Recent trends in the design of conventional and unconventional energy storage/conversion devices ranging from laboratory-scale prototypes to scaled-up pilot plants have been discussed. Unconventional EES technologies have not emerged as an independent option but rather as an alternative requirement, particularly in the field of energy storage due to their compatibility, durability, accessibility and sustainability. Their ability to thrive in non-optimal environments emphasizes the practical and fundamental importance of unconventional EES devices. The surge in the number of unconventional designs is triggered by the growing interest to adopt renewable energy solutions as society seeks to reduce carbon emissions to mitigate global warming. Technological advancements have facilitated an increase in the installation of stationary EES devices. The breadth of applications includes off-grid, high-performance portable electronics and point-of-care devices, increasing the electric vehicle battery range, reducing the cost of per kW h electricity offering an alternative during peak usage times. Their continued development will positively enhance the living standards in developing countries by the year 2040.

There are numerous outstanding challenges that continue to adopt novel battery technologies at large scale. Mobile and grid-scale stationary applications require rigorous standardization of experimental procedures, optimum electrocatalysis, well-understood transport phenomena, stable catalysts and optimized electrolyte/solvent interactions. Future battery materials must easily withstand mechanical abuses and large temperature fluctuations. The active materials used for energy storage must possess an optimal correlation between structure, surface chemistry, morphology, charge-transfer reactions and physical conditions. Electrode morphology, (sub) surface structure, and reaction and process conditions are key components from a mechanistic standpoint and from a system perspective. Advances that drive a breakthrough in capacity, durability and low-cost energy storage solutions are on the horizon. Adding short charging times, high power handling capacity > 1 kW h kg−1 and a longer cycle-life will ensure a commercially successful battery.

Future research and development must provide strong support for the production and application of EES technologies with a focus on simulation studies, EES device operation optimization for various applications, development of pilot plants and energy storage standards. Scaling up prototypes to commercially viable mass-produced working systems requires sustained efforts, rigorous engineering, safety, and durability tests. Further research is needed to couple unconventional EES devices with renewables. An advanced understanding of the variability of renewable resources and the impacts of shifting energy demands on broader spatial and temporal scales is required. Research that seeks to identify the influence of large-scale climate drivers on resources will support the deployment of this clean energy source. By improving the accuracy of predictions at multi-time scales, batteries will benefit the general public through housing, transportation and carbon-neutral industries adopting these clean energy solutions. This timely review of promising unconventional EES technologies provides an overview of their potential contribution to an economical low carbon future.

References

Covert, T., Greenstone, M., Knittel, C.R.: Will we ever stop using fossil fuels? J. Econ. Perspect. 30, 117–138 (2016). https://doi.org/10.1257/jep.30.1.11710.1257/jep.30.1.117

Lightfoot, H.D., Manheimer, W., Meneley, D.A., et al.: Nuclear fission fuel is inexhaustible. 2006 IEEE EIC Climate Change Conference. Ottawa, ON, Canada. IEEE, 1–8 (2006). Doi:https://doi.org/10.1109/EICCCC.2006.277268

Book review: BP statistical review of world energy. Energy Explor. Exploitation 7, 468 (1989). https://doi.org/10.1177/014459878900700615

Csala, D., Hoster, H.: Step on the natural gas for German cars. Nature 541, 157 (2017). https://doi.org/10.1038/541157b

Moriarty, P., Honnery, D.: What is the global potential for renewable energy? Renew. Sustain. Energy Rev. 16, 244–252 (2012). https://doi.org/10.1016/j.rser.2011.07.151

Lazard Freres: Levelized cost of energy and levelized cost of storage 2019. https://www.lazard.com/perspective/lcoe2019 (2019). Accessed 21 August 2020.

Tomabechi, K.: Energy resources in the future. Energies 3, 686–695 (2010). https://doi.org/10.3390/en304068610.3390/en3040686

Larcher, D., Tarascon, J.M.: Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 7, 19–29 (2015). https://doi.org/10.1038/nchem.2085

UNFCCC. Conference of the Parties (COP): adoption of the Paris agreement. Adopt. Paris Agreement. Propos. By Pres. 21932, 32 (2015). https://en.ccchina.org.cn/archiver/ccchinaen/UpFile/Files/Default/20151214161845142875.pdf

Obama, B.: The irreversible momentum of clean energy. Science 355, 126–129 (2017). https://doi.org/10.1126/science.aam6284

van Vuuren, D.P., Hof, A.F., van Sluisveld, M.A.E., et al.: Open discussion of negative emissions is urgently needed. Nat. Energy 2, 902–904 (2017). https://doi.org/10.1038/s41560-017-0055-2

IRENA: People planet and prosperity 2019. https://www.irena.org/publications (2019). Accessed 15 July 2019

Leo Mirani.: Nobody in the fuel cell industry has ever made a profit: this CEO could be the first. https://qz.com/135032/fuelcell-energy-fuel-cell-profit/ (2013). Accessed 21 August 2020

Huggins, R.A.: Energy Storage: Fundamentals, Materials and Applications. Springer International Publishing, Heidelberg (2016). https://doi.org/10.1007/978-3-319-21239-5

Facchini, A.: Distributed energy resources: planning for the future. Nat. Energy 2, 17129 (2017). https://doi.org/10.1038/nenergy.2017.129

Jain, R.K., Qin, J.J., Rajagopal, R.: Data-driven planning of distributed energy resources amidst socio-technical complexities. Nat. Energy 2, 17112 (2017). https://doi.org/10.1038/nenergy.2017.112

Dorotić, H., Doračić, B., Dobravec, V., et al.: Integration of transport and energy sectors in island communities with 100% intermittent renewable energy sources. Renew. Sustain. Energy Rev. 99, 109–124 (2019). https://doi.org/10.1016/j.rser.2018.09.033

Liu, F., Tait, S., Schellart, A., et al.: Reducing carbon emissions by integrating urban water systems and renewable energy sources at a community scale. Renew. Sustain. Energy Rev. 123, 109767 (2020). https://doi.org/10.1016/j.rser.2020.109767