Abstract

Semiconductors and the associated methodologies applied to electrochemistry have recently grown as an emerging field in energy materials and technologies. For example, semiconductor membranes and heterostructure fuel cells are new technological trend, which differ from the traditional fuel cell electrochemistry principle employing three basic functional components: anode, electrolyte, and cathode. The electrolyte is key to the device performance by providing an ionic charge flow pathway between the anode and cathode while preventing electron passage. In contrast, semiconductors and derived heterostructures with electron (hole) conducting materials have demonstrated to be much better ionic conductors than the conventional ionic electrolytes. The energy band structure and alignment, band bending and built-in electric field are all important elements in this context to realize the necessary fuel cell functionalities. This review further extends to semiconductor-based electrochemical energy conversion and storage, describing their fundamentals and working principles, with the intention of advancing the understanding of the roles of semiconductors and energy bands in electrochemical devices for energy conversion and storage, as well as applications to meet emerging demands widely involved in energy applications, such as photocatalysis/water splitting devices, batteries and solar cells. This review provides new ideas and new solutions to problems beyond the conventional electrochemistry and presents new interdisciplinary approaches to develop clean energy conversion and storage technologies.

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Electrochemical devices, including fuel cells, batteries and electrolyzers have shown great potential for large-scale clean energy conversion and storage applications. In clean energy conversion, fuel cells directly convert the chemical energy from fuels into electricity with high efficiency and low emissions, while in clean energy storage, a battery is a typical storage device with high energy density and good reversibility and durability. We selected these two systems for the present study, because they represent the current and near-future energy conversion and storage technologies with a high potential to be combined with renewable and sustainable energy sources. We use them as examples to give a comprehensive review of current research frontiers with emphases on semiconductor and band theory applications in both materials and devices/technologies as well as fundamental sciences, followed by extensions to related fields, e.g., photoelectrolysis or photocatalysts, solar cells, metal-air batteries, and electrolyzers.

The knowledge and operating principles of fuel cells have largely remained the same over the last century [1, 2]. The yttrium-stabilized zirconia (YSZ) electrolyte, a typical oxide material, has been the main focus of research and development for solid oxide fuel cells (SOFCs). However, the full and successful commercialization of SOFCs is hampered by the requirement for high temperature materials associated with high costs despite the inherent benefits of the technology. The high operating temperature, which is directly related to the ionic conductivity of solid oxide electrolytes, requires special attention from the aspects of the material durability and manufacturing. It also adversely affects the costs, impeding wide application of SOFC technology. For instance, many works have focused on developing ultrathin film electrolyte layers of YSZ and alternative doped ceria (e.g., Sm0.2Ce0.8O2-δ (SDC)) to minimize device ohmic loss and maintain desirable power output at reduced temperatures.

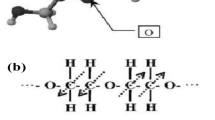

The oxygen transport properties in the electrode and electrolyte materials are not only of technological interest, as noted above, but also of fundamental importance. The energetics of oxygen transport in these oxides are affected by the material structure, composition, oxygen stoichiometry, doping and elastic strain, which comprise a wide range of parameters in optimizing the transport properties. In addition, lowering the temperature can cause slower electrode and electrolyte dynamic processes. To speed up the development of SOFCs, new solutions to these key challenges for the electrolytes and electrodes need to be found, i.e., to achieve sufficient ionic conductivity electrolytes and highly electrocatalytically active electrodes at lower operating temperatures. In addition, more radical approaches alternative to the traditional approach of using the three-layer anode-electrolyte-cathode electrochemical device structure and material systems are greatly sought after. In 2013, Singh et al. [3] noted that the anode, cathode and electrolyte in SOFCs, in terms of semiconductor principles, can be associated with an n-type regime, a p-type regime and an ion conducting electrolyte, respectively, as shown in Fig. 1a. In 2018, Asghar et al. [4] further proposed that wide bandgap semiconductors can be used for replicating the electrolyte functionality. This means that an SOFC could be conceptually handled as a semiconductor fuel cell system. If the middle electrolyte layer of the SOFC is removed or replaced with a wide bandgap semiconductor, then the fuel cell effectively resembles a p–n junction device (as Fig. 1b); i.e., a p–n junction is formed in situ under a fuel cell atmosphere by the same material that can block electrons, thus preventing short circuiting of the fuel cell in much the same way as in solar cells. Based on this principle, two types of novel fuel cell devices may be constructed based on either O2− or H+ conduction/transfer, as illustrated in Fig. 1c, d. We designate these devices as electrolyte-layer-free fuel cells (EFFCs) to distinguish them from the traditional SOFC structure. Naturally, the EFFC has the same functionalities as the traditional SOFC, but these can be realized through a different methodology employing a vastly simplified configuration. This difference delivers several advantages over a conventional three-layer fuel cell such as the following: (1) the two anode/electrolyte and cathode/electrolyte interfaces that cause major power loss due to the ionic/electronic interfacial polarizations are eliminated [1, 5]; (2) redox reactions, such as the hydrogen oxidation reaction (HOR) and the oxygen reduction reaction (ORR), can be readily performed to generate electricity on the spot, and ionic transport occurs in a more efficient way to complete the fuel cell reactions (Fig. 1a); and (3) a built-in electric field is formed at the anode (n) and cathode (p) junction, which can increase the H+ (Fig. 1c) and O2− (Fig. 1d) transfer mechanics to enhance the overall efficiency of the cell. EFFCs with simpler configurations and harmonious cell components have led to significant progress in the SOFC field.

Transition of the fuel cell from an ionic electrolyte device (a) to an electrolyte-layer-free device, e.g., an n–p junction assembly (b), along with the further H+ conducting fuel cell (c) and the O2− conducting fuel (d), in which a built-in electric field is formed between the anode (n) and cathode (p) junction to promote H+ and O2− transfer to complete the redox reactions and electricity generation on-site without the interfacial polarization and losses caused by the ionic electrolyte separator in conventional fuel cells (a) [3]. Partially redrawn with permission from Ref. [3].

The transition from the conventional ionic electrochemistry to advanced semiconductor electrochemistry is widely evidenced as reported for many other energy conversion and storage devices [6, 7], which makes the application of semiconductors and associated methodologies to the electrochemistry in energy materials and relevant electrochemical devices an emerging field. For instance, the successful development of photoelectrolysis from photoelectrochemical devices using semiconductors has made photocatalysts and water splitting hot topics [8,9,10]. Lithium-ion batteries (LIBs) have also experienced new progress based on the semiconductor properties of materials used in devices, e.g., energy band/heterojunction/built-in electric field [11, 12]. Semiconductors and their methodologies complement the conventional electrochemistry, introducing the new topic “semiconductor electrochemistry” and a new frontier in ion conducting semiconductors and novel fuel cell devices [1, 13, 14]. The name of this topic refers to the similarities found between the development of photocatalysts and LIBs and that of fuel cells.

Fuel cells and photoelectrochemical electrolysis have much the same origin as electrolyte-based electrochemical devices with anodes and cathodes, i.e., photoelectrochemical cells (PECs). Today, PECs are well known to be transferrable to photo-water splitting based on semiconductors and band structures [15]. A similar situation occurs for batteries, where semiconductors and energy bands, as well as built-in-field effects, play a significant role in designing material functions and the device performance. Solar cells have taken a reverse route from typical physics to electrochemistry, where ions play an important role in state-of-the-art perovskite solar cells (PSCs). The electrochemistry of the semiconductor–electrolyte interface or semiconductor–semiconductor interface provides great promise to handle these challenges through a deeper understanding. A logical deduction can be made that by employing semiconductor electrochemistry, because a semiconductor provides two energy levels (the conduction band (CB) and the valence band (VB)), the charge transfer occurring at these two energy levels can be easily controlled. Therefore, our idea about the variation in the electron density that is helpful for ionic transport at these two energy levels and the interfaces for clean energy conversion and storage devices need to be recapitulated. This work provides a new view of these novel aspects of state-of-the-art research and development in the energy sector, where the two typical fields of fuel cells and batteries are focused on realizing a comprehensive understanding of the roles of semiconductors and bands in energy conversion and storage, with extension to other energy applications in a broader view.

2 Electrochemistry of the Semiconductor–Electrolyte Interface and Fuel Cells

Electrochemistry is the core of developing multilayer devices and is most commonly used in assembling two-electrode cells and for referring the voltage to a reference electrode (RE). The science of electrochemistry is central to the manufacturing, performance, and reliability of multilayer devices. Semiconductor electrochemistry is a particularly relevant and fundamental area for fuel cell devices, including ion transport in fuel cells [14]. Semiconductor heterostructure-based fuel cells are convenient to scale using the energy levels relative to the vacuum level (VL) compared to those with an intrinsic ionic conductor. This allows us to track the local variations in energy, electrostatic potential, and Fermi energy (EF) inside the solids by a standard representation. Control of the flowing charge carriers across the junction is the most important point for SOFCs in that electrons must be prevented from crossing over the electrolyte membrane. Before we discuss the properties of the semiconductor-electrolyte interface, examining some of the general aspects of electron and ion transfer reactions at the semiconductor-electrolyte interface from the perspective of the energy band positions is beneficial.

An electrochemical cell (e.g., an SOFC) contains two electrodes (anode and cathode) separated by an electrolyte for completion of the redox reactions. However, to realize the redox reactions and prevent electrons from crossing over the electrolyte membrane, many different methods can be employed, e.g., (1) creating a metal–electrolyte interface (the Schottky-type junction, see Fig. 2a, or the Mott transition from a metal conductor to an electronic insulator (Fig. 2b) related to the band description of the Mott transition induced by H2 or H+ incorporation) where electrons are localized while ions conduct (a typical example is the strongly correlated perovskite SmNiO3, Fig. 2c); (2) constructing a semiconductor (n-type)-semiconductor (p-type) heterostructure to suppress electron conduction (Fig. 2d); (3) using electronically insulating and ionically conductive electrolytes in conventional fuel cells with the anode/electrolyte/cathode configuration (Fig. 2e); and (4) replacing this configuration by the “three-in-one” single-layer device in which macro-redox reactions occur at the anode and cathode separated by the electrolyte while nano-redox reactions can occur at nano-redox units, where each anode, electrolyte and cathode component can be compacted into n-type, ionic and p-type particles, respectively, as shown in Fig. 2f. Since a metal can provide or accept electrons easily at the surface when it is used as either an anode or a cathode, control of the semiconductor-electrolyte interface (SEI) structure and properties to allow stable ionic conductivity is a critical and highly challenging task. That is why the semiconductor–semiconductor interface (Fig. 2f, fuel cell reaction at the nanoscale) can provide more advantages than metals or SEIs because they have distinct energy levels, the CB and the VB. A spontaneous charge transfer reaction can occur depending on the nature of the doping and charge carrier density. In the case of the SEI, a spontaneous charge transfer reaction can occur depending on the nature of the energy levels or their overlap with those of the redox electrolytes. There are three distinct possibilities for such an overlap: (1) overlap with the CB, (2) overlap with the VB, and (3) overlap with both bands. These processes lead to energy band alignment or energy band reorientation.

Reproduced with permission from Ref. [16]. Copyright 2016 Springer Nature. d Using a p–n heterostructure material to tune the semiconductor into an ionic conductor with no net electron conduction. Reproduced with permission from Ref. [17]. Copyright 2014 RSC. e Realizing the fuel cell redox reactions at the electrolyte-separated macroscale and f nonelectrolyte or EFFC nanoscale

Various methods to block electron transfer: a Creating a metal–electrolyte interface (the Schottky-type junction). b Using the Mott transition to block electrons transferring to the electrolyte; c the strongly correlated perovskite SmNiO3 is an example of such a fuel cell.

The electrode/electrolyte interfaces in SOFCs are of significant importance, which, on the one hand, provide the active sites for electrode electrochemical reactions and, on the other hand, contribute to a major loss of the power output due to the different ionic and electronic natures [3, 4]. Gleaning an understanding from the fundamental aspects is therefore necessary to develop sustainable SOFCs in the future. Normally, electron–hole (e−/h+) pairs are separated on the anode and cathode sides by the band structure, i.e., CB and VB, and built-in electric field (BIEF) depending on the nature of materials, so the energy band provides an important pathway for the electrochemical reactions to occur.

At the interface of two distinct materials, the free electrons and holes in the CB (Ec) and the VB (Ev) of the anode and cathode exchange their charges with the electrolyte by diffusion-based processes, and charge neutrality accumulates at the interface. The Fermi levels (EF) attempt to reach an equilibrium position due to charge diffusion processes, and the resultant EF can be associated with the difference in the positions of their respective EF(s). These processes force the energy band structures to be rearranged and hence induce band bending. In semiconductors, the position of EF normally depends on the dopants (n-type or p-type) and their contents; in addition, there are no other reference energy states to assess the energy levels. Therefore, the position of EF is assessable only when the distance between EF and Ec or Ev is known. The position of EF is composed of two parts, the chemical potential (μe) and electrostatic potential (ex), and can be expressed as the following Eq. (1), providing that there is no additional charge:

where \(\mu_{\rm e}\) is the chemical potential of the bulk, while ex arises from the surface dipole; in the case of heterostructure semiconductors, dipoles are formed by the surface structure due to a particular ionic charge distribution. These effects depend on the crystal plane and the reconstruction of the surface atoms. This dipole also influences the electron affinity. In agreement with the band of a semiconductor with an electrolyte, the electrolyte can be visualized as possessing two distinct energy levels: an empty level as the oxidized level (represented by the most probable energy level \(E_{{{\text{ox}}}}^{{\text{O}}}\)) and a filled level as the reduced level (represented by the most probable energy level \(E_{{\rm re}}^{\rm O}\)).

Generally, band bending due to charge transfer at the interface can be of two types: (1) upward band bending and (2) downward band bending, depending on the type of material. In the case of an n-type semiconductor (the anode), the Fermi level is usually at higher energy (less negative) than the Fermi level of the electrolyte, and electrons try to move from the semiconductor (the anode) to the electrolyte to equilibrate the Fermi level. In this case, the Fermi level of the semiconductor decreases in energy until both Fermi levels overlap; hence, EF shifts to lower energy, which results in upward band bending, as shown in Fig. 3a, and creates a depletion layer close to the surface of the anode/electrolyte interface. In the case of p-type (normally on the cathode side) semiconductors, the Fermi level normally exists at lower energy (near the VB and more negative) than that of the electrolyte, and its EF shifts to higher energy (downward band bending) at the interface. A positive space charge region (h+) is therefore created near the surface of the anode interface due to electronic transformation in the electrolyte to achieve electronic equilibrium. A positive space charge means that fewer electrons are in this region. Hence, a charge accumulation/depletion region is formed at the cathode/electrolyte interface. Additionally, on the electrolyte side, when it is fully charged, the electrolyte interface will be left with non-absorbed ions with opposite charges, and they will form a Helmholtz double layer (Fig. 3a).

A space charge region (created due to a change in EF position) can be expected on the semiconductor side due to the difference in electrostatic potential in the process, and its charge will be transferred to the electrolyte, leading to energy loss and band structure rearrangement (see Fig. 3a). The concentration of the charges in the space charge region depends on the potential difference between the semiconductor and the electrolyte. The potential drop in the space charge region is much more than that in the Helmholtz layer because the former spreads over a large area and exists due to ionization of the acceptor solid, while the latter is built up at the single-atom level away from the electrolyte surface. The inhomogeneous distribution of charges in the interfacial region establishes a BIEF that crosses over the electrode–electrolyte interface (EEI), which can also aid in ion or charge carrier crossing of the interface barrier. In other words, the created electric field produces a “built-in potential difference”. Another significant aspect of such a built-in potential at the interface is to oppose the flow of electrons and holes across the junction, so it is denoted as the potential barrier to establish the device voltage. In practical devices, instead of using two interfaces (anode/electrolyte and cathode/electrolyte), a one-interface device (as shown in Fig. 3b), such as by joining an n-type semiconductor and a p-type semiconductor, can work efficiently (low space charge region) by creating a BIEF to block electron penetration while enabling high ionic transport. This advanced configuration should be employed to construct a device with one electrode by ohmic contact to reduce the polarization loss.

3 Semiconductor Electrochemistry in Fuel Cells

Based on the fundamentals of semiconductor electrochemistry briefly discussed in the above section, we further discuss both conventional ion-based electrolytes and semiconductor-based membranes for fuel cells, with an emphasis on how semiconductor-ionic conductors replace conventional ionic electrolytes, resulting in different scientific principles.

Generally, SOFC reactions can be expressed in Kröger-Vink notation as follows: in an O2- conducting electrolyte, the cathode reaction is \(0.5{\text{O}}_{2} + {\text{~}}2{\text{e}}^{ - } + {\text{~}} \to {\rm O}_{{\text{O}}}^{\rm x}\), and the anode reaction is \({\text{H}}_{2} + {\rm O}_{{\text{O}}}^{\rm x} \to {\text{H}}_{2} {\text{O}} + 2{\text{e}}^{ - } + V_{{\text{O}}}^{{ \cdot \cdot }}\), where \(V_{{\text{O}}}^{{ \cdot \cdot }}\) is the oxygen ion vacancy and \({\rm O}_{{\text{O}}}^{\rm x}\) is the lattice oxygen ion in the electrolyte.

In H+ conducting fuel cells, the reaction at the fuel side (anode) is \({\text{H}}_{2} {\text{~}} \to 2{\text{H}}^{ + } + 2{\text{e}}^{ - }\), and that at the air side (cathode) is \(2{\text{H}}^{ + } + \frac{1}{2}{\text{O}}_{2} + 2{\text{e}}^{ - } \to {\text{H}}_{2} {\text{O}}\). In both cases, the overall cell reaction is \({\text{~H}}_{2} + \frac{1}{2}{\text{O}}_{2} \to {\text{H}}_{2} {\text{O}}\). Both anode and cathode materials can now easily be conceptualized as semiconductors in a strongly reducing or oxidizing atmosphere. More importantly, electronic exchange with chemicals or electron/hole transport is crucial to realize electrochemical reactions and current collection. However, semiconducting properties were not explicitly noted until they were addressed by K. Singh in 2013 (see also Fig. 1a) [3]. The electrical conduction behavior of the electrode material of SOFCs changes at different oxygen partial pressures, leading to electron or hole conduction in reducing or oxidizing atmospheres, respectively. A particular example is the perovskite oxide series that has been extensively developed and investigated as electrode materials for SOFCs [18,19,20,21,22,23,24,25]. They have been used as electrode materials to yield reduced material and cell fabrication costs and higher resistance to carbon deposition and sulfur poisoning due to amphiprotic electron and hole conduction under different oxygen partial pressures [26, 27].

3.1 Electrolyte-based SOFCs

Regarding the electrolyte materials in SOFCs, significant effort has been put in developing materials with higher ionic conductivity but limited electronic conduction in a fuel cell atmosphere. Indeed, a large number of new oxide ionic conductor materials have been developed and reported in the literature, such as doped ceria [28], La0.9Sr0.1Ga0.8Mg0.2O3 [29], BaZr0.1Ce0.7Y0.2−xYbxO3−δ [30], Ln10(SiO4)6O3 [31], calcium-doped LaNbO4 [32], Na0.5Bi0.5TiO3 [33], and Sr1–xNaxSiO3–0.5x [34]. Most of them show higher ionic conductivity than that of the state-of-the-art electrolyte YSZ, particularly for low-temperature operation. In addition, proton conductors for low-temperature (LT) SOFCs have recently stimulated worldwide interest and research input [23, 25, 35,36,37,38]. However, none of these materials can replace YSZ for industrial deployment yet due to the intrinsic issues with these materials, such as the high reactive activity with cell components and instability under fuel cell conditions. In addition, neither YSZ nor the newer generation of O2− or H+ conducting materials can meet the high ionic conductivity demand of 0.1 S cm−1 below 600 °C, the so-called LT range. The electrolyte material and resultant system challenges remain in SOFCs.

In parallel, another stream of LT SOFC research involves developing two-phase composite electrolytes that have better ionic conductivity than single-phase electrolytes, as discussed above for single O2− or H+ ion conducting electrolytes, which highly rely on the oxygen vacancy concentration of the oxide matrix. These composite electrolytes originate from ceria-salt composites [39], with a focus on ceria-carbonate composite systems [5, 40,41,42,43,44,45,46,47,48]. In addition, ceria-carbonate electrolytes have a unique characteristic of hybrid or dual H+ and O2− conduction [5, 48,49,50,51,52,53,54,55,56,57,58,59,60], which was even stable over 6000 h [61]. Figure 4 illustrates these three types of ion conducting electrolyte-based SOFC devices. In all these electrolyte-based electrode devices, semiconductors, commonly perovskite oxides, for example, (La,Sr)(Co,Fe)O3, (La,Sr)MnO3, (La,Sr)CoO3, and (Ba,Sr)(Co,Fe)O3 [62,63,64, 64, 66], and transition metal oxides, e.g., LiNiO2 and LiNiCoAlO2 [67, 68], are used as electrode materials, and they can be described in the semiconductor electrochemical way as discussed in Sect. 2. Another interesting report given by Kim et al. [69] presented the development of a hybrid solid oxide cell-based mixed H+ and O2− conductive BaZr0.1Ce0.7Y0.1Yb0.1O3−δ electrolyte for the simultaneous electrolysis of water at the anode and cathode; significantly improved the electrolysis cell performance and stable operation during 60 h of nonstop testing were achieved.

Different from classic heteroelement structural doping, the oxygen ionic conduction in doped ceria occurs through bulk diffusion via oxygen vacancies, while Zhu et al. [68, 70] recently reported that nondoped CeO2 itself acts as a super proton conductor under fuel cell conditions. The precipitated CeO2−x materials treated at different temperatures (as-synthesized, 600 and 1000 °C) all showed defective particle surfaces with many oxygen defects on the surface according to careful high-angle annular dark-field scanning transmission electron microscopy and electron energy loss spectroscopy analyses. The lower the treatment temperature, the higher the oxygen vacancy concentration is. In addition, a charge depletion layer is formed between the interface of core ceria (intrinsic-type semiconductor, Ce4+) and surface ceria (n-type semiconductor, Ce3+), which favors superionic conduction. Moreover, the ionic transport through ceria was determined to be a proton conduction contribution instead of an oxygen ion contribution by intentionally adding a pure proton conductor layer between the electrolyte and cathode. An isotopic effect study also supported the claims. Consequently, the constrained surface region of CeO2−δ is believed to build long-term proton shuttles, suggesting a new methodology for and understanding of the proton transport in general oxides and a promising electrolyte material for new-generation proton ceramic fuel cells.

3.2 Semiconductor Membrane Fuel Cells

According to traditional knowledge, electrolytes with partial electronic conductivity will significantly reduce the cell voltage and system energy efficiency [71]. In 1992, Riess proposed the use of mixed ionic and electronic conductors (MIECs) to replace solid-state electrolytes to run SOFCs when the FC is operated close to its maximum power output [72]. More recently, a new research emphasis has been put on using semiconductor oxides, more specifically electronic insulating oxides under an applied fuel cell atmosphere, to substitute conventional ion conducting electrolytes for SOFCs. This research was initiated by the revolutionary inventions called a single-layer fuel cell (SLFC) and an EFFC. In these cases, one-layer semiconductor-ionic conductor composite components can replace the conventional three-layer components of the anode, electrolyte and cathode while providing functions that can make the fuel cell operate in the same way [73,74,75,76,77]. Such a single-layer material is made of a semiconductor-ionic mixed or heterostructure composite, which leads to the same fuel cell functionality and holds the potential for lower temperature and higher performance applications. Later, a series of semiconductor materials were shown as SLFCs in the same way, e.g., La0.9Sr0.1InO3−δ [78, 79], LixAl0.5Co0.5O2 [80], SmNiO3 [16], La0.2Sr0.25Ca0.45TiO3 [81], TiO2 [82], LiZnO [83], and Na0.5Bi0.5TiO3 [33]. From a classic SOFC perspective, electronic conduction through the electrolyte/membrane will cause significant losses in both cell voltage (open-circuit voltage, OCV) and energy efficiency, while for the semiconductor fuel cell, the fuel cell behavior is not influenced. Generally, the electrical conduction behavior of semiconducting materials is well recognized to be a function of the applied oxygen partial pressure, as seen from the aforementioned symmetric perovskite oxide electrode materials in SOFCs. Moreover, some materials show interesting electronic, pure ionic and hole conduction under low, intermediate and high oxygen partial pressure conditions at a certain temperature [78]. For example, the electrical conductivity of La0.9Sr0.1InO3−δ changes only slightly with oxygen partial pressures from 10–5 to 10–20 between 600 and 800 °C, a typical ionic conduction behavior, while it exhibits typical p-type and n-type semiconducting behavior under higher and lower oxygen partial pressure conditions [78, 79]. The constructed SOFCs based on only the La0.9Sr0.1InO3−δ material, called SLFCs, gave an OCV of higher than 1.0 V and a maximum power output of 3 mW • cm−2 at 800 °C. However, in such a single layer fuel cell, a functional layer of La0.9Sr0.1InO3−δ performing as an electrolyte layer remains, which is similar to that in the classic SOFC, its p- and n-type conduction behavior is utilized for electrode functionality.

Therefore, in semiconductor-based fuel cell devices, the working principles built on semiconductor and heterostructure membranes should differ from those of ion electrolyte membrane-based fuel cells. A technical illustration of the difference between classic and newly developed semiconductor-based SOFCs is shown in Fig. 5, which shows the SOFC based on the O2− conducting electrolyte without electron passage. However, in Fig. 5b, the coexistence of both ions (e.g., the O2− case) and electrons, which is commonly the case in semiconductors and their heterostructures, takes over the electrolyte. Surprisingly, the latter (Fig. 5b) can display even better performance than the electrolyte-based SOFC. This is truly a new phenomenon, and therefore, the semiconductor electrochemistry of fuel cells shows high potential for further deployment. It is naturally introduced in term of semiconductors and physical principles in the following.

Different from the above case, recently, mixed ionic and electronic conducting single-phase oxides have also been transformed into ionic conductors with ionic transfer number close to unity under fuel cell conditions, more accurately by proton incorporation, according to the reports by Lan [80] and Zhou et al. [16]. As a typical LIB electrode, the layered structure LixAl0.5Co0.5O2 (LCAO) can accommodate protons in the layer between two transition metal oxide layers or by replacing lithium ions (Fig. 6a). Therefore, the obtained proton-intercalated LixHyCoO2 at the cathode leads to a change in the oxidation states of transition metal ions, which consequently relieves the electronic conduction of traditional semiconducting LiCoO2; the substitution of Co with Al also leads to suppressed electronic conduction in the materials, changing the semiconductor to a pure ionic conductor with an almost unity ionic transfer number.

Reproduced with permission from Ref. [80]. Copyright 2014 Wiley–VCH. b For the SNO case. Reproduced with permission from Ref. [16]. Copyright 2016 Springer Nature

Working principle of SLFCs operated based on existing SOFC science, i.e., ionic (in the case of H+ conduction) electrolyte devices formed during in situ fuel cell operation, regardless of the construction of the semiconductor layer configuration. a For the LCAO case.

Similarly, a distinguished work by Zhou et al. [16] reported that the highly electronically conducting perovskite oxide SmNiO3 (SNO) was transformed into a unity-transference ionic conductor under fuel cell conditions (H2, Pt/SNO/Pt, air, Fig. 6b). An in-depth investigation showed that when SNO is exposed to a hydrogen anode, hydrogen dissociates into protons and electrons accompanied by the reduction of Ni3+ cations in SNO to Ni2+. The proton incorporation into the SNO lattice forms H-SNO because the concentration and potential gradient lead to filling-controlled Mott transitions such that electrons are no longer able to transport through the \(E_{{\text{g}}}^{2}\) manifold because of the large electronic bandgap. Such a transition enables hydrogenated SNO to provide the electrolyte functionality for SOFCs. Moreover, according to experimental measurements, the proton conductivity in H-SNO is higher than that in well-known high proton conductivity Ba(Ce,Zr)O3-based perovskite oxides at reduced temperatures. A micro-SOFC with optimal electrolyte thickness and an active Pt metal electrode gave a maximum power density of 225 mW• cm−2 at 525 °C, which is comparable to the best value in the applied temperature range. Therefore, both LCAO and SNO materials eventually transform from high electron (hole) conductors to common proton conducting electrolyte-based fuel cells, i.e., the proton ceramic fuel cell (PCFC) process, even though the SOFC devices are initially constructed as a semiconductor device. Hydrogenation of oxides leads to wide electronic bandgap materials, which is an interesting approach to design and obtain new-generation electrolytes for SOFCs working at low temperatures [4].

Another work by Dong et al. [82] reported that thin film TiO2, a typical semiconductor, could be used as an electrolyte for LT SOFCs. SOFCs based on a TiO2 thin film were fabricated by a spin coating method on an electrode supporter, giving an OCV of 1.1 V and a maximum power output of 364 mW• cm−2 at 550 °C. This certificates that typical semiconductors can be used as electrolytes for SOFCs. In this work, Dong proposed the use of the universal energy band principle instead of electronic conduction theory to evaluate the possible application of novel materials for fuel cell and photocatalysis applications. They proposed that the electronic conduction in electrolyte materials should not be blamed if the energy band diagram can be well aligned in a real fuel cell. Under a fuel cell atmosphere, TiO2 possesses a higher CB above the redox potential of H2/H+ and a lower VB than the redox potential of O2/O2−, which can help effectively block electron transport through the electrolyte. When TiO2 is combined with the electrode material LiNi0.8Co0.15Al0.05O2, a LT high-activity symmetric electrode, the electrons produced at the anode cannot move to the CB of TiO2; therefore, they can only follow the external circuit of the cell and transfer to the cathode, realizing the fuel cell function. The nearly Nernst theoretical voltage and excellent LT power output verified the feasibility and correctness of the adopted approach. More recently, SOFCs using the pure SrTiO3 “electrolyte” delivered a peak power output of 620 mW • cm−2 at 550 °C [81, 84, 85], while it is an intrinsic semiconductor and presents a high n-type electronic conductivity. Moreover, the ionic conductivity reached 0.24 S • cm−1 at 550 °C, which is higher than that of most current single-phase pure solid-state ionic conductive electrolyte materials. A deep examination of the material texture and morphology confirmed that a superhigh ionic conductivity layer with an amorphous structure is formed on the surface of SrTiO3 [85]. Regardless, the superior electrochemical activity suggests a new approach for LT SOFC applications.

3.3 Semiconductor Heterostructure Materials

Commonly, compared to the single-phase electrolyte drawback that it cannot meet all the strict requirements for reliable, robust and durable SOFCs, semiconductor heterostructures with one ionic material or another semiconductor phase incorporated can provide better performance, such as higher ionic conductivities, than conventional electrolytes and increase the triple-phase boundary for electrode reactions [1, 86]. For example, bulk p-n heterostructure materials have been proposed to tune semiconductors to superionic conduction because the p and n materials can balance free electrons/holes, thus suppressing electron leakage and resulting in no net electrons [17, 67, 87,88,89,90,91,92,93,94,95]. Compositing p-type LiZnO with the ionic conductor doped ceria (n-type under fuel electrode conditions) for LT SOFCs has been reported. Interestingly, this bulk hybrid electrolyte exhibits superionic conductivity (> 0.1 S • cm−1 over 300 °C) and excellent electrolytic performance (400–630 mW • cm−2) between 480 and 550 °C. Unexpectedly, the hybrid semiconductor shows net-electron-free transport in the electrolyte, as reflected by the sufficient OCV under H2/air fuel cell conditions. Later, as demonstrated by Zhu et al. [77] and Wang et al. [89], fuel cells based on the planar/bulk n-type/p-type semiconducting heterostructure gave impressive fuel cell performance under H2/air conditions. Wu et al. [96] synthesized a ZnO/SrTiO3 semiconductor by a hydrothermal method and used it as a photocatalytic hydrogen production catalyst and a fuel cell “electrolyte layer”. The photocatalytic cell based on this n/n-type semiconducting heterostructure gave a H2 production rate of 1317.44 μmol • g−1 within 5 h under solar-light irradiation and an OCV of 1.14 V, and SOFCs presented a maximum power density of 564 mW • cm−2 at 550 °C. In the interesting work by Cai et al. [97], they composited all the materials in a typical SOFC, such as a Ni(O)-YSZ anode, a YSZ electrolyte and an LSM-YSZ cathode, to identify each component that could function as a semiconductor-ionic membrane for electrolyte functioning. They also made an ‘all-components-in-one’ fuel cell, and the complex hybrid heterostructure layer with the NCAL electrode displayed a three times higher device performance than the conventional YSZ electrolyte-based fuel cell under the same operating conditions (temperature and fuel/oxidant partial pressure). The “all-in-one” heterostructures appear to have much better ionic transport properties than existing ionic materials by creating a motorway for ionic transport along the semiconductor and ionic interfaces, which normally contain a space charge layer and present band bending and an induced BIEF, facilitating ionic transport/transfer, which cannot be manipulated by single-phase materials.

Moreover, an EFFC can be superior to traditional electrochemical fuel cells due to the physical removal of the conventional ionic electrolyte layer and two physical interfaces between the electrolyte and the electrodes (the anode/the cathode). In particular, in semiconductors and heterostructures, coupling interactions between charge carriers, electrons (holes) and ions impact ionic transport and redox reactions from the conventional macro-redox in three-layer devices to the nano-redox in single-layer configuration devices (as shown in Fig. 2f) as new-generation energy devices. These results suggest that semiconductor electrochemistry could play an important role in improving the fuel cell performance and developing new science and technology to continuously increase fuel cell R&D [1, 2]. By integrating the band structure and alignment fundamentals into fuel cell design, many new energy devices/technologies jointly harnessing semiconductors and electrochemistry have been demonstrated with plentiful examples. In addition, band alignment can also make significant contributions to speed up the HOR and ORR by adjusting the reactant and intermediate phase absorption energies, thus lowering the required activation energy, which has been commonly demonstrated in the photochemical water splitting process and other related fields [15, 98]. From a reaction product aspect, facilitating fuel cell functions for a reversible process via photochemical water splitting to H2 and O2 is desirable to generate H2O and simultaneously produce electricity. These new emerging trends of semiconductors and the associated methodologies have changed the fuel cell electrochemistry and brought new scenarios for fuel cell R&D toward semiconductor-fuel cell science, which may pave the commercialization roadmap for SOFCs and impact other areas in chemistry, such as photocatalysis/electrolysis and batteries.

Without the ion conducting/electron insulating layer, a key question arises: how does such a device work? In fact, various semiconductors and heterostructures have been widely applied without by using the traditional anode/electrolyte/cathode structure based on multiple built-in junctions. These devices have been developed by introducing new functional semiconductor materials or a semiconductor with an ionic conductor to form heterostructures. Figure 7 presents an overview of these novel fuel cells based on three-layer, two-layer, and single-layer structures. A three-layer fuel cell device (Fig. 7a) employs a semiconductor (S) or a semiconductor heterostructure (S+) membrane instead of the sole ionically conductive electrolyte, but it can be tuned to an ion conducting electrolyte (function) via a semiconductor-ionic conductor transition in the fuel cell environment. This device has the three-layer configuration of the anode (n-semiconductor or metal)/S or S+/cathode (p-semiconductor). The abovementioned LCAO and SNO fuel cells belong to this type. This configuration may also include an electrolyte layer because the ionic conductor or wide bandgap semiconductor can be treated/tuned as an electrolyte [2]. Fig. 7b illustrates the fuel cell device constructed by using only two layers, an anode and a cathode; refer to Fig. 7b for a planar p–n junction device. Conventional SOFC technology commonly uses a three-layer structure, two electrodes using a mixture of semiconductor oxides, e.g., NiO for the anode and perovskite oxide for the cathode, and an ionic electrolyte, e.g., doped ceria or zirconia, to enhance the ionic conductivity in the electrodes and effectively minimize the electrode polarization while enhancing the power output. The double-layer device was previously reported [77] and has been verified by other interesting research work. These devices were constructed by using typical SOFC components/layers in contact without an electrolyte between them. By removing the middle electrolyte layer, the fuel cell can still function due to the p–n junction principle.

Reproduced with permission from Ref. [77]. Copyright 2011 RSC. (d) Fuel cell constructed by a Schottky junction device, in which the Schottky junction barrier is caused by band bending at the metal/semiconductor (electrolyte) interface

Schematic illustration of (a) a three-layer fuel cell device consisting of an n-semiconductor anode/semiconductor (S) or semiconductor heterostructure (S+) membrane/p-semiconductor cathode; (b) a two-layer fuel cell: A, anode; C, cathode; and (c) a 3-in-1 SLFC device. CC stands for current collection. All cases are considered with both H+ and O2− conduction; in the case of only one type of ions, either H+ or O2−, the corresponding H2O formation is only on one side, the former in the cathode (O2, which can be air) and the latter in the anode.

In the new semiconductor approach, as illustrated in Fig. 7c, the configuration looks very similar to that of the SOFC electrode component of mixed electrolyte and electrode materials: all three layer materials of anode, electrolyte, and cathode (where the anode and the cathode could be the same material, leading to symmetrical fuel cells) can function within a single component, i.e., the “three-in-one” type device [99], outperforming the traditional three-layer fuel cell functions, thus stimulating significant industrial and fundamental research interest with remarkable and additional contributions to fuel cell science and technology. From a technical aspect, the bulk heterojunction (BHJ) requires delicate nanoengineering to tailor the n and p conducting properties at the nanolevel using heterostructure composite technology.

In later developments, metal–semiconductor-based Schottky junctions were discovered to have a significant impact on fuel cell performance [100]. The Schottky junction fuel cell device, as shown in Fig. 7d, is constructed using only one type of semiconductor, either n- or p-type (more commonly) or a semiconductor-ionic heterostructure composite, as reported [100, 101]. In this case, a Schottky barrier is formed between the anodic reduced metal/alloy surface and a single layer of the p-type (or n-type) semiconductor (Fig. 7d), thus preventing electrons from passing through the device internally. Moreover, by applying energy band design/alignment to design fuel cells as a new fuel-to-electricity conversion technology, the performance can arguably surpass that of fuel cells [102]. The designed energy band and alignment based on PSC science can isolate the device (Fig. 8a, b), avoiding the electronic short-circuiting problem and simultaneously generating electricity with high power outputs > 1000 mW • cm−2 at 550 °C. There is a unique charge separation mechanism, discovered by Zhu et al. [103], as shown in Fig. 8c.

Reproduced with permission from Ref. [103]. Copyright 2017 Elsevier

a Nanoparticle contacts between the LSCF and Sm and Ca co-doped Ceria (SCDC), b energy diagram of the p–n BHJ for charge separation on the H2 contact side at the particle level, and c energy band diagram at the device level.

This can be a general methodology for new conversion devices based on semiconductors and principles. In the latest research, Dong et al. [82] also used the same strategy to construct a fuel cell with TiO2 as the electrolyte. They claimed that electronic conduction in electrolyte materials should not be blamed if the energy band diagram can be well aligned in a real fuel cell. In the fuel cell, the CB of the electrolyte, either a pure ionic conductor or a semiconductor, should be higher than the redox potential of H2/H+; therefore, the electrons cannot jump to the CB of the electrolyte, or are blocked by the electrolyte layer. TiO2 is a typical semiconductor with great application potential in photovoltaics and photoelectrochemistry [104,105,106,107,108]. At first glance, the use of TiO2 will cause the short-circuiting issue in fuel cell conditions. This does not happen in this fuel cell case since TiO2 possesses a higher CB above the redox potential of H2/H+ and a lower VB than the redox potential of O2/O2− [98, 105, 109, 110], which can help effectively block electron transport through the electrolyte. When combined with the advanced NCAL symmetric electrode for demo-SOFCs, the reduced electrode materials in the anode have a lower CB than the redox potential of H2/H+ and a higher VB than the redox potential of O2/O2−. The electrons and holes can easily move to and be collected in the electrode. Such a fuel cell device has been successful demonstrated, delivering 1.10 V (OCV) and 364 mW cm−2 at 550 °C under hydrogen/air conditions. The nearly Nernst theoretical voltage and excellent power output have verified the proposed methodology. Electronic conduction in electrolytes could be well managed by properly choosing the electrode material based on the energy band diagram method [111, 112]. More details will be further discussed in Sect. 5.

To this end, a summary of the developed semiconductor and/or heterostructure material-based fuel cells and their corresponding electrical properties, including ionic conductivity and fuel cell electrochemical performance, is presented in Table 1. The ionic conductivities of semiconductor or heterostructure materials are much higher than those of single-phase oxide ion conducting electrolytes, which enables superior fuel cell electrochemical performance at low temperatures. Semiconductor-based fuel cells may suggest an alternative promising approach to develop next-generation SOFCs or PCFCs.

4 Semiconductors and Semiconductor Electrochemistry in Batteries

4.1 LIB as a Typical System

Extensive examples of employing semiconductor bands and physics in electrochemistry can be widely found. One of the featured fields is the rechargeable batteries or secondary batteries, such as LIBs, Na-ion batteries, and Zn- and Mg-ion batteries, which reversibly convert electrical and chemical energy via redox reactions, thus storing electrical energy as a chemical potential in their electrodes [122, 123]. Metal ions are reversibly transported between the anode and cathode and through the electrolyte, releasing or storing energy. Generally, the specific capacity of electrodes and the working voltage of the battery determine the energy density of these devices, i.e., the differential chemical potentials between the cathode and the anode. In these typical electrochemical devices, semiconductor properties and band theories provide a new comprehensive understanding of the scientific principles for improving the electrochemical reaction kinetics to increase the rate performance. Taking the LIB as a typical system, Fig. 9 shows an example of understanding the lithium battery electrochemistry and cathode (positive electrode) materials from the semiconductor band structure and physics (Fig. 9a). The LiCoO2 positive electrode (cathode) energy as a function of the density of states, being relevant to the Fermi level of Co4+/3+ redox couples, is presented in the device energy level diagram with respect to the highest occupied molecular orbital (HOMO) and the lowest unoccupied molecular orbital (LUMO) of the liquid electrolyte, as shown in Fig. 9b [124]. The battery voltage, i.e., the OCV VOC can be expressed as Voc = (μc − μa)/e, where e is the magnitude of the electronic charge and the difference in chemical potential between the anode (a) and the cathode (c).

Reproduced with permission from Ref. [126]

a Schematic energy level diagram for a lithium cell; b with LiCoO2 as the cathode and lithium as the anode, illustrating the origin of Voc and relative energy positions with respect to the HOMO and the LUMO of the liquid electrolyte. The Fermi level of the lithium anode is drawn above the LUMO of the electrolyte, indicating that reduction of the electrolyte is usually observed. Note that the Fermi level of the cathode shifts downward during deintercalation. c Electronic band structure of LiCoO2 (Li = 1, left), Li0.5CoO2 (Li = 0.5, middle) and CoO2 (Li = 0, right), as deduced from DFT calculations and experimental measurements.

Normally, this working voltage is also determined by the electrochemical window of the electrolyte (see Fig. 9b), which is controlled by the energy gap between the HOMO and the LUMO. To work properly, the anode and cathode materials must follow the rule that μa is below the LUMO and μc is above the HOMO; otherwise, the electrolyte will be reduced on the anode surface or oxidized in the cathode zone, forming a passivating solid electrolyte interphase (SEI) film [125]. From a physical point of view, one may relate the cell voltage to the difference in the (electro)chemical potential of the electrons between the cathode and anode, as given by the position of their Fermi levels (see Fig. 9a). However, we should keep in mind that the Fermi level (electron chemical potential) of (single) electrode materials in the discussion of electrode potentials is not exact but quite often provides reasonable accuracy and results.

In Ensling’s work, the authors highlighted the significance of the (partially) covalent character of the device capacity and stability as well as electrode kinetics after investigating the electronic structure of the LiCoO2 cathode materials. Figure 9c presents three typical structures of LiCoO2 (Li = 1, left), Li0.5CoO2 (Li = 0.5, middle) and CoO2 (Li = 0, right) after Li+ removal from the LiCoO2 structure with different electronic bands, along with the differences in the chemical instability with respect to oxygen loss due to the overlapping of the Co4+/3+:t2g band with the O 2p orbitals. The changes within the structure and occupation of the density of states (DOS) of LixCoO2 during deintercalation are schematically summarized. The Fermi level (EF) reaches a critical value when the Co 3d states (Co4+/3+ couple) cross the top of the O 2p bands, which is accompanied by hole transfer to the O 2p states. A significant number of electrons can be removed from the O 2p band, leading to oxidation of Co ions and/or formation of oxygen vacancies, which is not favored for cathodic durability. Therefore, the proximity in energy of the t2g and O 2p bands determines the intrinsic voltage limit for the LiCoO2 cathode material [126]. The loss of oxygen from the lattice in the Li1 − xCoO2 system may explain the limited capacity (140 mAh • g−1), which is significantly lower than the theoretical value. Therefore, investigating the metastable character of partially deintercalated semiconductors of LixCoO2 is very important for the device process kinetics and durability, where the band structure plays an important role.

In the LIB field, further improvements in electrodes and cells are generally limited by an incomplete understanding of the interfaces, involved charge transfer, charge compensation, and chemical reaction processes. Much attention has been paid in the past to the electric potential gradient at the interface, although double (dipole) layers can have a significant impact on the energy level (mis)alignment [127]. Additionally, for ionic phases with low charge carrier concentrations, diffuse charge layers (space charge layers) are encountered at interfaces [128], which induce band bending and related charge carrier concentration changes that have a significant impact on the charge transfer rate and interface stability. Figure 10 shows an energy level diagram for the LiCoO2/diethyl carbonate (DEC) (alkyl carbonate solvent) electrolyte interface with a focus on the formation of the electrochemical double layer. Li ions are generally aligned with the ionic electrochemical potential of Li+ in the two phases (the chemical potential of Li ions is initially very low in the DEC adsorbate phase). According to theoretical considerations, the Li-ion energy level is bent in the opposite direction to the electron energy levels due to the opposite charge of the ion. With such an energy level diagram, the interface and its kinetic properties can be understood, as it contains energy level offsets as well as any charge carrier concentration changes, as evidenced by band bending [129].

Electron and ion energy level diagram of the LiCoO2/DEC interface established from LT adsorption of DEC (alkyl carbonate solvent) electrolyte. DEC: diethyl carbonate. Note that the Li-ion levels are deduced from theoretical considerations. Reprinted with permission from Ref. [130].

4.1.1 Band Theory for Tuning from Semiconducting to Ion Conducting Electrolytes

Currently, efforts are mainly devoted to the development of new solid-state electrolytes, such as oxide and sulfide, to increase the energy density and safety of lithium batteries. However, the ionic conductivity in solid-state ionic electrolytes is much lower than that in liquid electrolytes. The traditional design of ionic conductors is primarily based on substitutional doping of dissimilar valence cations into the unit lattice of the structure, resulting in inherent limits on the dopant concentration and thereby ionic conductivity. Recently, a very interesting example of applying semiconductors and electronic states to batteries is the strongly correlated perovskite SmNiO3 (SNO), which shows applicable lithium ion conductivity at room temperature. SNO has a metal conduction nature and can be electrochemically transformed by Li+ injection from an electronic conductor to an electronic insulator and a superior Li+ conductor as the electrolyte for a LIB [131]. Based on extensive experimental and theoretical calculations [131], Li+ ion shuttling and simultaneous suppression of electronic transport via the Mott transition are induced in such a system, which provides an alternative approach to develop novel LIBs or other energy devices.

Figure 11a–c shows that a large amount of mobile Li+ can be found in an electrochemically lithiated SmNiO3 (Li-SNO) system, which is located in interstitial sites of the perovskite, approaching one dopant ion per unit cell, accompanied by significant lattice expansion. Such interstitially inserted Li+ ions can facilitate fast Li+ conduction associated with a lower activation energy in comparison with the structural case. Figure 11b presents a design principle for solid-state Li+ conductors based on SNO. Pristine SNO is a narrow gap semiconductor after lithiation, i.e., the lithium-doped/inserted thin film SNO (Li-SNO), then transforms into an insulator, with a gap of approximately 3 eV (Fig. 11c). First-principles density functional theory (DFT) calculations showed that the pristine SNO exhibits a monoclinic cell without distortion, while with lithium entering SNO, Ni3+ is converted to Ni2+, resulting in a much different total DOS (Fig. 11d).

Reproduced with permission from Ref. [131] Copyright 2018 National Academy of Sciences

Strongly correlated nickelate as the ionic conductor in a LIB. a Electronic configuration of pristine SmNiO3 (SNO), a narrow gap semiconductor, at room temperature. b Self-designed electrochemical cell for lithiation of SNO. c Electronic configuration of lithiated SNO (Li-SNO). Electron filling leads to a large on-site Coulomb interaction, suppressing the electronic conduction pathway. Li+ occupies multiple interstitial sites of the unit cell. Electron localization-induced perovskite lattice expansion facilitates Li+ interstitial transport, which enables Li-SNO to be a potential lithium-ion conductor. d First-principles simulation of the total DOS for Li-SNO with 0–1 intercalated Li/SNO (gray). The projected DOS (PDOS) of the unoccupied Ni Eg states are shown in color. The lighter hues indicate Eg states of Ni3+, and the darker hues indicate those of Ni2+ including the newly occupied Eg states due to the localization of the added electron from the intercalated lithium below the Fermi energy.

The Li+-inserted Li-SNO has an expanded structure that allows for a 3D interconnected Li+ diffusion channel, and the interstitial Li+ is weakly bonded with oxygen ions, therefore exhibiting fast Li+ conduction behavior. Accompanying this transition, the pristine SNO shows insulation due to suppression of electron transport in SNO. The Li+ conductivity was determined to be 3.1 × 10–3 S·cm−1 at room temperature with an activation barrier of ∼0.24 eV. The corresponding Li-SNO battery demonstrated LIB capacity and good lithiation and delithiation cycle life with average coulombic efficiency of 96.8%. This work provides evidence for ion shuttling in the lattice and atomistic pathways [132,133,134]. Moreover, this strategy can be extended to other ions, such as Na+, demonstrating the generality of the approach.

A theoretical design of the Li+ conductor could be based on wide bandgap semiconductors. Wide bandgap semiconductors, especially dielectric materials, can potentially be used as electrolytes because of their large bandgap, which precludes the possibility of electrons being excited from the VB to the CB by thermal means. In addition, under electric field conditions, the electric dipole component in the dielectric materials can be adjusted, which may further affect the ionic transport properties [135,136,137,138]. Li+ and Na+ ions are large enough to form bent O-A-O symmetric bonds in some condensates of larger anion clusters with electric dipole moments, as illustrated in Fig. 12 for Na glass. The high-frequency dielectric constant is important because it represents the intrinsic property of the material and is directly related to the DC conductivity. Accompanying this electric dipole component, the electric dipole component of the electrolyte interface charge is increased by dipole coalescence. Using dielectric materials in the electrolyte may produce a very large energy gap window that makes it stable upon contact with both an alkali-metal anode and a high-voltage cathode without the formation of an SEI. The glass also contains electric dipoles that have a large dielectric constant. The Goodenough group applied dielectric materials as electrolytes for Li+ and Na+ batteries. For example, the Li+ and Na+ glass electrolytes A2.99Ba0.005O1+xCl1−2x with A = Li or Na were reported [128,129,130,−131]. Bragg and Goodenough et al. [128] reported that the dipoles are oriented under an applied electric field and aligned parallel to the field axis, which enables solid glass electrolytes A2.99Ba0.005O1+xCl1−2x with A = Li or Na to yield an ionic conductivity σi > 10–2 S • cm−1 and a very large dielectric constant, which is extremely important to develop safe rechargeable batteries of high energy density and long cycle life.

Reproduced with permission from Ref. [139]. Copyright 2016 ECS

Ab initio molecular dynamics calculations showing electric dipoles with a ratio of elementary dipoles to several unaligned clusters of 7:1 at 100 °C. a Box containing 81 Na+, 7 Cl− and 37 O2− ions. b Elementary dipoles and clusters. c Chain segments calculated before and proposed after alignment.

4.1.2 Role of the BIEF in Batteries

One of the most exciting characteristics of semiconductor and energy band theories in the battery field is that the band alignment of different battery components or compositions that induces a BIEF or alters the local electric field (LEF) can significantly improve the electrochemical performance of the device, including promotion of ion transport, increase of the cycle life and high-speed discharge–charge cycle, and enlargement of the battery capacity.

To speed up electrode Li intercalation at high charge–discharge rates and promote the Li+ ion diffusion process, a BIEF at the semiconductor particle (material) level has been reported. A typical example is reported by Xia et al. [11] for a TiO2-based electrode, as shown in Fig. 13. In comparison to bulk TiO2 (Fig. 13a) and nanocrystal TiO2 (Fig. 13b), Fig. 13c shows a structure consisting of a nanocrystalline stoichiometric core of an intrinsic-type TiO2 semiconductor and an amorphized nonstoichiometric outer layer TiO2−d n-type shell. Such a structure creates an i-n heterostructure [11] with the BIEF direction from the outer layer to the core, which is expected to promote Li+ diffusion during the lithium discharge process, i.e., help Li+ insertion (Fig. 13d). Once Li+ has been fully inserted or discharged into the TiO2 nanocrystal, the core will become LiyTiO2, turning into an intrinsic semiconductor. In contrast, the disordered layer takes up much less Li+ due to the existence of oxygen vacancies and becomes Liy−2x−rTiO2 − d, corresponding to a relative p-type semiconductor compared with LiyTiO2. Therefore, a new i-p heterostructure and a BIEF will be formed at the core/shell interface; thus, the new BIEF directed from the disordered layer to the crystalline core facilitates Li+ transport from the core to the shell, i.e., helps Li+ extraction in the charging process (Fig. 13e). In the end, with the assistance of the in situ formed i-n and i-p heterostructure and BIEFs, a higher ionic diffusion capability is obtained during the Li+ ion insertion/extraction process, increasing the rate performance.

Reproduced with permission from Ref. [11]. Copyright 2013 ACS

Comparison of charge diffusion in electrode materials made of a bulk crystals, b nanocrystals, and c surface-amorphized nanocrystals, and illustration of the facilitation of charge transport under a BIEF during discharge (d) and charge (e) processes. The length and width of the arrows illustrate the relative penetration depth and the charge transfer/transport coefficients of the lithium ion in the material, respectively.

Another interesting case is reported by Yan et al. [140] based on carbon-doped Co3O4 nanocrystals for superior Li-ion storage. The imbalanced charge distribution emerging from the carbon-dopant can induce an LEF to greatly facilitate charge transfer within unique sub-10 nm nanocrystal-assembled Co3O4 hollow nanotubes (HNTs). The resulting carbon-doped Co3O4 HNT-based electrodes demonstrated an excellent reversible capacity of 950 mAh • g−1 at 0.5 A • g−1 after 300 cycles and superior rate performance of the full battery with 853 mAh • g−1 at 10 A • g−1. Zheng et al. [12] also reported that the LEF effect can be built at atomic interfaces on ultrathin Bi2MoO6 (BMO) nanosheets (Fig. 14a–c). The unbalanced charge distribution between the [Bi2O2]2+ and [MoO4]2− layers induces an interfacial electric field at the interfaces, while the lopsided charge distribution around oxygen vacancies results in a local in-plane electric field, thus promoting ion diffusion/electron transport. Additionally, the 2D ultrathin construction can provide interconnected charge migration paths formed on the open surfaces, which could facilitate the charge transfer process in the BMO sheets. Therefore, both the in-plane and interfacial electric fields, as illustrated in Fig. 14d, induced by atomic-level engineering (Fig. 14e) can cause an unbalanced charge distribution within the crystal and induce a BIEF, which can significantly boost the lithium-ion transfer dynamics. Impressively, the lithium battery using the BMO nanosheet electrode shows a long-term cycling performance at 2000 mA • g−1. A possible mechanism for the improvement in lithium storage in atomically thin BMO nanosheets is proposed as shown in Fig. 14f.

Reproduced with permission from Ref. [12]. Copyright 2017 Wiley–VCH

Morphology of obtained BMO sheets. a TEM image, b enlarged high-resolution TEM image, and c atomic force microscopy (AFM) image with corresponding height. d Schematic diagram of the induced in-panel electric field and the interface electric field within the BMO sheets viewed in different directions. e Electric field distribution and corresponding crystal structure of the BMO sheets in (d). f Relationship between the electric field, migration paths, and Li transfer kinetics in BMO sheets and bulk BMO. d–f Summary of the enhanced high rate capacity mechanism of the BMO sheets for Li-ion storage.

In addition to LIBs, the construction of a BIEF/LEF has also been demonstrated to be very effective in developing high-performance sodium-ion batteries [141, 142]. Ni et al. [141] found that a BIEF can reduce the activation energy and accelerate charge transport significantly based on the synergy of the ordered architecture of iron oxide-based nanotube arrays and a BIEF. Figure 15a schematically illustrates such a material system and the BIEF-related mechanism. A BIEF spontaneously develops at the heterogeneous interface of n-Fe2O3 and p-FeS2, as verified by Kelvin probe force microscopy measurements across the heterointerface. Upon discharge (sodiation), the BIEF that has an n-to-p direction will push Na+ ions from Fe2O3 to neighboring FeS2, leading to enhanced transport kinetics. Then, for recharging, desodiation grows relatively Na+-rich FeS2 domains and Na+-deficient Fe2O3 domains, yielding a new BIEF with an electric field direction from FeS2 to Fe2O3 due to the potential difference. Therefore, the Na+ diffusion kinetics can be boosted in such an S-Fe2O3 system in both sodiation and desodiation states. More specifically, S-Fe2O3 exhibits a high initial current efficiency of 83%. The assembled S-Fe2O3//Na0.67(Mn0.67Ni0.23Mg0.1)O2 battery shown in Fig. 15b afforded a reversible capacity of approximately 500 mAh • g−1 (based on anode mass) and an average voltage of 2.5 V (Fig. 15c), leading to a specific energy of 160 Wh • kg−1 (based on both active materials) at a power density of 60 W • kg−1. The energy remained at 142 Wh • kg−1 under a specific power of 330 W • kg−1, which is comparable to that of commercial LiFePO4 batteries. Similar promotion effects were also observed in Bi2S3-Bi2O3 [142] for Na-ion batteries and in C@N–C@N P–C graded heterostructures for aluminum-ion batteries (AIBs) [143]. Such a design also serves as a perfect platform for exploring the underlying correlation of the BIEF and the electrochemical performance of secondary batteries.

Reproduced with permission from ref. [141]. Copyright 2019 Wiley–VCH

a Schematic of the formation of a BIEF and Na+ storage mechanism upon discharge and recharge, and electrochemical performance of the full cell of Fe2O3//Na0.67(Mn0.67Ni0.23Mg0.1)O2. b Schematic of the coin-type full cell. c Initial galvanostatic profiles of the S-Fe2O3//Na0.67(Mn0.67Ni0.23Mg0.1)O2 full cell at a rate of 0.2 A g−1 (based on the anode mass).

4.2 Coupled Energy Conversion and Storage Technologies with Semiconductors

The application of semiconductors to new energy conversion and storage has been widely reported. Coupling devices through the joining principle is an emergent frontier. Here, two typical examples of designing fuel cells by combining the approaches of solar cell coupling and using photoelectrolysis principles to design semiconductor-ionic fuel cell (SIFC) devices are reviewed. Figure 16a–c illustrates the band design of a fuel cell based on the PSC principle with the band structure and alignment as a new fuel-to-electricity conversion approach [102]. Similar to the PSC, we used electron and hole transport layers (ETL and HTL) and a semiconductor-ionic LSCF-SCDC material layer sandwiched between the ETL and HTL (Fig. 16b, c). Such a novel system consists of an LSCF-SCDC functional layer (Fig. 16d). The electrochemical performance was compared for a conventional 3-layer fuel cell, the type-I cell with an ETL and an HTL similar to a solar cell, and a type-II symmetrical heterojunction device (Fig. 16e). The latter two cells showed much-improved fuel cell performance over the conventional 3-layer fuel cell. In particular, the type-II cell provided a peak power density of 1080 mW • cm−2 at 550 °C with hydrogen fuel/air oxidant. The outstanding electrochemical performance, we believe, is ascribed to the much-improved ionic conductivity of the LSCF-SCDC layer, i.e., 0.188 S • cm-1 (4 times higher than that of the individual SCDC electrolyte at 600 °C) because of the enriched oxygen at the interface of LSCF and SCDC [121]. This work highlighted exploring wide bandgap semiconductors and energy band design for new-generation fuel-to-electricity conversion. Well-aligned energy bands can be designed and realized by unique semiconductor-ionic materials from anode n-type conducting to cathode p-type conducting materials with junction formation incorporated with ionic functions to maintain fuel cell electrochemical reactions, all were integrated into one device [113, 122, 123]. The key issue in such a semiconductor-ionic device is that there must be a charge separation mechanism to prevent the electrons and holes from passing through the device internally and forming an electron short-circuiting problem [103].

Reproduced with permission from ref. [102]. Copyright 2016 Elsevier

Energy level diagram of a a perovskite-type solar cell, b a fuel-to-electricity conversion device (fuel cell) inspired by the PSC structure (type I) and c a symmetrical fuel-to-electricity conversion device (type II) with an in situ formed Schottky junction. d Cross-sectional SEM image of the type-II device and close-up view of the LSCF-SCDC functional layer. e Device electrochemical performance comparison of the conventional 3-layer fuel cell, the type-I fuel-to-electricity device with an ETL and an HTL, and the type-II symmetrical heterojunction fuel-to-electricity device.

In another case, fuel cell devices based on energy band alignment were experimentally demonstrated to show no e−/h+ flow causing short circuiting based on a TiO2 functional layer as the electrolyte (Fig. 17) [82], in which a TiO2 thin film was deposited on the p-conducting semiconductor NCAL (LiNi0.8Co0.15Al0.05O2) ceramic substrate, with another NCAL thin electrode on top completing the fuel cell construction (Fig. 17a, b). As a wide bandgap semiconductor, TiO2 is suggested to hold the capability to suppress electron and hole conduction through the bulk (Fig. 17c), as reflected by an OCV close to the theoretical value based on the Nernst equation (Fig. 17d), and the cell gave a peak power output larger than 300 mW • cm−2 at 550 °C and an impressive electrochemical impedance value (Fig. 17e). This fundamental understanding and scientific design are important and naturally related to the photoelectrolysis and photocatalysis fields. The TiO2 fuel cell provides for the first time, from the detailed band parameters relevant to the photo-water splitting process and the products, the view that the photo-water electrolysis process, H2O = H2 + O2, is the reverse process to that in a fuel cell: H2 + O2 = H2O. Compared to photocatalyst TiO2 water splitting, there are some similarities in the TiO2 electrolyte fuel cell band structure and alignment. Therefore, a new and universal design for TiO2 electrolyte or other semiconductor-based fuel cells from the band structure and alignment in comparison with the TiO2 photo-water splitting process is shown in Fig. 18, in which the electrolyte layer is extended from a typical electronic conductor to a wide bandgap semiconductor, providing the specific requirement mentioned in the following paragraph. According to energy band theory, to adjust the carrier transport behavior in a device, materials with different energy band structures should be carefully designed. For example, in a PEC water splitting device [15, 144], the Fermi level of the metal counter electrode must be higher than the redox potential of H+/H2, while the VB level of the semiconductor photoanode must be lower than the redox potential of H2O/O2 (Fig. 18a). The fuel cell reaction product can be regarded as a reverse product of water splitting. In a typical fuel cell, electrons are generated at the anode/electrolyte interface and are then supposed to flow through the anode to the outer circuit when the circuit is connected. Meanwhile, no electrons are expected to flow through the electrolyte; otherwise, short circuiting occurs (Fig. 18b). Therefore, the electrons in the anode should be blocked by the electrolyte from the perspective of energy band theory. In a typical Ni-YSZ (Y-stabilized ZrO2) fuel cell, the redox potential of H2/H+ is approximately 4.5 eV relative to the vacuum energy (RVE), and the work function for a typical anode material Ni is approximately 5.1 eV RVE, which is lower than the potential of H2/H+; hence, electrons stemming from the oxidation of H2 can flow to the anode. Meanwhile, the CB of the YSZ electrolyte is higher than the redox potential of H2/H+; electrons cannot jump to the CB of the electrolyte; namely, the electrons are blocked by the electrolyte. However, if an electrolyte material has a lower CB level, then short-circuiting problems might occur (Fig. 18c). For example, the CB level of SDC, which is measured to be at approximately 5.65 eV, then the electron may flow to electrolyte, and the short-circuiting problem is often observed in SDC electrolyte fuel cells. When SDC is reduced by H2 in fuel cell operation, its electronic conductivity rapidly increases, and electrons can flow through it [145]. This is why the short-circuiting problem was observed in an SDC electrolyte fuel cell after a period of operation. In short, the energy band structure of a good SOFC should obey the following rules: (1) the CB level of the electrolyte should be higher than the redox potential of H2/H+, (2) the Fermi level of the metal anode (or the CB level of the semiconductor anode) should be lower than the redox potential of H2/H+, (3) the VB level of the electrolyte should be lower than the redox potential of O2/O2−, and (4) the CB level of the cathode should be higher than the redox potential of O2/O2−.

Reproduced with permission from Ref. [82]. Copyright 2019 RSC

a Construction of the fuel cell device using a TiO2 electrolyte functional layer; b SEM images of the cell configuration of the TiO2 electrolyte-based fuel cell device, c energy band diagram of the resulting thin film TiO2 electrolyte fuel cell with NCAL electrodes; d, e electrochemical performance of a proof-of-concept of the fuel cell at 550 °C in H2/air condition.

Reproduced with permission from Ref. [82]. Copyright 2019 RSC

Energy band diagrams of a PEC water splitting (the Honda–Fujishima effect), b a fuel cell, and c the fuel cell with the occurrence of short circuiting. If the anode of the fuel cell is not a metal but a semiconductor, then the CB level of this semiconductor should be lower than the energy level of H+/H2, as the electrons generated by H2 oxidation are expected to flow to the CB level of this semiconductor.