Abstract

Fog droplets are very often used as a cleaning agent when air pollution can be dangerous for health conditions and ecosystem. This work presents a new system to optimize the cleaning properties of fog by tuning its microphysical parameters. For this purpose, a newly developed system, which is based on the electromagnetic echo effect (EMEE) sensor, is used to detect the most efficient interaction between fog and impurities, i.e., which fog droplets can be used to most effectively clean a certain type of pollutant from the air. Fog droplet spectra controlled by the nozzle pressure system can be used to effectively remove pollutants from the air. For this purpose, an automated system for aerosol generation can allow an accurate control over the fog microphysical parameters and the use of fluids with specific concentrations of pulverized chemical compounds. Fog droplet size distribution is controlled by the feeding gas pressure at the nozzle and chemical simulants. The experimental results showed that the microphysical parameters (MP) are directly related to the impurity of species used in the cleanup simulation process. The MP parameters of fog are liquid water content (LWC), droplet mean radius (Rm), droplet number concentration (Nd), and both aerosol type and mass concentration. In the lab testing, harmless simulants of CBRN (chemical, biological, radiological and nuclear) species were used. During the tests, fog droplet size distribution is controlled by the air pressure at the nozzle and simulants. It is concluded that an integrated fog generator system (IFGS) with EMEE sensor developed in the current work can be utilized broadly to control fog microphysical parameters, leading to an optimum aerosol/chemical species’ cleaning process.

Similar content being viewed by others

1 Introduction

Air pollution is a serious global problem (Brook et al. 2003) and adversely affects human health. Aerosol removal from the atmospheric boundary layer can be very important for cleaning the air. Aerosols can also directly and indirectly affect our climate (Mcfarquhar et al. 2011; Penner et al. 2001) by changing cloud microphysical properties (Tao et al. 2012; Gultepe et al. 2017b, a).

Artificially generated aerosols can be dangerous for human health that is a part of the ecosystem. The lethal power of polluting agents and their ability to cause mass fatalities rely on their dispersion and diffusion in a complex weather environment. Aerosols are those agents dispersed in air that can penetrate into the lungs. For example, casualties caused by inhaling Anthrax spores dispersed in air are two orders of magnitude greater than those caused by a cutaneous infection of the same spores (Malizia and D’arienzo 2018). Pollution of the aerosols such as chemical and radiation agents can also be critical for human health (Goel 2015).

The impact of a dispersed chemical element on health can be reduced using various levels of fog physical conditions. This is usually true due to the exponential increase of the surface-to-volume ratio for decreasing sizes of fog droplets (Gultepe and Isaac 1996; Gultepe et al. 2006). The use of fine-dispersed emulsions (Brook et al. 2003) and small fog droplets (Tsujita et al. 2003) has been proven highly efficient and environmentally friendly for decontaminating equipment and complex facilities. The fog usage for cleaning poisonous aerosols from the air minimizes the amount of decontaminant required for cleaning procedures. Also, fog can be compatible with electrical and electronic equipment without any damages. Further, fog droplets can penetrate into complex holes and ducts, as well as venting ducts; therefore, it can be very useful for microclimate applications to remove harmful aerosols and bacteria.

Interestingly, Lee et al. demonstrate that hydrogen peroxide (H2O2) is spontaneously produced in micrometer-sized water droplets, generated by atomizing bulk water using nebulization, without the necessity of any chemical reagent, catalyst, or applied electric potential (Lee et al. 2019a, b). H2O2 production increases with decreasing microdroplet size. It is later reported (Lee et al., 2020), that the H2O2 can also be spontaneously generated in water microdroplets formed by condensation of water vapor from air on a cold surface. In addition, Lin and co-authors (Lin et al. 2023) uncover a size-dependent nature of the charge transfer between water microdroplets. The results could be used for green and inexpensive production of H2O2 for safe air pollution control (see, e.g., Deo 1988).

It is well known that both fog and rain, because of their washout effects, can be used as air cleaning agents, since they both have higher fall velocities compared to pollutants (Pilat et al. 1974; Guo et al. 2016). Recently, a study by Ardon-Dryer et al. (2015) suggested that rain having with large drops (> 100 micron) can be very effective for cleaning air in the atmosphere. It was discovered that, in general, the smaller the size of falling rain drops in the same mass concentration as in large drops, attracts many more aerosol particles, especially at lower relative humidity (RH) conditions. Moreover, a device designed for fast and massive decontamination of aerosols through the generation of sub-micron fog jets has been developed and tested successfully for removing the CBRN clouds (Pérez-Díaz et al. 2018). A precise assessment of the “cleaning” process requires a precise characterization of the fog microphysical properties.

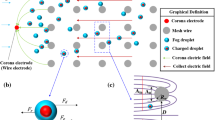

Using various air pressures at the nozzle in the climatic wind tunnels (Gultepe et al. 2019; Qing et al. 2018), aerosol number concentration (Nd) and mean diameter (Dm) of the droplet size distribution (DSD) are obtained when pulverizing fluids with specific mixture of the mass concentrations of chemical compounds. The sensors used for this purpose in the past have been operated on the basis of the “laser-induced charge effect” (Ivanov and Konstantinov 2002; Ivanov and Kuneva 2011). The study of Ivanov et al. (2020a) suggested that the name of this laser-induced charge effect should be changed to electromagnetic echo effect (EMEE) because this reflects better the nature of the effect. In this way, it cannot be confused with the photoelectric effect used commonly. The EMEE is represented by small, alternating voltage, and detected using targeted EMF on all kinds of substances (Ivanov et al. 1995; Park et al. 1996). The same technique has been also used for numerous applications (Ivanov and Kuneva 2011; Abbate et al. 1995; Ivanov and Konstantinov 1999; Ivanov 2004; Pérez-Díaz and Kuneva 2017) and also used for the development of fog sensors used for industrial applications. The new methods for contactless evaluation of fog microphysical parameters in artificially produced sprays have been previously used to detect aerosol impurities in the composition of fog (Ivanov et al. 2017a, b, 2020a, b, 2021; Ivanov and Pérez-Díaz 2020).

The analyzing of the fog-chemical composition in the atmosphere has been carried out by collecting the droplets from special mesh collectors and testing them in a laboratory, which is difficult and time consuming (Klemm et al. 2012). Earlier studies mainly focused on the chemical properties of the air pollution aerosols and their nucleation capability used in numerical studies (Tsujita et al. 2003; Marquez-Viloria et al. 2016) but not in the fog-aerosol interactions. Lately, time of flight fog-aerosol analysis is possible and used in the cloud droplet research (Hwajin et al. 2019).

The current study is related to the COUNTERFOG project which is funded by the European Commission (PN 312804) that aims to create a system for large-scale decontamination of air using fog droplets. The chemical pollutants are chosen as harmless simulants of the main types of CBRN agents. Since it was not possible for us to measure in real time the actual aerosol removal from air by using fogs (this requires very expensive equipment such as fog/cloud chambers), we conducted the experiments indirectly—we used the EMEE sensor system that is designed to measure in real time the relative amount of pollutants in the composition of various fogs. In this way, we can determine the parameters of fog droplets that have absorbed optimal quantities of pollutants, and these results can be used in real-life applications regarding aerosol removal from air. The fog generating systems can be designed and tuned to produce fog droplets with the required parameters for optimal removal of certain pollutants from the air.

The paper is structured as follows: Sect. 2 represents the experimental setup and an integrated fog generator system (IFGS). Sections 3 and 4 focus on the results and discussions. Section 5 provides the main conclusions.

2 System Setup and Measurements

The IFGS generates a controlled fog droplet size spectrum in a specific sampling volume. Artificial fog can be used as a cleaning agent to remove aerosols from the sampled air. To accomplish this goal, the purposed platform uses the EMEE sensor that measures the relative amount of pollution aerosols collected by the fog.

The relationship between fog physical parameters and aerosol chemical composition is investigated using the IFGS that operates on the basis of the EMEE. This IFGS prototype system, using various thresholds for chemical species, is able to generate aerosols with different chemical compositions that can lead to dedicated droplet size (Rm) and number concentration (Nd). The IFGS is designed to work with up to six different fluids and durations of spraying from 0.2 to 5.5 s. An important advantage of this system is that it provides a fast and easy way to pulverize different chemical solutions, and offers a precise control of the amounts of impurities in the fluids. As a result, generated fog can have various particle size distributions (PSDs) with changing LWC and effective size. The mixing of chemical species with pure water is not dispersed in air but are dissolved in the pure liquid water before releasing into the air.

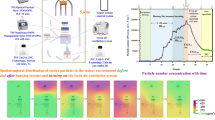

Figure 1 presents the automated IFGS. This system includes following units: the fog generator, fog measuring equipment, spray control unit with a timer, and signal detector unit. The flow diagram for the IFGS is shown in Fig. 2.

Block diagram of the automated system for generation of fog with impurities and the fog sensor – (1) laser sensor transmitter; (2) laser sensor receiver unit; (3) gas pressure tank, (4) valve; (5) atomizing nozzle; (6) valves; (7) fluid containers; (8) spraying control unit; (9) lock-in nanovoltmeter; (10) frequency generator

The numbers in Fig. 2 indicate the location of the ten units in the IFGS. The unit 1 is the receiver of the optical sensor used for fog droplet spectra measurements. The unit 2 is for the optical sensor transmitter. The unit 3 is for the generation of the gas (e.g., nitrogen) used under pressure that is fed from the tank (3) to the valve (unit 4), and then lead to the atomizing nozzle (Unit 5). The prototype IFGS has six valves (unit 6), so that switching between different containers representing various chemical species can be done quickly and easily. Thus, pulling water from a selected container (7) can be mixed with selected chemical species. The diameter of the nozzle is 0.4 mm with a spraying angle of 20° (suggested by the manufacturer, Lechler GmbH, Metzingen, Germany, https://www.lechler.com/de-en/). The nozzle (model #136.316.35.A2) is a pneumatic brass-plated atomizing nozzle, which works on the siphon/gravity principle.

A manometer and valves were mounted on the pressure gas tank, which allowed to precisely control the feeding pressure of the nitrogen gas, so that different characteristics of the generated fog can be obtained, such as the number concentration (Nd) and droplet size (Rm). Depending on the impurity (defined as a chemical composition) of a selected species, a specific container is selected to generate a specific fog type. The electromagnetic valve (unit 4) is controlled by a pulse generator (unit 8) and was designed locally. Different settings by unit 8 can be used to achieve desired durations of fog spraying. Fog produced by the nozzle is directed into the sensor sampling area consisting of a laser (unit 2) and a frequency generator (unit 10). The unit 10 modulates the transmitted laser intensity and its received absorption after fog extinction. The signal from the sensor is measured by a lock-in nanovoltmeter (9).

3 Method

In the analysis, a certain amount of pure water is mixed with a chemical species as well as nitrogen gas in the unit 5 nozzle system. The control unit generates uniform impulses at either 0.2- or 0.5-s increments from 0.2 to 5.5 s. When the desired values for the impulse duration are set, the generation of an impulse with the desired time duration is initiated via a button. This impulse is transferred to the electromagnetic valve (unit 4), and thus a fog spraying through the nozzle is generated.

For the experiments, four kinds of chemical species were dissolved in distilled water—potassium dihydrogen phosphate (KH2PO4), urea (CO(NH2)2), potassium hexacyanoferrate trihydrate (K3[Fe(CN)6]), and Cefazolin (an antibiotic with symbol of C14H14N8O4S3). The chemical species were chosen, because they have a similar chemical structure as the CBRN (chemical, biological, radiological and nuclear) agents, but they are harmless to be used in a laboratory. This way, the presence of a pollutant in fog droplets can be simulated. For example, KH2PO4 has been selected as a harmless simulant of the CBRN chemical poisonous agents. In a water solution, it dissociates to give phosphate ions which resemble a part of the abovementioned agents’ molecules. K3[Fe(CN)6] was chosen as a chemical agent simulant due to the presence of cyanide ions in its structure. They are bonded in a stable complex with iron, which makes the compound safe to work with (its solution is also used in photography). The cyanide functional group is a constituent of the blood agents Cyanogen Chloride and Hydrogen Cyanide.

The prepared solutions were used to generate fog DSD with different droplet number concentration Nd and mean diameter (Dm) at 2, 3 and 4 bar of feeding gas pressure (P). The Nd, liquid water content LWC, and droplet mean radius Rm are obtained from DSD assuming a relationship between nozzle pressure at the liquid exit and droplet characteristic size. The solution characteristics at each gas pressure were measured using a laser particle size analyzer (LPSA uses a 0.532-micron wavelength and it is the Winner 319A model, manufactured by Winner Particle Instrument Stock Co. Ltd., Jinan, China, http://en.jnwinner.com/) at a distance of 1 m. The LPSA has the measurement size range of 1–500 micron at 50 channels. For each case, 100 of the measurements are taken at 1 Hz sampling rate and then averaged. The duration (dt) of each spraying is selected as 0.4 s. For each gas pressure, six measurements of the signal intensity were recorded and then its average value for the dt is calculated. In the analysis, the droplet size of each solution (mean diameter, Dm) is obtained as a function of 3 pressure levels (e.g., 2, 3, and 4 bars, see Table 1). This procedure is repeated for each of the four solutions and results are summarized in next section.

4 Results

4.1 Solution Microphysical Characteristics

The results are summarized in Table 1 where Dm of DSD is measured by the particle size analyzer against the nozzle pressure (P) (from 2 to 4 bar) for each chemical species (four types and distilled water).

Table 1 shows that Dm decreases with gas pressure increasing. Larger Dm values are seen for the distilled water. On the other hand, cefazolin solution has a lower fog droplet Dm. It is clearly seen that Dm is significantly lower for mixtures compared to distilled water, indicating CCN effect on droplet formation.

The Dm versus nozzle pressure for the 4 chemical species are shown in Fig. 3. The fog mean diameters for each solution are obtained based on the three nozzle pressure levels. Results showed that increasing nozzle pressure leads to decreasing Dm which is consistent with theory.

It is clear to see that the presence of chemical species can alter the fog DSD, affecting the mean diameter. The fog generating system can be used to control fog microphysical properties including Dm, LWC, and Nd. Using the mass continuity concept of the fluid flow, the ratio of P1 to P2 (pressures in two different conditions) is assumed to be related to the ratio of Nd1 to Nd2 (droplet number concentration at P1 and P2). Nd1 is assumed as a fixed value (~ 100 cm−3) for typical marine fog conditions (Gultepe et al. 2017b). Then, Nd2 is calculated based on mass continuity concept for a given air flow. In reality, Nd is usually a function of aerosol number concentration, aerosol composition, and RH. Table 2 shows the fog droplet mean volume radius (Rm), LWC, visibility (Vis), as well as flow rate (Qr) and droplet speed (Vdn) at the nozzle. The dependence of LWC on Rm and Nd can be given by (Gultepe and Isaac 2004) as:

where ρw is the water density. Then, Vis related to LWC and Nd based on in-situ measurements using FM100 instrument is obtained (Gultepe et al. 2006) as:

This equation represents marine fog conditions and may be used for a general testing of measured DSD relation to chemical agents. Equation 2 is used for Vis calculation as function of LWC, Nd, and Rm for each chemical agent, and the results are summarized in Table 2.

The results from Table 2 can be summarized as follows:

-

Droplet number concentration is found to be critical for cleaning up the chemicals from the polluted environment because it is influenced by aerosol mass and size of the particles;

-

Droplets with Rm of 4.0 µm can be ideal for cleaning potassium hexacyanoferrate from the polluted environment;

-

Rm of 5.5 µm can be used to most effectively cleaning the urea;

-

Potassium dihydrogen phosphate is most successfully collected by droplets with Rm of 7.0 µm;

-

The solution containing Cefazolin with Rm of 5.0 µm can be used most effectively clean the polluted air.

4.2 Solution Droplet Size Spectra

In this subsection, spectral characteristics of solution droplets measured by the laser particle size analyzer are studied based on the scatter plot of the particle size (Dm) versus cumulative count values and number counts (Fig. 3). Figure 3 presents measurements for each of the four types of solutions. Based on the fog DSD in Fig. 3, the following points can be emphasized:

-

The fog containing 40% of droplets with sizes between 3 and 10 µm, and 60% of droplets between 14 and 50 µm optimally collect potassium hexacyanoferrate;

-

The fog that can be most effective in cleaning up urea from the air, contains about 75% of droplets between 3 and 13 µm, and 25% in the range 13–40 µm;

-

The fog that contains about 50% of its droplets having sizes between 3 and 10 µm, and the other 50%—between 10 and 55 µm, is most suitable for collecting potassium dihydrogen phosphate;

-

The fog in which 80% of the droplets have diameters in the range 3.5–10 µm, and the other 20% are between 10 and 50 µm, can be very effective cleaning up Cefazolin from the air.

From the results presented above, it is clear that each type of pollutant can be cleared from air by fog with specific size distribution parameters, such as Rm, LWC, and Nd that represent a specific DSD.

5 Discussion

In this study, an automated aerosol-water droplet generation system is developed to test chemical impurities effect on fog droplets that is measured by an LPSA. The fog droplet spectra are obtained using four chemical species and a gas water mixture, and controlled by the nozzle system. Fog droplet generating solutions are initially made by dissolving the chemicals into distilled water (Fig. 2). Then, the nitrogen under pressure is connected to the pneumatic nozzle of the pulverizing system to draw the solution from the container to the nozzle, generating fog droplets. At first, we sprayed the mixture towards the EMEE sensor to get the signal deviation, and then the same fog is sprayed towards the LPSA to determine the particle size spectra. After that, we can compare the signal deviation with the respective mean diameter. The higher the deviation, the greater the amount of the impurity carried by the corresponding droplets. In that way we can determine the Dm with the highest amount of impurity.

In the experiment described above, major difficulties can be summarized as:

-

Stability of the system with room RH and temperature T that were fixed at 85% and 25 °C, respectively;

-

If more than one chemical species is introduced into the composition of fog, the sensor at its current level of development would not be able to distinguish the concentration of each impurity separately. This will lead to large uncertainty in characteristic size of PSD;

-

The most important issue is that the LPSA was not able to provide direct measurements of Nd and this led to analysis difficult to be applied, and in future, this will be improved with a new supporting particle sizer.

Despite these aforementioned issues, the presented system is capable of quick analysis of fog pollution concentrations, since the EMEE sensor operates in real time.

6 Conclusions

In this work, the IFGS is developed and operates on the basis of the EMEE signal recognition for the aim of measuring fog droplets properties and optimization of the pollution cleaning process. The IFGS is an automated system that is used for fog simulation experiments in the laboratory conditions. The experimental setup allows an efficient interaction between fog droplets and various assumed pollutant amounts. The four chemicals as shown in Table 1 are prepared to simulate hazardous pollutants effects on fog size distributions. The best fog-chemical species interactions are determined by detecting the highest EMEE signal deviations. These results show that specific fog parameters exist for each pollutant type and can be used to remove the pollutant species, in this case, CRBN chemicals species. Creating databases as discussed here can improve the capabilities for pollution eradication and retrieval procedures. The following conclusions from this work can be drawn:

-

IFGS is found to be effectively used for fog generation with various PSD;

-

Chemical species led to varying Rm and changing droplet number concentration;

-

Droplet Rm was about 5–10 µm for urea and Cefazolin and 15–25 µm for potassium dihydrogen phosphate and potassium hexacyanoferrate trihydrate;

-

Largest uncertainty in the analysis occurred when the environmental RH and T fluctuates about 20% of the fixed values.

-

Results suggested that IFGS can be applicable for real environmental problems but needs to be further tested for varying environmental conditions.

It is suggested that creating proper databases related to fog formation as a function of various chemical species and controlled pressure systems can improve the capabilities for air pollution eradication and fog simulations. In future, as a continuation of the work within the COUNTERFOG project, we would like to simulate real atmospheric conditions to be tested for the removal process of dangerous chemical species.

References

Abbate A, Rencibia P, Ivanov O, Masini G, Palma F, Das P (1995) Contactless characterization of semi-conductor using photo-charge voltage measurements. Mater Sci Forum 173:221–226

Ardon-Dryer K, Huang Y, Cziczo DJ (2015) Laboratory studies of collection efficiency of sub-micrometer aerosol particles by cloud droplets on a single-droplet basis. Atmos Chem Phys 15:9159–9171. https://doi.org/10.5194/acp-15-9159-2015

Brook RD, Brook JR, Rajagopalan S (2003) Air pollution: the “Heart” of the problem. Curr Hypertens Rep 5:32–39. https://doi.org/10.1007/s11906-003-0008-y

Deo P (1988) The use of hydrogen peroxide for the control of air pollution. Stud Environ Sci 34:275–292. https://doi.org/10.1016/S0166-1116(08)71297-4

Goel AK (2015) Anthrax: a disease of biowarfare and public health importance. World J Clin Cases 3:20–33. https://doi.org/10.12998/wjcc.v3.i1.20

Gultepe I, Isaac GA (1996) The relationship between cloud droplet and aerosol number concentrations for climate models. Int J Climatol 16:1–6. https://doi.org/10.1002/(SICI)1097-0088(199608)16:8%3c941::AID-JOC57%3e3.0.CO;2-O

Gultepe I, Isaac GA (2004) An analysis of cloud droplet number concentration (Nd) for climate studies: Emphasis on constant Nd. Q J Roy Met Soc 130(602):2377–2390

Gultepe I, Müller MD, Boybeyi Z (2006) A new warm fog parameterization scheme for numerical weather prediction models. J Appl Meteorol 45:1469–1480

Gultepe I, Agelin-Chaab M, Komar J, Elfstrom G, Boudala F, Zhou B (2019) A meteorological supersite for aviation and cold weather applications. Pure Appl Geophys 176(5):1977–2017. https://doi.org/10.1007/s00024-018-1880-3

Gultepe I, Heymsfield AJ, Gallagher M, Ickes L, Baumgardner D (2017a) Ice fog: the current state of knowledge and future challenges: chapter 4 in ice formation and evolution in clouds and precipitation: measurement and modelling challenges. AMS Meteor Mon 58:4.1-4.24. https://doi.org/10.1175/AMSMONOGRAPHS-D-17-0002.1

Gultepe I, Milbrandt JA, Zhou B (2017b) Prediction, a chapter in the book of marine fog: challenges and advancements in observations, modeling, and forecasting. In: Darko K, Clive D (Eds.), Springer Publisher Company NY, pp 345–394

Guo L, Zhang Y, Lin H, Zeng W, Liu T, Xiao J, Rutherford S, You J, Ma W (2016) The washout effects of rainfall on atmospheric particulate pollution in two Chinese cities. Environ Pollut 215:195–202. https://doi.org/10.1016/j.envpol.2016.05.003

Hwajin K, Sonya C, Xinlei G, Jianzhong X, Yele S, Wenqing J, Youliang W, Pierre H, Qi Zh (2019) Chemical processing of water-soluble species and formation of secondary organic aerosol in fogs. Atm Environ 200:158–166. https://doi.org/10.1016/j.atmosenv.2018.11.062

Ivanov O (2004) Charging of solids by irradiation with electromagnetic field. Opt Commun 232:313–317

Ivanov O, Konstantinov L (1999) Temperature dependence of the surface photo-charge effect in CdS. Appl Surf Sci 143:101–103

Ivanov O, Konstantinov L (2002) Investigations of liquids by photo-induced charge effect at solid-liquid interfaces. Sensor Actuat B-Chem 86:287–289. https://doi.org/10.1016/S0925-4005(02)00215-0

Ivanov O, Mihailov V, Pustovoit V, Abbate A, Das P (1995) Surface photo-charge effect in solids. Opt Commun 113:509–512. https://doi.org/10.1016/0030-4018(94)00503-M

Ivanov O, Todorov P, Gultepe I (2020a) Investigations on the Influence of chemical compounds on fog microphysical parameters. Atm Basel 11:225–236. https://doi.org/10.3390/atmos11030225

Ivanov O, Todorov P, Pérez-Díaz JL (2020b) Contactless evaluation of the number and diameter of fog droplets by gravitational separation and measurement of electrical signals. In: Application № 112602/20.10.2017 of the Patent Office of the Republic of Bulgaria, issued on 10.12.2020, Registration number 67164 B1

Ivanov O, Kuneva M (2011) Quality control methods based on electromagnetic field-matter interactions. In: Ivanov O (ed) Application and experience of quality control. InTech, Vienna, pp 509–536

Ivanov O, Pérez-Díaz JL (2020) Detecting the presence of impurities in the composition of fogs and aerosols through measuring the electrical signal induced by surface photo-charge effect, Application № 112588/29.09.17 of the Patent Office of the Republic of Bulgaria issued on 15.11.2020, Registration number 67186

Ivanov O, Karatodorov S, Pérez-Díaz JL (2017a) Novel electromagnetic sensor for contaminations in fog based on the laser-induced charge effect. In: Proceedings of IEEE SENSORS 2017, CFP17SE, IEEE, ISBN:978-1-5386-4056-2, pp 1509–1511

Ivanov O, Ralev Y, Todorov P, Popov I, Angelov K, Pérez-Díaz JL (2017b) System for fog generation for development of sensors. In: Proceedings Military Science and Security—Fifth International Scientific and Technical Conference on Engineering, Technologies, Education and Security. vol 1, pp 44–47, ISSN: 2535-0315 (Print), 2535-0323 (Online)

Ivanov O, Todorov P, Pérez-Díaz JL (2021) Optimization of the cleaning properties of fog by means of a sensor operating on the basis of laser-induced photo-charge effect by measuring electrical signals. In: Application № 112601/20.10.2017 of the Patent Office of the Republic of Bulgaria, issued on 26.02.2021, Registration number 67262 B1

Klemm O, Schemenauer RS, Lummerich A, Cereceda P, Marzol V, Corell D, van Heerden J, Reinhard D, Gherezghiher T, Olivier J, Osses P, Sarsour J, Frost E, Estrela MJ, Valiente JA, Fessehaye GM (2012) Fog as a fresh-water resource: overview and perspectives. Ambio 41:221–234. https://doi.org/10.1007/s13280-012-0247-8

Lee J, Walker K, Han H, Kang J, Prinz F, Waymouth R, Nam H, Zare R (2019a) Spontaneous generation of hydrogen peroxide fromaqueous microdroplets. PNAS 116(39):19294. https://doi.org/10.1073/pnas.1911883116

Lee J, Han H, Chaikasetsin S, Marrona D, Waymouth R, Prinz F, Zare R (2019b) Condensing water vapor to droplets generateshydrogen peroxide. PNAS 117(49):30394. https://doi.org/10.1073/pnas.2020158117

Lin S, Cao L, Wang Z (2023) Size-dependent charge transfer between water microdroplets. PNAS. https://doi.org/10.1073/pnas.230797712

Malizia A, D’arienzo M (2018) Enhancing CBRNE safety & security. In: Proceedings of the SICC 2017 Conference Science as the first countermeasure for CBRNE and Cyber threats, https://doi.org/10.1007/978-3-319-91791-7

Marquez-Viloria D, Botero-Valencia JS, Villegas-Ceballos J (2016) A low cost georeferenced air-pollution measurement system used as early warning tool. In: 2016 XXI Symposium on Signal Processing, Images and Artificial Vision (STSIVA), Bucaramanga, Colombia, 31 Aug.-2 Sept., INSPEC Accession Number: 16467020, https://doi.org/10.1109/STSIVA.2016.7743366.

Mcfarquhar G, Schmid B, Korolev A, Ogren J, Russell P, Tomlinson J, Turner D, Wiscombe W (2011) Airborne intrumentation needs for climate and atmospheric research. Bull Amer Meteorol Soc 92:1193–1196. https://doi.org/10.1175/2011BAMS3180.1

Park N, Abbate A, Das P (1996) Characterization of semiconductors by laser-generated photocharge voltage spectroscopy. Inst Phys Conf Ser 145:593–598

Penner J, Andreae M, Annegarn H, Barrie L, Feichter J, Hegg D, Jayaraman A, Leaitch R, Murphy D, Nganga J (2001) Aerosols, their direct and indirect effects. In: Houghton JT et al (eds) Climate change 2001: the scientific basis. Contribution of working group I to the third assessment report of the intergovernmental panel on climate change. Cambridge University Press, Cambridge, pp 289–348

Pérez-Díaz J, Kuneva K (2017) Application of surface photo-charge effect for control of fluids in advances in biosensors reviews. In: Sergey YY (Ed) vol 1, pp 121–137, ISBN: 978-84-697-3467-4

Pérez-Díaz JL, Qin Y, Ivanov O, Quinones J, Stengl V, Nylander K, Hornig W, Álvarez J, Ruiz-Navas EM, Manzanec K (2018) Fast response CBRN high-scale decontamination system: COUNTERFOG: science as the first countermeasure for CBRNE and Cyber threats. In: Malizia A, D’Arienzo M (eds) Enhancing CBRNE safety & security. Springer, pp 61–69

Pilat MJ, Jaasund SA, Sparks LE (1974) Collection of aerosol particles by electrostatic droplet spray scrubbers. Environ Sci Technol 8:360–362. https://doi.org/10.1021/es60089a006

Qing T, Liping C, Ruirui Zh, Min X, Gang X, Tongchuan Y, Bin Zh (2018) Droplet spectra and high-speed wind tunnel evaluation of air induction nozzles. Front Agr Sci Eng 5(4):442–454. https://doi.org/10.15302/J-FASE-2017169

Tao W, Chen J, Li Z, Wang C, Zhang C (2012) Impact of aerosols on convective clouds and precipitation. Rev Geophys 50:14

Tsujita W, Kaneko S, Ueda T, Ishida H, Moriizumi T (2003) Sensor-based air-pollution measurement system for environmental monitoring network. In: TRANSDUCERS ‘03. 12th International Conference on Solid-State Sensors, Actuators and Microsystems, Digest of Technical Papers (Cat. No. 03TH8664), Boston, MA, USA, pp 544–547

Acknowledgements

This work has been accomplished with the financial support by the Grant No BG05M2OP001-1.002-0011-C02 financed by the Science and Education for Smart Growth Operational Program and co-financed by the European Union through the European Structural and Investment funds. This work has also been funded by FP7-SEC-2012-1 program of the EU Commission under grant number 312804, and by the Bulgarian Ministry of Education and Science in the frame of the National Roadmap for Research Infrastructure (support for ACTRIS BG).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors have no competing interests to declare that are relevant to the content of this article.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Todorov, P., Ivanov, O., Gultepe, I. et al. Optimization of the Air Cleaning Properties of Fog. Aerosol Sci Eng (2024). https://doi.org/10.1007/s41810-024-00220-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41810-024-00220-0