Abstract

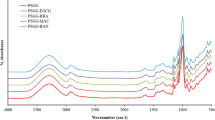

Biodegradable films are an excellent alternative to using non-biodegradable materials. Plant extracts are rich in antioxidant and antimicrobial components and can be used as components in active packaging to improve food preservation. This study demonstrated that the ethyl acetate fraction of the crude bark extract of Euphorbia umbellata presented high amounts of phenolic compounds (515.81 ± 29.61 mg of galic acid per gram of fraction) with concentration-dependent antioxidant potential (DPPH•—IC50 1.95 ± 0.01 μg/ml; ABTS•+—IC50 1.40 ± 0.15 µg/ml; FRAP–2,680.05 ± 0.02 µmol of trolox per gram of fraction), and antimicrobial activities against Staphylococcus aureus and Escherichia coli (inhibition halo diameter larger than 8 mm). The addition of this fraction into biodegradable starch-based films allowed the formation of an active matrix, with minor mechanical changes when the ethyl acetate fraction was used at 2.5 and 5.0% (w/w), registering tensile strength results of 29.5 ± 4.0 MPa for inert film; 29.5 ± 4.0 MPa for 2.5% (w/w) of E. umbellata ethyl acetate extract, and 25.1 ± 1.9 MPa for 5% (w/w) of E. umbellata ethyl acetate extract. A heterogeneous microstructure in the presence of ethyl acetate extract resulted in lack of homogeneity and rough surface of the films, maintaining important antioxidant and antibacterial activities. This material can be considered as an alternative for production and application as biodegradable and active food packaging.

Similar content being viewed by others

References

López-Córdoba A, Medina-Jaramillo C, Piñeros-Hernandez D, Goyanes S (2017) Cassava starch films containing rosemary nanoparticles produced by solvent displacement method. Food Hydrocoll 71:26–34. https://doi.org/10.1016/j.foodhyd.2017.04.028

de Léis CM, Nogueira AR, Kulay L, Tadini CC (2017) Environmental and energy analysis of biopolymer film based on cassava starch in Brazil. J Clean Prod 143:76–89. https://doi.org/10.1016/j.jclepro.2016.12.147

Edhirej A, Sapuan SM, Jawaid M, Zahari NI (2017) Cassava/sugar palm fiber reinforced cassava starch hybrid composites: Physical, thermal and structural properties. Int J Biol Macromol 101:75–83. https://doi.org/10.1016/j.ijbiomac.2017.03.045

Jaramillo CM, Gutiérrez TJ, Goyanes S, Bernal C, Famá L (2016) Biodegradability and plasticizing effect of yerba mate extract on cassava starch edible films. Carbohydr Polym 151:150–159. https://doi.org/10.1016/j.carbpol.2016.05.025

Hosseini SF, Rezaei M, Zandi M, Farahmandghavi F (2016) Development of bioactive fish gelatin/chitosan nanoparticles composite films with antimicrobial properties. Food Chem 194:1266–1274. https://doi.org/10.1016/j.foodchem.2015.09.004

Riaz A, Lei S, Akhtar HMS, Wan P, Chen D, Jabbar S, Abid M, Hashim MM, Zeng X (2018) Preparation and characterization of chitosan-based antimicrobial active food packaging film incorporated with apple peel polyphenols. Int J Biol Macromol 114:547–555. https://doi.org/10.1016/j.ijbiomac.2018.03.126

Avella M, De Vlieger JJ, Errico ME, Fischer S, Vacca P, Volpe MG (2005) Biodegradable starch/clay nanocomposite films for food packaging applications. Food Chem 93:467–474. https://doi.org/10.1016/j.foodchem.2004.10.024

Kähkönen MP, Hopia AI, Vuorela HJ, Rauha JP, Pihlaja K, Kujala TS, Heinonen M (1999) Antioxidant activity of plant extracts containing phenolic compounds. J Agric Food Chem 47:3954–3962. https://doi.org/10.1021/jf990146l

Leceta I, Guerrero P, Cabezudo S, De La Caba K (2013) Environmental assessment of chitosan-based films. J Clean Prod 41:312–318. https://doi.org/10.1016/j.jclepro.2012.09.049

Mwine JT, van Damme P (2011) Why do euphorbiaceae tick as medicinal plants? a review of euphorbiaceae family and its medicinal features. J Med Plants Res 5:652–662

Minozzo BR, Lemes BM, Justo ADS, Lara JE, Petry VEK, Fernandes D, Belló C, Vellosa JCR, Campagnoli EB, Nunes OC, Kitagawa RR, Avula B, Khan IA, Beltrame FL (2016) Anti-ulcer mechanisms of polyphenols extract of Euphorbia umbellata (Pax) Bruyns (Euphorbiaceae). J Ethnopharmacol 191:29–40. https://doi.org/10.1016/j.jep.2016.06.032

Munhoz ACM, Minozzo BR, Cruz LS, Oliveira TL, Machado WM, Pereira AV, Fernandes D, Manente FA, Vellosa JCR, Nepel A, Barison A, Beltrame FL (2014) Chemical and pharmacological investigation of the stem bark of synadenium grantii. Planta Med 80:458–464. https://doi.org/10.1055/s-0034-1368300

Lemes BM, Novatski A, Ferrari PC, Minozzo BR, Justo AS, Petry VEK, Vellosa JCR, Sabino SRF, Gunha JV, Esmerino LA, Beltrame FL (2018) Physicochemical, biological and release studies of chitosan membranes incorporated with Euphorbia umbellata fraction. Rev Bras Farmacogn 28:33–443. https://doi.org/10.1016/j.bjp.2018.05.001

Silva KM, Zielinski AAF, Benvenutti L, Bortolini DG, Zardo DM, Beltrame FL, Nogueira A, Alberti A (2019) Effect of fruit ripening on bioactive compounds and antioxidant capacity of apple beverages. Food Sci Technol 39:294–300. https://doi.org/10.1590/fst.25317

Zhang L, Kosaraju SL (2007) Biopolymeric delivery system for controlled release of polyphenolic antioxidants. Eur Polym J 43:2956–2966. https://doi.org/10.1016/j.eurpolymj.2007.04.033

Reddy N, Yang Y (2010) Citric acid cross-linking of starch films. Food Chem 118:702–711. https://doi.org/10.1016/j.foodchem.2009.05.050

Oleyaei SA, Zahedi Y, Ghanbarzadeh B, Moayedi AA (2016) Modification of physicochemical and thermal properties of starch films by incorporation of TiO2 nanoparticles. Int J Biol Macromol 89:256–264. https://doi.org/10.1016/j.ijbiomac.2016.04.078

Olivato JB, Marini J, Yamashita F, Pollet E, Grossmann MVE, Avérous L (2017) Sepiolite as a promising nanoclay for nano-biocomposites based on starch and biodegradable polyester. Mater Sci Eng C 70(1):296–302. https://doi.org/10.1016/j.msec.2016.08.077

Alves ACS, Mainardes RM, Khalil NM (2016) Nanoencapsulation of gallic acid and evaluation of its cytotoxicity and antioxidant activity. Mater Sci Eng C 60:126–134. https://doi.org/10.1016/j.msec.2015.11.014

De Araújo GKP, De Souza SJ, Da Silva MV, Yamashita F, Gonçalves OH, Leimann FV, Shirai MA (2015) Physical, antimicrobial and antioxidant properties of starch-based film containing ethanolic propolis extract. Int J Food Sci Technol 50:2080–2087. https://doi.org/10.1111/ijfs.12869

Zardo DM, Silva KM, Guyot S, Nogueira A (2013) Phenolic profile and antioxidant capacity of the principal apples produced in Brazil. Int J Food Sci Nutr 64:611–620. https://doi.org/10.3109/09637486.2013.763909

Modolo LV, de Souza AX, Horta LP, Araujo DP, de Fátima  (2015) An overview on the potential of natural products as ureases inhibitors: A review. J Adv Res 6:35–44. https://doi.org/10.1016/j.jare.2014.09.001

Müller CMO, Yamashita F, Laurindo JB (2008) Evaluation of the effects of glycerol and sorbitol concentration and water activity on the water barrier properties of cassava starch films through a solubility approach. Carbohydr Polym 72:82–87. https://doi.org/10.1016/j.carbpol.2007.07.026

Suriyatem R, Auras RA, Rachtanapun C, Rachtanapun P (2018) Biodegradable rice starch/carboxymethyl chitosan films with added propolis extract for potential use as active food packaging. Polymers 10:954. https://doi.org/10.3390/polym10090954

Piñeros-Hernandez D, Medina-Jaramillo C, López-Córdoba A, Goyanes S (2017) Edible cassava starch films carrying rosemary antioxidant extracts for potential use as active food packaging. Food Hydrocoll 63:488–495. https://doi.org/10.1016/j.foodhyd.2016.09.034

Medina-Jaramillo C, Ochoa-Yepes O, Bernal C, Famá L (2017) Active and smart biodegradable packaging based on starch and natural extracts. Carbohydr Polym 176:187–194. https://doi.org/10.1016/j.carbpol.2017.08.079

Apak R, Özyürek M, Güçlü K, Çapanoʇlu E (2016) Antioxidant activity/capacity measurement. 1. Classification, physicochemical principles, mechanisms, and electron transfer (ET)-based assays. J Agric Food Chem 64:997–1027. https://doi.org/10.1021/acs.jafc.5b04739

Burt S (2004) Essential oils: Their antibacterial properties and potential applications in foods—a review. Int J Food Microbiol 94:223–253. https://doi.org/10.1016/j.ijfoodmicro.2004.03.022

Acknowledgements

The authors would like to express their gratitude to Multi-user laboratory (CLABMU)” of the State University of Ponta Grossa (UEPG), for technical support. We are also grateful to Dr. Sean Stroud for checking and correcting the English version of the text.

Funding

The authors would like to express their gratitude to CAPES (scholarship), FINEP-CT/Infra (Research Grant 02/2013), and Fundação Araucária (convênio nº 09/2017) for financial support.

Author information

Authors and Affiliations

Contributions

MRR, BML, BRM, KAA, and ACMOC were responsible for conceiving the idea, carried out the experiments and wrote the manuscript, LAE, LRO, AA and AN assisted in the realization of experiments and discussion of results. FLB and JBO supervised the work, corrected and edited the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Rosas, M.R., Lemes, B.M., Minozzo, B.R. et al. Starch-based biodegradable active packaging with Euphorbia umbellata (PAX) Bruyns bioactive extract. J Package Technol Res 5, 97–106 (2021). https://doi.org/10.1007/s41783-021-00114-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41783-021-00114-3