Abstract

Steel packaging remains an important mean by which foodstuffs and other products can be stored safely for a prolonged period of time. The industry is being challenged by the dual legislative pressures which require the elimination of Chrome (VI) from the manufacturing process and the elimination of bisphenol A as a component from the lacquer system. Initial indications suggest lower adhesive performance, and it has been postulated that thermal treatment may be a mean of improving adhesion. Three substrates (two current and one future) were physically and chemically characterized prior and post treatment and the resultant impact of adhesion was quantified. The net impact of the thermal treatment is that it increases the adhesion of the lacquer on the surface. As there is minimal change in the physical characteristics of the surface, the authors propose that this is a result of changes in the chemical surface species, particularly the increase in the oxidic nature of each of the substrates which provides additional bonding sites for the organic species in the lacquer. These trends are observed for current substrate materials as well as next generation Chrome VI free substrate. Next generation replacement substrate materials perform better than current materials for dry adhesion while next generation bisphenol A non-intent lacquer materials perform poorer than the current epoxy phenolic materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Steel packaging is an important mean of protecting and preserving foodstuffs, providing significant improvements in product lifetime and providing physical protection for the product. Steel packaging has classically been protected via either tinplating, or for the past 30 years electrolytic chromium coated steel (ECCS). ECCS (also called tin free steel—TFS) was developed in the 1980s for the lacquered can market due to cost savings because it requires a much thinner coating to provide comparative protection. ECCS is manufactured using Chrome VI which has approximately 10–30 nm coating of chromium/chromium oxide, whereas tinplate require a 1-µm or higher tin coating thickness [19, 20]. In addition to these commercial substrates, new substrates are being developed as a result of the European directive on packaging material [22] which limits the use of Chrome (VI) which is an inherent part of current ECCS and tinplate passivation processing. Legislative pressure [14] is also leading the industry to move away from well-established epoxy phenolic lacquers towards materials which are deemed BPA free.

With both current and future material sets, there is an increasing amount of can decoration. When a printed pattern (for branding or product information) is applied to the external of a can, it is common to print this surface first before applying the lacquer which is to be in contact with the contents. This is preferable in the food packaging industry as possible contamination of the food contact surface is minimised. The curing of the external surface therefore subjects the inner surface to an additional 15 min of thermal treatment at 200 °C compared to a substrate where the external surface is not printed. Informal reports have hinted at changes in adhesion, but there is no evidence in the public domain literature. There is some evidence that thermal treatment, even at moderate temperatures, can induce changes in the surface chemical species and as these species lie at the metal/lacquer interface this may explain the beneficial impact of this practice in improving substrate/lacquer adhesion.

There is a limited amount of literature which is relevant to the present study and this largely reflects the mature status of the materials and product. Where the literature exists, this has primarily examined the impact of other variables, such as manufacturing, surface treatment or coating composition. The method of tinplate passivation has been shown to result a change in tinplate surface chemistry and subsequently on lacquer adhesion [2]. Dry and wet adhesion (the adhesion after exposure to high temperature steam of the foodstuff cooking process) between lacquer systems and tinplate substrates has been investigated [1] using EIS but this did not examine any thermal pretreatment. The presence of this DOS oil (dioctyl sebacate) which protects the surface from immediate oxidation and provides a lubricating surface) and the level of tin oxide on the surface has been shown to significantly affect tinplate substrate wetting [18], although no adhesion was considered. A post coating bake was found to improve UV coating adhesion with the improvement being attributed to improved bonding within the organic lacquer [11].

Few studies on ECCS substrates have examined surface lacquer adhesion although its corrosion properties are widely reported [26]. The dearth of literature on adhesion can be attributed to the excellent performance of the material with high levels of adhesion with epoxy phenolic lacquers reported [16], even under high strain [3, 5]. The substrate is also highly compatible with PET laminates [5, 27]. Any future material combinations imposed by EU legislation ideally need to meet the performance standards of ECCS and epoxy combination.

The literature has highlighted that there is a limited amount of information on the adhesion of novel lacquers and substrates and the means by which these may be used to improve any reductions in adhesion. The effect of thermal loading, which acts effectively as a pretreatment, has not been determined for current, let alone future substrates. Thus, there exists a knowledge gap in that the effect of this common temperature treatment (whether desired) is not known for common metal packaging substrates. There is therefore novel value in undertaking an experimental study to establish the relative adhesion performance of current and future substrate/lacquer combinations and whether the 200 °C required for curing the printed outside lacquer acts as a pretreatment. The aim of the study was to establish adhesion performance and to examine the role of thermal treatment on current and future lacquer combinations, and to determine the mechanisms by which a change in performance may occur through examination of the substrate surface structural and chemical characteristics.

Materials and Methods

To cover the widest possible range of packaging materials, three substrates were investigated in the study; tinplate with 311 passivation, electro-chromic coated steel (ECCS) and TCCT (Trivalent Chromium Coating Technology, based on Cr3+ salts), Table 1. The first two represent commercially mature substrates while the latter is a the development substrate where Chrome VI has been eliminated from the substrate processing and replaced with Chrome III. Within each substrate type, samples were chosen such that they possessed similar surface finishes and were intended for similar market applications. Two commercial lacquer systems, Vitalure 345 from AkzoNobel and Akzo Nobel white anhydride epoxy, were used as the lacquer and all subsequent curing steps were carried out in accordance with the manufacturer’s recommendations. These represent commercial systems, and are therefore representative of common industrial practice. In addition, a development formulation of a BPANI coating was used. In a BPANI lacquer, BPA may be present in trace volumes but it is not intentionally added to the formulation. This BPANI lacquer does not represent a fully commercial system but a pre-commercial release development product.

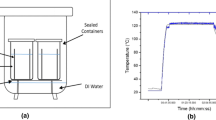

Substrate samples were put through a 3-m Thieme belt dryer and were subjected to an air temperature of 200 °C with a dryer residence time of 15 min. This is identical to the process which is used in an industrial environment. Samples were passed through the dryer as supplied with the rolling oil and without any cleaning. The lacquer was subsequently deposited using an RK automatic Meyer bar coating system which resulted in a coating thickness of approximately 10 μm which is comparable to that which is produced in an industrial scenario. The lacquer was cured by passage of the substrate through the dryer under identical conditions to the pretreatment.

Adhesion characterization carried out using a Sheen Instruments BS3359 scratch tester was operated in accordance with ISO 1518 [7]. A steel stylus was used where the point of adhesive failure being defined by the mass load required to provide the electrical continuity between the tool and the substrate. This method was chosen as other methods for examining the adhesion between the lacquer and substrate did not prove to be satisfactory for the study. The “pull off” and Erichsen dome tests [4, 10] imparted significant plastic deformation/substrate failure in the thin substrate prior to adhesion failure. The cross hatch tape test [6] was found to provide unsatisfactory variability between samples, and subsequently did not provide a meaningful objective metric of adhesion. Measurements were taken in the rolling direction.

Surface and near surface chemical analysis was carried out using a Kratos Axis Ultra at TATA Steel IJmuiden. The data were then analysed using CasaXPS. The Ar+ etch was set at 4 keV 20 mA with a 3 × 3 mm spot size. Measurements were carried out beyond the temperature of the normal curing temperature of 200 °C to ensure that changes which may occur close to the normal curing temperature would impact the results. XPS measurements on all substrates were carried out in air so that they would best mimic the pretreatment process. XPS (X-ray photoelectron spectroscopy) measurements on the ECCS substrate were also carried out in a UHV (Ultra high vacuum of 1 × 10−9 mbar) to investigate the effect of the atmosphere during heating. XRD (X-ray diffraction) characterisation was carried out on a Bruker D8 using measurements taken in 2θ mode between 20° and 110°. Substrate free surface energy was measured using a first ten Angstroms 1000 droplet analyser utilizing DI water, ethylene glycol and diiodomethane as liquids with calculation of the polar and dispersive elements using the best practice methods [21, 25]. Surface roughness was measured using a Veeco NT200 white light interferometer over a 305 × 232 μm area with each pixel representing 0.415 μm.

Results

Physical and Structural Characterization

The impact of the rolling is to impart non isotropy in the surface with peaks and valleys running in a direction parallel to the rolling direction, Fig. 1a–f. Similar surface structures are observed with the ECCS and TCCT substrates as this is predominately dictated by the finishing roller surface characteristics, Fig. 1a–d. There is no discernible change in the topological characteristics beyond which can be attributed to measurement position within the sample. The surface of the tinplate is somewhat smoother with areas of lower gradients in the valleys, associated with tin reflow process which occurs after tin deposition, but prior to chrome passivation, Fig. 1e, f. The impact of thermal exposure is minimal with each substrate showing only subtle changes in structure between the surface uncoated and thermally treated to 200 °C. No measureable difference in surface finish (as defined by Ra) was observed between the unheated and heated samples beyond the variability observed between areas on the same sample, Fig. 1g.

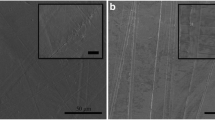

Further SEM (Scanning electron microscopy) microstructural examination of the substrates shows subtle changes between the untreated and heat-treated surfaces. This was not deemed to be significant given the natural local variations between areas on the substrate, Fig. 2. Generally, the changes observed were less noticeable than natural variations observed between individual topographic areas on any sheet.

The primary instance of differences between the pretreated and untreated substrates was observed on the 311 tinplate, Fig. 3a. Thermal treatment results in some evidence of FeSn2 growth at the peaks through the tin surface.

There is a greater, but not large, discrepancy between the untreated and treated subsurface structure Fig. 4. For ECCS, Fig. 4a, there is a slight structural change in the unit cell with the peak at 45° increasing and the peak at 65° decreasing in size relative to the peak at 82°. On the TCCT substrate, the Cr and iron peaks at 45°, 65° and 82°, respectively, remain more or less constant, Fig. 4b. The TCCT substrate does, however, experience a structural change in the surface with the carbide response increasing at 38° and decreasing at 80°. This implies that the meta-stable material which is only partially crystalline and that the effect of the temperature to increase crystallinity. For the tinplate substrate, there is a reduction of the peak for tin at 32° due to the reflowing of the material alongside a slight decrease in the tin peak at 62°, Fig. 4c.

For the current substrates there is a minimal change in the physical characteristics of the ECCS substrate and only subtle changes in the tinplate substrate due to some evidence of FeSn2 growth. The primary finding for the developmental substrate is the growth of the carbide layer near the surface.

Surface Chemical Characterization

Surface species provide the binding surface for the organic lacquer and thus plays an important role in determining lacquer adhesion [23]. Each substrate experiences some changes in surface chemistry over the temperature range considered, Fig. 5. For clarity, compounds with proportions less than 2% are omitted while the labels “OH” and “Oxide” represent the hydroxyl and oxidic species which are associated with the chrome [Cr2O3 and Cr(OH)3], respectively.

The surface of the ECCS substrate is dominated by hydroxide species, Fig. 5a, b. In air, the structural hydroxide within the chromium hydroxide remains stable until around 100 °C and then decreases as the temperature is increased. At 200 °C, the chromium hydroxide is reduced by around 12% with a complimentary increase in the surface oxide species. The water of hydration within the chromium structure is activated via thermal treatment, leading to the creation of a coordinated –OH network on the surface of the material for subsequent bonding within a chromium network. This olation process at the surface is followed by an oxolation process, with increased formation of Cr2O3 species [15]. The imposition of vacuum results in lower initial chromium hydroxide levels on the surface and earlier transition of the chromium hydroxide to chromium oxide, Fig. 5b. Thus, both temperature and partial pressure play a role in determining the thermodynamic stability of the chromium hydroxide species and the process of olation and oxolation to form the chrome oxide. There is significantly lower chromium hydroxide with the novel passivated TCCT material compared to the ECCS substrate, Fig. 5b. The rate of hydroxide to oxide conversion is relatively low at temperatures below 200 °C but becomes rapid beyond 200 °C. For the 311 tinplate, oxidation of the tin is clearly evident with a rapid increase in tin oxide growth as the temperature increases, Fig. 5c. The growth in oxide is a result of the thermal dehydration of the hydroxide which undergoes a corresponding reduction in relative abundance [13].

While the surface dictates the lacquer/substrate bonding, adhesion failure can be a result of changes in the subsurface, e.g. growth in brittle metal oxide layers. For this reason, further analysis of the near subsurface via depth profiling XPS through the substrate at room temperature and at 200 °C was carried out. For each substrate, the thermal regime has an impact on the subsurface chemistry, Fig. 6. By examining the change in chrome level (shown in green) between the unheated and heated samples then it is possible to identify the extent to which the high temperature exposure alters the near surface chemical composition. For ECCS there is a reduction in chrome level to 8 nm below the surface with a greater oxidation in the near surface layers, Fig. 6a, b. For the ECCS substrate, the results at room temperature show a similar structure to that measured in the literature [8] although this work provides a more detailed through layer composition map. The change in chrome layer between the unheated and heated samples for the TCCT substrate is proportionally larger than that observed with the ECCS substrate, Fig. 6c, d with the TCCT also exhibiting chrome oxidation. The primary difference between the ECCS and TCCT substrate in the sub surface layers is the presence of significant carbide proportions in the near surface area with the TCCT which are not present with the ECCS. With the TCCT, there is also some evidence of appreciable iron between 5 and 10 nm and at 200 °C which would tend to indicate some iron diffusion is occurring.

Exposure to 200 °C results in small changes in the subsurface chemical composition with the 311 tinplate, Fig. 6e, f. The dominant effect is again an increase in the chrome oxide levels near the surface region. A small amount of migration of iron from the black plate and its oxidation to iron oxide is also evident at a depth of 15 nm within the tinplate substrate.

The tinplate substrate exhibits solid state diffusion of iron into the tin which starts at 200 °C. This represents an interesting result as the nominal reflow temperature for tin is around 260 °C [12]. The passivation layer, however, tends to stay relatively stable. This is believed to be due to the very low level of metallic chromium actually deposited on the surface during the 311 passivation process. Hence, the passivation has no driver for oxidation of the metallic chromium to oxidic chromium. It does, however, show an increase in the thickness of the tin oxide layer and overall a larger proportion of hydrated chromium segregated at the surface of the material. The untreated tinplate measurements are in line with those in the literature [9, 17] although this dataset provides improved spatial and elemental resolution.

Thus, while the changes in surface chemistry are not hugely significant there is evidence that exposure to 200 °C does begin the process of removal of the hydroxide surface groups. These changes in surface and near surface chemistry will likely have an impact on the wet adhesion of any lacquer system [3], and is also likely to impact the corrosion mechanics for processes such as cathodic delamination and filiform corrosion [24] as it would likely affect the rate of water update on the surface of the materials.

The result of the chemical changes observed is that the thermal pretreatment also leads to an increase in the surface energy of each substrate, Fig. 7. In each instance, the dispersive element dominates surface energy and there is an increase in the overall surface energy of around 5 dynes/cm as a result of the thermal treatment. This increase in the surface energy can be related to the change in the surface oxide species and is also a reflection of the removal of the DOS oil which evaporates during the thermal treatment. Both mechanisms would be beneficial to the lacquer adhesion.

Adhesion

The net result of the changes in surface chemistry is to effect a change in the lacquer adhesion, Fig. 8. In all instances, the highest adhesion is observed with the epoxy phenolic coating, whether in transparent (vitalure) or white anhydride pigmented form. On the ECCS and TCCT substrates, the adhesion for the BPANI polyester materials is only around 50% of that observed with current generation epoxy phenolic materials. The poorest adhesive performance is observed with the tinplate substrate while the next generation substrate improves the dry adhesive performance by around a further 20% compared to the current ECCS substrate. This relatively lower adhesion strength on the tinplate substrate is attributed to an alternative failure mechanism which was observed for the tinplate with failure occurring within the brittle tin oxide layer below surface chrome/chrome oxide layers. The exact mechanism by which a small increase in adhesion is observed with heating may be associated with the presence of the DOS oil during film formation and some increased surface oxidation which improves adhesion. There is no clear trend observed between the adhesion and the presence of the pigment with adhesion behaviour. Both epoxy materials are similar in performance and thus the impact of pigment on the adhesion can be considered minimal.

The impact of the heat treatment is to increase the adhesion by around 13% for the ECCS, 10% for the 311 tinplate (although in absolute magnitude, this is less) and 10% for the TCCT substrate. From a dry adhesion perspective, the 200 °C pretreatment therefore has a positive impact on the adhesion properties. From the surface analysis and macro adhesion measurement, it is proposed that the primary mechanism in the improvement in adhesion is associated with increase in the number of oxidic bonding sites on the surface.

Discussion

Overall, the thermal treatment caused by 200 °C curing of the printed lacquer on the second side has a positive effect on lacquer adhesion for all substrates and lacquers. The change in adhesion can be related to change in the surface chemistry and not to any physical changes in the substrate surface. The reduction in chrome hydroxide and subsequent increase in surface oxide species increases number of bonding sites which are available to the organic lacquer. The chemical process of olation and oxolation occurs at temperatures of around 100 °C and the temperature is further reduced in the presence of a vacuum.

The practical impact of the work is that any thermal loading on the substrate up to 200 °C will have a positive impact the adhesion of lacquers, increasing the adhesion by between 5 and 15% depending on the substrate. Whether this improves product performance will depend on its impact on other key characteristics such as wet adhesion, corrosion and surface integrity during forming. The present study has examined the impact on the dry lacquer/substrate adhesion. This is important for defects caused by loss of adhesion during the forming process. However, loss of adhesion during product storage is dependent on lacquer—substrate adhesion under “wet” conditions. Thus, it would be beneficial to subsequently examine the impact of the thermal pretreatment on the adhesion when the lacquer and substrate has been exposed to the more demanding conditions during canning and the can-forming process.

The improvement in adhesion with the novel Chrome III replacement substrate is welcomed and is evidence of a significant technical advance in that improved performance (in terms of dry adhesion) can be obtained with a more friendly processing chemistry. Further work should examine whether this improvement transfers to improved adhesion under wet conditions and its corrosion performance.

The lower performance of the BPANI coating should be considered in context that the material is a development material compared to the commercially mature epoxy phenolic systems. Optimization of the formulation and curing conditions may close the gap between the BPANI and epoxy materials. However, a lower dry adhesion does not bode well for comparable performance in can performance given increased sensitivity of polyester-based materials to water vapour. As such there remains a significant challenge in formulating materials. The adhesion properties of BPANI materials under wet adhesion conditions need to be examined to correlate dry adhesion to wet adhesion characteristics.

The dataset created provides the first public dataset where the three steel packaging substrates (two current and one developmental) have been examined using identical characterization methods. It has quantified the relative adhesive performance of the substrates and has identified a mean by which adhesion can be increased by the addition of a process step, but without the need for additional capital expenditure.

Conclusions

An experimental study has been carried out on the effect of thermal pretreatment on the physical structure and surface chemistry characteristics of chrome-coated packaging steels. This has demonstrated that even the moderate temperatures have an impact on the surface chemical characteristics of the substrates. For all substrates, surface chrome species are oxidized and this leads to an improvement in the dry adhesion between the lacquer/substrate. The mechanism for the changes in substrate performance when thermally treated has been identified. The dry adhesion performance of the Chrome III shows a slight improvement on the current Chrome VI system. Further work should examine the changes in surface impact on wet adhesion, subsequent substrate corrosion and ultimately the product lifetime.

Abbreviations

- ECCS:

-

Electro-coated chromic steel

- BPA:

-

Bisphenol A

- BPANI:

-

Bisphenol A non-intent

- DOS:

-

Dioctyl sebacate

References

Barilli F et al (2003) Study on the adhesion of different types of lacquers used in food packaging. Prog Org Coat 46(2):91–96. https://doi.org/10.1016/S0300-9440(02)00215-1

Biermann MC, Sandenbergh RF, von Moltke TVS (2006) Characteristics and lacquer adhesion on dip and CDC chromium passivated tinplate. Corros Sci 48(10):2925–2936. https://doi.org/10.1016/j.corsci.2005.10.018

Boelen B, Den Hartog H, Van der Weijde H (2004) Product performance of polymer coated packaging steel, study of the mechanism of defect growth in cans. Prog Org Coat 50(1):40–46. https://doi.org/10.1016/j.porgcoat.2003.09.011

British Standards Institution BSI (2003) ‘BS EN ISO 4624; paints and varnishes—pull-off test for adhesion’, 3, pp 1–24. https://www.iso.org/standard/62351.html. Accessed Oct 2016

Bruton P, Parker JD, Bastable B (2001) Forming characteristics of coated products for packaging applications. Ironmak Steelmak 28(4):297–304. https://doi.org/10.1179/030192301678154

BS EN ISO 4618 : 2014 BSI Standards Publication (2014) Paints and varnishes—terms and definitions (ISO 4618 : 2014). https://www.iso.org/standard/56502.html. Accessed Oct 2016

ISO 1518-1 (2011) Paints and varnishes—determination of scratch resistance—Part 1: constant-loading method. https://www.iso.org/standard/59590.html. Accessed Oct 2016

Chen S (2015) The coating layer structure of commercial chrome plates. J Electron Spectrosc Relat Phenom 202:1–6. https://doi.org/10.1016/j.elspec.2015.01.006

Chen S, Xie L, Xue F (2013) X-ray photoelectron spectroscopy investigation of commercial passivated tinplate surface layer. Appl Surf Sci 276:454–457. https://doi.org/10.1016/j.apsusc.2013.03.115

BS EN 13523-6 (2002). https://www.iso.org/obp/ui/#iso:std:iso:1520:ed-3:v1:en. Accessed Oct 2016

Fragni R et al (2006) Adhesion improvement of the UV lacquers for food cans by applying a post-curing current treatment. Prog Org Coat 55(3):254–261. https://doi.org/10.1016/j.porgcoat.2005.11.009

Frankenthal RP, Loginow AW (1960) Kinetics of the formation of the Iron–Tin alloy FeSn2. J Electrochem Soc 107(11):920–923. https://doi.org/10.1149/1.2427542

Kitabayashi S, Koga N (2015) Thermal decomposition of Tin(II) oxyhydroxide and subsequent oxidation in air: kinetic deconvolution of overlapping heterogeneous processes. J Phys Chem C 119(28):16188–16199. https://doi.org/10.1021/acs.jpcc.5b04975

Lakind JS (2013) Can coatings for foods and beverages: issues and options. Int J Technol Policy Manag 13(1):80–95. https://doi.org/10.1504/ijtpm.2013.050999

Mandich NV (1995) Chemistry of chromium. Engineering 95(4):1055–1078. https://doi.org/10.1002/9780470048672.wecb213

Montanari A et al (1996) Quality of organic coatings for food cans: evaluation techniques and prospects of improvement. Prog Org Coat 29(1–4):159–165. https://doi.org/10.1016/S0300-9440(96)00625-X

Mora N et al (2002) Characterization of passivated tinplate for food can applications. J Coat Technol 74(935):53–58 + 8. https://doi.org/10.1007/bf02697957

Newland J, Arnold JC (2009) Influence of production parameters on surface energy of tinplate. Ironmak Steelmak 36(6):456–461. https://doi.org/10.1179/174328109X422557

Page B (2012) Rigid metal packaging. Packag Technol Fundam Mater Process. https://doi.org/10.1533/9780857095701

Robertson, G. L. (2012) Food packaging: principles and practice, 3rd edn. CRC Press. ISBN: 97814398624. https://www.crcpress.com/Food-Packaging-Principles-and-Practice-Third-Edition/Robertson/p/book/9781439862414

Rudawska A, Jacniacka E (2009) Analysis for determining surface free energy uncertainty by the Owen–Wendt method. Int J Adhes Adhes 29(4):451–457. https://doi.org/10.1016/j.ijadhadh.2008.09.008

European Union (1994) European Parliament and Council Directive 94/62/EC of 20 December 1994 on packaging and packaging waste, 1993(L), pp 10–23

Wake WC (1978) Theories of adhesion and uses of adhesives: a review. Polymer 19(3):291–308. https://doi.org/10.1016/0032-3861(78)90223-9

Wint N, de Vooys ACA, McMurray HN (2015) The corrosion of chromium based coatings for packaging steel. Electrochim Acta 203:326–336. https://doi.org/10.1016/j.electacta.2016.01.100

Zenkiewicz M (2007) Comparative study on the surface free energy of a solid calculated by different methods. Polym Test 26(1):14–19. https://doi.org/10.1016/j.polymertesting.2006.08.005

Zhang X et al (2007) Influence of uniaxial deformation on the corrosion performance of pre-coated packaging steel. Prog Org Coat 60(4):335–342. https://doi.org/10.1016/j.porgcoat.2007.08.005

Zumelzu E, Rull F, Boettcher AA (2006) Characterization and micro- and ultra-structural analysis of PET-based Co-rolled composite electrolytic chromium coated steel (ECCS). J Mater Process Technol 173(1):34–39. https://doi.org/10.1016/j.jmatprotec.2005.11.013

Acknowledgements

The authors would like to thank TATA steel packaging, Crown packaging and Akzo Nobel, EPSRC, European Social Fund and Swansea University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors have no conflict of interest in the publication of this article.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Melvin, C., Jewell, E., de Vooys, A. et al. Surface and Adhesion Characteristics of Current and Next Generation Steel Packaging Materials. J Package Technol Res 2, 93–103 (2018). https://doi.org/10.1007/s41783-018-0031-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41783-018-0031-8