Abstract

In this study, the effect of Co-Cr(0) and Co-Cr-B nanocatalysts on sodium borohydride hydrolysis was investigated. The extract obtained from the pods of the bean plant was produced using the environmentally friendly green synthesis method, along with the chemical reduction method as the production procedure for the catalysts. The analyses used to study the structure and surface morphology of catalysts are SEM, TEM, EDX, XRD, FTIR, and XPS. From the SEM and TEM pictures, the shape of the catalysts comprises of tiny spheres and has a porous nanostructure, and the particle size is 35–40 nm. The XRD investigation revealed that the catalysts had an amorphous structure. The catalysts’ structure has been confirmed to include the components Co, Cr, and B using EDX and XPS analyses. It was examined how different amounts of catalyst, different NaBH4/NaOH concentrations, and different solution temperatures affected the hydrolysis of sodium borohydride. The n-th order kinetic model was utilized to determine the activation energies of Co-Cr(0) and Co-Cr-B nanocatalysts, which were found to be 24.39 kJ/mol and 43.09 kJ/mol, respectively. Also, the turnover frequency (TOF) values of synthesized nanocatalysts Co-Cr(0) and Co-Cr-B at 60 °C were calculated as 19,210 mLmin− 1g− 1 and 12,410 mLmin− 1g− 1, respectively. The repeatability of catalysts in NaBH4 hydrolysis showed high activity even after the fifth use.

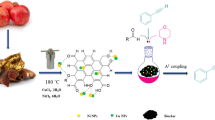

Graphical Abstract

The production scheme of Co-Cr(0) and Co-Cr-B nanocatalysts

Highlights

-

• Green synthesis provides an environmentally friendly, simple, economical and reproducible approach for faster metal nanoparticle production.

-

• Green synthesis method increased the activity of Co-based catalysts

-

• In kinetic studies, activation energies were calculated using the n-th order and Langmuir–Hinshelwood models.

-

• Co-Cr(0) and Co-Cr-B nanocatalysts, the activation energies were calculated to be 24.39 kJ/mol and 43.09 kJ/mol, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The energy crisis and environmental pollution are two big problems that need to be solved urgently around the world. The majority of energy sources rely on non-renewable fossil fuels like coal, oil, and natural gas, which have limited reserves and unstable and irregularly fluctuating prices. The worldwide demand for clean energy technologies is rising due to the various environmental hazards of fossil fuel-based energy, including pollution, climate change, and global warming [1]. Fuel cells, which convert chemical energy into electrical energy electrochemically, are among the cleanest energy technologies and are the strongest alternative to alleviate the problem of environmentally friendly power sources and eliminate the sustainability problem of other renewable energy sources [2, 3]. In addition, it has been observed that the utilization of hydrogen as a fuel in proton exchange membrane fuel cells (PEMFCs) results in zero emissions of environmental pollutants [4, 5]. The development of safe and convenient hydrogen storage and production systems is crucial for the realization of a truly efficient hydrogen-based technology. To exploit renewable energy sources in the transportation industry, an energy carrier like hydrogen is required. Since hydrogen is the most prevalent element in the universe and is easily produced using renewable energy sources, it represents an important alternative energy raw material [6, 7]. A very high energy conversion efficiency may be attained, especially when combined with hydrogen fuel cell technology [8]. When fuel cells, which create electricity with no emissions and high energy conversion, are powered by hydrogen, which is safe and simple to utilize in any industry, the only byproduct released into the environment is water or water vapour [9]. The storage of hydrogen in pressured tanks of gas or liquid, in metal alloys, and on activated or nanotube carbon has received a significant amount of effort [10]. Unfortunately, all these systems lack gravimetric and/or volumetric energy efficiency to meet the commercial application requirement [11]. PEMFCs are also gaining significant potential in onboard hydrogen production. Chemical hydrides (NaBH4, LiBH4, KBH4, etc.) are the most promising solutions for creating pure hydrogen for portable applications operating at room temperature [12,13,14]. One of them is sodium borohydride, which is regarded as a promising hydride. Sodium borohydride (NaBO2) and hydrogen gas are generated when sodium borohydride is hydrolyzed at room temperature [15, 16]. According to the following equation, spontaneous hydrolysis of NaBH4 occurs in ambient circumstances. The hydrogen release rate may be modified by altering the reaction conditions [17]:

At room temperature, sodium borohydride decomposes slowly in aqueous solutions and is unstable. Finding appropriate catalysts is therefore required to enhance its hydrolysis [18,19,20]. Researchers have thus developed non-precious metal-based catalysts with exceptional chemical stability as a substitute for noble metals in the hydrolysis-based production of hydrogen [16, 21,22,23,24]. Co-based catalysts are among numerous non-precious metal compounds that are thought to have promise because of their electrical structure and strong stability [25]. In recent years, many studies have been carried out to increase catalytic activity, and it has been stated that catalytic activity can be increased by expanding the contact area of nanoparticles and the number of active sites [26,27,28]. The activity of Co-B catalysts can be improved by increasing the number of active sites by doping with elements such as Ni [14, 29], Co [30], Ce, Mo, La [31,32,33] and P [34], and Cu [35]. Nowadays, NPs are produced using a variety of physical and chemical processes, including spray pyrolysis, thermal decomposition, co-precipitation, sol-gel, and hydrothermal methods [36,37,38]. However, these techniques also use dangerous chemicals and their costs are high. Thus, the creation of more ecologically friendly and sustainable synthesis techniques is required [39]. Agglomeration of nanoparticles during a process reduces their catalytic activity and makes them difficult to reuse [40, 41].

In recent years, there has been a growing interest in finding alternative methods for preparing NPs, with a particular focus on the use of green chemistry. One approach that has garnered significant research attention is the utilization of plant extracts [42]. Plant extracts contain a variety of bioactive compounds that can act as reducing agents, facilitating the reduction of metal ions to form NPs [43]. Furthermore, these compounds also can act as capping agents, which helps to prevent agglomeration of the targeted nanocatalysts during the synthesis process [44, 45]. Therefore, Co-Cr(0) and Co-Cr-B nanocatalysts were synthesized by using the extract of this plant, and sodium borohydride hydrolysis was applied for the first time in this study. In this study, Co-Cr(0) and Co-Cr-B nanocatalysts were prepared by green synthesis method from irradiance extract by chemical precipitation reduction method and used in NaBH4 hydrolysis. It was determined that Co-Cr(0) and Co-Cr-B nanocatalysts prepared with a new and environmentally friendly method have high activity in NaBH4 hydrolysis.

Material and method

Materials

Bean pods were obtained from the market in Siirt, Turkey. Sodium borohydride (NaBH4), sodium hydroxide (NaOH), cobalt chloride hexahydrate (CoCl2.6H2O), and chromium (III) nitrate nonahydrate (Cr(NO3)3.9H2O) were obtained from Merck.

Preparation of the bean shell extract

After the bean pods were washed with distilled water, it was dried, ground, and sieved. 25 g of the sieved bean pods and 250 mL of distilled water were left in a 500 mL flask and then boiled under reflux for 1 h. After the obtained extract was cooled to room temperature, it was separated from the environment by filtration. The obtained extract was kept in a closed container at 4 °C in the refrigerator to be used in the green synthesis of Co-Cr(0) and Co-Cr-B nanocatalysts.

Green synthesis of nanocatalysts

Green synthesis and the chemical reduction precipitation method were both used to produce nanocatalysts. Synthesis of Co-Cr-B nanocatalyst: After adding 0.05 mol of CoCl2.6H2O and 0.002 mol of Cr(NO3)3.9H2O into 50 mL of bean pods extract, it was dissolved and left in an ice bath and 0.26 mol of NaBH4 dissolved in 50 mL of pure water was added dropwise to the solution medium for catalyst reduction [23, 45]. The solution temperature was kept in the range of 0–5 ºC during the reduction of the catalyst. After the reduction was completed, the synthesized Co-Cr-B nanocatalyst was separated from the environment by filtration. The obtained Co-Cr-B nanocatalyst was dried in a nitrogen environment at 110 ºC for 3 h and stored in a closed container for characterization and sodium borohydride hydrolysis experiments. Synthesis of Co-Cr(0) nanocatalyst: After leaving 0.05 mol of CoCl2.6H2O and 0.002 mol of Cr(NO3)3.9H2O, 50 mL of bean pods extract was dissolved, and 0.26 mol of NaBH4 dissolved in 50 mL of pure was added dropwise to the solution medium for catalyst reduction. The reduction of the catalyst was carried out at room temperature. After the reduction was completed, the synthesized Co-Cr(0) nanocatalyst was separated from the environment by filtration. The obtained Co-Cr(0) nanocatalyst was dried at 110 ºC in a nitrogen environment for 3 h. Co-Cr(0) nanocatalyst were stored in sodium borohydride hydrolysis experiments and a closed container for characterization.

Sodium borohydride hydrolysis of Co-Cr(0) and Co-Cr-B nanocatalysts

The amount of hydrogen gas released in the hydrolysis experiments of sodium borohydride was measured by using catalytic hydrolysis measurements with Co-Cr(0) and Co-Cr-B nanocatalysts as catalysts, respectively. To conduct the experiments, 10 mL of distilled water was added to the reaction vessel along with 25 mg of catalysts and 2.5 wt% NaBH4 solution. The hydrogen gas released during the reaction was channeled via a tube and collected in an inverted burette using the principle of water displacement. The amount of hydrogen produced was calculated by measuring the change in water levels in the burettes. The present study investigates the effects of varying concentrations of NaOH and NaBH4 and different catalyst amounts and temperatures on the activities observed during sodium borohydride hydrolysis experiments.

Characterization of Co-Cr(0) and Co-Cr-B nanocatalysts

Characterization of synthesized green synthesis Co-Cr(0) and Co-Cr-B nanocatalysts was investigated with SEM, TEM, EDX, XRD, FTIR, and XPS.

Discussion

Characterization of nanocatalysts

SEM and TEM analyses were performed to study the morphology of the synthesized Co-Cr(0) and Co-Cr-B nanocatalysts. The SEM images of the nanocatalysts are presented in Fig. 1. According to the SEM images, nanocatalyst samples are composed of metallic particles of the order of one µm. The surface of the Co-Cr(0) nanocatalyst resembles a spongy, fibrous structure, and it can be seen from Fig. 1(a) that small Co-Cr(0) nanocatalyst forms on the surface. From Fig. 1(b), it can be seen that the Co-Cr-B nanocatalyst is made of small spherules and is nanostructured. It can be seen from Fig. 1 that Co(0) and Co-B nanocatalysts are porous. The catalyst dust is spherical on the Co-Cr(0) surface, while deep cracks are seen on the Co-Cr-B nanocatalyst under the same conditions. Moreover, flake structures were formed in the microstructure of the Co-Cr-B catalysts. The catalysts demonstrate a spherical form and a foamy sponge-like structure with various particle sizes, as shown in Fig. 1 [46]. Furthermore, aggregation and twinning phenomena were also observed in the distribution of Co-Cr(0) and Co-Cr-B particle promoters, which means that the catalysts can expose a more active surface for catalytic hydrolysis of NaBH4 [45, 47]. TEM measurements were performed to better understand their morphology and the corresponding micrographs are represented in Fig. 2.

TEM image (Fig. 2a, b) shows the morphology and particle size of the Co-Cr(0) and Co-Cr-B nanocatalysts. The morphology of Co-Cr(0) nanocatalyst is spherical and the particle size is roughly 35–40 nm. Under the same conditions, the surface morphology of the Co-Cr-B catalyst is also spherical and the particle size is 40 nm. Layers and agglomerates are seen on both catalyst surfaces. Moreover, the structure of the aggregated platelets of Co-Cr-B NPs and regular small spherical shapes are clearly defined. The TEM images appear to agree with the results obtained from the SEM analysis. At the same time, the black and white regions reveal the hydrophilic and hydrophobic natures of the nanoparticles, and the polycrystalline structure is consistent with the presence of white spots and rings in the dark nature [48]. Quantitative and qualitative analysis and homogeneity of green synthesis Co-Cr(0) and Co-Cr-B nanocatalysts were investigated by EDX analysis, and the results are given in Fig. 3.

It is clear from Fig. 3 that the green synthesis approach was effective in producing Co-Cr(0) and Co-Cr-B nanocatalysts. The C (carbon) element in the structure of the synthesized catalysts originates from the light extract. The presence of Co metal in the structures of both catalysts can be observed in Fig. 3 in the form of three distinct spectra. Metal B’s spectrum value is modest (0.17 KeV) in comparison to other metals, making it less noticeable. Figure 3 demonstrates the reduction and pure synthesis of both Co-Cr-B and Co-Cr(0) nanocatalysts. Wang et al. stated that B atoms are electron-deficient and Co atoms are electron-rich. Therefore, electron transfer between catalyst and reactant is easy, which is beneficial in the hydrolysis process of NaBH4, which will increase the rate of hydrolysis [8, 49]. The elemental compositions of the nanocatalysts are shown in Table 1.

To determine the phase purity and crystal structure of Co-Cr(0) and Co-Cr-B nanocatalysts, XRD analysis was performed, and the result is given in Fig. 4.

Figure 4 demonstrates that there is no discernible peak for either Co-Cr(0) or Co-Cr-B nanocatalysts. It is seen that Co-Cr(0) and Co-Cr-B nanocatalysts have an amorphous structure. The amorphous character of the catalyst is probably caused by the presence of boron metal in the surrounding environment [50]. Many unsaturated regions can improve the catalytic performance of amorphous catalysts [51]. Ozerova et al. have determined that the Co-B catalyst they synthesized to use in NaBH4 hydrolysis has an amorphous structure [52]. The results given in the hydrolysis section also support this. To determine the structure of the green synthesis Co-Cr(0) and Co-Cr-B nanocatalyst, FTIR analysis was performed in the range of 4000–400 cm− 1. Bean pods waste extract contains abundant polysaccharides [53].

A popular analytical method for analyzing polysaccharides, Fourier transform infrared (FTIR) spectroscopy offers important details on the functional groups of polysaccharides. The OH vibration peak at 3678 cm− 1 is caused by the presence of hydroxyl groups, and the faint absorption peak at 3208 cm− 1 is caused by the stretching vibration of CH groups, according to the FTIR spectra of Co-Cr-B and Co-Cr(0) catalysts shown in Fig. 5 [53, 54]. The presence of carboxylic groups in bean pods was detected through the observation of an absorption band at 2118 cm− 1, which is attributed to the asymmetric stretching of the C double bond O. This peak may also suggest the presence of ironic acids that are attached to the polysaccharides [55]. The peak at 1504 cm− 1 was observed due to the bending vibration of CH3 groups and the broad absorption peak at 866 cm− 1 of C─O─C asymmetric stretching, which is the characteristic peak of the polysaccharides due to the glycosidic linkage [54]. The surface element composition and electronic states of Co-Cr and Co-Cr-B nanocatalysts were analyzed using X-ray photoelectron spectroscopy (XPS), as seen in Fig. 6.

The C 1s spectrum seen in Co-Cr(0) and Co-Cr-B nanocatalysts, as shown in Fig. 6, has a binding energy of 284.80 eV. Furthermore, the existence of organic molecules, namely the C-C group, is confirmed by the detection of the sp2 peak [56]. The observed peak may be attributed to the presence of Bean pod extract. This observation also suggests that the extract was generated using nanoparticles. The B 1s spectrum seen in the Co-Cr-B nanocatalysts’ structure has a peak at around 191 eV, which may be attributed to the presence of B2O3 and/or certain borates [57]. The presence of the B element in the Co-Cr-B structure suggests that it is generated in an oxygen-rich environment during the extraction process. The appearance of peaks at 577 eV and 585 eV in the Co-Cr and Co-Cr-B nanocatalysts suggests the existence of Cr peaks in the Cr 2p spectrum. Survilienė et al. (2008) reported comparable findings in the X-ray photoelectron spectroscopy (XPS) data obtained from the manufactured Co-Cr alloy [58]. The existence of CoCrO may be inferred from the 781 eV peak seen in Co-Cr and Co-Cr-B nanocatalysts [59]. The presence of the O element in the CoCrO structure originates from the extract.

Sodium borohydride hydrolysis

Effect of NaOH concentration on sodium borohydride hydrolysis

The hydrolysis of sodium borohydride in an acidic medium is kicked off when an assault of hydronium ions on the borohydride anion takes place. A decrease in the rate of hydrolysis occurs in an alkaline solution due to the reduction of proton concentration. Since the majority of earlier studies on the catalytic hydrolysis of sodium borohydride were conducted in an alkaline medium, hydrolysis of sodium borohydride was also conducted using Co-Cr(0) and Co-Cr-B nanocatalysts produced from bean shell extract by using the green synthesis method as the catalyst. Catalytic hydrolysis of sodium borohydride was carried out in five different NaOH solutions (0, 1.0, 2.5, 5.0, and 7.5 wt% NaOH) to analyze the impact of NaOH concentration on the catalytic activity of Co-Cr(0) and Co-Cr-B nanocatalysts (Fig. 7).

Figure 7 shows the volume of hydrogen generated versus time during the hydrolysis of 2.5 wt% sodium borohydride in different NaOH solutions at 30 ºC and catalyzed by 25 mg of Co-Cr(0) and Co-Cr-B nanocatalysts. The inset of Fig. 7a makes it crystal clear that the rate of hydrogen creation initially rises to 2.5 wt% NaOH, which is unexpected, and then falls with the increasing concentration of NaOH, which is predicted. This observation necessitates the use of 2.5 wt% NaOH for further studies of the catalytic hydrolysis of sodium borohydride using the Co-Cr(0) nanoclusters catalyst. In the appendix, Fig. 7b shows that the hydrogen production rate first increases up to 5 wt% NaOH and then decreases with increasing NaOH concentration, as expected. Based on this result, it was decided that 2.5 wt% NaOH is better for future research that involves using Co-Cr-B nanocatalyst as a catalyst to hydrolyze sodium borohydride. The presence of NaOH, which stimulates the formation of active Co-Cr-B components up to a concentration of 5% by weight, might be to blame for this phenomenon. On the other hand, it prevents the hydrolysis reaction of sodium borohydride due to its increased stability. The amount of NaOH in the solution has a significant impact on the hydrolysis of sodium borohydride. According to the literature, NaBH4 solution becomes stable at increasing pH levels, making it essential to analyze the impact of catalysts at various NaOH concentrations. The hydrolysis rate increases with the increase in NaOH concentration for Co and Ni-based catalysts [60, 61]. It has been suggested put forth that an increase in pH results in heightened desorption of B(OH)4− from catalyst surfaces, leading to an improvement in the regeneration of active sites for chemical reactions.

NaBH4 concentration effect on sodium borohydride hydrolysis

The concentration of sodium borohydride plays an important role in the hydrolysis of sodium borohydride. In the current study, sodium borohydride was studied at different molar concentrations (1%, 2.5%, 5%, and 7.5 wt%) for the catalytic hydrolysis reaction of NaBH4. For the Co-Cr(0) and Co-Cr-B nanocatalysts, the NaOH concentrations and catalyst amounts were kept constant at 2.5 wt% and 25 mg, respectively.

Figure 8(a-b) illustrates how the behavior of Co-Cr(0) and Co-Cr-B nanocatalysts changes in varying amounts of sodium borohydride. Figure 8 shows that the volume of hydrogen that is produced increases in proportion to the concentration of NaBH4. The hydrogen volume generated from 2.5 wt% NaBH4 in the Co-Cr(0) nanocatalyst reached 680 mL in 10 min. In contrast, the Co-Cr-B nanocatalyst produced the same amount of hydrogen in 25 min. The Co-Cr(0) nanocatalyst were able to finish the sodium borohydride hydrolysis reaction faster than the Co-Cr-B nanocatalyst. In the process of hydrolyzing sodium borohydride, the rate of hydrogen generation rose from a previous value of 1472 mLmin− 1g− 1 to a value of 4439 mLmin− 1g− 1 when the quantity of NaBH4 increased from 1 wt% to 7.5 wt% with the use of the Co-Cr(0) nanocatalyst. It was determined that the use of the Co-Cr-B nanocatalyst resulted in an increase in the rate of hydrogen generation from 1199 mLmin− 1g− 1 to 2709 mLmin− 1g− 1 under the same circumstances. That is, the hydrogen production rate increases significantly as the NaBH4 concentration increases, indicating that the NaBH4 concentration affects the hydrolysis catalyzed by Co-Cr(0) and Co-Cr-B catalysts. It was observed that the Co-Cr(0) catalyst gave better results compared to the Co-Cr-B catalyst. As a possible reason for this, the reactant solution can’t come into contact with the catalyst since sodium borate (NaBO2), the by-product of the reaction, forms an impermeable surface layer at the interface of the reaction. The quantity of sodium borohydride that is utilized as a substrate has a direct relationship with the amount of borate that is produced [60, 62,63,64]. In the literature, it was stated that the viscosity and alkalinity of the solution increased with the increase in NaBH4 concentration. Therefore, the mass transfer of NaBH4 onto the catalyst surface is limited due to these two considerations [19, 65]. It is anticipated that, in practical implementation, complete and rapid liberation of all hydrogen molecules from sodium borohydride will occur. Thus, according to the principles of green chemistry and sustainable energy, it is imperative to utilize the optimal concentration of NaBH4 during the catalytic hydrolysis process for hydrogen production. The present study has ascertained that the optimal weight% of NaBH4 for hydrogen production via NaBH4 hydrolysis is 2.5 wt%.

The effect of catalyst amount on sodium borohydride hydrolysis

The self-hydrolysis of NaBH4 exhibits a sluggish reaction rate. Due to this factor, the experiment conducted in the absence of a catalyst does not yield 100% hydrogen [62]. Because the quantity of catalyst largely determines the rate of hydrolysis of sodium borohydride, the impact of various catalyst quantities was also investigated. Figure 9(a–b) show the findings from the analysis of the impact of Co-Cr(0) and Co-Cr-B nanocatalyst amounts (10, 25, 35, and 50 mg) on the rate of NaBH4 hydrolysis.

Figure 9(a-b) illustrates the connection between the rate of hydrogen generation and the quantity of catalyst for both catalysts under identical circumstances, demonstrating that the time to complete the reaction decreases rapidly as the amount of catalyst increases. In addition, the rate of the NaBH4 hydrolysis reaction shows good linear agreement with the amount of catalyst. While the hydrolysis of sodium borohydride was completed in 12 min using 25 mg of Co-Cr(0) catalyst (Fig. 9a), it was observed that the reaction was completed in 25 min with the use of Co-Cr-B catalyst under the same conditions. The Co-Cr(0) catalyst was shown to provide better results than the Co-Cr-B catalyst (Fig. 9b). As a result, it can be inferred that the hydrogen generation activity is connected to the catalyst loading, meaning it may be changed. So, 25 mg of Co-Cr(0) and Co-Cr-B catalysts were used in the next experiments to get better catalytic performance with the least amount of catalyst possible.

Effect of temperature on sodium borohydride hydrolysis

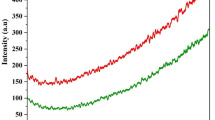

Hydrolysis of sodium borohydride was carried out under standard conditions (stabilized with 2.5 wt% NaBH4 and 2.5 wt% NaOH), using 25 mg of Co-Cr(0) and Co-Cr-B nanocatalysts at a temperature range of 30–60 °C. Figure 10 (a–b) shows the effect of reaction temperature on the hydrogen production rate. It was found that higher reaction temperatures made the rate of hydrogen production from the hydrolysis of sodium borohydride faster.

The hydrogen generation rate was enhanced by increasing the temperature from 30 to 60 °C using Co-Cr(0) and Co-Cr-B nanocatalysts. In the use of the Co-Cr(0) catalyst in the hydrolysis of sodium borohydride, the volume of 680 mL of hydrogen was measured at 30 °C reaction temperature in 10 min, and the hydrogen production rate was calculated as 2951 mLmin− 1g− 1 (Fig. 10a). For the Co-Cr-B nanocatalyst, 680 mL of hydrogen volume was measured at 30 °C reaction temperature in 25 min, and the hydrogen production rate was calculated as 1365 mLmin− 1g− 1 (Fig. 10b). The hydrogen production rate was determined to be 8565 mLmin− 1g− 1 when the reaction temperature reached 60 °C. The Co-Cr(0) nanocatalyst yielded 730 mL of hydrogen during a 2-minute timeframe at an elevated temperature. The hydrogen generation rate in the Co-Cr-B nanocatalyst was calculated to be 6920 mLmin− 1g− 1, and 710 mL of hydrogen was measured in 3 min. The Co-Cr(0) nanocatalyst is more active than the Co-Cr-B nanocatalyst, and the catalytic manufacturing process has a big impact on the catalyst’s activity, according to the data. Furthermore, it can be observed that the increase in the hydrogen production rate occurs from 30 °C to 60 °C. This suggests that the reaction temperature has a bigger impact on the hydrolysis of an alkaline sodium borohydride solution at low temperatures.

Kinetics study of catalyst

This shows that sodium borohydride hydrolysis into water is an nth-order process. The nth-order-orderangmuir-Hinshelwood models were used to determine how quickly sodium borohydride breaks into water. Detailed information about the nth-order and Langmuir-Hinshelwood kinetic models has been shown in our previous studies [22, 66]. The Arrhenius behavior of the nth-order kinetics can be represented as follows:

Figure 11a Co-Cr (0) and Fig. 11 b Co-Cr-B nanocatalysts display an Arrhenius plot of ln k against the reciprocal of absolute temperature (1/T). Using the n-th order kinetic model the activation energy of the hydrolysis process of Co-Cr (0) and Co-Cr-B nanocatalyst was calculated as 24.39 kJ/mol and 43.09 kJ/mol, respectively.

The activation energy of NaBH4 hydrolysis in the presence of Co-Cr(0) and Co-Cr-B nanocatalysts was calculated from the slope in Fig. 11, and the results of this determination are shown in Table 2, along with a comparison to the literature.

The data shown in Table 2 demonstrates that the activation energy for the hydrolysis of NaBH4, when using Co-Cr(0) and Co-Cr-B nanocatalysts, is much lower than the activation energies reported in previous studies. The nanocatalysts exhibits superior catalytic activity and reduced activation energy, making it a very promising catalyst for NaBH4 hydrolysis in hydrogen generation.

The activation energies for Co-Cr(0) and Co-Cr-B nanocatalysts were computed as 24.43 and 48.45 kJ/mol using Eq. 2 for the k values obtained using the Langmuir-Hinshelwood kinetic model, respectively. Activation energy results also show that the Co-Cr(0) nanocatalyst is more active than the Co-Cr-B nanocatalyst and has a larger surface area. In addition, enthalpy and entropy values for Co-Cr(0) and Co-Cr-B nanocatalysts were also calculated using Eyring’s equation (Eq. 3).

The slope and intercept of the Eyring plot of ln(rate/T) vs. 1/T were used to compute the values of ΔH = 18.26 kJ/mol and ΔS = -80.81 J/mol.K for the Co-Cr(0), and Co-Cr-B NPs catalyst for calculated the values of ΔH = 29.22 kJ/mol and ΔS = -118.3 J/mol.K.

The Langmuir-Hinshelwood mechanism [72, 73] was proposed for the catalytic hydrolysis of NaBH4. This mechanism takes into account the adsorption of both reactants (NaBH4 and H2O) on a catalyst (Fig. 12).

Reusability tests of catalysts

A catalyst’s reusability and stability have a significant influence on the uses of that catalyst. For this reason, the reusability of Co-Cr(0) and Co-Cr-B nanocatalysts made with the use of green synthesis techniques was examined. The results provided in Fig. 13 indicate that the quantity of hydrogen produced after five distinct cycles decreased by an extremely insignificant amount. In Fig. 13, it was seen that the percentage of reusability of the Co-Cr(0) nanocatalyst was higher than that of the Co-Cr-B nanocatalyst. It was tested at 90% in the Co-Cr(0) nanocatalyst and 86% in the Co-Cr-B nanocatalyst. The used catalyst was removed from the by-product solution using an external magnet during the catalytic hydrolysis process. The catalyst was then washed with deionized water before being used again. Between tests, there was a minor decline, nevertheless. This may be explained by the finding of metaborates on the surface of catalysts, which may impede and poison. It is good knowledge that the presence of metaborates makes the solution more viscous, which is bad for hydrogen production [12]. Still, the results show that the Co-Cr(0) and Co-Cr-B nanocatalysts have a highly stable structure and outstanding activity.

Conclusion

In this study, the effect of Co-Cr(0) and Co-Cr-B nanocatalysts on the sodium borohydride hydrolysis process was investigated. From the SEM and TEM pictures, the shape of the catalysts comprises of tiny spheres and has a porous nanostructure, and the particle size is 35–40 nm. The XRD investigation revealed that the catalysts had an amorphous structure. The catalysts’ structure has been confirmed to include the components Co, Cr, and B using EDX and XPS analyses.

The activation energies were calculated through the utilization of the n-th order and Langmuir-Hinshelwood kinetic models. In the nth-order kinetic model: For Co-Cr(0) and Co-Cr-B nanocatalysts, the activation energies were calculated to be 24.39 kJ/mol and 43.09 kJ/mol, respectively. In the Langmuir-Hishelwood kinetic model, it was calculated as 24.43 and 48.45 kJ/mol, respectively. The activation energies are close to each other, and the catalyst behaviour complies with both kinetics. The Langminuer kinetic model came up with an activation energy value that is close to the nth-order kinetic model value. This supports the nth-order kinetic model of sodium borohydride hydrolysis. The activity results also suggested that the Co-Cr(0) and Co-Cr-B nanocatalysts can be reused for five cycles with a slight loss of activity. In general, it was concluded that Co-Cr(0) and Co-Cr-B nanocatalysts synthesized from bean pods extract by the green synthesis method are more active in hydrogen production than other Co-based catalysts, and the prepared nanocatalysts are promising for the hydrolysis of NaBH4.

Data availability

Not applicable.

References

Asongu, S.A., Agboola, M.O., Alola, A.A., Bekun, F.V.: The criticality of growth, urbanization, electricity and fossil fuel consumption to environment sustainability in Africa. Sci. Total Environ. 712, 136376 (2020)

Jamil, M.F., Biçer, E., Kaplan, B.Y., Gürsel, S.A.: One-step fabrication of new generation graphene-based electrodes for polymer electrolyte membrane fuel cells by a novel electrophoretic deposition. Int. J. Hydrog. Energy. 46(7), 5653–5663 (2021)

Şahin, Ö., Akdag, A., Horoz, S., Ekinci, A.: Synthesized PdNi/C and PdNiZr/C catalysts for single cell PEM fuel cell cathode catalysts application. Fuel. 346, 128391 (2023)

Fernandes, R., Patel, N., Miotello, A.: Hydrogen generation by hydrolysis of alkaline NaBH4 solution with Cr-promoted Co–B amorphous catalyst. Appl. Catal. B. 92(1–2), 68–74 (2009)

Sahin, O., Akdag, A., Horoz, S., Ekinci, A.: Physical and Electrochemical Effect of bimetallic Pd-Mo Nanoalloys supported on Vulcan XC-72R Carbon as Cathode catalysts for Proton Exchange Membrane Fuel Cell. Electrocatalysis. 14(2), 202–212 (2023)

Fang, B., Chaudhari, N.K., Kim, M.-S., Kim, J.H., Yu, J.-S.: Homogeneous deposition of platinum nanoparticles on carbon black for proton exchange membrane fuel cell. J. Am. Chem. Soc. 131(42), 15330–15338 (2009)

Şahin, Ö., Baytar, O., Kutluay, S., Ekinci, A.: Potential of nickel oxide catalyst from banana peel extract via green synthesis method in both photocatalytic reduction of methylene blue and generation of hydrogen from sodium borohydride hydrolysis. J. Photochem. Photobiol., a. 448, 115301 (2024)

Wang, Y., Pang, Y., Xu, H., Martinez, A., Chen, K.S.: PEM fuel cell and electrolysis cell technologies and hydrogen infrastructure development–a review. Energy Environ. Sci. 15(6), 2288–2328 (2022)

Ekinci, A., Horoz, S., Baytar, O., Şahin, Ö.: Hydrogen generation by hydrolysis of NaBH4 with efficient Co-La-WB catalyst for PEM fuel cells. J. Optoelectronic Biomedical Mater. 12(2), 25–32 (Vol 2020)

Kaur, M., Pal, K.: Review on hydrogen storage materials and methods from an electrochemical viewpoint. J. Energy Storage. 23, 234–249 (2019)

Frith, J.T., Lacey, M.J., Ulissi, U.: A non-academic perspective on the future of lithium-based batteries. Nat. Commun. 14(1), 420 (2023)

Tong, C., Tong, C.: Hydrogen and Fuel Cells. Introduction to materials for advanced energy systems 2019:587–653

Lang, C., Jia, Y., Yao, X.: Recent advances in liquid-phase chemical hydrogen storage. Energy Storage Mater. 26, 290–312 (2020)

Ekinci, A., Şahin, Ö., Horoz, S.: Kinetics of catalytic hydrolysis of NaBH 4 solution: Ni-La-B catalyst. J. Aust. Ceram. Soc. 2021:1–9

Krishna, R., Fernandes, D.M., Dias, C., Ventura, J., Freire, C., Titus, E.: Facile synthesis of novel Co-B@ Ni/RGO nanocomposite: A cost effective catalyst for improved hydrogen generation with enhanced electrochemical activity. Int. J. Hydrog. Energy. 41(27), 11498–11509 (2016)

Li, H., Li, B., Zou, Y., Xiang, C., Zhang, H., Xu, F., et al.: Modulating valence band to enhance the catalytic activity of Co-Cr-B/NG for hydrolysis of sodium borohydride. J. Alloys Compd. 924, 166556 (2022)

Ouyang, L., Chen, W., Liu, J., Felderhoff, M., Wang, H., Zhu, M.: Enhancing the regeneration process of consumed NaBH4 for hydrogen storage. Adv. Energy Mater. 7(19), 1700299 (2017)

Li, Y., Hou, X., Wang, J., Feng, X., Cheng, L., Zhang, H., et al.: Co-mo nanoparticles loaded on three–dimensional graphene oxide as efficient catalysts for hydrogen generation from catalytic hydrolysis of sodium borohydride. Int. J. Hydrog. Energy. 44(55), 29075–29082 (2019)

Wei, Y., Wang, M., Fu, W., Wei, L., Zhao, X., Zhou, X., et al.: Highly active and durable catalyst for hydrogen generation by the NaBH4 hydrolysis reaction: CoWB/NF nanodendrite with an acicular array structure. J. Alloys Compd. 836, 155429 (2020)

Ekinci, A., Sahin, Ö., Horoz, S.: Investigation of the kinetic properties of co-la-ce-b catalyst for sodium borohydride solutions to generate hydrogen for polymer electrolyte membrane fuel cell. Desalination Water Treat.;237. (2021)

Li, T., Xiang, C., Zou, Y., Xu, F., Sun, L.: Synthesis of highly stable cobalt nanorods anchored on a Ti4N3Tx MXene composite for the hydrolysis of sodium borohydride. J. Alloys Compd. 885, 160991 (2021)

Baytar, O., Şahin, Ö., Ekinci, A.: Effect of environmentally friendly and efficient metal-free hydrochars as catalysts on sodium borohydride hydrolysis. Fuel. 346, 128308 (2023)

Baytar, O.: Investigation of high-activity activated carbon-supported co-cr-b catalyst in the generation of hydrogen from hydrolysis of sodium borohydride. Acta Chim. Slov. 65(2), 407–415 (2018)

İZGİ, M.S., BAYTAR, O., ŞAHİN, Ö.: HOROZ S. Studies on catalytic behavior of Co–Cr–B/Al2O3 in hydrogen generation by hydrolysis of NaBH4. (2019)

Song, Q., Li, J., Wang, S., Liu, J., Liu, X., Pang, L., et al.: Enhanced electrocatalytic performance through body enrichment of co-based bimetallic nanoparticles in situ embedded porous N‐doped carbon spheres. Small. 15(44), 1903395 (2019)

Ekinci, A., Cengiz, E., Kuncan, M., Şahin, Ö.: Hydrolysis of sodium borohydride solutions both in the presence of Ni–B catalyst and in the case of microwave application. Int. J. Hydrog. Energy. 45(60), 34749–34760 (2020)

Li, T., Xiang, C., Chu, H., Xu, F., Sun, L., Zou, Y., et al.: Catalytic effect of highly dispersed ultrafine Ru nanoparticles on a TiO2-Ti3C2 support: Hydrolysis of sodium borohydride for H2 generation. J. Alloys Compd. 906, 164380 (2022)

Şahin, Ö., Saka, C., Ekinci, A., Balbay, A.: Hydrogen production by hydrolysis of NaBH4 with Cr-Ni-WB Catalyst: Effects of cold plasma and chromium content. Int. J. Chem. Reactor Eng. 14(1), 351–359 (2016)

Fang, S., Chen, Y., Wang, S., Xu, J., Xia, Y., Yang, F., et al.: Modified CNTs interfacial anchoring and particle-controlled synthesis of amorphous cobalt-nickel-boron alloy bifunctional materials for NaBH4 hydrolysis and supercapacitor energy storage. J. Alloys Compd. 936, 167990 (2023)

Baytar, O., Izgi, M.S., Horoz, S., Sahin, O., Nar, S.: Al2O3 supported Co-cu-b (Co-Cu-B/Al2O3) catalyst for hydrogen generation by hydrolysis of aqueous sodium borohydride (NaBH4) solutions. Dig. J. Nanomater Biostruct. 14(3), 673–681 (2019)

HOROZ, S., EKİNCİ, A.: Co-la-b Katalizörünün Sentezlenmesi ve Yakıt Pilinde Kullanılması. Bitlis Eren Üniversitesi Fen Bilimleri Dergisi. 9(2), 892–900 (2020)

Ma, Y., Chen, M., Geng, H., Dong, H., Wu, P., Li, X., et al.: Synergistically tuning electronic structure of porous β-Mo2C spheres by Co doping and Mo‐vacancies defect engineering for optimizing hydrogen evolution reaction activity. Adv. Funct. Mater. 30(19), 2000561 (2020)

Ekıncı, A.: Hydrogen generation by Hydrolysis of NaBH 4 with efficient Co–La–Mo–B Catalyst for PEM Fuel cells. Kinet. Catal. 61, 589–594 (2020)

Hwang, B., Jo, A., Sin, S., Choi, D., Nam, S., Park, K.: NaBH 4 Hydrolysis reaction using Co-PB Catalyst supported on FeCrAlloy. Korean Chem. Eng. Res. 51(1), 35–41 (2013)

Deonikar, V.G., Rathod, P.V., Pornea, A.M., Puguan, J.M.C., Park, K., Kim, H.: Hydrogen generation from catalytic hydrolysis of sodium borohydride by a Cu and Mo promoted Co catalyst. J. Ind. Eng. Chem. 86, 167–177 (2020)

Cao, N., Su, J., Luo, W., Cheng, G.: Hydrolytic dehydrogenation of ammonia borane and methylamine borane catalyzed by graphene supported Ru@ Ni core–shell nanoparticles. Int. J. Hydrog. Energy. 39(1), 426–435 (2014)

Rabbi, M.A., Akter, M.B., Chaki, B.M., Latif, M.A., Al-Amin, M., Rasel, M.Z.U., et al.: Preparation of stable Fe 2 O 3/Ag nanocomposite particles with catalytic, antioxidant and antibacterial properties. New J. Chem. 48(12), 5278–5288 (2024)

Rubel, M., Hossain, M., Parvez, M., Rahaman, M., Islam, M., Kumada, N., et al.: Low-temperature synthesis of potassium triniobate (KNb 3 O 8) ceramic powder by a novel aqueous organic gel route. J. Aust. Ceram. Soc. 55, 759–764 (2019)

Gour, A., Jain, N.K.: Advances in green synthesis of nanoparticles. Artif. Cells Nanomed. Biotechnol. 47(1), 844–851 (2019)

Guo, K., Li, H., Yu, Z.: Size-dependent catalytic activity of monodispersed nickel nanoparticles for the hydrolytic dehydrogenation of ammonia borane. ACS Appl. Mater. Interfaces. 10(1), 517–525 (2018)

Hossain, K.M., Rubel, M.K., Hossain, M.K., Ishraque Toki, G., Marasamy, L., Haldhar, R., et al.: Hydrothermal synthesis, phase analysis, and Magneto-Electronic characterizations of lead-free ferroelectric BM2+ (zn, ca, mg) T–BFO system. ACS omega 2024.

Akhlaghi, N., Najafpour-Darzi, G., Younesi, H.: Facile and green synthesis of cobalt oxide nanoparticles using ethanolic extract of Trigonella foenumgraceum (fenugreek) leaves. Adv. Powder Technol. 31(8), 3562–3569 (2020)

Mittal, A.K., Chisti, Y., Banerjee, U.C.: Synthesis of metallic nanoparticles using plant extracts. Biotechnol. Adv. 31(2), 346–356 (2013)

Salam, M.A., AbuKhadra, M.R., Mohamed, A.S.: Effective oxidation of methyl parathion pesticide in water over recycled glass based-MCM-41 decorated by green Co3O4 nanoparticles. Environ. Pollut. 259, 113874 (2020)

Ekinci, A., Kutluay, S., Şahin, Ö., Baytar, O.: Green synthesis of copper oxide and manganese oxide nanoparticles from watermelon seed shell extract for enhanced photocatalytic reduction of methylene blue. Int. J. Phytoremediation. 25(6), 789–798 (2023)

Li, C., Wang, D., Wang, Y., Li, G., Hu, G., Wu, S., et al.: Enhanced catalytic activity of the nanostructured Co–W–B film catalysts for hydrogen evolution from the hydrolysis of ammonia borane. J. Colloid Interface Sci. 524, 25–31 (2018)

Ghidan, A.Y., Al-Antary, T.M., Awwad, A.M.: Green synthesis of copper oxide nanoparticles using Punica granatum peels extract: Effect on green peach aphid. Environ. Nanatechnol. Monit. Manage. 6, 95–98 (2016)

Badri, A., Slimi, S., Guergueb, M., Kahri, H., Mateos, X.: Green synthesis of copper oxide nanoparticles using Prickly Pear peel fruit extract: Characterization and catalytic activity. Inorg. Chem. Commun. 134, 109027 (2021)

Ekinci, A., Genli, N., Şahin, Ö., Baytar, O.: Facile green synthesis of a novel Co–W–B catalyst from Rheum ribes shell extract and its effect on sodium borohydride hydrolysis: Kinetic mechanism. Int. J. Hydrog. Energy. 51, 796–808 (2024)

Delmas, J., Laversenne, L., Rougeaux, I., Capron, P., Garron, A., Bennici, S., et al.: Improved hydrogen storage capacity through hydrolysis of solid NaBH4 catalyzed with cobalt boride. Int. J. Hydrog. Energy. 36(3), 2145–2153 (2011)

Zhang, H., Wei, Q., Wu, G., Qiu, S., Zou, Y., Xia, Y., et al.: Zn-MOF-74-derived graphene nanosheets supporting CoB alloys for promoting hydrolytic dehydrogenation of sodium borohydride. J. Alloys Compd. 930, 167486 (2023)

Ozerova, A., Simagina, V., Komova, O., Netskina, O., Odegova, G., Bulavchenko, O., et al.: Cobalt borate catalysts for hydrogen production via hydrolysis of sodium borohydride. J. Alloys Compd. 513, 266–272 (2012)

Ahmad, M.M.: Characterization and antioxidant activities of polysaccharides extracted from flageolet bean pods waste. Curr. Res. Green. Sustainable Chem. 4, 100154 (2021)

Liu, X.-X., Yan, Y.-Y., Liu, H.-M., Wang, X.-D., Qin, G.-Y.: Emulsifying and structural properties of polysaccharides extracted from Chinese yam by an enzyme-assisted method. LWT. 111, 242–251 (2019)

Zhang, H., Zou, P., Zhao, H., Qiu, J., Mac Regenstein, J., Yang, X.: Isolation, purification, structure and antioxidant activity of polysaccharide from pinecones of Pinus koraiensis. Carbohydr. Polym. 251, 117078 (2021)

Carton, O., Ben Salem, D., Bhatt, S., Pulpytel, J., Arefi-Khonsari, F.: Plasma polymerization of acrylic acid by atmospheric pressure nitrogen plasma jet for biomedical applications. Plasma Processes Polym. 9(10), 984–993 (2012)

Yan, J., Zeng, X., Ren, T., van der Heide, E.: Boundary lubrication of stainless steel and CoCrMo alloy based on phosphorous and boron compounds in oil-in-water emulsion. Appl. Surf. Sci. 315, 415–424 (2014)

Survilienė, S., Jasulaitienė, V., Češūnienė, A., Lisowska-Oleksiak, A.: The use of XPS for study of the surface layers of Cr–Co alloy electrodeposited from Cr (III) formate–urea baths. Solid State Ionics. 179(1–6), 222–227 (2008)

Oku, M., Hirokawa, K.: X-ray photoelectron spectroscopy of Co3O4, Fe3O4, Mn3O4, and related compounds. J. Electron Spectrosc. Relat. Phenom. 8(5), 475–481 (1976)

Manna, J., Roy, B., Vashistha, M., Sharma, P.: Effect of Co + 2/BH4– ratio in the synthesis of Co–B catalysts on sodium borohydride hydrolysis. Int. J. Hydrog. Energy. 39(1), 406–413 (2014)

Ingersoll, J., Mani, N., Thenmozhiyal, J., Muthaiah, A.: Catalytic hydrolysis of sodium borohydride by a novel nickel–cobalt–boride catalyst. J. Power Sources. 173(1), 450–457 (2007)

Kiren, B., Ayas, N.: Nickel modified dolomite in the hydrogen generation from sodium borohydride hydrolysis. Int. J. Hydrog. Energy. 47(45), 19702–19717 (2022)

Dönmez, F., Ayas, N.: Synthesis of Ni/TiO2 catalyst by sol-gel method for hydrogen production from sodium borohydride. Int. J. Hydrog. Energy. 46(57), 29314–29322 (2021)

Lim, D., Özkan, G., Özkan, G.: Ni–B and Zr–Ni–B in-situ catalytic performance for hydrogen generation from sodium borohydride, ammonia borane and their mixtures. Int. J. Hydrog. Energy. 47(5), 3396–3408 (2022)

Chen, B., Chen, S., Bandal, H.A., Appiah-Ntiamoah, R., Jadhav, A.R., Kim, H.: Cobalt nanoparticles supported on magnetic core-shell structured carbon as a highly efficient catalyst for hydrogen generation from NaBH4 hydrolysis. Int. J. Hydrog. Energy. 43(19), 9296–9306 (2018)

Ekinci, A.: Positive roles of microwave irradiation in hydrogen production from hydrolysis of sodium borohydride using iron oxide catalyst synthesized with watermelon seed peel extract by green method. Int. J. Hydrog. Energy (2023)

Wu, Z., Ge, S.: Facile synthesis of a Co–B nanoparticle catalyst for efficient hydrogen generation via borohydride hydrolysis. Catal Commun. 13(1), 40–43 (2011)

Liu, B.H., Li, Z.P., Suda, S.: Nickel-and cobalt-based catalysts for hydrogen generation by hydrolysis of borohydride. J. Alloys Compd. 415(1–2), 288–293 (2006)

Beheshti, A.K., Rezaei, M., Alavi, S.M., Akbari, E., Varbar, M.: Cobalt nanoparticle synthesis through the mechanochemical and chemical reduction method as a highly active and reusable catalyst for H2 production via sodium borohydride hydrolysis process. Int. J. Hydrog. Energy. 51, 661–670 (2024)

Ke, D., Tao, Y., Li, Y., Zhao, X., Zhang, L., Wang, J., et al.: Kinetics study on hydrolytic dehydrogenation of alkaline sodium borohydride catalyzed by Mo-modified Co–B nanoparticles. Int. J. Hydrog. Energy. 40(23), 7308–7317 (2015)

Wang, Y., Zou, K., Zhang, D., Cao, Z., Zhang, K., Xie, Y., et al.: Cobalt–copper–boron nanoparticles as catalysts for the efficient hydrolysis of alkaline sodium borohydride solution. Int. J. Hydrog. Energy. 45(16), 9845–9853 (2020)

Baye, A.F., Abebe, M.W., Appiah-Ntiamoah, R., Kim, H.: Engineered iron-carbon-cobalt (Fe3O4@ C-Co) core-shell composite with synergistic catalytic properties towards hydrogen generation via NaBH4 hydrolysis. J. Colloid Interface Sci. 543, 273–284 (2019)

Shih, Y.-J., Su, C.-C., Huang, Y.-H., Lu, M.-C.: SiO2-supported ferromagnetic catalysts for hydrogen generation from alkaline NaBH4 (sodium borohydride) solution. Energy. 54, 263–270 (2013)

Acknowledgements

I would like to thank the authors who contributed to the study.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Contributions

Ömer Şahin: Supervision, investigation, visualization, writing—review & editing. Orhan Baytar Conceptualization, investigation, visualization, writing—review & editing. Gurbet Canpolatİnvestigation, visualization, writing—review & editing. Arzu EkinciConceptualization, investigation, visualization, writing—review & editing.

Corresponding author

Ethics declarations

Consent for publication

Informed consent was obtained prior to performing the procedure, including permission for publication of all photographs and images included herein.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Baytar, O., Şahin, Ö., Canpolat, G. et al. Synthesis of Co-Cr(0) and Co-Cr-B catalysts from bean pods extract by the green synthesis method and their application in sodium borohydride hydrolysis. J Aust Ceram Soc (2024). https://doi.org/10.1007/s41779-024-01043-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41779-024-01043-5