Abstract

Qandilite Mg2TiO4 ceramic was prepared from MgO-TiO2 powder/borosilicate glass composite. Composite materials were prepared by nominal MgTiO3 alone and with 10, 30, and 50% borosilicate glass. The sintering process resulted in qandilite alone either in nominal Mg2TiO4 alone or with 10% glass. Incorporation of 30% and 50% glass gave crystalline magnesium titanate (MgTi2O5) in both sintered samples with either forsterite (Mg2SiO4) in 30% containing glass or rutile (TiO2) and enstatite (MgSiO3) in 50% containing glass. The microstructure of sintered samples presented clear tetragonal or octahedral which referred to qandilite in the case of nominal MgTiO3 alone or that containing 10% glass. Also, the later crystals appeared in the case of 70% glass-containing samples whereas in the case of 50% containing glass, in addition to the later clear crystals, rod-like crystals were embedded in glassy matrix. The dielectric constant of the studied composite samples was decreased with increasing the glass fraction until 30 wt%, and then increased to lead to the highest values of dielectric constant (⁓125 at room temperature and 1 kHz) at a glass fraction of 50 wt%. The activation energy (Ea) attained values in the range 0.145–0.438 eV. The results of Ea values and AC conductivity may indicate the dominance of electronic mechanism over the ionic transfer one in the studied sample. The prepared composite samples exhibited a semiconducting nature.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The rapid growth of the telecommunication, mobile communications, wireless applications, and intelligent transport systems [1] led to the emission of harmful rays, which may cause a series of problems for the human health and the environment. Various materials were previously investigated for absorbing these harmful rays.

One of these materials are spinels (AB2O4), which are actual appealing topics for materials research and engineering applications. These are very rigid, diversely colored minerals, having generally octahedral crystals, which were found to happen in igneous and carbonate rocks. A and B can be divalent, trivalent, or quadrivalent cations. The significant elements of spinels are Mg, Al, and O with Fe,Ti, Zn, Ca, and Mn as the greatest common impurities [2].

Preceding studies suggested that Mg2TiO4 is a distinctive n-type semiconductor having a cubic symmetry with nearly perfect inverse spinel. However, its electrical and optical properties can be facilely altered by compositional modifications or structural [3]. Many researchers tried to improve the microstructures and microwave dielectric properties of Mg2TiO4 ceramics, and to decrease the sintering temperature, by incorporating several additives or by changing the processing parameters. For example, Li et al. reported that 0.92 (Mg0.95Co0.05)2TiO4-0.08(Ca0.8Sr0.2)TiO3 ceramics with 0.5 wt.% B2O3 addition can be sintered at only 1200 °C [4].

On the other hand, borosilicate glasses establish a family of glasses with a huge number of applications, mostly owing to their low coefficient of thermal expansion, like that of silicon (3.4 × 10–6 °C) [5], high electrical resistance (1011–1013 Ω m) [6], low dielectric constant (4.8 at 1 MHz) [7], and high resistance to chemical attack. As a result of their low softening temperature (800 °C), some borosilicate glasses as powders have specific interest for their use in the production of sintered glasses with controlled porosity [8] and for their implementation in the manufacture of sintered glass–ceramic composites. If these composites present suitable properties (e.g., high electric resistivity, low dielectric constant, sufficient mechanical strength, good chemical and environmental stability, and coefficient of thermal expansion matching that of IC chips), they can be used as substrates for microelectronic packaging [9].

MgO/TiO2 nanocomposite rods were successfully synthesized by the microwave-assisted method using room temperature ionic liquids. The structural properties of the nanocomposite rods were investigated [10]. Thermoluminescence (TL) properties of some borate glasses co-doped with different concentrations of TiO2 and MgO were examined [11]. Strong, deep-red emission can be achieved by the incorporation of Mn4+ ions [12, 13], and the emission is used to improve the color-rendering index of phosphor-converted white-light-emitting diodes. Nitrogen-doped Mg2TiO4 spinel has been synthesized and investigated as a photocatalyst for antibacterial activity [3]. Impacts of mechanical activation on structural, microstructural, thermal, and optical properties of Mg2TiO4 nano-ceramics prepared by high-energy ball milling and mechanical alloying method were reported [14] and exhibited promising optical properties which are suitable for commercial optoelectronic applications. Also, the dielectric properties and AC electrical conductivity of Mg2TiO4 ceramics synthesized via high-energy ball milling process have been studied [15] and promising this material for commercial technological applications. The effects of phase composition on the dielectric properties of the ceramics which are based upon the compounds of MgO–TiO2–SiO2 system have been studied [16]. The synthesis and characterization of Mg2TiO4 doped with different transition elements (Mn, Fe, Co) were reported [17] and their electrical properties have been compared. Structural and electrical properties of Mg2TiO4 inverse spinel have been studied using X-ray diffraction (XRD), Raman spectroscopy, AC conductivity, and dielectric spectroscopy [18]. It was reported that the MgO–TiO2 system has three stable phases, namely, MgTiO3, Mg2TiO4, and MgTi2O5 [19, 20], which are used for microwave engineering/RF applications. These binary magnesium titanates (MgTiO3, Mg2TiO4, and MgTi2O5) differed extremely from other materials due to their good dielectric properties. The magnesium orthotitanate (Mg2TiO4) is a promising dielectric material with excellent microwave dielectric properties [20]. Due to unique electrical properties, Mg2TiO4-based ceramics have wide-range applications, such as dielectric resonators, filters, antennas, radar, and global positioning system [21]. The spinel-structured Mg2TiO4 coating on Li-rich cathode material significantly suppresses the continuous oxygen release, endowing batteries with remarkable cyclability and well-inhibited voltage decay [22].

The ultimate goal of the present study was to prepare pure Mg2TiO4 qandilite phase at lower temperatures by incorporating it in a borosilicate glass matrix to help in reducing the temperature of precipitation. The composite samples were characterized by XRD, and scanning electron microscopy (SEM) with energy dispersive X-ray microanalysis (EDX). Also, the dielectric constant and AC conductivity of the synthesized composites were measured.

Experimental and methods

Materials and preparation

The studied batches were designed to prepare composite materials from nominal MgTiO3 and borosilicate glass (SiO2: 73.5%, B2O3: 23.5%, Li2O: 1.5%, and Al2O3: 1.5%) [23]. The nominal MgTiO3 powder (MgO: 56.47%–TiO2: 43.54%) was admixed with borosilicate glass 100:00, 90:10, 70:30, and 50:50 respectively (Table 1). The samples were thoroughly mixed and then cast in discs of 1.0-cm diameter using PVA binder (7%) and applying uniaxial pressure of 20 KN. The sintering process was within the temperature range between 700 and 1300 °C.

Characterization of materials

The X-ray diffraction (XRD, X-ray diffractometer model BRUKER Axs, D8ADVANCE, Germany) was used for phase identification after the sintering process. The microstructure of the composite samples was investigated using SEM/EDX with energy dispersive X-ray spectrometer EDX (SEM/EDX SEM Model Quanta 250, Holland). The fresh fracture surface was etched by solution containing 1%HF-1%HNO3 for SEM/EDX analysis.

The AC conductivity (σac) and the dielectric constant (ε′) of the sintered samples were measured using LCR Hi Tester (HIOKI, 3532–50, Japan) over a frequency range from 0.042 kHz to 1 MHz and a temperature range from 298 to 573 K. Increasing the temperature was provided by increasing the input voltage of a Variac transformer connected to the wire-wound resistance heater. The temperature was determined using a copper/Constantine thermocouple in close proximity to the sample. The dielectric constant (ε′) and the AC conductivity (σac) were calculated using the following expressions [24]:

where, C is the capacitance of the sample (F), d is the thickness (m), A is the cross-sectional area of the sample (m2), εο is the free space permittivity (8.85 × 10–12 F/m), ω is the angular frequency, and tan δ is the loss tangent which is obtained directly from the instrument.

Results and discussion

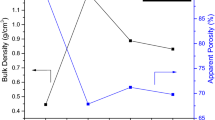

Characterization of the samples

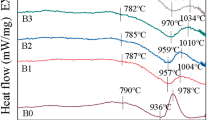

Incorporation of borosilicate glass lowers the sintering temperatures from 1300 °C in MT10 and MT9 samples to 1200 °C in the MT7 and MT5 composite samples. Qandilite Mg2TiO4 (ICCD, 25–1157, cubic) was developed alone in MT10 and in MT9 composite samples after sintering at 1300 °C. Increasing borosilicate glass to 30% (MT7) and 50%(MT5) led to decrease in the sintering temperature to 1200 °C. Karroite MgTi2O5 (ICDD, 35–0796, orthorhombic) was developed as the major phase in the later samples but with olivine Mg2SiO4, (ICDD, 87–0061, orthorhombic) besides the traces of qandilite phase in MT7 and with enstatite (MgSiO3, ICDD 22–0714, orthorhombic) and rutile (TiO2, ICDD 82–0514, tetragonal) in MT5 sample as shown in Fig. 1.

It must be noticed that other than crystalline magnesium titanate major phase, incorporation of borosilicate glass enhances the crystallization of Mg karroite (MgTi2O5) and enstatite (MgSiO3) as well as rutile (TiO2) in the case of the highest borosilicate ratio. Also, a combination of glass means increase at the silica ratio and facilitates the crystallization of enstatite when compared to the olivine formation seen at a low silica ratio. In case of the highest borosilicate ratio containing MT5 sample, rutile TiO2 of tetragonal structure was crystallized which is considered in higher order after cubic structure other than the other formed orthorhombic phases that developed in the present composite.

The SEM micrographs of the composite sample had developed after sintering at 1200 and 1300 °C are given in Figs. 2 and 3. In both MT10 and MT9 composite samples, orthorhombic crystals (1 to 5 µm in width) of qandilite were developed in glassy matrix. In the MT7 and MT5 composite samples, orthorhombic or rod-like crystals of magnesium titanate were appearing in glassy groundmass, respectively (Fig. 3).

The EDX microanalysis in the MT10 and MT7 samples was referred to the main crystalline phases Mg2TiO4 and MgTi2O5 in MT10 and MT7, respectively (Fig. 4).

Electrical measurements

Figure 5 depicts the variation of dielectric constant with temperature at various frequencies (1 kHz, 100 kHz, 800 kHz, and 1 MHz) for all composite samples studied. For samples MT10 and MT9, it can be seen that the dielectric constant increases with increasing temperature (Fig. 5a and b). This is normal behavior that can be attributed to the increased vibration of the molecules/atoms as a result of weakening in the binding force between them with increasing the temperature. Accordingly, an increase in the polarization occurs, hence increasing the dielectric constant (ε′) [25], in addition to the increase of the number of charge carriers (mainly electrons) with temperature, which causes the observed increase in dielectric constant (ε′) [26]. However, it is noticeable that the increase is not significant and very small, especially at higher frequencies. While for composite samples MT7 and MT5, the dielectric constant decreases with increase in temperature which is an unexpected behavior. The decreasing trend of dielectric constant can be correlated with the presence of Mg2SiO4 and MgSiO3 phases in MT7 and MT5 samples, respectively.

These phases may result in microstructure defects due to the possibility of the formation of the liquid phase in MT7 and MT5 samples. This behavior may obstruct polarization, affecting the dielectric constant of these samples. The present conclusion is in accordance with the studies previously reported [27], where the formation of liquid phase causes the hindrance of polarization which finally affects the dielectric constant. However, this behavior of decreasing dielectric constant with temperature is quite in agreement with that reported in other materials [28,29,30].

The ε′ decreases with increasing frequency, as shown in Fig. 5. Such a decrease can be attributed to the material’s dielectric polarization mechanism. Dielectric polarization can take place through electronic, ionic, interfacial, or dipolar polarization. The high-frequency range is dominated by electronic and ionic polarizations, while the low-frequency range is dominated by the other two mechanisms. When the frequency is increased, the dipoles can no longer rotate quickly enough, causing their oscillations to lag behind those of the field [25, 26]. As a result, ε′ decreases.

Figure 6 depicts the relationship between the dielectric constant (ε′) and the glass fraction at 25 and 300 (°C) and at different frequencies. It can be noticed that ε′ reduces with the addition of the glass fraction until 30 wt% (sample MT7). This decrease may be attributed to presence of a higher amount of glassy phase in the composite samples [31, 32]. The lower ɛ′ of sample MT9 compared with that of sample MT10 (Table 2 and Fig. 6) may indicate the presence of minor amounts of glassy phase present in sample MT9 with 10 wt% of glass which is undetectable by X-ray. In addition, this decrease of ɛ′ in the sample MT7 with 30 wt% of glass can reveal the presence of the crystallized secondary phase of forsterite (Mg2SiO4), which is confirmed by XRD (Fig. 1). This phase possesses a lower ε′ value [33] than that of the Mg2TiO4 phase [34,35,36] present in samples MT10 and MT9; consequently, the ɛ′ values decrease. Furthermore, it has been reported that the dielectric properties of ceramic materials depend on the average grain size as well as the processing conditions (sintering temperature) where the dielectric constant increases with the sintering temperature [37]. The results obtained (Fig. 5) show that the dielectric constant values of sample MT9 are higher than those of sample MT7 due to its higher sintering temperature (1300 °C). For example, at room temperature and 1 kHz, the ε′ decreases from about 28 for sample MT10 to 14 and 12 for samples MT9 and MT7, respectively, although it is observed (Fig. 6) that sample MT5, with the highest glass fraction (50 wt%), has the highest dielectric constant values. This is due to the presence of TiO2 (rutile phase) (Fig. 1) which is distinguished by high ε′ [38, 39]. For example, the ε′ for sample MT5 reaches ⁓125 at room temperature at 1 kHz.

The AC conductivity as a function of reciprocal temperature 1000/T for the investigated samples at 1 kHz is illustrated in Fig. 7. Because of the thermal activation process which is related to the hopping of charge carriers that are bound in localized states [23, 40], the electrical conductivities of the samples increase with the increase in temperature, implying a typical semiconducting behavior [41]. According to Fig. 7, conductivity increases among the various samples studied in the following order: MT7 < MT9 < MT10 < MT5. The conductivity values decrease by increasing the glass weight fraction sampling case of sample MT7 which contains 30 wt% of glass then it increases in sample MT5 with 50 wt% of glass. For example, at RT (room temperature) and at 1 kHz, the electrical conductivity of sample MT10 (without glass fraction) decreases from 3.98 × 10–7 to 5.38 × 10–8 S m−1 for sample MT7. This decrease of conductivity may be attributed to the presence of the crystallized phase of olivine (Mg2SiO4) (Fig. 1) which is characterized by the extremely low electrical conductivity [42,43,44] in sample MT7. Nevertheless, the relative increase of conductivity in sample MT5 can be attributed to the role played in the conduction mechanism by Li+ ions (ionic radius 90 pm), which was accompanied by an increase in glass fraction as well as the possibility of Ti4+ and Ti3+ ion formation. As a result, electron hopping between these ions may contribute to an increase in conductivity.

The activation energies associated with AC conduction can be estimated using the slopes of the linear fit in the studied temperature range of 25–300 (°C). The activation energies obtained for various samples are listed in Table 2. The activation energy (Ea) is found to be between 0.15 and 0.44. (eV). These findings may point to the dominance of the electronic mechanism over the ionic transfer one.

For sample MT10, the value of activation energy suggests that the conduction process occurs through electronic mechanism by the localized electron hopping between the Ti3+ and Ti4+ ions. The participation of the ionic conduction mechanism via Li+ ions, which requires relatively higher activation energy than the electronic one, can be attributed to the increased activation energy in the entire temperature range for samples MT9 and MT7 (Table 2) to values of 0.37 and 0.44 (eV), respectively. The increase in the glass weight fraction causes the increase in Li+ ions. The activation energy of sample MT5, which contains 50 wt% of glass, was reduced to 0.15 eV. This finding is consistent with the sample’s conductivity increasing to 9.32 × 10–7 S m−1. Such a decrease of activation energy can be related to the possibility of the formation of Ti4+ and Ti3+ ions which may cause the electronic mechanism to take precedence over the ionic transfer mechanism, and also may come from interstitial Ti3+ and oxygen vacancies causing the n-type conductive nature of TiO2 [45, 46].

Conclusions

The dielectric constant of the investigated composite samples decreases with increasing glass fraction up to 30 wt% then increases to show the highest values of dielectric constant (⁓125 at room temperature and 1 kHz) at a glass fraction of 50 wt%. The electrical conductivities of the samples increase with the increase in temperature, implying a typical semiconducting behavior. The conductivity of the composite samples seems to proceed dominantly by electronic conduction over the ionic transfer one by the localized electron hopping process between the Ti3+ and Ti4+ ions. Therefore, they may present good candidates to be applied as semiconductor materials in electronic devices. Especially, the sample is free from any addition of glass fraction which exhibits no significant increase of ɛ′ and σac with temperature that allows it to be used in electronic devices in a wide range of temperatures.

References

Cheng, L., Liu, P., Qu, S.-X., Cheng, L., Zhang, H.: Microwave dielectric properties of Mg2TiO4 ceramics synthesized via high energy ball milling method. J. Alloy. Compd. 623, 238–242 (2015)

Singh, A.K., Kumar, R., Senguttuvan, T., Siddiqui, A.M.: Synthesis and structural analysis of Al-doped qandilite (Mg2TiO4), in: AIP Conference Proceedings, American Institute of Physics, pp. 235–236. (2011)

Chang, S., Hu, Y., Qian, J., Shao, Y., Ni, S., Kong, L., Dan, W., Luo, C., Jin, S., Xu, X.: Mg2TiO4 spinel modified by nitrogen doping as a Visible-Light-Active photocatalyst for antibacterial activity. Chem. Eng. J. 410, 128410 (2021)

Bhuyan, R., Kumar, T.S., Pamu, D.: Liquid phase effect of Bi2O3 additive on densification, microstructure and microwave dielectric properties of Mg2TiO4 ceramics. Ferroelectrics 516, 173–184 (2017)

Park, J.H., Lee, S.J.: Mechanism of preventing crystallization in low-Firing glass/ceramic composite substrates. J. Am. Ceram. Soc. 78, 1128–1130 (1995)

Boccaccini, A., Thomas, B., Brusatin, G., Colombo, P.: Mechanical and electrical properties of hot-pressed borosilicate glass matrix composites containing multi-wall carbon nanotubes. J. Mater. Sci. 42, 2030–2036 (2007)

El-Kheshen, A., Zawrah, M.: Sinterability, microstructure and properties of glass/ceramic composites. Ceram. Int. 29, 251–257 (2003)

Nakashima, K., Noda, K., Mori, K.: Time–temperature–transformation diagrams for borosilicate glasses and preparation of chemically durable porous glasses. J. Am. Ceram. Soc. 80, 1101–1110 (1997)

Lima, M., Monteiro, R., Graça, M., Da Silva, M.F.: Structural, electrical and thermal properties of borosilicate glass–alumina composites. J. Alloy. Compd. 538, 66–72 (2012)

Ashok, C., Venkateswara, R., Shilpa-Chakra, C.: Synthesis and characterization of MgO/TiO2 nanocomposites. Nanomed. Nanotechnol 6, 2–5 (2015)

Alajerami, Y., Hashim, S., Ghoshal, S., Saleh, M., Kadni, T., Saripan, M., Alzimami, K., Ibrahim, Z., Bradley, D.: The effect of TiO2 and MgO on the thermoluminescence properties of a lithium potassium borate glass system. J. Phys. Chem. Solids 74, 1816–1822 (2013)

Ye, T., Li, S., Wu, X., Xu, M., Wei, X., Wang, K., Bao, H., Wang, J., Chen, J.: Sol–gel preparation of efficient red phosphor Mg2TiO4: Mn4+ and XAFS investigation on the substitution of Mn4+ for Ti4+. Journal of Materials Chemistry C 1, 4327–4333 (2013)

Medić, M.M., Brik, M.G., Drazic, G., Antic, Z.M., Lojpur, V.M., Dramićanin, M.D.: Deep-red emitting Mn4+ doped Mg2TiO4 nanoparticles. The Journal of Physical Chemistry C 119, 724–730 (2015)

Bhuyan, R.K., Mohapatra, R.K., Nath, G., Sahoo, B.K., Das, D., Pamu, D.: Influence of high-energy ball milling on structural, microstructural, and optical properties of Mg2TiO4 nanoparticles. J. Mater. Sci.: Mater. Electron. 31, 628–636 (2020)

Bhuyan, R., Pamu, D., Sahoo, B.: Dielectric studies of single phase Mg2TiO4 inverse spinel ceramics via high energy ball milling. Int. J. Sci. Eng. Res. 9, 185–190 (2018)

Ovchar, O., Vyunov, O., Durilin, D., Stupin, Y.D., Belous, A.: Synthesis and microwave dielectric properties of MgO–TiO2–SiO2 ceramics. Inorg. Mater. 40, 1116–1121 (2004)

Flot, D., Irvine, J.: Synthesis, electrical properties and thermal analysis of transition metal-doped Mg2TiO4 spinels. Solid State Ionics 135, 513–518 (2000)

Kumar, S., Kumar, R., Koo, B., Choi, H., Kim, D.U., Lee, C.G.: Structural and electrical properties of Mg2TiO4. J. Ceram. Soc. Jpn. 117, 689–692 (2009)

Belous, A., Ovchar, O., Durilin, D., Krzmanc, M.M., Valant, M., Suvorov, D.: High-Q Microwave Dielectric Materials Based on the Spinel Mg2TiO4. J. Am. Ceram. Soc. 89, 3441–3445 (2006)

Bhuyan, R.K., Kisan, B., Parida, S.K., Patra, S., Kumar, S.: Synthesis of Nano-Composites Mg2TiO4 Powders via Mechanical Alloying Method and Characterization, in: Magnesium Alloys Structure and Properties, IntechOpen, London U.K., pp. 206. (2022)

Bhuyan, R.K., Pamu, D., Sahoo, B.K., Sarangi, A.K.: Structural and thermal study of Mg2TiO4 nanoparticles synthesized by mechanical alloying method. Micro Nanosystems 12, 87–91 (2020)

Zhang, W., Sun, Y., Deng, H., Ma, J., Zeng, Y., Zhu, Z., Lv, Z., Xia, H., Ge, X., Cao, S.: Dielectric polarization in inverse spinel-structured Mg2TiO4 coating to suppress oxygen evolution of Li-rich cathode materials. Adv. Mater. 32, 2000496 (2020)

Margha, F.H., Morsi, R.M., Hamzawy, E.: Characterization and electrical properties of tausonite (SrTiO3) in nano ceramic composites. J. Mater. Sci.: Mater. Electron. 30, 16257–16265 (2019)

Samyuktha, V., Subbarao, T., Suvarna, R., Kumar, A.: Synthesis, characterization, dielectric and thermoelectric properties of calcium doped magnesium titanate Mg(1–x) CaxTiO3 (x= 0.1, 0.3 & 0.5) ceramics. J. Ovonic Res. 13, 33–43 (2017)

Morsi, R.M.M., El-Ghany, A., Ibrahim, S., Morsi, M.M.: Electrical properties of silicate glasses of low level gadolinium oxide doping including dielectric and infrared measures. J. Mater. Sci.: Mater. Electron. 26, 1419–1426 (2015)

Aravind, G., Ravinder D., Nathanial, V.: Structural and electrical properties of Li–Ni nanoferrites synthesised by citrate gel autocombustion method, Phys. Res. Int., 2014, 672739 (2014)

Chang, C.R., Jean, J.H.: Crystallization kinetics and mechanism of low-dielectric, low-temperature, cofirable CaO-B2O3-SiO2 glass-ceramics. J. Am. Ceram. Soc. 82, 1725–1732 (1999)

Field, R., von Hippel A.: Dielectric materials and applications, ed. AR von Hippel, Wiley, New York, p. 734. (1954)

Amnerkar, R., Adgaonkar, C., Yawale, S., Yawale, S.: Microwave properties of vanadium borate glasses. Bull. Mater. Sci. 25, 431–434 (2002)

Lo, C.L., Duh, J.G., Chiou, B.S., Lee, W.H.: Low-temperature sintering and microwave dielectric properties of anorthite-based glass-ceramics. J. Am. Ceram. Soc. 85, 2230–2235 (2002)

Thakur, O., Kumar, D., Parkash, O., Pandey, L.: Dielectric and microstructural behaviour of strontium titanate borosilicate glass ceramic system. Bull. Mater. Sci. 18, 577–585 (1995)

Yadav, A.K., Gautam, C., Singh, P.: Dielectric behavior of lanthanum added barium strontium titanate borosilicate glass ceramics. J. Mater. Sci.: Mater. Electron. 26, 5001–5008 (2015)

Fathi, M., Kharaziha, M.: Mechanically activated crystallization of phase pure nanocrystalline forsterite powders. Mater. Lett. 62, 4306–4309 (2008)

Shanker, V., Kumar, S., Surendar, T.: Dielectric behaviour of sodium and potassium doped magnesium titanate. Bull. Mater. Sci. 35, 1165–1171 (2012)

Haefke, H., Lang, H., Sum, R., Güntherodt, H.J., Berthold, L., Hesse, D.: Mg2TiO4 as a novel substrate for high-temperature superconducting thin films. Appl. Phys. Lett. 61, 2359–2361 (1992)

Ctibor, P., Sedlacek, J.: Selected aspects of dielectric behavior of plasma sprayed titanates. J. Adv. Ceram. 1, 50–59 (2012)

Faruk, M.: Effect of the sintering temperatures on the dielectric properties of polycrystalline Ca0. 6Zn0. 4Cu3Ti4O12. Int. J. Adv. Res. Phys. Sci. (IJARPS) 4, 11–14 (2017)

Jain, P., Kumar, D., Kumar, A., Kaur, D.: Structural, optical and dielectric properties of ZnTiO3 ceramics, Optoelectronics and Advanced Materials-Rapid. Communications 4, 299–304 (2010)

Morsi, R.M., Margha, F.H., Hamzawy, E.: Preparation and electrical characterization of Zn-titanate/borosilicate glass composites. SILICON 11, 1845–1852 (2019)

Naidu, K.B., Sarmash, T.S., Maddaiah, M., Kumar, A.G., Rani, D.J., Samyuktha, V.S., Obulapathi, L., Subbarao, T.: Structural and electrical properties of PbO-doped SrTiO3 ceramics. J. Ovonic Res. 11, 79–84 (2015)

Yao, C., Meng, J., Liu, X., Zhang, X., Meng, F., Wu, X., Meng, J.: Effects of Bi doping on the microstructure, electrical and electrochemical properties of La2-xBixCu0.5Mn1.5O6 (x= 0, 0.1 and 0.2) perovskites as novel cathodes for solid oxide fuel cells. Electrochimica Acta 229, 429–437 (2017)

Hossain, S.S., Mathur, L., Singh, P., Majhi, M.R.: Preparation of forsterite refractory using highly abundant amorphous rice husk silica for thermal insulation. J. Asian Ceram. Soc. 5, 82–87 (2017)

Tamin, S., Dzulkurnain, N.A., Adnan, S.B.R.S., Jaafar, M.H., Mohamed, N.S.: Mg2− xMnxSiO4 compound obtained via sol–gel method: structural, morphological and electrochemical properties. J. Sol-Gel. Sci. Technol. 86, 24–33 (2018)

Sembiring, S., Riyanto, A., Simanjuntak, W., Situmeang, R.: Effect of MgO-SiO2 ratio on the forsterite (Mg2SiO4)) precursors characteristics derived from amorphous rice husk silica. Orient. J. Chem. 33, 1828–1836 (2017)

Kalyanasundaram, K.: Photochemical and photoelectrochemical approaches to energy conversion. Dye-sensitized Solar Cells 1, 1–38 (2010)

Ramos, R.A., Jr., Boratto, M.H., Scalvi, L.V.: On the photo-induced electrical conduction related to gas sensing of the Sb: SnO2/TiO2 heterostructure. Sens. Actuators, A 281, 250–257 (2018)

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hamzawy, E.M.A., Margha, F.H. & Morsi, R.M.M. Crystallization and electrical measurements of sintered qandilite (Mg2TiO4)-borosilicate glass composite. J Aust Ceram Soc 59, 281–290 (2023). https://doi.org/10.1007/s41779-023-00850-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-023-00850-6