Abstract

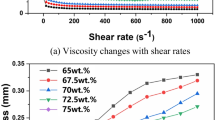

In the research of digital light processing (DLP)-based ceramic three-dimensional printing technology, one of the key steps is to prepare proper slurry. Zirconia slurries were made of near-spherical zirconia powder and self-designed ultraviolet (UV) light curing resin system by the introduction of different dispersants in this paper. The effect of the dispersant types and concentrations on the rheological properties and stabilities of the slurries were investigated by means of rotary rheometer, scanning electron microscope (SEM), and Fourier transform infrared spectroscopy (FT-IR). The results show that the dispersants Oleic acid (OA), sodium polyacrylate (PAA-Na), ammonium polyacrylate (PAA-NH4) and ammonium citrate (AC) can be successfully coated on the surface of zirconia particles and are beneficial to disperse these particles and prevent them from aggregating. But OA has the best effect to improve the rheological property and stability, and the effect varies with its concentration, and the best of it is 0.5 wt%. And, the slurry can be cured by UV light with the wavelength of 405 nm through the mechanism of the cracking and polymerization of unsaturated C = C in the resin by initiating the mechanism of photoinitiator.

Similar content being viewed by others

References

Preis, V., Behr, M., Hahnel, S., Handel, G., Rosentritt, M.: In vitro failure and fracture resistance of veneered and full-contour zirconia restorations. J. Dent. 40(11), 921–9288 (2012)

Leo, S., Tallon, C., Stone, N., Franks, G.V.: Near-net-shaping methods for ceramic elements of (body) armor systems. J. Amer. Ceram. Soc. 97(10), 3013–3033 (2015)

Donatella, D., Federico, M., Maria, F.: Biomaterials for dental implants: current and future trends. J. Mater. Sci. 50(14), 4779–4812 (2015)

Wang, W., Yu, H., Liu, Y., Jiang, X., Gao, B.: Trueness analysis of zirconia crowns fabricated with 3-dimensional printing. J. of Prosthet. Dent. 121(2), 285–291 (2019)

Wei, L., Zhang, J., Yu, F., Zhang, W., Meng, X., Yang, N., Liu, S.: A novel fabrication of yttria-stabilized-zirconia dense electrolyte for solid oxide fuel cells by 3D printing technique. Int. J. Hydrogen Energ. 44(12), 6182–6191 (2019)

Ferrage, L., Bertrand, G., Lenormand, P., Grossin, D., Ben-Nissan, B.: A review of the additive manufacturing (3DP) of bioceramics: alumina, zirconia (PSZ) and hydroxyapatite. J. Aust. Ceram. Soc. 53, 11–20 (2016)

Varghese, G., Moral, M., Castrogarcia, M., Lopezlopez, J.J., Marinrueda, J.R., Yaguealcaraz, V., Hernandezafonso, L., Ruizmorales, J.C., Canalesvazquez, J.: Fabrication and characterisation of ceramics via low-cost DLP 3D printing. Bol. Soc. Esp. Ceram. 57(1), 9–18 (2017)

Mitteramskogler, G., Gmeiner, R., Felzmann, R., Gruber, S., Hofstetter, C., Stampfl, J., Ebert, J., Wachter, W., Laubersheimer, J.: Light curing strategies for lithography-based additive manufacturing of customized ceramics. Addit. Manuf. 1–4, 110–118 (2014)

Halloran, J.W.: Ceramic stereolithography: additive manufacturing for ceramics by photopolymerization. Annu. Rev. Mater. Res. 46, 19–40 (2016)

Zhang, K., Xie, C., Wang, G., He, R., Ding, G., Wang, M., Dai, D., Fang, D.: High solid loading, low viscosity photosensitive Al2O3 slurry for stereolithography based additive manufacturing. Ceram. Int. 45(1), 203–208 (2019)

Borlaf, M., Serracapdevila, A., Colominas, C., Graule, T.: Development of UV-curable ZrO2 slurries for additive manufacturing (LCM-DLP) technology. J. Eur. Ceram. Soc. 39(13), 3797–3803 (2019)

Wang, X., Sun, Y., Peng, C., Luo, H., Wang, R., Zhang, D.: Transitional suspensions containing thermosensitive dispersant for three-dimensional printing. ACS Appl. Mater. Inter. 7, 26131–26136 (2015)

Li, K., Zhao, Z.: The effect of the surfactants on the formulation of UV-curable SLA alumina suspension. Ceram. Int. 43(6), 4761–4767 (2017)

Zhang, J., Huang, D., Liu, S., Dong, X., Li, Y., Zhang, H., Yang, Z., Su, Q., Huang, W., Zheng, W., Zhou, W.: Zirconia toughened hydroxyapatite biocomposite formed by a DLP 3D printing process for potential bone tissue engineering. Mater. Sci. Eng. C 105, 1–15 (2019)

Peng, Y., Zhang, Y.: Preparation of highly dispersible glass frit powders and its application in ink-jet printing ink. J. Eur. Ceram. Soc. 40(9), 3489–3493 (2020)

Jang, K.J., Kang, J.H., Fisher, J.G., Park, S.W.: Effect of the volume fraction of zirconia suspensions on the microstructure and physical properties of products produced by additive manufacturing. Dent. Mater. 35(5), 97–106 (2019)

Zhang, S., Sha, N., Zhao, Z.: Surface modification of α-Al2O3 with dicarboxylic acids for the preparation of UV-curable ceramic suspensions. J. Eur. Ceram. Soc. 37(4), 1607–1616 (2017)

Rödel, C., Müller, M., Glorius, M., Potthoff, A., Michaelis, A.: Effect of varied powder processing routes on the stabilizing performance and coordination type of polyacrylate in alumina suspensions. J. Eur. Ceram. Soc. 32, 363–370 (2012)

Rueschhoff, L., Costakis, W., Michie, M., Youngblood, J., Trice, R.: Additive manufacturing of dense ceramic parts via direct ink writing of aqueous alumina suspensions. Int. J. Appl. Ceram. Tec. 13, 821–830 (2016)

Zhu, X., Duan, X., Chen, H.: Effects of three dispersants on stability of ITO suspension. Chin. J. Nonferrous Met. 17(1), 161–165 (2007)

Zhang, J., Wei, L., Meng, X., Yu, F., Yang, N., Liu, S.: Digital light processing-stereolithography three-dimensional printing of yttria-stabilized zirconia. Ceram. Int. 46(7), 8745–8753 (2020)

Krieger, I.M., Dougherty, T.J.: A Mechanism for non-Newtonian flow in suspensions of rigid spheres. Trans. Soc. Rheol. 3, 137–152 (1959)

Einstein, A.: Investigations on the theory of Brownian movement. Dover Publications, New York (1956)

Balakin, B.V., Shamsutdinova, G., Kosinski, P.: Agglomeration of solid particles by liquid bridge flocculants: Pragmatic modelling. Chem. Eng. Sci. 122, 173–181 (2015)

Funding

This research was financially supported by the Open Project Foundation (No.2019CQKT0700) of Chongqing Institute of East China Normal University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiaqi, L., Bing, L., Weijiu, H. et al. The preparation of zirconia slurry based on DLP additive manufacturing technology. J Aust Ceram Soc 58, 1015–1023 (2022). https://doi.org/10.1007/s41779-022-00758-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-022-00758-7