Abstract

The global transition to clean and sustainable energy sources has sparked interest in hydrogen as a potential solution to reduce greenhouse gas emissions. Efficient and safe transportation of hydrogen is crucial for its integration into the energy network. One approach is utilizing existing natural gas infrastructure, but it introduces unique challenges. Hydrogen has distinct characteristics that pose potential hazards, requiring careful consideration for safe transportation through natural gas pipelines. Moreover, the absence of field data on component failure rates adds to the existing uncertainty in Quantitative Risk Assessment (QRA) for hydrogen transportation. QRA plays a vital role in enabling the safe deployment of hydrogen transportation through existing pipelines and is increasingly integrated into the permitting process. The lack of data impedes the comprehensive understanding of risks associated with hydrogen transportation. This paper aims not only to analyse the effects of hydrogen blending ratios on gas dispersion, release rates, jet fires, and explosions in natural gas pipelines, but also highlight the disparities in leak frequencies currently used for hydrogen or blended hydrogen. A QRA for hydrogen blending in natural gas pipelines is novel and timely because the behaviour of hydrogen in natural gas pipelines, a novel process with potential hazards, is not fully understood. Conducting a thorough QRA on hydrogen blending in gas pipelines, our study reveals innovative insights: higher blending ratios reduce release rates, impact safe distances, and maintain stable flame lengths. Despite an elevated explosion risk, scenarios remained below lethal overpressure values. This paper offers unique contributions to safety considerations in hydrogen transportation, guiding stakeholders toward informed decisions for a secure and sustainable energy future.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The current global shift towards sustainable and eco-friendly energy sources has ignited a burgeoning fascination with H2 as a viable remedy for mitigating carbon dioxide emissions up to 20% by 2050 and tackling the issue of climate change [1]. Hydrogen’s potential lies in its capacity to generate energy without any carbon emissions through fuel cells or combustion procedures. Yet, the safe and effective transportation of hydrogen remains a vital determinant in unlocking its full potential within the energy grid [2].

One viable approach to hydrogen transportation is utilizing existing natural gas infrastructure, which offers the advantage of cost savings and minimizes the need for extensive new infrastructure [3].

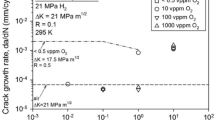

Transporting hydrogen presents several challenges, including the need to modify existing infrastructure, guarantee safety, avoid embrittlement, handle fatigue, and effectively detect leaks, especially since hydrogen lacks distinct odorants. Additionally, adapting current infrastructure for hydrogen use introduces added complexity and expenses as hydrogen’s lower energy density compared to other fuels necessitates more stringent compression requirements [4]. Moreover, Hydrogen possesses distinct characteristics, including a low boiling point and density, low ignition energy, wide flammability range, and high burning velocity compared to conventional fuels [5]. These characteristics give rise to potential hazards that must be carefully addressed to ensure the safe transportation of hydrogen through natural gas pipelines. Adding to that, the lack of system data for hydrogen transportation in transmission pipelines, which is essential for developing valid component reliability data. The absence of field data on component failure rates contributes to the uncertainty surrounding hydrogen risk assessment. Addressing these challenges is pivotal for unlocking hydrogen’s potential as a clean energy solution in our transition to a low-carbon future. Wu et al. examine high-strength steel failure from hydrogen, stressing the need for more research on embrittlement mechanisms, demanding extensive experimental and simulation support [6]. Pluvinage, Capelle, and Meliani propose adjustments for steel pipes in hydrogen transport, advocating for altering design factors and using specialized tools for defect evaluation, while also exploring hydrogen embrittlement’s effects on fatigue endurance [7]. Regarding ignition probabilities, Astbury et al. thoroughly analysed potential ignition mechanisms for hydrogen safety [8]. Dagdougui et al. assessed thermal hazards from pipeline releases [9], while Viana et al. proposed risk mitigation for pipelines [10]. Similarly, studies by Jo and Ahn [11], Russo, de Marco, and Parisi [12], Li et al. [13], and Jeong, Jang, and Lee cover various aspects of hydrogen transportation and risk assessment [14], yet none specifically tackle the frequency of hydrogen releases during dispensing operations. This gap underscores the need for further research in this critical area to ensure comprehensive safety measures in hydrogen transportation systems. This paper fills this gap by introducing a novel Quantitative Risk Assessment (QRA) for hydrogen blending in natural gas pipelines, a novel process with limited operating knowledge and substantial potential hazards. It addresses the lack of understanding regarding hydrogen behaviour in these pipelines and the frequency of hydrogen releases during dispensing operations. By analysing blending ratios and safety parameters, it offers insights into hydrogen transportation risks and emphasizes the need for refined risk assessment methods.

To facilitate broader adoption of hydrogen across various sectors, thorough investigations into safety and risk factors are crucial. Quantitative risk assessment (QRA) plays a key role in enabling the safe implementation of hydrogen transportation in transmission pipeline and is increasingly integrated into the permitting process. In addition to the challenges outlined, QRA serves as a paramount tool for systematically evaluating and quantifying potential risks associated with the transportation of hydrogen. This analytical approach is essential for identifying vulnerabilities, predicting worst-case scenarios, and implementing targeted safety measures to mitigate risks effectively [15, 16].

The purpose of this paper is to analyse and compare the changes in dispersion behaviours and risks associated with transporting blended and pure hydrogen in existing natural gas (NG) pipelines. The research gap in this context is the lack of understanding and reliable data regarding the accuracy and reliability of risk assessments for hydrogen transportation. There is a need for further research and data collection to improve the reliability of quantitative risk assessments. Moreover, the research also aims to address the lack of understanding on how leak frequencies can affect risk values and subsequently impact decision-making in hydrogen transportation pipeline systems. By employing a Quantitative Risk Assessment (QRA) methodology, the paper aims to shed light on the relationship between leak frequencies and overall risk levels. The study includes a case study on a specific 32” onshore natural gas pipeline in Egypt to provide insights into safety considerations crucial for the successful integration of hydrogen transportation using existing natural gas infrastructure. Through this research, the paper seeks to contribute to the development of comprehensive safety mechanisms, including risk assessment, hazard analysis, and safety indices specifically tailored for hydrogen transportation, while addressing the lack of guidance on establishing input data for safety and reliability engineering analyses in situations where little or no field data exists.

Methodology

Methodology Introduction

The in-depth analysis methodology employed in this study utilized the classical Quantitative Risk Analysis (QRA) procedure. QRA is a valuable tool for assessing risk and aiding decision-making processes. The guidelines for conducting QRA were established by the Centre for Chemical Process Safety and are documented in their publication titled “Guidelines for Chemical Process Quantitative Risk Analysis” [17]. The process is shown in Fig. 1.

QRA begins by defining the system and using qualitative techniques to identify hazards and select scenarios for modelling. Accidents and impacts are estimated through frequency and consequence modelling to develop risk measures. Criteria for acceptable risk levels are introduced, and if risks are unacceptable, measures to reduce risk may be necessary and evaluated using a cost-benefit analysis [18]. The detailed description of the proposed steps of Fig. 1 is provided below:

Methodology Steps

Step 1 Hazard Identification/Failure Case Selection

Hazard identification is a crucial step in QRA for mitigating potential hazards [19]. Techniques like engineering codes, checklists, and hazard index methods are used for hazard assessment. Selecting failure cases involves listing all incidents without bias and identifying significant ones. For hydrogen leaks, investigating a limited range of hole sizes (e.g., 5 mm, 25 mm, 100 mm) and modeling up to 10 leak sizes is important. Hole size choice significantly impacts risk assessment results, as well as release rates when pressure fluctuations are accounted for. Failure cases are classified as small, medium, or large with rates of 1 kg/s, 10 kg/s, and 100 kg/s, respectively, although values can vary widely [18].

Step 2 Consequence Analysis

Consequence estimation is a technique to assess potential harm resulting from specific incidents, which may cause multiple outcomes [20]. Consequence analysis is crucial for evaluating the potential harm caused by incidents [21]. It involves using explosion and fire models, as well as source and dispersion models. Source models define the release scenario, while dispersion models convert the outputs into concentration fields [22].

Source models calculate the release rate based on factors like pressure, hole size, and phase. The rate determines the gas cloud size and resulting fire or smoke plume. Dispersion models consider momentum, wind, and ventilation to determine gas cloud spreading and ignition/fatality zones [23].

The impact of thermal radiation is mainly determined by the thermal radiation flux and the duration of exposure. However, other factors such as clothing type, availability of shelter, and individual characteristics can also affect the outcomes. The following information offers guidance on the expected lethality levels in typical situations, considering how these factors may influence the results. Table 1 presents a summary of thermal radiation exposure effects at various radiation flux levels, based on the guidelines provided by IOGP 434 − 14 Vulnerability of humans [24].

Explosions cause damage to structures and create projectiles like fragments and shattered glass. Overpressure effects on humans are categorized as direct, secondary, and tertiary injuries. Direct injuries result from the pressure change, secondary injuries from fragments or debris, and tertiary injuries from individuals colliding with objects or structures due to blast force. In QRA, lethality estimation considers the combined effects of these categories. Casualties requiring treatment usually occur when overpressures exceed 1 barg. However, secondary effects and thermal injuries often have a greater impact, making direct blast injuries a small portion of total casualties [24].

Step 3 Frequency Analysis

Frequency analysis estimates the likelihood of failure cases like pipe leaks identified during hazard identification. Approaches include historical accident data, Fault Tree Analysis (FTA), Event Tree Analysis (ETA), Event Sequence Diagrams (ESDs), etc… Strengths and weaknesses of each technique are outlined in guidelines for quantitative risk analysis [17].

Frequency analysis in this context primarily focuses on the occurrence of undesired hydrogen releases and the development of risk scenarios. It involves estimating leak frequencies from different components. SANDIA data includes state-transition probabilities for Event Sequence Diagrams (ESDs), such as immediate or delayed ignition probabilities (Table 2), based on estimated hydrogen release rates [25]. Table 2 lists the ignition probabilities of hydrogen, which were determined based on the rate at which hydrogen was released.

These ESDs are based on the existing ESDs for GH2 (gaseous hydrogen) releases found in the HyRAM software, as shown in Fig. 2.

ESD for GH2 releases [25]

Step 4 Risk Estimation/Risk Assessment

Quantitative risk analysis generates numerical values that, on their own, may not hold significant meaning. It is during the assessment phase, where these numbers are carefully examined and interpreted, that meaningful conclusions and actionable recommendations can be derived. This phase is crucial as it allows for the extraction of valuable insights and practical outcomes from the risk analysis. The integrated QRA model combines consequences and frequencies to produce numerical risk values. The calculated risks are combined and presented in the appropriate format. Utilization of risk estimates involves using the results to make decisions, such as ranking risk reduction strategies or comparing to specific risk targets [26]. Risk analysis provides measurable insights into potential risks associated with a facility or activity. Acceptability of these risks is determined by experts’ judgment, comparing calculated risk values to predetermined criteria.

Risk evaluation for personnel, the public, on-site companies, and adjacent offices follows the Individual Risk Per Annum (IRPA) criteria based on HSE guidelines from Reducing risks, protecting people (R2P2). Risks exceeding 1.00E-3 per year for on-site individuals or 1.00E-4 per year for the public are considered intolerable. Risks below 1.00E-6 per year are generally deemed acceptable. Societal risk is assessed using an FN curve, projecting the R2P2 point based on UK HSE guidance. The curve in Fig. 3 examines the relationship between the number of fatalities (N) and cumulative frequency (F) [27].

IRPA represents the likelihood of an individual’s death from exposure to hazards or activities for one year as:

where the variable f represents the respective fractions of spent time spent by an individual on-site during a year. IRPA values are depicted through frequency contours that rely on manning distribution. While Location-Specific Individual Risk (LSIR) quantifies the likelihood of a hazardous event causing death to an unprotected individual in a specific location over a year, LSIR is the cumulative impact of toxic, thermal, and overpressure effects on individuals. It is assumed that the person is present 24/7, 365 days a year. LSIR is measured in year− 1. Evaluation of LSIR using different notations is given by CCPS process safety calculations [26].

HSE intolerability criterion for societal risk [28]

Case Study Philosophy and Approach

The hazard assessment for hydrogen follows similar techniques as the chemical industry. sources of accident data that can be used during hazard reviews for Hydrogen are the HIAD database, the H2Incidents website, and technical references on the hydrogen compatibility of materials [29]. In this study, the planned use of HYRAM software had to be reconsidered due to its inability to analyse risks associated with hydrogen blends, despite being mentioned in their technical report [25]. As a result, PHAST 8.7 and SAFETI 8.7 software from DNV were employed to support the Quantitative Risk Analysis (QRA) process. Both have proven to be effective in assessing risks in petrochemical plants, chemical plants, and other similar facilities, including those related to hydrogen.

System Description

In this case study, a 32” onshore natural gas pipeline spanning 120 km in Egypt is designed to transport natural gas between two cities in Egypt. The pipeline route passes through or in close proximity to four residential populations, referred to as Population 1, Population 2, Population 3, and Population 4 within the case study. The total length of the pipeline is approximately 120 km, with a maximum capacity of around 388 million Standard Cubic Feet Per Day (MMSCD) of Natural gas (NG) and usually buried under 1 meter.

This case study utilizes the Design and Project documentation as its basis, and the subsequent Table 3 provide a summary of crucial operating conditions and pipeline data.

Key Assumptions

To use natural gas pipelines for hydrogen transportation, consistent heating values at delivery points must be ensured. This is because hydrogen requires approximately three times more volume compared to natural gas [29]. Understanding the conditions and challenges associated with hydrogen transportation is crucial to meet these requirements effectively. In this study, a simulation model is used to increase the volumetric flow rate of blended hydrogen (448.5 MMSCFD) and pure hydrogen (1234 MMSCFD) to maintain consistent heating value. The study also examines the resulting pressure drop in hydrogen and blended hydrogen.

Methodology Application

Hazard Identification/Failure Case Selection

Risk in the context of pipeline failures is determined by the likelihood of failure and the resulting negative impact. It’s important to understand that not all failures have severe consequences, and there are two types: leaks and ruptures. In the case of natural gas and hydrogen transmission, leaks contribute minimally to the overall risk, while ruptures being the primary concern [18]. Both scenarios are estimated and considered relevant. To analyse accident scenarios and assess risks, it is necessary to estimate the number of components and pipe lengths by examining the PFD. The representative release scenario considered for each segment of the pipeline is the same. Population 4 has the largest surface area and highest population, making it a representative for evaluating individual and societal risk. Risk calculations will focus on different pipeline failures near Population 4, considering various leak sizes. Pipeline Line Segment length considered is 1 Km.

The gas pipeline operates at a pressure of 70 bars; however, risk evaluation will be based on the design pressure of 77 bars and a temperature of 25 °C. The gas composition consists of 97% methane (by mole) and 5% heavier hydrocarbon components. As mentioned earlier, the selected segment is representative of the typical population densities along the entire length of the gas pipeline, taking into account the presence of ignition sources. It is considered that any other segment along the pipeline route can be adequately represented by the proposed segment.

Consequence Analysis

When assessing the risk of an accidental pipeline release or rupture, it’s essential to differentiate between two types of effects: overpressure from a physical explosion and thermal radiation emitted by a jet fire. Generally, the overpressure effects have a relatively small impact on the overall risk, while thermal radiation dominates [30]. However, for this study, the consequence scenario considered is gas dispersion, thermal radiation and overpressure.

In Consequence Modelling, a sensitivity analysis was carried out that involved examining 15 cases, considering various release sizes and hydrogen blending ratios. The chosen release sizes of 1 inch, 6 inches, and full rupture (31 inches) represent a range of potential release sizes. This allows us to explore the consequences of both smaller and larger releases, including the worst-case scenario of a full rupture. Additionally, the hydrogen blending ratios of 0%, 20%, 50%, 80%, and 100% represent different levels of hydrogen concentration in the release. These ratios enable us to understand the impact of various hydrogen mixtures on the model’s outcomes.

By conducting this sensitivity analysis across the 15 cases, we can better understand the sensitivity of the consequence model to changes in release diameter and hydrogen blending ratio. This information will be valuable for evaluating the potential risks associated with different operating conditions and aid in making informed decisions for safe distance or land use planning. For each designated release event, an extensive analysis involving dispersion modelling flash fire and explosion assessments, as well as fire size calculations relating to jet fires, are methodically executed with Det Norske Veritas (DNV) advanced consequence and risk modelling software tool, SAFETI (Version 8.7) [31].

Frequency Analysis

To quantify the overall risk associated with a hydrogen pipeline, it is important to identify the potential types of accidents that can occur. Leakage of hydrogen from pipelines can lead to jet fires, flash fires, or explosions depending on the ignition source. The frequency and consequences of these accidents depend on the size of the leak and the system pressure. To model these accidents in a Quantitative Risk Assessment, it is desirable to establish component leak frequencies based on leak size and system pressure [32].

However, there is a lack of available data specifically focused on hydrogen component leakage events for QRA purposes. Existing databases, such as the DOE Hydrogen Incident Reporting database, provide valuable insights from major events but often lack comprehensive data on smaller leakage events and operating hours. As a result, most QRAs for hydrogen facilities have relied on published values from non-hydrogen sources. For example, the EIGA recommends leak rates for various components based on a review of leak frequencies from different sources.

Sandia National Laboratories (SANDIA) utilized a statistical analysis method to combine various data sources. It combines data from various sources using traditional and Bayesian statistics. This statistical approach offers several advantages over traditional methods. Firstly, it enables the generation of leakage rates for different leak sizes. Secondly, the Bayesian approach provides uncertainty distributions for the leakage rates, allowing for the propagation of uncertainty in the risk assessment. Lastly, the Bayesian approach allows for the incorporation of limited hydrogen-specific leakage data, thus providing estimates for leakage rates specific to hydrogen components [33]. There exist two methods of data analysis: traditional statistical techniques and Bayesian statistics. Bayesian techniques prove to be better in some cases. However, when there is an abundance of data, the advantages of Bayesian techniques are limited.

According to SANDIA report, Bayesian analyses have two main drawbacks: subjectivity due to the use of subjective prior distributions and higher computational power compared to traditional analyses. However, sensitivity studies with different prior distributions can address the subjectivity issue. Bayesian techniques should be used in the Quantitative Risk Assessments of the hydrogen based on currently available data. Bayesian analysis enables greater consideration of relevant and specific data sets, generating uncertainty distributions, and allowing for more flexibility when new data is introduced [33]. In this study, data from different sources were utilized to assess the risk associated with hydrogen transportation. A sensitivity analysis was conducted to examine the impact of using various sources of leak frequencies currently available for hydrogen, including the European Gas Pipeline Incident Data Group (EGIG) pipelines database and the SANDIA report on hydrogen [33].

In this study, the IRPA values and FN Curves for individuals residing near the pipeline in Population 4 will be determined by considering factors such as occupancy and the time spent by individuals indoors and outdoors. Four distinct cases were examined to assess the variations in the risk associated with the transportation of natural gas, blended hydrogen, and pure hydrogen. The assumptions for each case are summarized in Table 5.

Case 1

involves natural gas with leak frequencies from SANDIA database and ignition probabilities of 0.2 and 0.1. Case 2 is a blend of 20% hydrogen and 80% natural gas with leak frequencies still sourced from SANDIA database and ignition probabilities of 0.23 and 0.12. Case 3 is pure hydrogen with specific leak frequencies from SANDIA database and same ignition probabilities as Case 2. Case 4 is pure hydrogen with leak frequencies from natural gas data and same ignition probabilities as Case 2.

Ignition Probability

Tchouvelev et al. established the ignition probabilities for hydrogen and natural gas, which can be found in Table 2. These probabilities are based on the release rate of hydrogen or natural gas and provide immediate and delayed ignition probabilities depending on the rate of release. The release of hydrogen into the atmosphere carries a higher likelihood of ignition compared to other fuels, primarily due to its lower minimum ignition energy (MIE) and wider flammability range [34]. Consequently, the ignition probabilities for hydrogen, both for delayed and immediate ignition, surpass those of natural gas. When dealing with blended hydrogen, the ignition probabilities specifically for hydrogen are taken into account, as the ignition behaviours for blend have been found to be near that of pure hydrogen.

Population Data

Understanding population distribution is important for estimating risk, even if complete data on the entire population is not always available. Population density, which measures population distribution, is typically obtained from sources like census reports, maps, and site inspections. In cases where specific population data is lacking, guidelines for quantitative risk analysis suggest using occupancy categories as a substitute. Assuming a suburban town setting with a population density ranging from 5,000 to 19,000 people per square mile, an average value of 14,500 people per square mile was used. Additionally, 90% of the population was estimated to be indoors during the risk assessment period, with occupancy of 24/7, 365 days a year. Estimated population densities are shown in Table 6.

Meteorological Data

In the analysis of releases, weather conditions play a significant role in determining the spread of the released material. Meteorological data, such as wind directions, wind speeds, and atmospheric stability categories, can be obtained from sources like the National Oceanic and Atmospheric Administration (NOAA) and nearby airports. These data provide valuable information on the frequency and characteristics of wind patterns [35]. For this study, weather data was obtained from the Egyptian Meteorological Authority to ensure adherence to best practices in Quantitative Risk Assessment weather data. A representative weather condition, known as D5, was chosen to model the dispersion of each release scenario. D5 represents neutral stability and a wind speed of 5 m/s, which is widely considered as the most probable inland condition, occurring in up to 80% of cases. A uniform wind rose was assumed to represent the worst-case scenario.

Results & Discussion

Heating Value

The findings indicate a pressure drop in both hydrogen and blended hydrogen, but the impact is not significant. Figure 4 illustrates the results of the three simulation cases: natural gas, pure hydrogen, and blended hydrogen, highlighting the observed pressure drop in each case. It’s important to note that despite increasing the molar flow rate to maintain the same heating value, the mass flow rate decreases in blended and pure hydrogen compared to natural gas. This decrease is due to hydrogen’s lower density compared to natural gas, resulting in a reduced mass flow rate even with a constant pipeline volume.

Only three operating conditions were considered in the risk quantification, Pure hydrogen, natural gas and blend with 20% of hydrogen, as a study was conducted on gas networks at a university concluded that a blending ratio of 20% is considered safe and demonstrated the successful transportation of blended hydrogen through natural gas networks [2].

Consequence Modelling Results

A total of 15 cases were investigated, considering different release sizes (1 in, 6 in, and full rupture) and hydrogen blending ratios (0%, 20%, 50%, 80%, and 100%). Other parameters were set as follows: internal pressure of 77 bar, which represents the maximum allowable working pressure for the pipeline; wind speed of 5 m/s; vertical upward leakage direction; and ambient temperature of 25 °C. Explosions and jet fires are the primary consequences of transmission pipeline leaks, mainly due to the physical and chemical properties of hydrogen and natural gas. Therefore, the consequences of explosions and jet fires were modelled for different scenarios [36].

Below results were extracted from the PHAST consequence summary report for the case study, NG. The report includes analyses on gas dispersion and release rates, jet fire characteristics, and explosion characteristics, examining the effects of varying hydrogen blending ratios. These results offer valuable insights into the influence of hydrogen blending on different aspects of the study.

Effects of Varying Hydrogen Blending Ratios on Gas Dispersion and Release Rates

Dispersion

Flammable gas cloud concentrations for a full rupture have been extracted from PHAST and analysed, where Fig. 5 shows the influence of different hydrogen blending ratios on the safe separation distance of flammable concentrations and the change in distance to the lower flammable limit (LFL) was analysed. The results showed that there was no significant difference in the distance to LFL between hydrogen-blended gas and natural gas downwind distance on the ground, as it ranged from 5.4 m for hydrogen to 6.4 m for natural gas.

Release Rates

The release rates of natural gas, blended hydrogen, and pure hydrogen were compared for different leak scenarios. Although the pressure upstream of the leak is constant for all cases at 77 bar, the hydrogen blending ratios had an impact on the release rates for all release sizes (1-inch, 6-inch, and full-bore ruptures). The full rupture scenario resulted in the highest release rates, with hydrogen having a release rate of 3272 kg/s, natural gas 8556 kg/s, and the 20% hydrogen blend 6850 kg/s. Figure 6 shows peak flow rate values at different release sizes (1”, 6” & full rupture (31”)).

Release Rates and Dispersion Behaviours of Natural Gas, Pure Hydrogen, and Hydrogen Blends Discussion

Hydrogen and natural gas possess distinct physical properties. The composition of natural gas primarily consists of methane along with smaller quantities of ethane, propane, butane, and other higher-order hydrocarbons and gases [29]. These hydrocarbons exhibit significantly higher molecular mass and volumetric heating value compared to hydrogen.

The introduction of hydrogen into methane has significant impacts on its physical and chemical properties, which can have implications for consequence analysis. The addition of hydrogen to methane leads to a decrease in gaseous density, which affects dispersion in downwind direction, particularly in the absence of ignition. Consequently, due to these and other factors, the behaviour of a blended gas following a pipeline leak will vary based on the blend ratio.

Hydrogen demonstrates a buoyancy that exceeds air by a factor of 14.5, whereas methane is only 4 times more buoyant. To determine the releasing flowrate (ṁ) and assess the fluid dynamic data at the outlet section, the following equation is employed [37].

In this equation, 𝜌𝑒, 𝛾, R, and T0 represent the gaseous density, specific heat ratio, ideal gas constant, and initial temperature, respectively.

As a result, both the internal pressure and density have an impact on the release mass flow rate. Since the internal pressure remains constant in this study (77 Bar), an increase in fluid density causes a proportional increase in the release flow rate. Due to hydrogen having a lower density than methane, an increase in the hydrogen blending ratio leads to a decrease in density and, consequently, the mass flow rates released and dispersion.

Effects of Varying Hydrogen Blending Ratios on Jet Fire Characteristics

The calculation of the results in this study involves assessing the potential risks associated with fire in the surrounding areas. These risks include temperature damage, smoke inhalation, and thermal radiation. Among these risks, the damage caused by pipe jet fires primarily arises from the thermal radiation, which can result in burns and fatalities. In this study, the focus was on analyzing the safe distance required to mitigate the intensity of thermal radiation in the event of a full pipe rupture, taking into account the hydrogen blending ratio. To determine the hazard zone of the jet fire, specific heat flux levels were used as reference values. For example, heat flux levels of 4 KW/m2 were considered to correspond to radiation values that can cause first-degree burns. Heat flux levels of 12.5 KW/m2 were associated with human fatalities in close proximity to the pipeline, while radiation values of 37.5 KW/m2 were observed to cause structural collapses.

By considering these heat flux levels and their associated radiation values, the study aimed to assess and quantify the potential risks and hazards posed by jet fires in different scenarios, particularly in relation to the hydrogen blending ratio.

Figure 7 presents the variations in the required safe distance to mitigate thermal radiation intensity, taking into account the hydrogen blending ratio in the event of a full rupture. It demonstrates the impact of the hydrogen blending ratio on the safe separation distance. As the hydrogen blending ratio increased from 0 to 20%, the decrease in flame length and distance downwind for a thermal radiation intensity of 4 kW/m2 was less than 5%. However, with further increases in the hydrogen concentration to 50%, 80%, and 100%, the distance downwind decreased by approximately 12% and 17%, while it increased by 5% for pure hydrogen compared to Blend 80/20 at an intensity level of 37.5 kW/m2 (See Fig. 8).

Figure 9 illustrates the variations in flame length for flammable gas clouds at different blending ratios and release rates. It is evident that for small release sizes of 1 and 6 inches, there was no significant change in jet flame length across different blending ratios (0%, 20%, 50%, 80%, and 100%). However, in the case of a full rupture release, natural gas resulted in the longest jet flame length.

The results of the study indicate that natural gas jet fires tend to have a higher overall heat flux compared to hydrogen jet fires. This finding suggests that natural gas poses a greater jet fire hazard than hydrogen in terms of thermal radiation. The study examined the changes in hazard zones and lethality percentages for different blending ratios of hydrogen and natural gas in the event of a full rupture scenario, which can be found in below figures. The analysis revealed that when the hydrogen blending ratio was below 20%, the impact on the safe separation distance was minimal. In other words, the addition of hydrogen in low blending ratios did not significantly affect the distance required to mitigate the intensity of thermal radiation.

However, it was observed that pipelines blending hydrogen with natural gas had shorter separation distances compared to pipelines transporting natural gas alone under similar working conditions. This implies that the presence of hydrogen in the gas mixture can lead to a reduction in the safe separation distance required to mitigate thermal radiation hazards. These findings highlight the importance of considering the blending ratio of hydrogen in natural gas pipelines when assessing the jet fire hazard. The results suggest that higher blending ratios of hydrogen may contribute to shorter safe separation distances, potentially impacting the overall safety and risk management strategies for such pipelines.

Jet Fire Behaviours of Natural Gas, Pure Hydrogen, and Hydrogen Blends

Regarding the length of the flame, in all cases, an increase in release rate results in a longer cloud, and hydrogen has a lower release rate compared to methane and blended hydrogen. Moreover, the combustion of hydrogen is known to generate a lower level of radiant heat compared to hydrocarbons that are comparable, thereby reducing the possibility of igniting adjacent materials.

The addition of hydrogen can affect gaseous density in two ways. It can lead to dispersion either in a downwind or horizontal direction, which can have a significant impact on the area involved, especially if there is no ignition. Additionally, the speed of sound in hydrogen is 2.7 times that of methane, which affects the volumetric flow rate. Furthermore, the difference in density affects the specific energy content of the flammable mixture, as evidenced by the lower heat of combustion per unit of volume [37].

Effects of Varying Hydrogen Blending Ratios on Explosion Characteristics

When a hydrogen pipeline damage, the released hydrogen gas disperses and remains within its explosive concentration range. In the absence of an immediate ignition source, the accumulated vapour cloud has the potential to disperse and ignite later, resulting in a vapour cloud explosion. Such an explosion can cause various damaging effects, including shock waves and thermal radiation, which can have a significant impact over a considerable area.

Both hydrogen and methane possess the ability to undergo detonation under specific conditions involving fuel/air mixture, confinement, and ignition source strength. However, hydrogen has a lower explosive limit (LEL) and a broader range of explosiveness compared to natural gas. As a result, hydrogen is more prone to explosion hazards than natural gas in general, making it an important consideration for safety measures. Considering the heightened explosion hazards associated with hydrogen, safety measures become crucial in mitigating risks. These measures may include strict adherence to rigorous inspection and maintenance protocols for hydrogen pipelines, implementation of robust leak detection systems, appropriate ventilation and containment strategies, and ensuring proper grounding and electrical safety measures to prevent ignition sources. Additionally, emergency response plans should be in place to address any potential vapor cloud explosions promptly.

Figure 10 provides a compelling visual comparison of the maximum explosion distances at a 0.2-bar overpressure for different blending ratios. Notably, the blending ratio of 20% hydrogen exhibits the highest explosion distance at 0.2 bar among the blends, reaching an impressive distance of about 85 m. Additionally, hydrogen itself demonstrates the highest explosion distance of approximately 95 m. This finding underscores the profound impact of hydrogen due to its stronger explosion characteristics when compared to natural gas.

Furthermore, below figures depict maximum overpressure hazard zones related to explosion due after a full rupture scenario. These figures reveal an intriguing observation: as the methane content increases, the overall range of overpressure decreases. This phenomenon can be attributed to the superior explosion characteristics of hydrogen compared to natural gas, further highlighting the potential hazards associated with hydrogen (See Fig. 11.

Explosivity Hazards of Natural Gas, Pure Hydrogen, and Hydrogen Blends Discussion

The overpressures produced by methane/hydrogen mixtures containing 20% by volume are considerably higher than those generated by natural gas alone. Therefore, incorporating less than 20% by volume of hydrogen in pipeline networks would not significantly increase the likelihood of explosion. However, mixtures containing 50% or more hydrogen pose a noteworthy risk of generating detrimental overpressures and the possibility of deflagration to detonation transition (DDT) [38].

The properties and behaviour of hydrogen and natural gas have significant implications for their explosion risks. While pure and blended hydrogen may have a lower release flow rate compared to natural gas, its higher speed of sound results in a higher volumetric flow rate in the choked regime for hydrogen-containing mixtures. The presence of hydrogen increases reactivity and lowers ignition conditions, suggesting that hydrogen-enriched methane could lead to more severe consequences in the event of delayed ignition compared to natural gas [39].

The physical properties of hydrogen, such as its large deflagration index, contribute to its increased consequences in the event of an incident. On the other hand, natural gas (methane) has a higher heat of combustion. Considering these properties alone, hydrogen presents a higher risk primarily due to its greater probability of ignition. However, it is important to note that in all scenarios analysed, the overpressure values never exceed 0.2 bar. Even in open or confined areas with congestion, this level of overpressure does not result in any lethality, making it an insignificant scenario.

Risk Quantification Results

Risk on Population

Individual Risk

The criterion of IRPA (Individual Risk of Fatality per Annum) is a widely employed measure for assessing spatial risks related to pipeline transport. It quantifies the probability of an individual’s death resulting from pipeline operations. The analysis of IRPA involves evaluating and quantifying the risks along the pipeline. The calculation of IRPA is typically multiplying the LSIR * fractions of spent time spent by an individual during a year.

Figure 12 showcases an ALARP (As Low as Reasonably Practicable) chart that displays the values of IRPA (Individual Risk of Fatality per Annum) for outdoor personal which were observed higher values. The corresponding results are summarized in Table 7.

The results indicate that in Case 3, where pure hydrogen leak frequencies and ignition probabilities from SANDIA were utilized, the maximum IRPA (Individual Risk of Fatality per Annum) for the indoor population was found to be 4.89E-07 per year, while for the outdoor population, it was 8.31E-07 per year. These findings demonstrate a significant reduction in risk values compared to the natural gas scenario. In the natural gas case, the maximum IRPA for outdoor populations was 2.4E-05 per year.

In Case 4, a distinct approach was taken by applying natural gas components leak frequencies to hydrogen transportation. This assumption presumed that the leak frequencies for H2 and natural gas components were equivalent.

According to the data in Table 7, it can be observed that when the blending ratio was 20/80, the maximum IRPA rose to 3.84E-05 per year for the indoor population and 5.67E-05 per year for the outdoor population, which are higher in comparison to Case 1 (which involved only natural gas) with the same components leak frequency but higher ignition probabilities.

Societal Risk

Group/societal risk refers to the risk faced by a collective of individuals. It is a combination of the individual risk levels and the population exposed. The use of FN curves illustrates the group risk in this study. These curves depict the frequency of different consequences and are often plotted with cumulative frequencies and logarithmic scales [40].

The construction of the FN curves inherently impacts the assessment of group risk. Instead of manipulating probabilities within the model, the measure is evaluated by altering the number of individuals exposed to the risk of grounding. This modification directly influences the resulting FN curves, which depict the relationship between the frequency of events (F) and the number of people affected (N). Decreasing the number of individuals shifts the curves to the left while increasing the number of individuals shifts the curves to the right.

Below figures, present the FN curves, which serve to demonstrate the group risk as determined by the model. These curves specifically pertain to Population 4, which consists of approximately 150,000 individuals, roughly equivalent to the population of this town. On the curve, the leftmost point, located beyond the minimum criterion line, corresponds to a single fatality, and represents the range of 0–24% fatalities.

Upon reviewing below figures, it becomes apparent that the majority of the FN curve falls within the ALARP (As Low as Reasonably Practicable) region for cases 1, 3, and 4. However, in the case 2, the curve falls in the broadly acceptable region below the minimum criterion line. It is important to note that the FN curves are influenced by the population size and various factors such as PLL (including leak frequencies, ignition probabilities, and material type).

Comparing FN cruces for Case 2 involving a blend with a 20/80 ratio and increased ignition probabilities, it is evident that the number of fatalities shows a minimal increase compared to Case 1. In Case3, the modified leak frequencies proposed by SANDIA are utilized, resulting in lower leak frequencies compared to natural gas, along with a higher probability of ignition to account for the low ignition energy of hydrogen. The societal risk experiences a significant reduction, as indicated by the curve shifting into the acceptable region when compared to all other cases. Even in Case 4, where normal leak frequencies for natural gas are applied to hydrogen, it can be observed that at the same leak frequencies of 1 E-05, the number of fatalities in Case 4 is approximately 180, compared to nearly 220 in Case 1 (See Fig. 13).

IRPA Values and FN Curves for Natural Gas, Pure Hydrogen, and Hydrogen Blends Discussion

The assessment revealed a marginal increase in risk values and the FN curve for blended hydrogen (20/80) compared to the natural gas case. This can be attributed to the elevated ignition probability for blended hydrogen in comparison to natural gas. This suggests that the introduction of hydrogen into the blend poses some additional risk.

However, when considering the case of pure hydrogen (Case 3) using leak frequencies proposed by SANDIA, there was a substantial decrease in both individual and societal risk values. This decrease can be attributed to the reduced frequency of component leaks in the pure hydrogen scenario. In comparison to both Case 1 (natural gas) and Case 2 (blended hydrogen), the risk reduction achieved with pure hydrogen was significant.

It is important to note that all calculated risk levels in this analysis were found to be below the established intolerable risk criteria. This indicates that the risks associated with the studied scenarios fall within the As Low as Reasonably Practicable (ALARP) zones, which signifies an acceptable level of risk. However, it is crucial to emphasize that appropriate risk reduction measures should still be implemented, as long as they are deemed reasonably practicable. While the assessed risks are considered acceptable, it is important to continually assess and mitigate risks to ensure safety. Additionally, factors such as the blending ratio and the frequency of component leaks play critical roles in determining the level of risk and should be taken into account during risk assessment and management processes.

Conclusion

The paper investigates the safety implications of blending hydrogen with natural gas in pipelines through Quantitative Risk Assessment (QRA), focusing on factors like gas dispersion, release rates, fires, and explosions. It also examines variations in leak frequencies for hydrogen and its blends with natural gas. The findings unveiled significant disparities in the distance to the lower flammable limit (LFL) between hydrogen-blended gas and natural gas. Moreover, the release rates were influenced by the hydrogen blending ratios, indicating that higher blending ratios led to lower release rates in all leak scenarios. This phenomenon can be attributed to the lower density of hydrogen, resulting in reduced mass flow rates during a release. The study also examined the necessary safe distance to mitigate thermal radiation intensity, considering the hydrogen blending ratio. The results indicated that as the blending ratio increased, there was a slight decrease in the downwind distance required to reach specific heat intensity levels. However, this decrease became more pronounced at higher blending ratios.

In terms of flame length, no significant change was observed across different blending ratios for small release sizes. However, in the case of full rupture release, natural gas displayed the longest jet flame length. Additionally, the study observed that natural gas jet fires exhibited a higher overall heat flux compared to hydrogen, highlighting greater jet fire hazards associated with natural gas. When it comes to explosions, hydrogen presents an increased risk due to its stronger explosion characteristics and broader explosiveness range. Nevertheless, the scenarios analyzed in the study did not yield overpressure values exceeding 0.2 bar, which indicates zero lethality even in open, confined, or congested areas.

Furthermore, blending hydrogen with natural gas at an 80% hydrogen and 20% natural gas ratio results in behaviours similar to pure hydrogen in terms of release rate and jet flame length. However, the explosion distance is still higher for the blended gas compared to pure hydrogen, albeit lower than the pure hydrogen scenario. The physical properties of hydrogen and natural gas play a significant role in determining the risks associated with the blended gas, with hydrogen’s ignition probability being a primary factor.

In the context of this case study, the transportation of hydrogen through natural gas pipelines was determined to have no significant impact on safe distance requirements or land use planning. However, it is important to note that blends of hydrogen exceeding 20% can result in reduced thermal radiation distances compared to pure natural gas. Furthermore, a comparison between pure hydrogen and pure natural gas using the leak frequencies Bayesian approach proposed by SANDIA revealed lower individual and societal risk values associated with hydrogen. However, it is worth noting that when using the current leak frequencies for natural gas and applying them to the hydrogen case, there was a slight increase in risk values. This increase can be attributed to the higher ignition probability of hydrogen compared to natural gas.

These findings emphasize the critical importance of conducting comprehensive studies and developing realistic leak frequency data. By doing so, researchers and industry groups can obtain a more accurate assessment of the risks associated with hydrogen transportation. This, in turn, will facilitate the development of appropriate safety measures that effectively mitigate potential hazards. Moreover, collaboration between researchers, industry stakeholders, and regulatory bodies is vital for establishing standardized methodologies and guidelines for assessing hydrogen-related risks.

Abbreviations

- f :

-

Spent time by an individual during a year

- ṁ:

-

Releasing Flowrate

- ?e:

-

Gaseous Density

- 𝛾:

-

Specific Heat Ratio

- R:

-

Ideal Gas Constant

- T0 :

-

Initial Temperature

- H2 :

-

Hydrogen

- QRA:

-

Quantitative Risk Assessment

- HSE:

-

Health and Safety Executive

- HIAD:

-

Hydrogen Incident and Accident Database

- CCPS:

-

Centre for Chemical Process Safety

- EGIG:

-

European Gas Pipeline Incident Data Group

- ALARP:

-

As Low as Reasonably Practicable

- PHAST:

-

Process Hazard Analysis Software Tool

- IOGP:

-

International Oil and Gas Producers

- FTA:

-

Fault Tree Analysis

- ETA:

-

Event Tree Analysis

- ESDs:

-

Event Sequence Diagrams

- MIE:

-

Minimum Ignition Energy

- IRPA:

-

Individual Risk Per Annum

- R2P2:

-

Reducing risks, protecting people

- LSIR:

-

Location-Specific Individual Risk

- PFD:

-

Process Flow Diagram

- MMSCFD:

-

Million Standard Cubic Feet Per Day

- NG:

-

Natural Gas

- SANDIA:

-

Sandia National Laboratories

- NOAA:

-

National Oceanic and Atmospheric Administration

- DNV:

-

Det Norske Veritas

- LFL:

-

Lower Flammable Limit

- DDT:

-

Deflagration to Detonation Transition

- FN:

-

Frequency-Number of Fatalities

- IR:

-

Individual Risk

References

Staffell I, Scamman D, Abad AV, Balcombe P, Dodds PE, Ekins P, Shah N, Ward KR (2019) The role of hydrogen and fuel cells in the global energy system. Energy Environmental Science 12:463–491

Isaac T (2019) HyDeploy: The UK’s First Hydrogen Blending Deployment Project

Witkowski A, Rusin A, Majkut M, Stolecka K (2018) Analysis of compression and transport of the methane/hydrogen mixture in existing natural gas pipelines. Int J Press Vessels Pip 166:24–34

Lipiäinen S, Lipiäinen K, Ahola A, Vakkilainen E (2023) Use of existing gas infrastructure in European hydrogen economy. Int J Hydrog Energy 48(80):31317–31329

Aarskog FG, Hansen OR, Strømgren T, Ulleberg Ø (1 2020) Concept risk assessment of a hydrogen driven high speed passenger ferry. Int J Hydrog Energy 45(2):1359–1372

Wu X, Zhang H, Yang M, Jia W, Qiu Y, Lan L (2022) From the perspective of new technology of blending hydrogen into natural gas pipelines transmission: mechanism, experimental study, and suggestions for further work of hydrogen embrittlement in high-strength pipeline steels. Int J Hydrog Energy 47(12):8071–8090

Pluvinage G, Capelle J, Hadj Meliani M (2019) Pipe networks transporting hydrogen pure or blended with natural gas, design and maintenance. Eng Fail Anal 106:104164

Astbury G, Hawksworth S (2007) Spontaneous ignition of hydrogen leaks: a review of postulated mechanisms. Int J Hydrog Energy 32:2178–2185. https://doi.org/10.1016/j.ijhydene.2007.04.005

Dagdougui H, Garbolino E, Paladino O, Sacile R (2010) Hazard and risk evaluation in hydrogen pipelines. Manage Environ Qual 5:1477–7835. https://doi.org/10.1108/14777831011067971

Viana F, Alencar M, Ferreira RJP, Almeida ATD (2022) Multidimensional risk assessment and categorization of hydrogen pipelines. Int J Hydrog Energy 47(42):18424–18440

Jo Y-D, Ahn BJ (2006) Analysis of hazard area associated with hydrogen gas transmission pipelines. Int J Hydrog Energy 31(14):2122–2130

Russo P, Marco AD, Parisi F (2020) Assessment of the damage from Hydrogen Pipeline explosions on people and buildings. Energies 13(19):5051

Li Y, Kuang Z, Fan Z, Shuai J (2023) Evaluation of the safe separation distances of hydrogen-blended natural gas pipelines in a jet fire scenario. Int J Hydrog Energy 48(49):18804–18815

Jeong S, Jang D, Lee M (2022) Property-based quantitative risk assessment of hydrogen, ammonia, methane, and propane considering explosion, combustion, toxicity, and environmental impacts. J Energy Storage 54:105344

Yousefpour F, Hoseyni SM, Hoseyni SM, Hashemi Olia SA, Karimi K (2017) Creep rupture assessment for Level-2 PSA of a 2-loop PWR: accounting for phenomenological uncertainties. Nucl Sci Tech 28(8):1–9

Pourgol-Mohammad M, Hoseyni S, Hoseyni S, Sepanloo K (2016) A practical sensitivity analysis method for ranking sources of uncertainty in thermal–hydraulics applications. Nucl Eng Des 305:400–410

CCPS (2000) GUIDELINES FOR Chemical Process Quantitative Risk Analysis, SECOND ed

Spouge J (2005) A guide to quantitative risk Assessment for Offshore installations. Energy Institute

Hoseyni SM, Yousefpour F, Araei AA, Karimi K, Hoseyni SM (2014) Effects of soil-structure interaction on fragility and seismic risk; a case study of power plant containment. Ournal Loss Prev Process Industries 32:276–285

Hoseyni SM, Francesco DM, Zio E (2019) Condition-based probabilistic safety assessment for maintenance decision making regarding a nuclear power plant steam generator undergoing multiple degradation mechanisms. Reliability Engineering System Safety 191:106583

Hoseyni SM, Hoseyni SM, Yousefpour F, Karimi K (2017) Probabilistic analysis of containment structural performance in severe accidents. Int J Syst Assur Eng Manage 8:625–634

Lees F (2012) Lees’ loss prevention in the process industries: hazard identification, assessment and control. Butterworth-Heinemann, Amsterdam

IOGP (2010) IOPG Report 434-7 Consequence modelling

IOGP (2023) Vulnerability of humans

Ehrhart BD, Hecht ES (2022) SANDIA REPORT Hydrogen Plus Other Alternative Fuels Risk Assessment Models (HyRAM+) Version 5.0 Technical Reference Manual

CCPS (2021) In: Benintendi R (ed) Process safety calculations (Second Edition). Elsevier, pp 623–644

Boult M (2000) Risk management of LPG transport activities in Hong Kong. J Hazard Mater 71(1):85–100

HSE (2001)

Tools H (2023) Hydrogen Compared with Other Fuels, 7 [Online]. Available: https://h2tools.org/bestpractices/hydrogen-compared-other-fuels

Al-Douri A, Ruiz-Tagle A, Groth KM (2023) A quantitative risk assessment of hydrogen fuel cell forklifts. Int J Hydrog Energy, 6

DNV (2023) QRA and risk analysis software - Phast and Safeti

Li Y, Kuang Z, Fan Z, Shuai J (2023) Evaluation of the safe separation distances of hydrogen-blended natural gas pipelines in a jet fire scenario. Int J Hydrog Energy, 2

Ehrhart BD, Hecht ES, Groth KM (2021) SANDIA REPORT Hydrogen Risk Assessment Models (HyRAM) Version 3.1 Technical Reference Manual

Tchouvelev AV (2008) Risk assessment studies of hydrogen and hydrocarbon fuels fuelling stations: description and review. Revision 1, IEA:; International Energy Agency (IEA). Hydrogen Implementing Agreement. X, p. Medium. Size: 86 pages.

NOAA, Classes PS (2023) [Online]. Available: https://www.ready.noaa.gov/READYpgclass.php

Jafari MJ, Zarei E, Badri N (2012) The quantitative risk assessment of a hydrogen generation unit, 12 [Online].

Pio G, Carboni M, Mocellin P, Pilo F, Vianello C, Maschio G, Salzano E (2022) Jet fires of hydrogen-methane mixtures. Chem Eng Trans 91:289–294

Defteraios N, Kyranoudis C, Nivolianitou Z, Aneziris O (2020) Hydrogen explosion incident mitigation in steam reforming units through enhanced inspection and forecasting corrosion tools implementation. J Loss Prev Process Ind 63:104016

Mahajan D, Tan K, Venkatesh T, Kileti P, Clayton CR (2022) Hydrogen Blending in Gas Pipeline Networks—A Review, Energies, vol. 15, no. 10, 5

Even Ø, Tysdahl (2020) A BBN Risk Analysis of Cruise Ship groundings in Northern Norway during Winter

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Amer, M.O., Hoseyni, S.M. & Cordiner, J. Fuelling the Future with Safe Hydrogen Transportation Through Natural Gas Pipelines: A Quantitative Risk Assessment Approach. Trans Indian Natl. Acad. Eng. (2024). https://doi.org/10.1007/s41403-024-00482-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41403-024-00482-7