Abstract

Studies on captan, boscalid and trifloxystrobin residues in apples of four varieties treated within 2 months before their harvest were carried out. Just after the application of Captan 80 WG on July 28 at rates 1.9 kg per ha on each of those varieties, the average captan residues were in the range from 3.19 ± 1.01 to 4.76 ± 1.54 mg kg−1, while after the treatment using Bellis 38 WG on August 29, the average boscalid residues ranged from 0.19 to 0.50 mg kg−1. Based on the obtained exponential equations, decay rate constants (k) of captan on the varieties Golden Delicious and Gloster were 0.164 and 0.127 day−1, while on Elise and Gala they were 0.141 and 0.213 day−1. Captan residues, when applied on July 31, within 32–51 days should drop below 0.0051 mg kg−1, while if applied a month later they were still significantly higher than 0.01 mg kg−1. After the application of Bellis 38 WG, carried out just before September 16, the average boscalid residues were 0.25 mg kg−1 (Golden Delicious), 0.36 mg kg−1 (Gloster) and 0.33 mg kg−1 (Elise), and at harvest they were below 0.25 and 0.36 mg kg−1 (Golden Delicious and Gloster), 0.10 mg kg−1 (13 days after last treatment) and below 0.18 mg kg−1 (a week before harvest), and they remained still significantly higher than the residues allowed in products designed for babies and toddlers 0.01 mg kg−1.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Apples are the basic fruits produced and used in Poland [3, 7]. They are eaten as fresh fruits, preferably straight from the tree, though, usually after several months of cold storage in a controlled atmosphere [20]. The need to store apples, before they are transported to the consumer, forces growers to protect fruits during the storage, what is realized out by spraying apple trees at 14 and/or 7 days before harvest (pre-harvest intervals; PHIs). Deposits of fungicides, that appeared on the fruits immediately after the treatments, and then, remained on the subsequent days, are a necessary condition for effective protection. It is, therefore, obvious that those treatments generate the highest residues. Storage of fruits at controlled atmosphere, even over several months, does not cause major changes in residue levels [16].

However, the apples with particularly valuable properties, as the sweet variety Golden Delicious [10], which are used for the production of baby food, require special protection [8, 18]. Such the program has been prepared by the Institute of Pomology in Skierniewice [9]. Moreover, the baby food manufacturers have imposed further restrictions and, as a result, the protection program of apple trees against pests and diseases must terminate at the end of June. This program does not solve all problems of growers. So the key question is when to carry out the final treatments in apple orchards that the fruits could meet the rigorous standard of 0.01 mg kg−1 set by the EU baby food directive [2]. This concerns above all the very valued plant protection products based on captan, which belongs to the phthalimide fungicides, and is used at a relatively high application rate.

The aim of the study was to determine captan and boscalid residues after their applications in the formulations Captan 80 WG and Bellis 38 WG, in apple orchards of four varieties: Golden Delicious, Gloster, Elise and Gala. Another objective of the study was the assessment of their levels (in the light of the toxicological and legal aspects in force in the year when the study was conducted) for both adults and toddlers, and to determine the period to elapse to decrease the average residue levels for captan, fungicide very valuable for the grower, below 0.01 mg kg−1, which is the standard for baby food.

Materials and methods

Field trials

The field trials were carried out in a commercial orchard (a total area of approx. 60 ha) in 2014 at 1 ha area for each of the four varieties, i.e., Golden Delicious (M26 rootstock), Gloster (M9 rootstock), Elise (P60 rootstock) and Gala (M26 rootstock). Distances between trees in the rows were 1 m for Gloster and 1.25 m for the remaining studied apple varieties. Height of the trees of all studied varieties ranged from 3.2 to 3.5 m. In each case, row distances were 4 m. Tree crowns of all investigated varieties were cut and shaped into a narrow spindle.

Totally, four trials were performed, and as a result, the levels of captan and boscalid residues in apples of different maturity just after treatments were determined. The mentioned substances were the active ingredients (AIs) of Captan 80 WG, Bellis 38 WG and Zato 50 WG, fungicides that effectively protect the apples against fungal diseases that develop also during the cold storage.

Spraying

For the treatments, an Agrola Optimum 1500 V cross-flow sprayer with a 1500 l tank and totally 18 nozzles (9 on each side) was used. Fungicides were applied with 400–500 l/ha using TXA 80015 VK hollow cone nozzles, insecticides with 700–750 l/ha using TXA 8003 VK hollow cone nozzles.

Sampling

The first treatments in the frame of our study were carried out on July 31, with the use of Captan 80 WG at the application rate 1.9 kg per ha, the equivalent to 1.52 kg of captan. Sampling started the next day after those treatments and was continued every week until the August 29. The first Bellis 38 WG application was carried out before the August 29, and the second one before the September 16. Then apple samples were collected on August 29 and September 16 and 29. On each sampling date and for each the combination of active ingredient—variety, four laboratory samples (each consisting of 8 mature fruits) were collected from eight randomly selected trees (1 apple from each tree) and then the samples were transported to the laboratory (2 h), where they were prepared for analysis by grinding and mixing (Blixer 4) to eliminate the probability of error as much as possible. Such prepared samples were frozen to −17 °C to avoid their decay during storage.

Extraction procedure

Analytical portions of mature fruits were homogenized in a Waring Commercial 8010 EG blender with 150 mL of acetone and filtered under vacuum in a Büchner’s funnel [14]. The blender jar was flushed with 50 mL of acetone, and the washings were used to wash the filter cake. One-fifth of the volume of the obtained filtrate was used for further analysis (the equivalent of approx. 15.4 g of fruits) and placed in a separatory funnel together with 100 mL of 2.5% solution of sodium sulfate (Na2SO4). The pesticide residues were extracted three times with 20, 10 and 10 mL of dichloromethane. The combined extracts were evaporated to dryness, dissolved in approx. 10 mL of petroleum ether and cleaned up on a Florisil mini-column [19]. Pesticides were eluted with 70 mL of a mixture of ethyl ether–petroleum ether 3:7 (v/v) and then 70 mL of the mixture of acetone–petroleum ether 1:9 (v/v).

Gas chromatographic determination

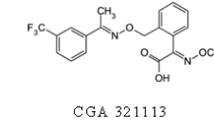

The final extracts were analyzed on Agilent 7890 gas chromatograph equipped with electron capture detector (µECD) and fused silica column (HP-5 MS Ultra Inert column, 30 m length, 0.32 mm I.D. and 0.25 µm film thickness). The temperatures of the injector and detectors amounted accordingly to 250 and 300 °C. Extracts of samples (2 µL) were injected in splitless mode. The oven temperature was programmed as follows: 100 °C—0 min → 10 °C/min → 180 °C—4 min → 3 °C/min → 220 °C—15 min → 10 °C/min → 260 °C—11 min; the total time of the analysis was 55.3 min. Nitrogen (purity 6.0, flow 4.14 mL min−1) was the carrier gas and the makeup gas for the ECD (30 mL min−1).

Method validation study

To ensure a quality of analytical results, the method was validated before the use to determine the fungicide residues in the apple samples [15]. Limits of Detection (LOD) for captan, boscalid and trifloxystrobin were, respectively, 0.002, 0.002 and 0.001, while Limits of Quantification (LOQ) were 0.005, 0.005 and 0.002.

Disappearance kinetics

Pesticide residues of the tested compounds were expressed in mg kg−1, and then for each the sampling day, their average levels, and also the amount in micrograms per single apple, were calculated. Nevertheless, the disappearance trends for captan residues were described by using exponential functions, corresponding to the first-order rate equation:

where R t represents the concentration (residue) of any pesticide after t time (in days), R 0 represents the initial concentration of the pesticide (in mg kg−1), and k is the rate constant (in day−1). Based on those equations, the half-life (t 1/2 = ln2/k) for each substance was determined, as well as R t=7 and R t=14, which represent their residue levels after 7 and 14 days (PHI),

and \(t_{{R = 0.01\;{\text{mg}}\;{\text{kg}}^{ - 1} }}\) represents the minimum time that must elapse before the residues fell below the level of 0.01 mg kg−1,

Derived from exponential equation, the average residue levels of the tested substances, immediately after their application (R 0; mg kg−1), were compared to Maximum Residue Levels (MRLs), as well as they were used for estimation the Safe Consumption Level (SCL; kg) of apples for toddlers [body weight (b.w.) = 16.7 kg] and for adult consumers (b.w. = 60.0 kg) according to the following equation:

Results and discussion

Spraying program and sampling

Generally, in Poland the program of orchard protection against pest and diseases is based on the principles of Integrated Plant Protection (IPP). However, in order to realize the aims of our study, the grower applied the Captan 80 WG (application rate: 1.52 kg of captan per hectare) on July 31, therefore, 1 month later than it is recommended for protection of apple varieties intended for the production of baby food. Sampling started on August 1, and then it was continued for a period of 2 months (Table 1), at weekly intervals until the next treatment using Captan 80 WG on August 29 and, then, in every 2 weeks after the treatment using Bellis 38 WG, which was carried out on the day before August 29. Samplings were completed on August 29 (Gala), September 16 (Golden Delicious and Gloster) and September 29 (Elise), in the case of each variety 2–4 days before commercial harvest.

Residues of captan, boscalid and trifloxystrobin in apple fruits for 6–8 weeks to harvest

The average captan residues in apples of four varieties, taken for analysis just after the treatments carried out on July 31 in 2014, were differentiated, ranging from 3.19 to 4.76 mg kg−1 (what constituted from 100 to 150 of the MRL established for captan in ripe apples at the level of 3 mg kg−1 [5]), while the average boscalid residues after the treatments carried out on the day before August 29, mainly due to its application rate, were on lower levels from 0.18 to 0.50 mg kg−1 (from 9 to 25% of MRL set at 2 mg kg−1 [4]). Based on the average mass of a single apple (from 106.0 to 121.1 g; see Tables 2, 3, 4, 5), the average amounts of captan, which was deposited on apple surfaces during spraying on August 31, ranged from 350 to 507 µg per single fruit, while the average amounts of boscalid, which was deposited on apple surfaces during spraying on the day before the August 29, ranged from 27.9 to 87.4 µg per single fruit. Such the significant differences among the average residues, as well as among the average amounts of captan and boscalid in a single fruit, might be attributed to their natural variability, due to uneven distribution of the PPP on the surface of the fruit. The average captan and boscalid residues in successive sampling dates are presented in Tables 2, 3, 4 and 5.

In laboratory samples of apples of four varieties taken for analysis on August 1, the average trifloxystrobin residues, after its application in the formulation Zato 50 WG on May 9 and 27, were at the level of 0.003–0.006 mg kg−1 (from 0.6 to 1.2% of MRL set at 2 mg kg−1 [6]), therefore significantly below the standard for baby food (0.01 mg kg−1), and then in ripe fruits (about 2 months later) were slightly above the Limit of Detection (0.001 mg kg−1).

Golden delicious

The initial captan and boscalid residues in Golden Delicious were proportional to their application rates, i.e., 1.52 and 0.192 kg ha−1, respectively (Table 1). As a result, just after the treatment with Captan 80 WG, captan residues in apples with an average single fruit mass of about 109.7 g reached the average level 3.19 ± 1.01 mg kg−1 and then dropped significantly, probably due to weather conditions, within the next week after the treatment, consequently, before the next application, carried out on the day before August 29, was 0.14 ± 0.11 mg kg−1. On August 29, the average captan residue was slightly higher 3.86 ± 1.92 mg kg−1, and before harvest (PHI: about 20 days) was, on average, 1.23 ± 0.22 mg kg−1, therefore, constituted 41% of MRL (Table 2).

The average boscalid residues after treatments carried out on the day before August 29 and September 16 were 0.19 ± 0.03 and 0.25 ± 0.09 mg kg−1, therefore constituted 9.5 and 12.5% of its MRL for apple, respectively (Table 2).

Gloster

Gloster variety was sprayed on the same date, and, therefore, just after the treatment, the captan and boscalid residues were on similar levels to those found in apples of Golden Delicious variety. Thus, the average captan residue after the Captan 80 WG application on July 31 reached a value 4.46 ± 1.00 mg kg−1 (the average mass of apple was 106.0 g) and then dropped significantly within the first week, and before the next application was 0.34 ± 0.21 mg kg−1. After the treatment, the average captan residue was 1.31 ± 0.47 mg kg−1 and then, a week before harvest (PHI: over 18 days), its residue was 1.09 ± 0.18 mg kg−1, therefore, constituted more than 30% of MRL (Table 3).

The average boscalid residues on August 29 and September 16 were, respectively, 0.20 ± 0.15 and 0.36 ± 0.13 mg kg−1 (10–18% MRLs) (Table 3).

Elise

The captan residue after the treatment carried out on July 31 reached the average level 3.80 ± 1.00 mg kg−1 (127% of MRL), while the average boscalid residues after the treatments carried out just before sampling on August 29 and September 16 were, respectively, 0.50 ± 0.23 and 0.33 ± 0.09 mg kg−1 (25 and 16.5% of MRL). Captan residues dropped significantly within the first week after its application on July 31 and before the next application on August 14 was, on average, 0.62 ± 0.79 mg kg−1. After the next treatment, the average captan residue was 1.63 ± 0.56 mg kg−1 (54% of MRL) and dropped by more than 50% of the initial level, while boscalid residue was 0.33 ± 0.09 mg kg−1 and dropped by more than 30% of its MRL (Table 4).

Gala

The average captan residue reached the highest value 4.76 ± 1.54 mg kg−1 (160% of MRL), while the average boscalid residue was 0.18 ± 0.21 mg kg−1 (9% of MRL). Captan residues dropped significantly within the first week after its application on July 31 and before the second application was still at relatively high level 1.25 ± 1.92 mg kg−1. After the next treatment carried out on August 22, the average captan residue was 3.35 ± 1.77 mg kg−1; therefore, within the week, it dropped also by more than 30% of MRL (Table 5).

Dissipation of captan deposits on apples

In general, the initial amount of any AI of PPP reaching the plant surface (also apples) decreases according to two factors: biological dilution (mass growth of a single fruit) and a real disappearance (caused by volatilization, rainfall and/or the degradation process) [1, 13].

Dissipation trends of captan deposits in apples, expressed in mg kg−1 and in µg per single fruit after the application of Captan 80 WG on July 31, were described by exponential equations, which, in the cases of Gloster, Elise and Gala, were fit very well (correlation coefficients: from 0.9383 to 0.9897). Based on all established exponential equations, decay rate constants (k) of captan residue for Golden Delicious and Gloster, were 0.164 and 0.127 day−1, while for Elise and Gala varieties were 0.141 and 0.213 day−1. The amount of captan in the single apples was decreasing quite similarly, though significantly slower (Table 7: k = 0.149 vs. k = 0.164, k = 0.110 vs. k = 0.127, k = 0.126 vs. k = 0.141 and k = 0.194 vs. k = 0.213 day−1) (Table 6).

According to parameters of exponential dissipation (Table 6), the captan residues after 7 and 14 days (potential PHIs for captan) for different apple varieties should be in the range from 0.6 to 1.41 mg kg−1 and from 0.20 to 0.47 mg kg−1, respectively. It means that at the same time the captan quantities in a single apple after 7 and 14 days should be at the range from 81 to 179 µg and from 29 to 83 µg, respectively.

Based on the parameters of exponential equation, we calculated also the approximate period required for the reduction in the average captan residue to the level of 0.005 mg kg−1, equivalent to 0.75 µg in a single ripe apple weighing about 150 g. The results obtained indicated that within 32 (Gala variety) and 57 days (Gloster) after the treatment, the mean captan residues (Table 6) should drop below the rigorous standard of 0.01 mg kg−1, established for baby food by Commission Directive 2006/141/EC.

Disappearance of boscalid

Just after the application of Bellis 38 WG, made on the day before August 29, the average residues of boscalid in apple samples of the varieties Golden Delicious, Gloster, Elise and Gala, were 0.19; 0.20, 0.50 and 0.18 mg kg−1, respectively, while after the treatments carried out before September 16 were 0.25, 0.36 and 0.33 mg kg−1 and before harvest were, respectively, 0.09 (13 days after last treatment), 0.36 (a week after last treatment), 0.10 (13 days after last treatment) and 0.18 (a week after last treatment).

Disappearance of trifloxystrobin

Surveys of trifloxystrobin residues were included in our studies due to unpublished reports of long persistence of this substance in fruits, and its potential redistribution which may cause residues in ripe apples at the level above 0.01 mg kg−1. According to the statement of the grower, Zato 50 WG has been used twice on May 9 and 27. Trifloxystrobin residues persisted throughout the study period but the level of 0.01 was found only in apples of Gloster variety taken for analysis on August 22.

Pesticide residues in ripe apples and their daily intakes versus Maximum Residue Levels (MRLs) and Acceptable Daily Intakes (ADIs)

According to European Commission, the Maximum Residue Level (MRL) is the highest level of a pesticide residue (active ingredients of plant protection products) that is legally tolerated in food or feed when pesticides are applied in accordance with [12]. MRLs, therefore, are derived after a comprehensive assessment of the properties of the active substance and from the field trials carried out according to the Good Agricultural Practices (GAP) defined for a given crop. An indispensable precondition for setting MRLs is estimation of consumer’s health hazards (the residue intake by a consumer must not exceed the toxicological reference values).

Captan residues, a week before harvest of ripe apples, ranged from 0.75 (Elise) to 1.75 mg kg−1 (Gala) and accounted for no more than 60% of the current MRL (Gala). Due to lower application rate, boscalid residues ranged from 0.10 (Elise) to 0.36 mg kg−1 (Gloster) and thus accounted for no more than 20% of the current MRL (Gloster variety). Trifloxystrobin residues, the result of Zato 50 WG application on May 7 and 20, were detected at a trace level close to 0.001 mg kg−1 (Table 7).

To estimate the consumer’s health hazards based on ADI levels [4–6, 11], we decided to calculate, and compare, the SCLs for ripe apples containing possibly the highest residue levels before harvest. As can be seen in the Table 7, the estimated SCLs of apples by toddlers at a daily basis over a lifetime without an appreciable health risk were not less than 1.0 kg for toddlers (Gala variety) (after two applications of Captan 80 WG, carried out 2 months and 2–4 weeks before harvest) and 3.4 kg of apples by adult consumer. Consumption of fresh apples which contained residues as those found in our study immediately before harvest should be safe for the both groups of consumers. In general, Acute Reference Doses (ARfDs) are set two to five times larger than ADIs. For the Captan, ARfD has been set at 0.3 mg/kg b.w. Therefore, in the light of the obtained results, we can conclude that apples containing captan and boscalid residues should not cause any acute health problems. The more that in Poland, in 2014, their average daily consumption per capita was less than 0.04 kg [17].

Conclusions

The average captan residues in apples of the four varieties immediately after treatments with Captan 80 WG, carried out on July 31 (about 2 months before harvest), were in the range from 3.19 to 4.76 mg kg−1, while after treatments carried out on the day before August 22 and 29, they were 1.63 and 3.35 mg kg−1 (Elise and Gala), and 3.86 and 1.31 mg kg−1 (Golden Delicious and Gloster), respectively.

Just after applications of Bellis 38 WG, made before August 29, the average boscalid residues in apples of Golden Delicious, Gloster, Elise and Gala varieties averaged: 0.19; 0.20, 0.50 and 0.18 mg kg−1, respectively, while in apples of Golden Delicious, Gloster, Elise after the treatments before September 16 were 0.25, 0.36 and 0.33 mg kg−1.

Two to four days before harvest, the average captan residues ranged from 0.75 (Elise) to 1.75 mg kg−1 (Gala); therefore, it accounted for no more than 60% of its previous MRL.

Due to lower application rate, the average boscalid residues were contained in the range from 0.10 (Elise) to 0.36 mg kg−1 (Gloster) and thus accounted for no more than 20% of the current MRL (Gloster variety).

Trifloxystrobin residues, the result of Zato 50 WG application on May 7 and 20, were detected at a trace level close to 0.001 mg kg−1.

Safe consumption level of apples was larger than 1.0 kg for toddlers (Gala variety) and 3.4 kg for adult consumers, even if two applications of Captan 80 WG were carried out for 2 months and, consequently, 2–4 weeks before harvest. Therefore, consumption of fresh apples containing captan residues as those in our study in a week before harvest should be safe for the both groups of consumers. Based on the established trend of exponential decay for captan, we found that Captan 80 WG must be applied not later than 2 months before the harvest since mature apples do not contain the residues above 0.01 mg kg−1.

References

Bedos, C., Cellier, P., Calvet, R., Barriuso, E., & Gabrielle, G. (2002). Mass transfer of pesticides into the atmosphere by volatilization from soils and plants: overview. Agronomie, 22, 21–33.

Commission Delegated Regulation (EU) 2016/127 of 25 September 2015 supplementing Regulation (EU) No 609/2013 of the European Parliament and of the Council as regards the specific compositional and information requirements for infant formula and follow-on formula and as regards requirements on information relating to infant and young child feeding. Official Journal of the European Union. 2.2.216. L25/1.

Dmochowska, H. (ed.) (2015). Concise statistical yearbook of Poland 2015. Central Statistical Office. Statistical Publishing Establishment. Warszawa 2015. http://stat.gov.pl/obszary-tematyczne/roczniki-statystyczne/roczniki-statystyczne/maly-rocznik-statystyczny-polski-2015,1,16.html. Accessed 09 June 2016.

EFSA (European Food Safety Authority). (2014). Reasoned opinion on the review of the existing maximum residue levels (MRLs) for boscalid according to Article 12 of Regulation (EC) No 396/2005. EFSA Journal, 12(7), 3799.

EFSA (European Food Safety Authority). (2014). Reasoned opinion on the review of the existing maximum residue levels (MRLs) for captan according to Article 12 of Regulation (EC) No 396/2005. EFSA Journal, 12(4), 3663.

EFSA (European Food Safety Authority). (2014). Reasoned opinion on the review of the existing maximum residue levels (MRLs) for trifloxystrobin according to Article 12 of Regulation (EC) No 396/2005. EFSA Journal, 12(2), 3592.

Konopacka, D., Jesionkowska, K., Kruczyńska, D., Stehr, R., Schoorl, F., Buehler, A., et al. (2010). Apple and peach consumption habits across European countries. Appetite, 55(3), 478–483.

Łozowicka, B. (2015). Health risk for children and adults consuming apples with pesticide residue. Science of the Total Environment, 502, 184–198.

Olszak, R. W., & Bielenin, A. (2011). Plant Protection Program of Fruit 2011. Skierniewice: Research Institute of Pomology and Floriculture, Hortpress.

Paprštein, F., Blažek, J., & Michalek, S. (2006). Effects of climatic conditions on fruit quality of apple cultivars assessed by public sensory evaluations in the Czech and Slovak Republics 1999–2004. Journal of Fruit and Ornamental Plant Research, 14(2), 219–227.

EU Pesticides Database. http://ec.europa.eu/food/plant/pesticides/eu-pesticides-database/public/?event=product.selection&language=EN. Accessed 29 May 2016.

Regulation (Ec) No 396/2005 of the European Parliament and of the Council of 23 February 2005 on maximum residue levels of pesticides in or on food and feed of plant and animal origin and amending Council Directive 91/414/EEC. Official Journal of the European Union. 16.03.2005. L70.

Rose, M. T., Crossan, A. N., & Kennedy, I. R. (2008). The effect of vegetation on pesticide dissipation from ponded treatment wetlands: Quantification using a simple model. Chemosphere, 72, 999–1005.

Sadło, S., Szpyrka, E., Stawarczyk, M., & Piechowicz, B. (2014). Behavior of pyrimethanil, pyraclostrobin, boscalid, cypermethrin and chlorpyrifos residues on raspberry fruit and leaves of Laszka variety. Journal of Environmental Science and Health. Part B: Pesticides, Food Contaminants, and Agricultural Wastes, 49(3), 159–168.

Sadło, S., Walorczyk, S., Grodzicki, P., & Piechowicz, B. (2016). Usage of the relationship between the application rates of the active ingredient of fungicides and their residue levels in mature apples to creating a coherent system of MRLs. Journal of Plant Diseases and Protection. doi:10.1007/s41348-016-0015-2.

Sadło, S., Walorczyk, S., Grodzicki, P., & Piechowicz, B. (2016). Disappearance of captan, boscalid, pyraclostrobin and trifloxystrobin residues in ripe apples during cold storage under controlled atmosphere. Fresenius Environmental Bulletin, 6, 1959–1965.

Strojewska I. (2015). Spożycie owoców, warzyw i ich przetworów w Polsce. Rynek owoców i warzyw. Biuletyn informacyjny, 3, 2–10. http://www.arr.gov.pl/data/400/biuletyn_informacyjny_arr_3_2015.pdf. [in polish].

Szpyrka, E., & Walorczyk, S. (2013). Dissipation kinetics of fluquinconazole and pyrimethanil residues in apples intended for baby food production. Food Chemistry, 141, 3525–3530.

Valverde-Garcia, A., Gonzalez-Pradas, E., & Auilera-del Real, A. (1993). Analysis of buprofezin residues in vegetables: Application to the degradation study on eggplant grown in a greenhouse. Journal of Agricultural and Food Chemistry, 41, 302–308.

Villatoro, C., Lopez, M. L., Echeverria, G., & Graell, J. (2009). Effect of controlled atmospheres and shelf life period on concentrations of volatile substances released by ‘Pink Lady’ apples and on consumer acceptance. Journal of the Science of Food and Agriculture, 89, 1023–1034.

Acknowledgements

Funding was provided by Financial support of the University of Rzeszów (Grant No. 507).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Sadło, S., Grodzicki, P. & Piechowicz, B. Dissipation of captan, boscalid and trifloxystrobin residues in apples of four varieties within 2 months before their harvest. J Plant Dis Prot 124, 177–184 (2017). https://doi.org/10.1007/s41348-016-0069-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41348-016-0069-1