Abstract

The demand for the autonomous adaptive control of manufacturing lines has been growing to realize productivity improvement and carbon neutrality. We propose a methodology to realize the autonomous control of product quality under the existence of effects from non-measurable parameters. By local linear regression modeling with temporal neighborhood data, a single manufacturing parameter is selected by the obtained regression coefficients. Simulation results demonstrated that the straightforward multiple regression modeling often resulted in unstable control behavior with vibrations in product quality. We tested three approaches (scaling the amount of control, introduction of control interval, and semiparametric regression modeling for regression) to cope with the unstable behavior. The semiparametric regression model exhibited the best performance in realizing the stable control by correctly selecting the control target parameter with the additional non-linear term, that compensates the time-dependent non-measurable parameters.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, thanks to the development of IT systems in the field of production industry, it became possible to record huge amount of data by sensors integrated in manufacturing lines. This enables us to real-time monitor the current situation of the manufacturing lines, opening a door to autonomous control by computers without manual operations. To appropriately control in response to the time-dependent changes occurring in the manufacturing lines, conventional manual control needs skilled workers who deeply understands the behavior of the manufacturing lines with a long-time operation experience. To mimic the manual operations by skilled workers, we have to build a methodology of autonomous adaptive control, which can adaptively respond to the changes in the manufacturing process without manual intervention. The demand for the autonomous adaptive control has been growing to reduce the labor cost, to address labor shortage, to set up early a new factory including a brand-new manufacturing line, and so on. In addition, the autonomous control enables us to quickly correct deviations of product quality from the ideal values by high-frequency control, which is not possible by manual control. This will eliminate the need for additional processing of the products required to correct the deviations, thereby contributing to carbon neutrality by reducing CO2 emissions.

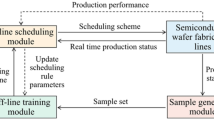

One of the promising approaches to realize the adaptive control is a model predictive control (MPC). In MPC, a model of a target system is constructed from the stored data and use its predictions to determine the next input for control. This repeated loop of on-line prediction with system modeling enables to control most of the control problems including the manufacturing industry (Kano and Ogawa 2009; Schwenzer et al. 2021). In particular, in the field of semiconductor manufacturing systems, run-to-run (R2R) control approach is widely used with the combination of MPC algorithm (Liu et al. 2018).

The existence of many variables in manufacturing lines affecting the quality of output products is one of the most difficult aspects to realize the control of quality of output products. One of the approaches to cope with this difficulty is to realize the dimension reduction. Lasso approach was utilized to select the control parameter for controlling complex IT systems with multiple tunable parameters (Yao et al. 2015). Principal component analysis (PCA) was also used for the dimension reduction in control procedures (Jackson and Mudholkar 1979).

Another difficulty in controlling multivariable systems is the existence of non-measurable variables. Some of the variables are observable as they are input for manufacturing equipment or easy to observe with low-cost or easy-to-install sensors. Meanwhile, some of them are not-observable because of the high-cost or impossible-to-install sensors. In this situation, it is useful to refer to the concept of soft sensor (Curreri et al. 2020), which is an inferential model to estimate the hard-to-observe variables from observable variables. The predictive accuracy of soft sensors often decreases by the time-dependent change of target system, which is called model degradation (Kaneko and Funatsu 2013a). Three approaches have been proposed to cope with the model degradation. A moving window (MW) model (Joe Qin 1998; Kaneko et al. 2009) uses most recently observed data points to construct the soft sensor models. A just-in-time (JIT) model (Kaneko et al. 2009) uses data points whose distances to the current data point are small. A time difference (TD) model (Kaneko and Funatsu 2011, 2013b) uses the time difference of variables. One of the important aspects of these approaches is to use a limited range of data points which should include information on the behavior of the current target system from the stored data. This idea is a sort of lazy learning, which has been utilized in a wide range of applications (Aha 1997).

In this work, we conducted a preliminary study to realize the autonomous adaptive control of manufacturing lines. We borrow the idea of on-line modeling from MPC and MW model from soft sensors. In our method, to keep the product quality, we determine input manufacturing parameters used for the next item production based on the on-line statistical linear models built from the recently observed data points. Finally, the performance of our method was evaluated by control simulations.

2 Target system for control including non-measurable variables

2.1 Product quality in manufacturing lines by MISO process

In this paper, we describe control methodology to keep the product quality in manufacturing lines. To model the manufacturing lines, the target quality is assumed to be described by a multiple input single output (MISO) system. The input parameters are a wide variety of parameters involved in manufacturing lines, e.g., coolant temperatures, pressing pressures, feed rates, surrounding humidity, and so on. The output is the product quality mostly determined by the input parameters. Our goal is to stably keep the product quality in control limits. However, this goal is often difficult to achieve because of non-measurable changes of several parameters, e.g., coolant temperatures depending on weather conditions, degradation of cutter equipment, and so on. Some of them (such as coolant temperature) can be measured by installing sensors but it requires a budget. And worse, it is often impossible to directly observe some parameters (such as degradation of cutter).

In the following discussion, we assume the existence of such non-measurable variables, whose behavior is unknown and unobservable.

2.2 Control triggering by control chart

Control chart (Porter and Caulcutt 1992) is one of the mostly used statistical process control tools to keep the product quality in manufacturing lines. We use this chart to detect the necessity of control intervention. Figure 1 provides an example of a control chart. The qualities of the product items are measured as y(t) (plotted as gray dots), where t is the timestamp of product items. We keep the product quality near the target value [center line (CL)] by control interventions triggered by the deviation from the range between upper limit of control (UCL) and lower limit of control (LCL). It should be noted that the tolerance of the product is further away from the LCL/UCL and thus products out of the LCL/UCL does not always be the defective products.

We detect the necessity of control interventions by LCL/UCL range of the control chart. For example, when the quality of the latest product item is larger than the UCL, a control intervention is needed to decrease the quality of the succeeding items. As a trivial idea, it is possible to consider a simple condition of y(t) out of the LCL/UCL range. However, this would result in unstable control behavior because the deviation can be caused by a large noise spike. To avoid this instability, we adopt a simple moving average (SMA) for the triggering condition: SMA of y(t) is out of the LCL/UCL range.

2.3 Generation process of product quality

In this section, we describe the assumed generation process of product quality. For each product item at timestamp t, p-dimensional manufacturing parameter x(t) is recorded as column vectors

Additionally, q-dimensional non-measurable parameter h(t), such as coolant temperature and degradation of equipment, for the same product is assumed as column vectors

Then, the product quality y(t) is determined by a function f with a noise term e(t) as

For the control of quality y(t), we can use only the information x(t) in the following discussion.

3 Control algorithm of product quality by local data regression

3.1 Amount of target control determined by control chart

As described in the previous section, control intervention is triggered when the SMA of product quality y(t) is out of the range of LCL/UCL. Here, we determine the amount of control on y, yint, in the control intervention. As a simple approach, to match the target CL and the quality after the control intervention, the value is calculated as

where \({\text{SMA}}(y(t)) = \frac{1}{k}\sum\limits_{\tau = t - k + 1}^{t} {y(\tau )}\) is a simple moving average of y(t) with the number of time periods k. The moving averaging was adopted to reduce the effect of noise on y(t) in the control operations.

3.2 Local regression modeling of product quality

After determining the control amount yint, we calculate the amount of control on the manufacturing parameter x. To this end, we need a model describing the relationship between y and x. We assume that the manufacturing line is under operation within a stable region and thus the relationship between x and y can be approximated by linear regression models. Because of the existence of non-measurable variable h, global regression analysis with all the observed data {x(t), y(t)} (t = 1, …, n), where n is the number of observed data points, suffers from the model degradation and not appropriate in our goal to realize adaptive control. Accordingly, we use an adaptive local regression approach to follow the h changes by MW approach. The data for linear regression is limited to the temporal neighborhood as {x(t), y(t)} (t = n–tw+1, n–tw +2,…, n), where tw is the length of the time window.

We tested two linear regression modeling. The first one is a simple multiple regression model as

where \({{\varvec{\upbeta}}} = \left( {\beta_{1} ,\beta_{2} , \ldots \beta_{p} } \right)^{{\text{T}}}\) is a regression coefficient column vector, and β0 is an intercept. This equation assumes that the function f(x(t), h(t)) in Eq. 3 is approximated by the formula βTx(t) + β0. The second one is a semiparametric regression model (SRM) as

where s(t) is a time-dependent non-linear function. As we will discuss later, the term s(t) can well describe the changes derived from the non-measurable variable h, resulting in more accurate fitting of f(x(t), h(t)) by the formula βTx(t) + β0 + s(t) compared to the multiple regression model in Eq. 5. We used ‘gam’ function with default parameters in ‘mgcv’ R package (Wood 2011), which implements a generalized additive model regression, to execute SRM fitting. In this setting, the term s(t) is fitted by penalized regression splines based on generalized cross-validation criterion with thin-plate splines. (Wood and Augustin 2002).

3.3 Control volume determined by regression model

We have determined the control amount on y as yint and the linear models between y and x in Sects. 3.1 and 3.2, respectively. Next, we calculate the amount of control on manufacturing parameter x, xint. Since we use the regression coefficient vector β to obtain xint, our approach described below is common for both the modeling approaches, multiple linear regression and SRM.

For the application in manufacturing lines, we adopted a following requirement by the voice of workers; in each control operation, only one manufacturing parameter is adjusted with a minimum amount. This requirement is an important rule of thumb for conventional manual control by operators of the manufacturing lines. Thus, we first have to determine the control target variable xc from the p-dimensional vector x. We selected xc with the largest absolute value of t value of regression coefficient obtained by the regression modeling. Then, from the linear relationship between y and xc, the amount of control is calculated as

3.4 Tricks for stabilize control behavior

By the above-mentioned procedure, it is expected to successfully control MISO systems. However, as we will discuss later, it often results in unstable control behavior. To cope with the instability, we introduce following two approaches. The first is a scaling of the amount of control xint by an arbitrary scaling factor s (0 < s < 1) as sxint. The second is an introduction of control interval nint. During nint items of production after a control intervention, we do not trigger the control intervention. These approaches help the control to avoid the unstable behavior.

4 Control simulation conditions

We executed three simulations with different effects of time-dependent changes in non-measurable variable h(t). In this section, common conditions in all the simulations are described.

As described in Sect. 3.1, the control intervention is triggered by the deviation of SMA(y(t)) from the LCL/UCL range in control chart. The timestamp t is considered as a discrete variable with a cycle time 1 min. The operation of the manufacturing line begins at 8:30 with an initial product item, and after then the line produces one product item per the cycle time, 1 min. The parameters of the control chart are CL = 240, LCL/UCL = 200/280, and the tolerance of the product is 360/120 (i.e., a product item with quality y(t) > 360 or < 120 is a defective product). The period of the SMA for the control intervention judgement is 3-period. For the local regression modeling described in Sect. 3.2, the length of the time window tw is 25. The length of the vector x is p = 6.

In the simulations, the artificial data of manufacturing parameters x(t) and product quality y(t) are generated as follows. First, we consider the linear relationship between y and x. We set the target value \({\mathbf{x}}^{{{\text{target}}}} (t) = \left( {x_{1}^{{{\text{target}}}} (t), \ldots x_{6}^{{{\text{target}}}} (t)} \right)^{{\text{T}}}\) as the input value for the manufacturing process, and x is generated by adding a noise term to xtarget as

where N(μ, σ2) is a random number generated by normal distribution with mean μ and variance σ2. The noise term is added to reproduce the manufacturing variability. The initial values of xitarget(t) are given as simulation parameters and updated as

in each control intervention by Eq. 7. Then, the quality y(t) is generated by a linear formula with time-dependent regression coefficient vector β(t) and intercept term β0(t) including a noise term as

In our simulations, we consider the existence of time-varying non-measurable variable h(t) by giving a time-varying changes on coefficients as β(t) and β0(t).

We execute three simulations by the linear model with different time-dependent behavior of β(t) and β0(t). In all the simulations, the initial value of the target manufacturing parameter is set as xtarget = (0, 0, 0, 0, 0, 0)T and parameters of the noise terms are σxi2 = 1.0 (i = 1, …, 6) and σy2 = 6.0.

In simulation 1 [Fig. 2(a)], the intercept β0(t) linearly changes during the operation. The coefficient vector is constant as β = (10, 8, 6, 4, 0, 0)T and the initial value of the target manufacturing parameters is xtarget = (0, 0, 0, 0, 0, 0)T. The intercept changes as β0 = 240 (30 min from 8:30 to 8:59), linearly increase from 240 to 480 (120 min from 9:00 to 10:59), and β0 = 480 (30 min from 11:00 to 11:29). In simulation 2 [Fig. 2(b)], the β0(t) term changes discretely. The constant value is β = (10, 8, 6, 4, 0, 0)T and the initial value is xtarget = (0, 0, 0, 0, 0, 0)T. The intercept changes as β0 = 240 (30 min from 8:30 to 8:59), discretely changes to β0 = 170 and keeps (60 min from 9:00 to 9:59), and discretely changes to the initial value β0 = 240 and keeps (30 min from 10:00 to 10:29).

In simulation 3 (Fig. 2(c)), the β0 term shows a random walk and β1 changes linearly. Our purpose of this combination of changes in β0 and β1 is to show the versatility of our control procedure involving the time-dependent changes in the regression coefficients. The initial values are β = (10, 8, 6, 4, 0, 0)T, β0 = 140, and xtarget = (10, 0, 0, 0, 0, 0)T. The values are constant in the initial 30 min (from 8:30 to 9:00). Then, the random walk of β0 starts by adding N(0, 82) to β0 every minute and, at the same time, β1 changes linearly from 10.0 to 5.2 for 240 min (from 9:00 to 12:59). Finally, β and β0 are constant in the final 30 min (from 13:00 to 13:29).

5 Results and discussion

5.1 Stable and unstable control results for simulation 1

One of the results of simulation 1 by the linear regression modeling (Eq. 5) is shown in Fig. 3(a). The product quality y (top plot) is calculated from the manufacturing parameters x (bottom plot) and time-dependent β values in Fig. 2(a). During the initial 30 min (8:30 to 8:59), the β values are constant, and y is stable around the CL. Then, the linear increase of the intercept β0 forces y to deviate from the CL toward the UCL direction. Without control intervention, y continues to increase by the amount of change of β0, 240, and will exceed the tolerance of the product to produce defective products.

The initial control intervention was triggered at 9:13 by the criteria of 3-period SMA of y(t), 280.42, out of the LCL/UCL range. Before the intervention, the target value vector is constant as xtarget = (0, 0, 0, 0, 0, 0)T and xi(t) values fluctuates around 0. A local regression modeling was executed with a time window data from 8:49 to 9:13 (length of 25). The multiple regression by Eq. 5 with the data {x, y} resulted in β = (12.52, 3.85, − 1.95, 3.41, − 3.32, 1.27)T and t value of β = (7.10, 1.65, − 0.81, 1.81, − 2.16, 0.65)T. The coefficient of determination, R2, of the regression was 0.791. The control target variable x1 was determined by its largest absolute value of the t value. The amount of control for x1 was calculated by Eq. 7 as.

\(x_{1}^{{\text{int}}} = \frac{{{\text{CL}} - {\text{SMA}}(y(t))}}{{\beta_{1} }} = \frac{240 - 280.42}{{12.52}} = - 3.228\)

Then, this value is added to xtarget = (0, 0, 0, 0, 0, 0)T by Eq. 9 and the operation of the manufacturing line continues with xtarget = (− 3.228, 0, 0, 0, 0, 0)T. This control successfully pulls the quality back near the CL.

The second control intervention was triggered at 9:38. The local regression modeling from the time window data from 9:14 to 9:38 resulted in β = (7.97, 7.27, 9.69, 10.18, − 2.26, 2.42)T and t value of β = (2.66, 1.90, 2.43, 2.22, − 0.76, 0.77)T. The control variable was selected as x1 with its amount of control as − 5.345. The following control interventions were triggered at 10:01, 10.34, and 10:44 with the control variable x1, x3, and x1, respectively. As a result, this simulation successfully controlled the quality y within the LCL/UCL range by the local regression modeling.

The simulation described above properly controlled the quality y. However, another simulation with a different random seed affecting the terms N(0, σxi2) and N(0, σy2) in Eqs. 8 and 10 resulted in unstable vibrational behavior in y between 9:41 and 10:04 as shown in Fig. 3(b). This vibration was caused by the underestimation of β1. In the first control intervention of the vibration at 9:41 by the deviation out of UCL, the control target variable was selected as x1 with coefficient β1 = 7.98, which is smaller than the true value 10.0. As a result, the amount of control by Eq. 7 is overestimated compared with the ideal value obtained by the true coefficient 10.0. Then, the quality y was controlled too much and immediately out of the LCL. In the next control intervention, most of the local data for the local regression modeling is common with the previous control intervention and thus the tendency to underestimation was kept. This again overestimates the amount of control and repeats to trigger the control intervention. In summary, when the local data regression underestimates the regression coefficient, it often induces the undesirable vibrational behavior in the control process.

5.2 Solution to avoid control instability

To avoid the vibrational behavior, we adopted three approaches. The first and second are the scaling factor s and control interval nint as mentioned in Sect. 3.4, respectively. The former deals with the too large amount of control derived from the underestimation of regression coefficients. The latter avoids the immediate control intervention which often results in the vibrational behavior. The third is to use SRM instead of the multiple regression. The time-dependent β0 is expected to cause the low accuracy and precision of the multiple regression modeling. The introduction of time-dependent non-linear function s(t) in SRM is expected to consider the effect of β0 change and provide high precision regression coefficients.

We additionally executed three control simulations with the same random number seed used in Fig. 3(b) with the three approaches; with the scaling factor s = 0.5 [Fig. 4(a)], with the control interval nint = 3 [Fig. 4(b)], and with the SRM [Fig. 4(c)]. With the three approaches, the vibrational behavior observed in the original simulation in Fig. 3(b) was avoided, and the quality y was successfully controlled. It should be noted that, as a natural consequence, the number of control intervention 8 with the scaling factor is larger than 5 by the other two approaches. In Fig. 4(d), we plotted the obtained term s(t) by the SRM at the initial control intervention at 9:18. The estimated value of β0 and range of s(t) are 256.1 and − 22.4 ~ 20.0, respectively, resulting in the range of the term (β0 + s(t)) in Eq. 6 as 243.7 ~ 276.0. This term partly reproduces the true time-dependent change of β0, 240.0 at 8:54 ~ 8:59 and linear increase from 240.0 to 276.0 at 9:18. By this additional term, the estimated coefficient β1 approaches to the true value 10.0 compared to that obtained by the multiple regression modeling, resulting in the avoidance of the underestimation and stable control of the quality y.

To statistically analyze the efficiency by the tried approaches, we repeated the simulations with the original multiple regression approach (‘MR’) and three approaches (‘MR_s’ with the scaling factor, ‘MR_i’ with the control intervention, and ‘SRM’ with the SRM). In Fig. 5, we plotted the results of four features (in all of them, smaller is better). In this simulation 1, no defective product was produced in all the conditions.

Statistics of the 100-repeated simulation 1 displayed by boxplot, bee swarm, and average (as a cross). MR, MR_s, MR_i, and SRM are results from the original procedure with multiple regression, that with scaling, that with control interval, and that with SRM, respectively. The four plots show the number of control interventions, number of products out of the LCL/UCL range, number of control intervention with the control target selection x5 or x6, and number of defective products, respectively

There is a benefit from a small number of control intervention to operate the manufacturing lines. For the original MR, in a few simulations, the number exceeded 15, reflecting the occurrence of the vibrational behavior. For other three approaches, the vibration behavior was almost completely avoided. The number is obviously high for MR_s, as we have discussed in the previous section. The average and median of MR_i and SRM are smaller than that of MR, indicating the efficient control. However, if we compare the number of products out of the LCL/UCL range, those of MR_i is larger than those of MR. This occurs because, in MR_i during the control interval, the control intervention is not triggered even if the product is out of the LCL/UCL range. This behavior is not appropriate in the case of responsiveness is important.

In the simulations, we included x5 and x6 as parameters independent of quality y. Thus, selection of x5 or x6 as the control target is an obvious failure. Several simulations of MR, MR_s, and MR_i resulted in the ratio of x5 or x6 selection > 5%. The limited number of data points for the local regression analysis (tw = 25) and the time-varying β0 change causes noise in the regression coefficient and its t value to wrongly select x5 or x6. On the other hand, in SRM simulations, all the 100 simulations successfully select y-dependent variables.

The simulation statistics by 100 simulations revealed that the undesirable vibrational behavior observed in the original procedure was successfully avoided by the three approaches. However, there are drawbacks for the scaling and control interval approaches reflected by the increased number of control intervention and lack of responsiveness, respectively. The SRM approach is better than the original approach in all the criteria tested in this section.

5.3 Control results for simulation 2

Next, we executed simulation 2, in which the intercept β0 changes discretely between 240 and 170 at 9:00 and 10:00 as shown in Fig. 2(b). Examples of the simulation results are shown in Fig. 6.

a, b Results of simulation 2 by a linear regression and b SRM with the same random seed. c, d Scatter plots between y and predicted y by the c multiple regression and d SRM at the initial control intervention at 9:01. The color of dots shows the timestamp of the data points from dark blue (at 8:37) to light blue (at 9:01). e The term s(t) by the SRM at 9:01 (color figure online)

By the linear regression with the original condition, the β0 change at 9:00 resulted in the decrease of y and SMA(y) was out of the LCL at 9:01 to trigger the initial control intervention [Fig. 6(a)]. Then, additional control interventions were triggered at 9:02, 9:05, 9:15, 9:18, and 9:38 to correct the y change caused by the β0 change at 9:00. In addition, after the second β0 change at 10:00, the control interventions resulted in the undesirable vibrational behavior, and it took 16 control interventions to correct the y change. Meanwhile, a simulation with the SRM with the same random number seed took only 2 and 4 control interventions to correct the first and second β0 changes, respectively [Fig. 6(b)]. In addition, with this random number seed, the approaches with the scaling factor and control intervention also improved the control behavior.

The difference between the multiple regression and SRM is attributed to the discrete change of β0, which reduces the accuracy and precision of the estimated regression coefficients as we have discussed above for simulation 1. In Fig. 6(c), we plotted a scatter plot between y and predicted y by the multiple regression modeling at the initial control intervention at 9:01. There are two obvious outliers with y values around 170, that are produced after the discrete β0 change. Meanwhile, in the scatter plot by the SRM in Fig. 6(d), the predicted values of the two outliers are around the true y values. This elimination of the outliers is derived from the additional term s(t) in the SRM simulation [Fig. 6(e)]. The initial 23 values of s(t) are almost constant around 0 followed by the final 2 values with minus values. Thus, the term s(t) partially compensates the discrete β0 change and would improve the accuracy and precision of estimated regression coefficients. In fact, the estimated coefficient β1 at 9:01 by the multiple regression and SRM are 14.19 and 12.86, respectively. The latter is closer to the true β1 value 10.0.

We repeated 100 simulations and the statistics are summarized in Fig. 7. The inappropriate control behavior with the number of control larger than or equal to 15 were observed 16, 4, 0, and 0 times out of the 100 simulations for MR, MR_s, MR_i, and SRM, respectively, indicating the efficacy of the three approaches. Compared to the average number of x5 or x6 selection ratio around 10% with MR, MR_s, and MR_i, that of SRM is 0% by completely selecting y-dependent x variable as the control target. The number of control simulations failed by producing defective products are 6, 2, 6, and 1 for MR, MR_s, MR_i, and SRM, respectively.

5.4 Control results for simulation 3

Next, we executed simulation 3, in which the intercept β0 changes by a random walk and true coefficient β1 linearly changes as an example shown in Fig. 2(c). As we have described above for the results of simulation 2, the multiple regression modeling in simulation 3 also suffers from low accuracy and precision of estimated regression coefficients derived from the time-dependent β0 and β1, and SRM can partly compensate the changes. The statistics from 100 simulations are shown in Fig. 8. The original procedure (MR) often showed vibrational behavior and wrong control target selection as indicated by the large number of control interventions and x5 or x6 selection ratio. The former is almost avoided by the three approaches. However, the number of control intervention is large in the control with the scaling (MR_s) because the scaled amount of control is often too small to follow the y changes derived by the time-dependent β0 and β1. The x5 or x6 selection ratio is nearly zero for the control by the SRM. This stabilizes the control behavior to realize the observation of no defective products in SRM simulations.

6 Summary

This study reported a methodology to realize the autonomous adaptive control of MISO systems (multiple input of manufacturing parameters, and a single output of quality of product items) under the existence of effects from non-measurable parameters. By local linear regression analysis with MW approach, in which temporal neighborhood data is used for the modeling, the control of the output quality was realized by tuning a single manufacturing parameter selected by the regression coefficients. Simulation results demonstrated that multiple regression modeling often exhibits unstable control behavior with vibrations in product quality due to low precision and accuracy of estimated coefficients. We tested three approaches (scaling the amount of control, introduction of control interval, and SRM regression) to cope with the unstable behavior. The SRM regression exhibited the best performance in realizing the stable control by correctly selecting the control target parameter with the additional non-linear term, that compensates the time-dependent non-measurable parameters.

References

Aha DW (ed) (1997) Lazy learning. Springer, Dordrecht

Curreri F, Fiumara G, Xibilia MG (2020) Input selection methods for soft sensor design: a survey. Futur Internet 12:97. https://doi.org/10.3390/fi12060097

Jackson JE, Mudholkar GS (1979) Control procedures for residuals associated with principal component analysis. Technometrics 21:341–349. https://doi.org/10.1080/00401706.1979.10489779

Joe Qin S (1998) Recursive PLS algorithms for adaptive data modeling. Comput Chem Eng 22:503–514. https://doi.org/10.1016/S0098-1354(97)00262-7

Kaneko H, Funatsu K (2011) Development of soft sensor models based on time difference of process variables with accounting for nonlinear relationship. Ind Eng Chem Res 50:10643–10651. https://doi.org/10.1021/ie200692m

Kaneko H, Funatsu K (2013a) Classification of the degradation of soft sensor models and discussion on adaptive models. AIChE J 59:2339–2347. https://doi.org/10.1002/aic.14006

Kaneko H, Funatsu K (2013b) Discussion on time difference models and intervals of time difference for application of soft sensors. Ind Eng Chem Res 52:1322–1334. https://doi.org/10.1021/ie302582v

Kaneko H, Arakawa M, Funatsu K (2009) Development of a new soft sensor method using independent component analysis and partial least squares. AIChE J 55:87–98. https://doi.org/10.1002/aic.11648

Kano M, Ogawa M (2009) The state of the art in advanced chemical process control in Japan. IFAC Proc 42:10–25. https://doi.org/10.3182/20090712-4-TR-2008.00005

Liu K, Chen Y, Zhang T, Tian S, Zhang X (2018) A survey of run-to-run control for batch processes. ISA Trans 83:107–125. https://doi.org/10.1016/j.isatra.2018.09.005

Porter LJ, Caulcutt R (1992) Control chart design a review of standard practice. Qual Reliab Eng 8:113–122. https://doi.org/10.1002/qre.4680080207

Schwenzer M, Ay M, Bergs T, Abel D (2021) Review on model predictive control: an engineering perspective. Int J Adv Manuf Technol 117:1327–1349. https://doi.org/10.1007/s00170-021-07682-3

Wood SN (2011) Fast stable restricted maximum likelihood and marginal likelihood estimation of semiparametric generalized linear models. J R Stat Soc Ser B. https://doi.org/10.1111/j.1467-9868.2010.00749.x

Wood SN, Augustin NH (2002) GAMs with integrated model selection using penalized regression splines and applications to environmental modelling. Ecol Modell 157:157–177. https://doi.org/10.1016/S0304-3800(02)00193-X

Yao J, Liu X, Zhu X, Guan H (2015) Control of large-scale systems through dimension reduction. IEEE Trans Serv Comput 8:563–575. https://doi.org/10.1109/TSC.2014.2312946

Funding

This work was financially supported by DENSO Corporation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Communicated by Shuichi Kawano.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Takayanagi, M., Yoshino, M., Kikuchi, G. et al. Autonomous adaptive control of manufacturing parameters based on local regression modeling. Behaviormetrika 51, 499–513 (2024). https://doi.org/10.1007/s41237-022-00176-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41237-022-00176-w