Abstract

Recycled wastewater in construction presents an opportunity to ease freshwater scarcity while advancing sustainability. This study investigated the influences of cement-type and treated wastewater source on setting time and mechanical properties of cement paste and mortar. Three cement types: ordinary Portland cement (CEM I), CEM III/A, and CEM IV/A-P, were encountered. Four plants treated wastewater versus potable water as control were included. Fifteen mixes were encountered; every 5 mixes addressed certain cement types along with specified treated water types. Two phases were designed: Phase I for pastes toe value setting time and Phase II for the mortar to evaluate the flexural and compressive strengths of tool 90 specimens, 6 at 2 and 28 days of age. The significant impact of both variables was observed. CEM III/A displayed the fastest setting among the other mixes, while CEM I was the slowest. Wastewater accelerated setting versus distilled water. The mechanical performance also varied based on the cement–wastewater combination. CEM IV/A-P provided optimal strength enhancement up to 50% in flexural and 35% in compressive strength with wastewater compared to CEM I control. Results were attributed to cement–water interactions influencing hydration and microstructure, while CEM I underperformed with wastewater, CEM III/A, and CEM IV/A-P benefits, especially at early ages. Considerable variability highlights the complex interplay of factors governing performance. Coupled chemical-microstructural analysis was recommended to elucidate underlying mechanisms. Overall, tailored cement–wastewater selection shows promise for sustainable concrete, pending further optimization and durability testing. The study provides a platform for context-specific development of eco-efficient construction materials utilizing locally available resources.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water scarcity is considered a global crisis that needs the globe to stand against; as UNICEF [49, 50] mentions, the world needs to get water smart. Everyone has a role to play, and we cannot afford to wait. The article directs people to the fact that humanity will have sooner or later to adapt to the available and limited water resources. The water scarcity problem expanded and enlarged yearly, reaching, according to UNICEF [49, 50]. Four billion people—almost two-thirds of the world's population—experience severe water scarcity for at least one month each year. Only 0.3% of the water on earth is drinkable and accessible, especially in our area of the Middle East. It is reported by UNICEF [49, 50] that approximately 9 out of 10 children in the Middle East and North Africa (MENA) region live in high water stress with severe consequences on their health, nutrition, cognitive development, and future livelihoods. The MENA region's water scarcity problem is worsening, as Hofste et al. [38] reported. The latter recorded seventeen countries, one to one-quarter of the World's Population, face extremely high water stress. Twelve of these countries are in the MENA region; thus, it is considered the most water-stressed region on earth. So, saving freshwater as a higher priority for humanity, especially children, makes more sense and logical than using these water resources to build new arid buildings. The extensive usage of water in the concrete is a tremendous burden globally. Concrete is considered the second most-used material on earth after water usage and most valuable building material of all time, and the base of modern development. According to the Global Cement and Concrete Association (GCCA), cement production is 4.1 billion tons to meet society's demands. Engineers and researchers worldwide aim and are working to find better and cleaner versions of the used techniques and materials in the construction industry specifically in enhancing the concrete mixture and its qualities. An essential aspect of enhancements that many researchers work on is the environmental aspect, especially concrete. It has many impacts on the environment related to the production of Portland cement, which is believed to emit 1 ton of CO2 in return for 1 ton of Portland cement. The extensive use of freshwater in the mixture may account for around 15–20% of concrete produced. Few studies [22, 40, 52] have investigated concrete's fresh and mechanical properties using different types of treated, seawater, and non-treated wastewater. Sandrolini and Franzoni [45] investigated using treated waste wash water collected from concrete plants in concrete mixing. The study concluded that using this wastewater did not lower the compressive strength by more than 5% and that all samples had a slump consistency class S3. The study found that the theory of having poor confidence in concrete containing waste wash water does not seem scientifically well-grounded.

Al-Ghusain [3] concluded that using different types of water did not affect the slump and density of concrete. The study also explored the preliminary and secondary treated wastewater that lowered the concrete strength development rate for ages up to 1 year. As the water quality decreased, the possibility of corrosion increased according to half potential cell test results. Chatveera et al. [31] performed 24 mixes using different w/c ratios and percentages of sludge water by weight exceeding the standard limits of ASTM in terms of PH values and solid particles. Compressive strength results for cube specimens varied between 85 and 94% when compared to the control mix. The replacement of water type did not affect the unit weight of concrete but tended to decrease slump value. Al-Jabri et al. [4] tested the creation of high-strength concrete using wastewater collected from car washing stations. No significant effect was recorded on the compressive strength of concrete when replacing tap water with this type by 25, 50, 75, and 100% by weight. Shekarchi et al. [47] used three types of domestic wastewater in mixing and curing concrete. The slump revealed similar results to Al-Ghusain [3], where there was no significant effect on the slump value of concrete. Furthermore, concrete samples created using tertiary treated wastewater recorded higher compressive strength than tap water's control mix. Mahasneh [41] examined the possibility of using raw and treated wastewater in mixing concrete. The results showed that treated wastewater was a better and more logical option, which was reflected in their mechanical properties, and compressive strength satisfying the ASTM limit. Asadollahfardi et al. [7] concluded that using treated wastewater in mixing concrete had a minor effect on compressive strength and approximately no effect on slump value. The author also conducted an ANOVA test on previous literature data and found a 95% confidence no significant difference when using treated wastewater before chlorination in concrete mixing and curing. Asadollahfardi and Mahdavi [5] investigated the feasibility of using treated industrial wastewater. The results showed a reduction of 8.7% in compressive strength for cube specimens. The SEM images of concrete wastewater specimens provided well-formed crystals; however, the drinking water concrete had unformed crystals, which may explain the reduction in compressive strength. Ghrair et al. [36] concluded that using raw and treated gray water in concrete mix resulted in a minor decrease in slump value and slightly impacted the compressive strength of concrete. The study also mentioned that gray water is suitable for concrete mixes and is in harmony with the requirements of ASTM C109 [9] and ASTM C94 [10]. Meena and Luhar [42] concluded that using tertiary and secondary treated wastewater in mixing and curing concrete affects concrete's mechanical and durability properties. The compressive strength of the cube specimens made using treated wastewater was 85–94% of the compressive strength of the samples made using tap water. Their results recommended the use of superplasticizers to enhance workability. Asadollahfardi et al. [6] explored 50 concrete mixes using concrete wash water, and the mixes varied in cement content, superplasticizer, and water replacement. The study's findings indicated that concrete wash water did not significantly influence the durability or strength that using this type of water might be practical in producing fresh concrete. Taha et al. [48] examined the possibility of using brackish and production wastewater in concrete mixing regarding sustainable development, materials efficiency, and waste reduction. Their results concluded that using nonpotable water in mixing and curing concrete had a minor effect on compressive strength even after one and a half years. Yehia et al. [51] studied using recycled aggregates and treated wastewater to mix high-strength concrete by adding silica fume, slag, and superplasticizer. The study used 20% replacement of recycled aggregates and tertiary treated wastewater by curing the samples in tap water, treated wastewater, and saltwater. The study concluded that using such materials had an insignificant effect on the compressive strength of high-strength concrete when not cured in treated wastewater. Asadollahfardi et al. [8] produced self-compacting concrete (SCC) using treated wastewater with additives such as fly ash, silica fume, and zeolite. The results revealed that water had a negligible effect on the filling ability of SCC and still fit European guidelines. However, the presence of treated wastewater reduced compressive strength by 0.5–2% at 90-day age, which can be considered a negligible reduction. Raza et al. [44] mixed concrete using recycled aggregates with different types of industrial wastewater. The study tested concrete's compressive, tensile, and flexural strengths and chloride penetration test, the tests' results were satisfactory for various mixes. Fadil et al. [34] used raw wastewater from a factory in Baghdad and fresh non-treated water from the Tigris River to examine the effect of water type on the mechanical properties of concrete, and results showed a slight enhancement in compressive strength when river water was used. Still, an acceptable downgrade occurred when using wastewater in all mechanical properties, with an average 40% decrease in compressive, tensile, and flexural strengths. High TDS and salts can cause this, and conductivity recorded in the raw wastewater sample reached triple the tap water rates analyzed. Delnavaz et al. [32] performed 12 mixes of mortar and concrete samples with freshwater and treated wastewater from the treatment plant effluent of the ready-mix concrete batching plant. The consistency, slump, permeability, and chloride penetration increased with treated wastewater, while compressive strength, setting times, and electrical resistivity decreased slightly. According to the Life Cycle Assessment performed at the Iranian concrete factory, the number of pollutants and GWP (Global Warming Potential) emissions produced by the case study concrete plant will drop by 3900 to 8700 tonnes per year if the mix designs suggested in this study are adopted. Mohe et al. [43] examined the effect of potable water, direct river water, deep well water, and rainfall water on the concrete mechanical properties when mixing and curing concrete, all water samples were analyzed. The results showed that samples mixed and cured with such types of water gained 90% of the compressive strength required after 28 days of curing. Halawa and Al-Sheikh [37] examined the effect of primary, secondary, and tertiary treated wastewater on the properties of high-strength concrete. It was concluded and confirmed that tertiary treated wastewater is possibly a good alternative to freshwater and can be used in concrete mixing. Furthermore, other treated wastewater types did not affect the compressive strength of concrete at 28 days of testing. Most research did not investigate the durability of specific corrosion effects after a long term at different ages. Thus, the research target like this one is to stop the enormous use of freshwater in concrete mixing and to save more freshwater for critical activities due to the massive gap in water use resulting in water scarcity. This research aims to replace freshwater with different treatment types of wastewater on compressive, tensile, and flexural strengths. Slump value and rebar corrosion potential in concrete were also tested using the Schmidt hammer test. Wastewater was captured from the wastewater treatment plant. This research aims to save much more water resources consumed by the construction industry by making concrete production greener and more environmentally friendly. Furthermore, the examination of such treated wastewater on the corrosion of steel reinforcement in concrete was not before examined using a potential half-cell test, and using these phases of secondary treated wastewater was not much discussed and elaborated on in the literature.

Experimental program

In this study, the engineering properties, such as specific gravity, densities, and the grain size distribution of fine and coarse aggregates, were determined according to the ECP 203 [33], ASTM C33 [15], and BS EN 197-1 [28]. The following section states the properties of the materials used in the produced mixtures.

Materials

Cement

The cement type was Ordinary Portland Cement with grade 42.5 MPa and normal strength development as per the data provided by the manufacturer. The manufacturer provided the datasheet for cement's physical, chemical, and mechanical properties, as shown in Table 1. The cement types used here in this study were Grade 42.5 and typical ordinary reactivity with an air Blaine fineness of 3780 cm2/kg.

Water and treated wastewater analysis

A treatment plant provided the wastewater. The water analysis was examined in terms of PH value and total dissolved solids (TDS), as shown in Table 2. Two wastewater types were used inside the concrete mix ingredient, while the control mix used potable water for comparison. The first mixture was taken after primary treatment processes and some secondary treatments, such as activated sludge, before the chlorination process. The water used in the second group was captured from the same plant at a different phase, which is the middle of the chlorination process. It should be mentioned that the examined water was left in the laboratory for three months. This action was due to the lockdown for the COVID-19 pandemic. Thus, it was noticed that some organic substances appeared in the water samples within the containers and were filtered and removed before pouring concrete, as shown in Fig. 1.

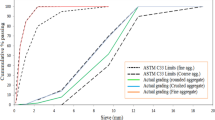

Fine and coarse aggregate

Figure 2 shows the grain size distribution of coarse and fine aggregates and the upper and lower bound of ASTM C33 [29]. The natural coarse used in this study had a nominal maximum aggregate size of 25 mm, within the upper and lower limit of ASTM C33 [15]. The specific gravity of coarse and fine aggregate was valued at 2.63 and 2.67, respectively, as shown in Table 3. The fine aggregate used in this study was the standardized size sieved from 4.75 mm to 0.6 mm with a maximum size of 2.36 mm. The other properties, such as fineness modulus valued at 2.6, as per ASTM C136 [13], the absorption of the fine and coarse aggregate used was 1.21 and 0.6%. Table 3 provides the fine aggregate (sand)'s physical properties.

Mix designs

Table 4 provides the concrete ingredients data used for the concrete mix design of a one-meter cube. According to the ACI 211.1-91 [2] American Concrete Institute guidelines for concrete mix design, the concrete mixtures were designed. The Egyptian Code [33] for designing and constructing concrete installations—Manual of testing, governs all testing ASTM C127 [11], ASTM C128 [12], and BS 882 [26] as noted. As stated earlier, three mixes were set to account for the total replacement of potable water with wastewater treated at two different phases. The exposure factor considered was moderate for all mixes. The type of target concrete was non-air-entrained concrete with a strength of 300 kg/cm2 (≈ 30 MPa). Other parameters were considered while designing the control mixture, such as the water-to-cement ratio of 0.55 and cement content of 382 kg/m3. The fine aggregate was valued at 622.3 kg/m3, while the coarse aggregate was valued at 1157.7 kg/m3.

Sample preparation

Each mix includes seven cubes dimensioned 15 cm; three cylinders lengthened 200 mm, a diameter of 100 mm; three prisms of 10 cm height, 10 cm depth with a length of 50 cm. Finally, a slab of 1 m in width and length with a thickness of 15 cm was reinforced with 5Φ10 mesh. Three concrete mixtures were cast using three types of mixing water; tap water (control), secondary treated wastewater before chlorination, and secondary treated wastewater after chlorination. The specimens were mixed, designed, cast, cured, and tested per ASTM C39/C39M [16]. The concrete mixture is mixed for 10 min in the mixer. Then, specimens were cast, as shown in Fig. 3. Then, cured under standard conditions using water tanks. Before the casting, the interiors of the molds are coated with a thin layer of release agent (oil) using a clean brush. The mix of concrete is poured into the mold into several layers. During pouring the concrete, each layer was tapped with a tamping rod for 25 drips to ensure appropriate compaction. The specimens were inserted into the molds on the vibrating table, ensuring that the cement was thoroughly compacted. The slab specimens were compacted using a tamping rod rather than a needle vibrator. The specimens were placed in the mold at room temperature for 24 h in the laboratory. Then, the specimens were removed from the mold and placed inside curing tanks according to the aging periods. It should be mentioned that the normal curing process is performed according to BS 1881-130 [29]. These specimens were cast to evaluate the compressive, flexural strength, and splitting tensile strength of the concrete specimens, besides the effect of the water type used on the corrosion of reinforcement in concrete. Various testing procedures for different qualities were made to emphasize and know the effect of different treated wastewater types on these qualities in concrete mixes.

Test method

A slump test was conducted as per ASTM-C143 (2022), and the mix temperature was measured before casting. Hardened concrete was tested for mechanical properties, as shown in Fig. 4a, b. The tests executed were compressive strength, after 7 and 28 days of water curing as per BS 1881-Part 116 [23], on the cube specimens set up in a compression universal testing machine of capacity 2000 KN for compression load testing. The cube specimens were placed in contact with the bearing surface of the universal testing machine, as shown in Fig. 5a. The compressive strength of the cube was determined by the ultimate compression machine capacity of 2000 KN adjusted at a pacing rate of 240 kg/cm2 per minute as per the ECP 203 [28] requirements until the specimen failure, as shown in Fig. 5a. As per ASTM C78 [19] and BS 1881-Part 118 [25], the prism specimens were tested at a pacing rate of 24 kg/cm2 per minute by implementing compression loading on the prism specimens' longitudinal direction for evaluating the flexural strength at 28 days, as shown in Fig. 5b. The tensile strength at 28 days was assessed as per ASTM C496-96M [17] and BS 1881-Part 117 [24] using the cylinder specimen lying on the longitudinal side, setting up for splitting tensile testing. The cylinder specimens were tested by implementing compression loading in the cylinder specimens' longitudinal direction using the compression machine at a pacing rate of 12 kg/cm2 per minute, see Fig. 5c. It should be noted that after curing concurrently with the day of testing and getting the specimens out from the curing tank, the specimens dried in the air, and then tested. All the curing processes were relevant to BS 1881-127 [27] and tested mechanical properties such as compressive, flexural, and splitting tensile strengths.

Nondestructive testing is a way to assess existing concrete structures after the concrete has hardened. Three of these testing was introduced here in this study. The Schmidt hammer test is used to evaluate the compressive nondestructively. According to ASTM C805 [20], the device is based on the rebound of the hammer that hit the concrete. Cube specimens were prepared for each mix to be tested destructively and nondestructively. The cube was set between the compression machine bearing plates to apply a minimal bearing to handle the cube while testing using a Schmidt hammer. Then, the load was released to apply the compression force for failure to get the corresponding compressive strength. Nine readings were obtained from each cube specimen. The device is presented in Fig. 6. Ultrasonic pulse velocity tests assess the compressive strength of the hardened concrete through pulse wave velocity. The tests could be performed in two ways: directly or indirectly. Each could provide more properties about the concrete homogeneity, weak depth in concrete, and crack depth of the existing structure. The tests were performed following ASTM C597 [18], and the device and the methods are shown in Fig. 7a and b, respectively. Furthermore, the reinforced slab was tested using a potential half-cell test as per ASTM C876 [21] with a Canin Pro device to determine the existence of steel corrosion due to wastewater treatment. A promotional image for the device is shown in Fig. 7c.

Test results and discussion

The experimental program has been conducted through three mixes using secondary treated wastewater from different phases and tap water (control mix). The fresh and mechanical properties of the concrete were examined. Three slabs were constructed, and corrosion accelerated to see the influence of the used water on the embedded reinforcement. The results and analysis are discussed below in the upcoming sections.

Fresh properties

Slump test results

Some fresh concrete tests were conducted on all mixes on at least one of the batches taken randomly, and the results of slump testing and temperature measurement are shown in Fig. 8. A slump test is made to check how flowable and workable the freshly made concrete mixture is; temperature is measured in the freshly concrete mixture to check that the hydration of the cement process has started in the mix and that the setting of cement would occur.

As stated earlier, a slump test was prepared as per ASTM C143 [14]. The results of the slump for the three mixes are presented in Fig. 8. As shown in Fig. 8, the control mix performed by tap water had a slump of 4 cm, while mix 1 changed to 3.5, which lowered by 12.5%. Mix 2 recorded a slump value of 5.3 cm, meaning an enhancement of workability, although mix 2 was the wastewater after secondary treatment within the middle of the chlorination processes. The percentage of enhancement reached 32.5% from the control. Thus, as long as the wastewater is treated, the slump value would increase; however, the phase primary and secondary treatment would not increase the workability of tap water. Similar results were deduced when using treated wastewater before chlorination by Asadollahfardi et al. [7] as in mix 1 for this study. Similar results were also reported by Meena and Luhar [42], with a reduction percentile reaching 20.5%. It should be mentioned that their mixed design was nearly similar to the authors' study. The news in this study is that wastewater was used from the middle of chlorination after secondary treatment and improved the slump. Most results imported and investigated the slump at or after the tertiary process as it showed the most significant enhancement. The slump improvement might reach 25% from that concrete produced by tap water only by Asadollahfardi et al. [7]. Results showed that the change in slump value in the three mixes was negligible. Furthermore, the effect of filtration performed on the water for mix 2 had a positive impact in increasing the mix workability as what could be described as the organic matter was removed from the wastewater before being used for cast mixture 2. These results comply with the past literature where the slump measured did not show any change in values from the control mix, which uses tap water [42]. Results also showed nearly no effect of mixing water type on the workability of the concrete mixes. Still, the researcher concluded that the mixtures with secondary and tertiary treated wastewater had increased slump value as they had more solids.

Temperature

All the casts reached a temperature of 30–31°C, so the hydration process started. It should be mentioned that the temperature should be around 23° C in the case of the large cast as per ECP 203 [33]; however, due to the slump testing time and preparation of molds, in addition to the delay in taking the temperature measurement, the temperature appears initiating the hydration process. Also, this is a good indication of the usual initial and final setting time as expected by OPC. Asadollahfardi et al. [7], whose results showed the different values of the initial setting for mortars when using treated wastewater compared to tap water, the Final setting was concluded, as revealed by their results. Some researchers, such as AlGhusian and Terro (2003), Lee et al. [39], and Cebeci and Soatie [30], attributed these results to the existence of impurities in the treated wastewater, which initiated the higher setting time. No existing literature review mentioned temperature measurement; thus, there is no data for comparison in this area. Temperature readings showed that the hydration process had taken place in the three mixes and that the cement was activated and ready to be used. This action can indicate that the secondary treated wastewater did not affect the start of the hydration process, that it had no effect on the reaction between cement and other mixture contents, and that the concrete is starting to work typically. Test findings of the temperature rise from room temperature for the concrete mixed with tap water only (OPC), and those mixed with various percentage replacements of sludge water are provided in Fig. 8. Cement particles interact with water as a result of the hydration reaction. They produce heat, which causes the temperature to quickly increase to its peak within 12 h and then gradually drop to near room temperature within 5 days. Due to the presence of a tiny quantity of un-hydrated cement particles in sludge water, concretes mixed with sludge water tend to experience a slight increase in temperature at the beginning. It demonstrates that the use of sludge water in concrete mixes has no appreciable influence on the temperature rise caused by the hydration reaction. Noticeably, the increase in the water-to-cement (w/c) ratio tends to lower the concrete's temperature due to the cement content reduction in the mix [31].

Destructive testing

The first phase of the destructive testing was performed after 7 days of curing, during the second phase after 28 days. Thus, the compressive, tensile, and flexural testing results are discussed in the following sections. It is essential to mention that although nearly no code has mentioned a limitation for concrete tensile and flexural strengths, it is a critical measuring clue to help understand the behavior of the concrete. This action would provide more clues on how concrete reacts to such treated wastewater and whether this filtration technique is feasible or needs more enhancement and research.

Compressive strength

The compressive strength of the three mixes at 7 and 28 days is presented in Fig. 9. From Fig. 9, it is clear that using tap water provided the highest compressive strength value. At the same time, values varied according to the wastewater type used. The compressive strength of the cube specimen revealed values of 195.9 and 289.4 kg/cm2 for mix 1, while 341.8 and 330.3 kg/cm2 for mix 2 at 7 and 28 days. The reduction in compressive strength when using treated wastewater by primary and secondary treatment was about 32% and 16.2% at 7 and 28 days. Similarly, in mix 2 which the treated wastewater was during the chlorination process, the behavior was different at 7 days. An enhancement of 18.7% was observed. This behavior was advised by a reduction of 28 days of 4.4%, although the reduction at 28 days was slightly significant. It is recommended to have further investigation for long-term effects by testing the compressive strength at the age of 90 days, 2 months to one entire year periods to stand on the strength development and gaining through aging factor.

Nevertheless, the compressive strength provided by mix 2 is still higher than that provided by mix 1 by 42.7% and 14% at 7 and 28 days. These results contradict those submitted by Asadollahfardi et al. [7] and Meena and Luhar [42], as their results discussed the only rate of reduction between 7 and 28 days at differently treated wastewater. None of them have similar behavior as here in this study. The minor filtration process might explain these results that the treated wastewater undergoes when left for a while, especially for those used in mix 2, which was obtained during the chlorination process.

From the above results, it seems clear that the development of compressive strength along the aging parameter is strength gaining in mix 1, in which wastewater undergoes primary and secondary treatment only, and the compressive strength at 7 days was about 68% of those 28 days compared to 83.3% for the control which uses tap water. On the contrary, this development did not occur when using wastewater treated during chlorination. The strength gained from 7 to 28 days was negligible and slightly significant. Thus, it is recommended to study for long-term effects. A compressive strength test was made on 3 cubes of 15 × 15 × 15 cm. The average compressive strength is shown in Fig. 9. The compressive strength of mix 1 is not acceptable as it did not gain 70% of the control mix's strength after 7 days. On the other hand, mix 2 gained more compressive strength than the control mix by around 20%, which may give a clue that the solids that were not filtered from mix 1 had an impact on the concrete compressive strength at the early age of 7 days, as illustrated in Fig. 9. After 28 days, the results changed significantly, as shown in Fig. 9. The results were not as expected based on the 7-day test. Both mixes made using phases of secondary treated wastewater gained compressive strength of an acceptable range as mix 1 got more than 83% of the control mix strength and mix 2 had more than 95%. The results also show that water type did not adversely affect the compressive strength, which can be expected as treated wastewater had more solid content. This Solid content may have acted as a filler material, which may enhance the strength and performance of concrete after a long time. This explanation was found to be true when Al-Ghusain [3] conducted compressive strength testing after 1.5 years, and the results showed significant enhancement in concrete made by treated wastewater.

It may be valid to mention that past results in many cases also showed that the degree of reliability of the concrete mix containing treated wastewater increased. The compressive strength enhanced with time increase. This behavior was noted by Meena and Luhar [42], which showed a significant enhancement in compressive strength after 28 days in comparison to the 7-day test. Results and observations of the compressive strength of the concrete mixes using treated wastewater also complied with many past works, such as the reported work of Al-Jabri et al. [4].

Flexural and tensile strength

The splitting and flexural strength of the three mixes are presented in Fig. 10. The results follow similar trends of compressive strength; however, the results obtained were at 28 days only. Thus, the development between ages is not counted, and more investigation is required. Tensile strength was measured using three cylinders of 30 cm in height and 15 cm in diameter. The results are shown in Fig. 10. Tensile strength testing can be used as an additional indication of compressive strength and, generally, the performance and quality of concrete, besides its paramount importance in resisting the application of tension on concrete elements. Flexural strength was measured using 3 prims of 50 × 10 × 10 cm. Results are presented in Fig. 10. Flexural strength is an important aspect that has to be studied in concrete. The aspect of cracking resulting in flexing must be controlled in specific applications, like tanks, which may have great potential for concrete made using treated wastewater as it may be used to store such water type from the first place. For mix 1, both tensile and flexural strength decreased by 34% and 23% compared to the control. On the other hand, mix 2 showed almost the same values with a slight reduction reaching 13.9% for tensile strength and an increase in flexural strength by 2.2% compared to the control value. These values may be evidence that this type of water has a positive or nearly negligible effect on the mechanical properties of concrete. Also, it was shown by the work published by Meena and Luhar [42] that water type had no adverse effect on the flexural strength of concrete mix using different types of water in the mixing and curing of concrete.

Meena and Luhar [42] investigated the flexural strength of mortar created using treated wastewater and denoted the treated wastewater did not influence that strength gaining at any treatment phase. On the contrary, Asadollahfardi et al. [7] confirmed the results approached in this study when exploring the tensile strength at 28 days only. Their results revealed that the treatment type would affect ion tensile strength. However, most mixes provided tensile strength lower or similar to that mix using tap water. Again, for mix 2, the reason that explains the similarity in flexural and tensile strength would probably be due to the minor filtration process that occurred and removed some biological impurities that appeared for an extended stay in containers without use (i.e., due to COVID-19 pandemic). Results of tensile strength show a change in the mixes using treated wastewater, especially mix 1, which gives a relatively insufficient tensile strength. These values have no valid reason and do not comply with nearly any past research, and mix 2 shows much better results and can be comparable to the control mix result. The results of the control mix and mix 2 comply with what was found in the work performed by Raza et al. [44].

Nondestructive testing (NDT)

After 28 days, nondestructive testing (NDT) was performed on hardened concrete. These tests included the ultrasonic pulse velocity test (UPVT) using direct and indirect methods to get the dynamic modulus of elasticity and check the concrete samples' homogeneity. Furthermore, a potential half-cell test was made to check if secondary treated wastewater affects steel reinforcement corrosion in reinforced concrete. The NDT generally offers averagely reliable results and can significantly increase the understanding of the concrete produced by such water type. Also, it is essential to check if the treated wastewater has a negative effect in one way or another on the results presented by NDTs. The NDT is becoming increasingly essential and spreading much faster due to its ability to reach out to some qualities that other destructive testing methods cannot easily detect. The NDT is also becoming a crucial part of quality control programs on concrete structures to enhance the checking of safety and eligibility of such elements and buildings, especially in substantial construction projects.

Ultrasonic pulse velocity tests (UPVT)

There are several methods in which the UPV could be used to assess the concrete physically and mechanically [35]. Direct and indirect ultrasonic pulse velocity tests were performed on cylinders of 30 cm height and 15 cm diameter, and DMOE was calculated. The idea of UPVT tests is to measure the velocity of a pulse generated or transmitted by the device's first head and received by the second head, which acts as a receiver to the pulse. The time is taken for the pulse to complete this trip. The transmission can indicate a clue on the quality of the concrete; if there is a variation in time, there is a change in the medium of the concrete structure, which voids, honeycombing, or any other discontinuity in the element can cause. These tests are meant to check the mixture's homogeneity, and the velocity is used to calculate the concrete element's dynamic modulus of elasticity (DMOE).

One of these methods is indirect testing by moving the receiver for an equal constant distance from the transmitter as per ASTM C597 [18]. The results of this method are shown in Fig. 11. The test was handled indirectly on prism specimens, as explained. The results revealed that the concrete produced using treated wastewater provided a similar homogeneity for both mixes compared to that of control with a slight negligible improvement. The best homogeneity for concrete was in the control mix than mix 1, followed by mix 2. These results indicate that concrete produced using treated wastewater at any phase provides almost similar homogeneity with no significant voids compared to tap water. The existing literature review did not investigate nondestructive testing; thus, there are no results to compare with the existing data in this research. A further recommendation is to consider long-term evaluation of NDT for concrete production using treated wastewater.

On the other hand, when measuring the cylinder specimens, the receiver and transmitter were aligned directly to each other at a distance of 0.3 m (height of cylinder). Then, the measured UPV should show the homogeneity of concrete more evident, as shown in Fig. 12. Results of the UPV direct method shown in Fig. 12 indicate that the control mix is in an excellent concrete grade and that the mixes using treated wastewater may be better graded and are considered excellent and high-quality concrete grade. This result complies with the earlier mentioned results of destructive testing that shows that the performance of concrete made using treated wastewater is acceptable and comparable to tap water-made concrete. Moreover, the type of water did not affect the UPVT test results, as the organic matter in the treated wastewater did not significantly affect the testing. The results of the UPV indirect method are shown in Figs. 11 and 12, showing a slight change compared to direct testing, but that did not change the fact that the results are acceptable and indicate that good-quality concrete is made. Thus, the type of wastewater, whether before or after the chlorination process in secondary treatment, did not negatively affect the concrete quality. Still, on the contrary, the results show an enhancement in the homogeneity of the mixture. From these results, homogeneity could be determined band similar to the indirect method; the DMOE was calculated and plotted as a chart column, as shown in Fig. 13. Similar to the DMOE values, UPV increased to use of treated wastewater in the concrete mix as clear. An improvement in homogeneity was declared by the indirect method, which confirmed the results obtained from the indirect method by calculating the reciprocal of the slope.

This action has confirmed the velocity of mix 2 higher than those of mix 1, and control, ensuring uniformity and homogeneity of the concrete. The importance of the modulus of elasticity can be understood by knowing that concrete elements are not constantly exposed to tensile or compressive strength. Still, the elements experience a mixture of compressive and tensile strengths and creep. Furthermore, concrete is called brittle material as it fractures with elastic deformations when subjected to stresses. Results found in this study show no adverse effect on concrete strength and modulus of elasticity when using treated wastewater in the mixture.

Schmidt hammer (rebound hammer) test

The Schmidt hammer is used to assess the compressive strength of existing structures, as shown by the corresponding Rebound hammer to the average compressive strength at 28 days. The linear relationship for all mix data explains no significant influence on using the treated wastewater in the concrete mixture. Schmidt hammer (Rebound hammer) testing was done on the four cubes after 28 days of curing. A rebound hammer is an NDT that gives a convenient and rapid sign of the compressive strength of the concrete element tested. The idea of a rebound hammer is that it has a pre-measured rebound index known as the rebound number provided by the manufacturer; this number is related to compressive strength. This method is used to assess the uniformity of concrete; also, it must be considered that the compressive strength calculated by the Schmidt hammer is related to the point of application of the hammer. This action is considered suitable for knowing the poor area of concrete elements but can indicate an inappropriate structure.

Relationship between mechanical properties

A comparison of average compressive, flexural, and tensile strengths measured with destructive testing (DT) and nondestructive testing (NDT) is shown in Fig. 14. On the contrary, Fig. 15 shows the relationship between measured average compressive, flexural, and tensile strengths. The results of the NDT show better compressive strength for the treated wastewater mixes. This behavior may be due to poor quality control and maintenance of the hammer, as these are considered one of the main disadvantages of using a Schmidt hammer. The comparison shows a poor relation between the destructive test and NDT. The NDT shows non-justified enhancement in mix 2. On the other hand, NDT also reduces the strength in control mix and mix 1, which cannot be explained or related to the type of water. The rebound hammer test results indicate that the water type in the 3 mixes did not have a significant or influential major effect on the compressive strength of concrete, while the secondary treated wastewater with partial chlorination used in mix 2 may have enhanced the quality of the concrete produced. The secondary axis on the right represents the flexural strength, while the left represents the splitting tensile strength. The flexural and tensile strength represents about 7 and 20% of the corresponding compressive strength, which is considered to be within the usual limits. Again, no significant impact would affect the concrete produced using treated wastewater.

Half-cell potential test

After testing the three slabs left for aging for more than one year, the potential mapping was obtained from the Canin device, as shown in Fig. 16a–c. The dark-shaded area, shown in Fig. 16a, representing control, showed high susceptible corrosion. However, mixes 1 and 2 showed less susceptibility to corrosion. Mix 1 and 2 have fewer darker-shaded areas than the control mix. In addition, mix 2 showed the least susceptibility to corrosion in the less dark-shaded area. The level is considered to be light–dark, not dark. Half-cell potential test (HCPT) was made using the Canin Pro device on slabs made using the three mixes, and the results are shown in Fig. 16a–c. The importance of such a test is that the corrosion rate is one of the main factors to be considered while setting up the maintenance strategy to detect potential corrosion in a structure. Many parameters, such as moisture content, oxygen availability, and temperature, govern the corrosion rate. Hence, it may be appropriate to repeat this test in regular time intervals considering the environmental factors for a more accurate assessment. The same as UPVT, HCPT is location and time-related, as the value revealed approximately gives an indication only on the point where the measurement is occurring. The test results show that the potentiality and risk of corrosion did not rise with the use of treated wastewater. The value of HCP increases, and the potential of corrosion decreases. The result revealed low values of more than – 200 mV as the device used in the test uses a copper–copper sulfate cell. The results also show that the potential of corrosion decreases in concrete made using treated wastewater. This slight change in value is of no significance, according to Satish [46], as it is mentioned that the limit to change the degree of probability of corrosion is – 200 mV. There are no existing data on measuring corrosion; however, some researchers [42, 46, 51] tested the durability of concrete in terms of chloride penetration, water absorption, sorptivity, and finally, carbonation. These durability properties' test results have shown a positive impact on concrete produced using treated wastewater. For instance, Meena and Luhar [42] showed that carbonation depth and chloride penetration resistance were lowered when using treated wastewater mixed. However, Yehia et al. [51] demonstrated that indirect testing techniques, such as RCPT and resistivity, demonstrated minimal to very low chloride ion permeability for all mixtures, indicating that the mixtures are durable. However, the Volhard direct test method revealed a chloride concentration for the RATWW-SW mixture that exceeded the permitted limit of 0.20%, indicating the likelihood of steel corrosion. Therefore, it is important to explore different durability tests before a conclusion can be drawn on the durability of such mixes.

On the other hand, Asadollahfardi et al. [8] concluded that the treated wastewater instead of tap water reduced electrical resistivity (assessment of chloride ion permeability) in the hardened self-compacting specimens in different concrete mix designs. However, the results of chloride ion permeability remained in the low range (37–254 Ω/m) of the AASHTO [1] standard.

Raza et al. [44] denoted that the test results provided the highest WA, among all other different RAC mixes, was shown by concrete fabricated utilizing domestic sewerage wastewater, i.e., almost 114% and 121% at 28 and 90 days, respectively, as compared to WA of concrete made with potable water. 4. The use of FFW depicted the highest CP (123% compared with potable water RAC mix). At 28 days, the RAC mixes made utilizing TFW, DSW, SSW, and SFW reported the CP that was 117%, 102%, 111%, and 108% of the CP of the mix made with potable water. 5. The mass loss due to the acid attack was maximum for the RAC mix that utilized FFW, i.e., 19% at 120 days. This behavior may be attributed to the fact that the pH value of FFW was the lowest (2.5) because a decrease in pH value increases the mass loss. At 120 days, the RAC mixes made utilizing TFW, DSW, SSW, and SFW presented mass losses of 116%, 103%, 115%, and 112% compared with the mix made with potable water. The ANOVA test depicted significant differences in the CS and CP results of various RAC mixes. Conversely, the STS, WA, and acid attack resistance of RAC mixes showed no significant differences. Conclusively, the studied kinds of wastewater can be utilized to fabricate a feasible concrete in terms of waste material availability and a sustainable environmental impact.

Conclusions

To sum up, using treated wastewater in concrete mixes needs many proofs, legislations, and codes to be shown, discussed, and set before allowing this revolutionary approach to take place. It is believed that thinking of freshwater as one of the world's most precious resources, especially in the MENA region, will help accelerate the use of alternatives and replacements in different fields. All in all, the conclusions of this research are summarized in the following points.

-

1.

Using secondary treated wastewater did not affect the mechanical properties of concrete negatively, and all the effects occurring were within the limits stated by the codes.

-

2.

Schmidt hammer results were inhomogeneity and compliance with compressive strength results in destructive testing, showing comparable results between tap water and secondary treated wastewater in concrete mixing.

-

3.

When using ultrasonic pulse velocity testing, the results have shown a super-homogeneity of concrete samples.

-

4.

The secondary treated wastewater before and after the chlorination process slightly enhanced the homogeneity of the concrete or did not show any difference from conventional concrete.

-

5.

The half-cell potential test executed has shown no rise in the risk of corrosion when using secondary treated wastewater.

-

6.

More tests are needed to be done to check the durability and serviceability of concrete made using secondary treated wastewater.

-

7.

More analysis for treated wastewater (output) has to be executed to measure the effect of the quality and type of raw wastewater (input) and to see if it differs and varies depending on treatment plants and countries.

Data availability

Data will be available upon request.

References

AASHTO T283 (1995) Resistance of compacted bituminous mixture to moisture induce damage, a standard method of testing, American association of state highway and transportation officials, Washington DC, USA

ACI 211.1-91 Committee (2009) Standard practice for selecting proportions for normal. Heavyweight, and Mass Concrete

Al-Ghusain I (2003) Use of treated wastewater for concrete mixing in Kuwait. Kuwait J Sci Engrg 30(1):213–228

Al-Jabri KS, Al-Saidy AH, Taha R, Al-Kemyani AJ (2011) Effect of using wastewater on the properties of high strength concrete. Proc Eng 14:370–376. https://doi.org/10.1016/j.proeng.2011.07.046

Asadollahfardi G, Mahdavi AR (2018) The feasibility of using treated industrial wastewater to produce concrete. Struct Concr 20(1):123–132. https://doi.org/10.1002/suco.201700255

Asadollahfardi G, Asadi M, Jafari H, Moradi A, Asadollahfardi R (2015) Experimental and statistical studies of using wash water from ready-mix concrete trucks and a batching plant in the production of fresh concrete. Constr Build Mater 98:305–314. https://doi.org/10.1016/j.conbuildmat.2015.08.053

Asadollahfardi G, Delnavaz M, Rashnoiee V, Ghonabadi N (2016) Use of treated domestic Wastewater before chlorination to produce and cure concrete. Constr Build Mater 105:253–261. https://doi.org/10.1016/j.conbuildmat.2015.12.039

Asadollahfardi G, Yahyaei G, Salehi AM (2020) Workability, mechanical, and durability properties of self-compacting concrete using the treated wastewater. Struct Concr. https://doi.org/10.1002/suco.201900447

ASTM C109 (2020) Test method for compressive strength of hydraulic cement mortars (using 2-in. or [50-mm] cube specimens). ASTM International. https://doi.org/10.1520/c0109_c0109m-20

ASTM C94 (2022) Specification for ready-mixed concrete. ASTM International. https://doi.org/10.1520/c0094_c0094m-22a

ASTM C127 (2016) ASTM C127 15 standard test method for relative density (specific gravity) and absorption of coarse aggregate. ASTM International.

ASTM C128 (2016) ASTM C128 15 standard test method for relative density (specific gravity) and absorption of fine aggregate. ASTM International.

ASTM C136/C136M (2015) Standard test method for sieve analysis of fine and coarse aggregates. ASTM International

ASTM C143 (2022) Slump of hydraulic cement concrete. ASTM International.

ASTM C33 (2018) Specification for concrete aggregates. ASTM International. https://doi.org/10.1520/c0033_c0033m-18

ASTM C39 (2018) Test method for compressive strength of cylindrical concrete specimens. ASTM International. https://doi.org/10.1520/c0039_c0039m-21

ASTM C496-96 (2017) Standard test method for splitting tensile strength of cylindrical concrete specimens. ASTM International.

ASTM C597 (2016) Standard test method for pulse velocity through concrete. ASTM International

ASTM C78/C78M-22 (2022) Standard test method for flexural strength of concrete (using simple beam with third-point loading). ASTM International.

ASTM C805 (2019) Standard test method for rebound number of hardened concrete. ASTM International

ASTM C876 (2016) Standard test method for corrosion potentials of uncoated reinforcing steel in concrete. ASTM International

Aziz SQ, Omar IA, Bashir MJK, Mojiri A (2020) Stage-by-stage design for primary, conventional activated sludge, SBR, and MBBR units for residential wastewater treatment and reusing. Adv Environ Res 9(4):233–249. https://doi.org/10.12989/AER.2020.9.4.233

BS 1881: Part 116: 1983, Method for determination of compressive strength of concrete cubes. British Standard Institution.

BS 1881: Part 117: 1983, Method for determination of tensile splitting strength. British Standard Institution.

BS 1881: Part 118: 1983, Method for determination of flexural strength. British Standard Institution.

BS 882 (1992) Specification for aggregates from natural sources for concrete. British Standards Institution, London

BSI–BS 1881-127 Testing concrete–Part 127: Method of verifying the performance of a concrete cube compression machine using the comparative cube test

BSI (2011) BS EN 197-1:2011–Cement. Composition, specifications and conformity criteria for common cement. London, UK

BSI (2013c) BS 1881-130:2013–Testing concrete. Method for temperature-matched curing of concrete specimens. London, UK

Cebeci OZ, Saatci AM (1989) Domestic sewage as mixing water in concrete. ACI Mater J 86(5):503–506

Chatveera B, Lertwattanaruk P, Makul N (2006) Effect of sludge water from ready-mixed concrete plant on properties and durability of concrete. Cement Concr Compos 28(5):441–450. https://doi.org/10.1016/j.cemconcomp.2006.01.001

Delnavaz M, Sahraei A, Delnavaz A, Farokhzad R, Amiri S, Bozorgmehrnia S (2022) Production of concrete using reclaimed water from a ready-mix concrete batching plant: Life cycle assessment (LCA), mechanical and durability properties. J Build Eng 45:103560. https://doi.org/10.1016/j.jobe.2021.103560

ECP 203 (2020) Egyptian code of practice for designing reinforced concrete structures.

Fadil S, Al-Kindi G, Tobeia S (2023) Study the effects of using different water types on the mechanical properties of concrete. Ecol Eng Environ Technol 24(1):175–184. https://doi.org/10.12912/27197050/154940

Gholizadeh S, Leman Z, Baharudin BTHT (2015) A review of the application of acoustic emission technique in engineering. Struct Eng Mech 54(6):1075–1095. https://doi.org/10.12989/SEM.2015.54.6.1075

Ghrair AM, Al-Mashaqbeh OA, Sarireh MK, Al-Kouz N, Farfoura M, Megdal SB (2018) Influence of grey water on physical and mechanical properties of mortar and concrete mixes. Ain Shams Eng J 9(4):1519–1525. https://doi.org/10.1016/j.asej.2016.11.005

Halawa MAE, Al-Sheikh S (2022) Effect of treated wastewater on properties of high strength concrete mixture. Eng Res J 173:376–390. https://doi.org/10.21608/erj.2022.223594

Hofste RW, Reig P, Schleifer L (2019) 17 Countries, home to one-quarter of the world's population, face extremely high water stress. https://www.wri.org/insights/17-countries-home-one-quarter-worlds-population-face-extremely-high-water-stress

Lee OS, Salim MR, Ismail M, Ali MI (2001) Reusing treated effluent in concrete technology. Jurnal teknologi 34:1–10

Lee JS, Kim ES, Jang KP, Park CK, Kwon SH (2022) Prediction of concrete pumping based on correlation between slump and rheological properties. Adv Concrete Construct 13(5):395–410. https://doi.org/10.12989/ACC.2022.13.5.395

Mahasneh B (2014) Assessment of replacing wastewater and treated water with tap water in making concrete mix. Electron J Geotech Eng 19:2379–2386

Meena K, Luhar S (2019) Effect of wastewater on properties of concrete. J. Build. Eng. 21:106–112. https://doi.org/10.1016/j.jobe.2018.10.003

Mohe NS, Agon EC, Shewalul YW (2022) Experimental investigation on mechanical properties of concrete using different sources of water for mixing and curing concrete. Case Stud Construct Mater. https://doi.org/10.1016/j.cscm.2022.e00959

Raza A, Rafique U, Haq F (2021) Mechanical and durability behavior of recycled aggregate concrete made with different kinds of wastewater. J Build Eng 34:101950. https://doi.org/10.1016/j.jobe.2020.101950

Sandrolini F, Franzoni E (2001) Waste wash water recycling in ready-mixed concrete plants. Cem Concr Res 31(3):485–489. https://doi.org/10.1016/s0008-8846(00)00468-3

Satish VL (2020) Half cell potential testing for durability studies of concrete structures in coastal environment. https://www.ndt.net/search/docs.php3?id=26122

Shekarchi M, Yazdian M, Mehrdadi N (2012) Use of biologically treated domestic Wastewater in concrete. Kuwait J Sci Eng 39(2B):97–111

Taha RA, Al-Harthy AS, Al-Jabri KS (2010) Use of production and brackish water in concrete mixtures. Int J Sustain Water Environ Syst 1(02):39–43. https://doi.org/10.5383/swes.01.02.001

UNICEF (2021a) Programmatic approaches to water scarcity. https://www.unicef.org/documents/programmatic-approaches-water-scarcity

UNICEF (2021b) Running dry. https://www.unicef.org/mena/reports/running-dry-impact-water-scarcity-children

Yehia S, Alhoubi Y, Elmesalami N, Ahmed S, Abed F (2021) Effect of recycled aggregates and treated wastewater on concrete subjected to different exposure conditions. Constr Build Mater 266:120930. https://doi.org/10.1016/j.conbuildmat.2020.120930

Zongping C, Mo L, Yaqi C, Zhang Y (2021) Investigation on compression properties of seawater-sea sand concrete. Adv Concrete Construct 12(2):93–103. https://doi.org/10.12989/ACC.2021.12.2.093

Acknowledgements

The authors wish to acknowledge the Civil Engineering Department at the German University in Cairo, Egypt, and the Laboratory of Materials. They also would like to acknowledge the technician Mr. Ali for his effort and dedicated work with the students in performing their testing throughout the project.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study's conception and design. Material preparation, data collection, and analysis were performed by Moemn ElGazzar and Amr ELNEMR. The draft of the manuscript was written and revised by Bassam A. Tayeh. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

For this type of study, no informed consent is required.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

ElGazzar, M., Elnemr, A. & Tayeh, B.A. Nondestructive testing on concrete-based treated wastewater. Innov. Infrastruct. Solut. 9, 177 (2024). https://doi.org/10.1007/s41062-024-01463-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-024-01463-z