Abstract

Scheduling repetitive construction projects poses a significant challenge in optimally utilizing multiple concurrent crews and sequencing their work to minimize project duration and cost. To address this challenge, this study presents the development of a multi-objective scheduling optimization model for repetitive construction projects consisting of three modules. First, a scheduling module ensures the harmonious coordination of multiple concurrent crews for each activity while considering varying productivity rates, work continuity constraints, and project precedence relationships. Second, a cost module incorporates various contractual cost components to enable a thorough evaluation of project costs and provides flexibility to contractors encountering different contract terms. Third, an optimization module utilizes a genetic algorithm to identify optimal combinations of crews working in parallel and their optimal work sequence, to simultaneously minimize project duration and cost. An application example from the literature was analyzed to validate the model and demonstrate its superiority over previous models. The results showed significant reductions of 8% and 0.78% in project duration and overall costs, respectively, compared to previous models. Furthermore, the capabilities of the model were demonstrated through a real-life case study involving a highway development and renovation project, highlighting its practical benefits and effectiveness in a real-world construction scenario.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Repetitive construction projects, such as high-rise buildings and highways, typically require construction crews to replicate their work at different locations in the project, shifting from one location to another [1]. These types of projects require to be scheduled in such a way that enables their construction crews to move from section to another without having to wait until their predecessor crews finish working in the same section [2, 3]. This scheduling requirement for such projects is frequently referred to crew work continuity constraint [3]. Complying with this continuity constraint proved useful for retaining skilled labor, maximizing the benefits of the learning curve effect [4], and eliminating the idle time of utilized crews [5]. To achieve this, activity progress rates should be adjusted in such a way that harmonizes the work of all utilized crews. The progress rate of each repetitive activity depends on the productivity rate of the crew/s utilized to perform this activity. Each activity can be performed using different available crew options, where each option has unique daily output and cost rates depending on its size and formation [6]. For example, the available crews to perform the excavation activity in a highway construction project may include: (1) crew B-14A, which has a daily production and cost rate of 3,060 (B.C.Y/day) and 3,928($/day), respectively; and (2) crew B-14F, which has a daily production and cost rate of 6,750 (B.C.Y/day) and 5,187 ($/day), respectively [7]. Crew B-14F provides about 120% increase in productivity and only 32% increase in cost compared to crew B-14A; however, utilizing the crew of the higher productivity rate may result in crew idle time due to asynchrony with the other related activities in the project. Therefore, selecting the optimal crew formation that concurrently minimizes project duration and cost is a challenging task for this type of project [8]. Several models have been developed to identify the optimum combination of utilized crews to eliminate the idle time of construction crews by balancing their production rate throughout all activities [9]. These models are based on two main scheduling techniques: (1) Linear Scheduling Method (LSM); (2) Line of Balance (LOB). First, LSM was developed to produce flexible schedules that account for the variation in production rates of construction crews utilized for each activity [10]. Thus, LSM enables addressing both typical and atypical repetitive activities [11, 12]. However, this technique assumes that each activity is constructed using a single crew moving from the first to the last unit sequentially [9]. Second, the LOB technique maximizes resource utilization by balancing the production rate of each activity [13]. This is performed by recognizing the optimum crew configurations to be utilized to prevent overuse of resources [14, 15]. This technique enables the utilization of multiple concurrent identical crews to perform each activity by applying the natural rhythm approach [15], as shown in Fig. 1a. However, it assumes a constant progress rate for all repetitive activities, thus addressing typical activities only [14, 16,17,18]. This assumption does not fully comply with reality, where numerous repetitive construction projects comprise typical and atypical repetitive activities [19, 20] and the production rates of construction crews differ according to their configurations [10]. Due to this variation in the productivity rate of construction crews utilized for each activity, the sequence of work of these concurrently utilized crews can significantly affect activity duration and, by extension, project duration [21]. Consequently, there is a need to develop a scheduling technique that balances the output rate of activities in repetitive construction projects by harmonizing the work of multiple same/different crews concurrently with/without natural rhythm, as shown in Fig. 1a, b, respectively. To overcome the aforementioned challenges, this study presents a multi-objective scheduling optimization model that allows for the concurrent utilization of multiple same/different crews among all feasible crew options available for each activity, enables the selection of the optimum crews, and identifies their optimal sequence of work to minimize project duration and cost simultaneously.

Literature review

Several models have been developed to minimize the project duration and/or cost for repetitive construction projects by optimizing the utilization of their construction crews. First, models were developed to minimize project cost. For example, Hegazy and Kamarah [22] utilized GAs to develop a scheduling optimization model for high-rise buildings that minimizes project costs, while adhering to project timelines and resource constraints. The model considered logical relationships within and among floors, ensured work continuity, synchronized crews, accounted for seasonal productivity factors to determine the optimal combination of construction methods, crew sizes, and work interruptions. However, it considered utilizing identical crews only, does not account for atypical activities, and does not consider minimizing project duration. Fan et al. [23] presented an optimization model to address repetitive construction projects with soft logic. The model enabled the generation of an optimal schedule by minimizing project cost considering various production rates and logical sequences. Huang et al. [24] developed an optimization formulation that takes into consideration soft logic to recognize work order between units, activity start times, and a set of activity modes to minimize project while fulfilling a user-specified project deadline. Second, models were developed to minimize project duration. For example, Hyari and El-Rayes [25] utilized a genetic algorithm to present a multi-objective scheduling optimization model for repetitive construction projects that maximizes the crew’s work continuity and minimizes project duration. the multi-attribute utility theory is utilized to ease the selection of the best overall plan for the project under consideration. The model comprises three key components: scheduling, optimization, and ranking. While the model offers valuable insights and decision-making support for construction planners, it does not account for the utilization of multiple concurrent crews in each activity and does not consider project cost during the optimization process. Altuwaim and El-Rayes [26] presented a model that aimed to minimize project duration and maximize crew work continuity in repetitive construction projects. Altuwaim and El-Rayes [26] presented a multi-objective optimization model that concurrently minimizes project duration, maximizes crew work continuity and minimizes interruption costs. Third, models were developed to generate optimal trade-offs between the project duration and cost. For example, Long and Ohsato [6] presented a method for scheduling repetitive construction projects with multiple objectives, including optimizing project duration and cost. The method effectively addresses constraints associated with activity precedence relationships and resource work continuity. It takes into account various attributes of activities, such as interruptions, and considers different relationships between direct costs and durations, including linear and nonlinear correlations. The proposed approach utilizes a genetic algorithm to determine suitable activity durations and a scheduling algorithm to establish appropriate start times. However, the method focused on finish-to-start relationships only and does not account for the utilization of multiple crews in each activity. El-Rayes and Kandil [27] utilized a multi-objective genetic algorithm to develop a scheduling model for repetitive construction projects comprising repetitive and non-repetitive activities. The model enabled the generation of time–cost-quality trade-offs. Through its formulation, quality quantification, and implementation stages, the model offered indispensable support to decision makers engaged in highway construction and rehabilitation projects, particularly in contracts emphasizing high-quality performance. Hyari et al. [28] Utilized a genetic algorithm to develop a multi-objective optimization model for scheduling repetitive construction projects that minimizes both project duration and cost. The model considers incentives and penalties for early and late completion, respectively. The model produced optimal trade-offs between the project duration and cost. Razek et al. [29] introduced a multi-objective optimization model, referred to as modified critical path method with genetic algorithms (MCPMWGAs), with the objective of achieving optimal resource utilization plans for repetitive construction projects. The primary focus of the model is to minimize construction time and cost while maximizing project quality. It integrates the key principles from LOB and Critical Path Method CPM and utilizes Genetic Algorithms (GAs). This study demonstrates the effectiveness of the model in considering quality in the optimization process and achieving an optimal trade-off among construction time, cost, and quality. Abd El Razek et al. [30] developed a practical software system called "AMTCROS" to address time–cost-quality trade-off optimization in construction projects. By integrating LOB, CPM, and GAs, the software assists planners in optimizing resource utilization, minimizing project cost and duration, and maximizing project quality. The software includes modules for data storage, calculations, activity modifications, and user interaction. Aziz [31, 32] focused on estimating tender data for repetitive construction projects encompassing variables such as project duration, cost, bid price, cash flows, maximum working capital, and net present value. These studies proposed a multi-objective optimization formulation and an Optimizing Software Strategy (OSS) to calculate the best tender data. The objective was to minimize the project duration, bid price, and maximum working capital while maximizing net present value. These studies provide practical support to contractors by optimizing resource utilization. Tran et al. [33] introduced a new technique for scheduling repetitive construction projects that performs generation jumping using opposition-based learning technique (OBL) to enhance the variety of the initial population. The model produces optimal plans that concurrently minimize project duration, cost, quality, and crew work continuity. Altuwaim and El-Rayes [34] utilized genetic algorithms to present a multi-objective optimization model that concurrently minimizes project duration, work interruptions, and overtime hours. Despite the original contributions of the aforementioned models, they are incapable of one or more of the following: (1) utilizing multiple same/different crews working concurrently without natural rhythm to construct each activity; (2) harmonizing the concurrent work of multiple concurrent crew formations with same/different productivity rates within each activity; (3) accounting for all types of precedence relationships; (4) identifying the optimum number of crews and their optimal sequence of work to minimize project duration and cost simultaneously; and (5) incorporating different contractual cost options such as project incentives, penalties, and occupational rental costs. Consequently, this paper presents the development of a scheduling optimization model for repetitive construction projects to overcome the aforementioned limitations.

Objective

The objective of this research is to present the development of a multi-objective scheduling optimization model for repetitive construction projects that searches for and identifies the optimal selection of the number of construction crews to be utilized concurrently and their optimal sequence of work for each activity that simultaneously minimizes both project duration and cost. As shown in Fig. 2, the computations of the proposed model are performed in three main modules: (1) a scheduling module that is capable of (a) considering both typical and non-typical repetitive activities; (b) harmonizing the work of multiple crews with same/different productivity rates that are concurrently utilized for each activity; (c) complying with crew work continuity constraints; (d) accounting for all types of precedence relationships among project activities; (2) a cost module that calculates project direct and indirect costs, in addition to different contractual cost options such as project incentives (saving/penalty) and project occupational rental costs; and (3) an optimization module that generates the optimal set of resource utilization plans that represent the optimal trade-offs between project duration and cost; These three modules are described in detail in subsequent sections.

Scheduling module

This module is designed to calculate feasible schedules for repetitive construction projects that are capable of: (1) considering both typical and non-typical repetitive activities; (2) assigning concurrent multiple crews with the same or different productivity rates that work with or without natural rhythm for each activity; (3) complying with crew work continuity constraints; and (4) providing flexibility to construction planners in dealing with different types of precedence relationships among project activities such as Finish to Start (FS), Finish to Finish (FF), Start to Start (SS), and Start to Finish (SF). To overcome the challenge of achieving consistency/harmony between multiple utilized crews of different productivity rates, a new scheduling algorithm is developed to calculate the start and finish dates of each activity in all repetitive units that comply with the crew availability constraint. As shown in Fig. 3, the scheduling computation in this module is performed at the project and activity levels. First, project-level calculations which require the user to specify all relevant Project data: (1) number of activities (\(I\)); and (2) precedence Relationships between activities, Activity data: (1) number of repetitive units in each activity (\(J\)); and (2) quantity of work (\({Q}_{i.j}\)) in each repetitive unit, and Resources data: (1) available crews (\({N}_{i}\)) for each activity; (2) crew productivity rate (\({P}_{i,n}\)); (3) crew cost rate (\({\mathrm{CR}}_{i,n}\)); and (4) material unit cost (\({\mathrm{MR}}_{i}\)). It should be noted that more than one crew of the same or different productivity rates can work simultaneously in each activity. These input data were utilized to calculate the schedule of all activities in the project starting from the first activity \((i = 1)\) through the last activity\((i= I)\). Second, activity-level calculations were designed to utilize multiple concurrent crews in each activity \((i)\) to perform the assigned units, starting from the first utilized crew \(({m}_{i}=1)\) to the latest utilized crew \(({m}_{i}={M}_{i})\) for each activity\((i)\). Calculations at the activity level are performed in two steps that are designed to: (1) calculate the initial start and finish times for each crew \({(m}_{i})\) in each activity unit \((i,j)\) that comply with crew availability and precedence relationships (see Fig. 4). It is worth mentioning here that for activities of more than one predecessor\(({k}_{i}=1 \mathrm{to} {K}_{i} )\), crew schedule computations are repeated considering each predecessor separately, and consequently, the maximum schedule is considered; and (2) adjust the start and finish times of each activity unit to maintain crew availability and precedence relationships while complying with the crew work continuity constraint. Once the final schedule of all utilized crews in all activity units is calculated, the model calculates the overall project duration (TD) as the finish date\(({F}_{I,\mathrm{latest} j}\)) of the last executed repetitive unit (\(j\)) for the latest activity (\(I\)) as shown in Eq. 1.

Cost module

This module is designed to calculate the total project cost components that account for the project’s direct cost \((DC)\) and indirect cost \((IC)\). First, the project direct cost includes all costs required to accomplish the work of all project activities, such as material, labor, and equipment costs, as shown in Eq. 2.

where \(\mathrm{DC}\), project direct cost; \({Q}_{i.j}\), quantity of work required for activity unit \(\left(i,j\right)\); \({\mathrm{MR}}_{i}\), material cost rate for activity \(\left(i\right)\); \({d}_{i,j}^{{m}_{i}}\), duration of activity \(\left(i\right)\) in unit \(\left(j\right)\) utilized by crew \({(m}_{i})\); \({L}_{i,j}^{{m}_{i}}\), labor cost rate per unit duration of crew \({(m}_{i})\) performing activity unit \(\left(i,j\right)\); \({E}_{i,j}^{{m}_{i}}\), equipment cost rate per unit duration of crew \({(m}_{i})\) performing activity unit \(\left(i,j\right)\).

Second, project indirect cost which directly depends on the project duration and the daily indirect cost rate that covers overhead costs such as office overhead, supervision, and site utilities as shown in Eq. 3.

where \(\mathrm{IC}\), project indirect cost; \(\mathrm{TD}\), total project duration; \(\mathrm{ICR}\), indirect cost rate.

In addition, this module is designed to consider different contractual cost options that provide more flexibility to planners, such as project incentives \((\mathrm{PI})\) and project occupational rental cost \((\mathrm{OC})\). First, project incentives \((\mathrm{PI})\) include: (1) bonus/saving costs for early project completion considering the bonus rate (B) and saving time in project duration (see Eq. 4); and (2) penalty cost for delay in project duration beyond the user-specified deadline, considering the penalty rate (P) and the time increment in project duration (see Eq. 4).

where \(\mathrm{PI}\), project incentives (bonus or penalty). \(\mathrm{SD}\), project-specified duration in contract; \(B\), specified bonus rate; \(P\), specified penalty rate.

Second, project occupational rental cost \((\mathrm{OC})\), which represents the costs of partially/full closure, occupation, or disabling buildings or facilities to enable project completion; for example, partially/fully closing roads or highways to enable highway maintenance and development projects. Such closure often results in traffic congestion which adversely affects road users in terms of cost and time and, by extension, deteriorates the local economy [35]. To minimize the duration of such projects, transportation departments often stipulate this type of cost in their contracts, where the contractors are obliged to pay a specified fee for each day of occupying the road to finish project activities [28]. The value of occupational cost depends on the occupation duration in days and the road user occupation cost rate \((\mathrm{OR})\) specified by the owner, which can be calculated as shown in Eq. 5. The total project cost \((TC)\) is calculated by summing all the aforementioned cost components as shown in Eq. 6.

where \(OC\), project occupational rental cost. \(\mathrm{TD}\), total project duration. \(\mathrm{OR}\), user occupation cost rate.

Optimization module

The purpose of the optimization module is to search for and identify the optimal selection of the number of construction crews and their optimal sequence of work for each activity in the project that simultaneously minimizes the total project duration and cost. The development of the optimization module includes three phases: (1) decision variables, (2) objective functions, and (3) implementation. A detailed description of each phase is provided in the following subsections.

Decision variables phase

The decision variables of the current model are designed to represent all possible alternatives for scheduling repetitive construction projects that affect the project duration and cost. Two decision variables were identified in the model. First, the selection of the number of construction crews and their formations (\({M}_{i}\)) that can be utilized simultaneously to construct each activity (\(i\)) (see Fig. 5). This variable (\({M}_{i}\)) is formulated with positive integers, and its range can be expressed as shown in Eq. 7.

where \({N}_{i}\) is the number of all available crews for each activity (\(i\)); \({J}_{i}\) is the number of repetitive units in activity (\(i\)).

For example, (\({M}_{A}=3\)) indicates that three crews are selected from the six available construction crews (\({N}_{A}=6\)) for activity (\(A\)), as shown in Fig. 5. It should be noted that the model assumes that only one crew can be assigned to each unit; hence, (\({M}_{i}\)) cannot be greater than the number of units (\({J}_{i}\)) of activity (\(i\)). Second, the sequence of work for each crew variable (\({s}_{i,m}\)), which represents the movement order of each selected crew (\({m}_{i}\)) to perform the work assigned to this crew among required units (e.g., sequence variable \({s}_{\mathrm{i},1}\)= \(\left[1, 2, 4\right]\), refers to the assignment of three work units to the first utilized crew (\({m}_{i} = 1\)), and the sequence of work for this crew will be in the following order: unit one, unit two, and unit four, as shown in Fig. 5.

Objective functions phase

The current optimization model combines two objective functions that are designed to minimize: (1) project duration; and (2) project total cost. The first objective function is achieved by generating feasible schedules for repetitive construction projects that minimize the finish date of the last executed repetitive unit (j) in the latest activity (I) of the project, as shown in Eq. 8. The second objective function is achieved by optimizing the selection of construction crews and their sequence of work to minimize the total construction cost of the project, as shown in Eq. 9.

where \(\mathrm{TD}\), total project duration; \(\mathrm{TC}\), total project cost.

It is worth mentioning here that the optimization model is intended to handle concurrent multiple objectives and result in the optimal front that represents the best trade-off between these two objectives.

Implementation phase

The optimization computations in this model are performed using a genetic algorithm-based technique. The model utilizes the Non-dominated Sorting Genetic Algorithm (NSGA-II), which is a powerful decision space inspection drive [36]. Genetic Algorithms are commonly utilized in solving multi-objective construction engineering and management problems [34, 37] owing to their capability of: (1) formulating nonlinear and discontinuous objective functions and constraints such as those encountered in this model; (2) searching for and identifying optimal/near-optimal solutions for problems with a large number of decision variables and large solution space within sensible computation time; (3) successfully excluding all dominated solutions and creating a Pareto optimal front for multi-objective optimization problems [8, 34, 38]. According to a study by Rainville et al. [39], Distributed Evolutionary Algorithms in Python (DEAP) framework is utilized to perform the optimization computations of the current model in the following steps:

-

1.

Identify relevant project data: (1) number of activities (\(I\)); and (2) precedence relationships between activities, activity data: (1) number of repetitive units in each activity (\(J\)); and (2) quantity of work (\({Q}_{i.j}\)) in each repetitive unit, and resources data: (1) available crews (\({N}_{i}\)) for each activity; (2) crew productivity rate (\({P}_{i,n}\)); (3) crew cost rate (\({\mathrm{CR}}_{i,n}\)); and (4) material unit cost (\({MR}_{i}\)).

-

2.

Generate an initial population that consists of a set of randomly selected solutions \(\left(s=1 \mathrm{to} S\right)\), where each solution represents the overall selection of crews to be utilized from all available crews (\({N}_{i}\)) for each activity (\(i\)) in the project and their sequence of work (see selection in Fig. 5), which establishes the population of the first generation \((g=1)\).

-

3.

Evaluate the fitness of each solution in the present generation by calculating the corresponding duration and cost of each resource utilization option using the scheduling and cost modules defined in the subsequent sections.

-

4.

Rank all the solutions using (NSGA-II) according to their fitness evaluation and the non-domination criteria to define the optimal front among the two optimization objectives that represent the optimal trade-offs between project duration and cost and to select the best solutions that will be used as parents to generate the population of the next generation.

-

5.

Based on the rank provided by the previous step, the best solutions are selected, and GA operators such as elitism, crossover, and mutation are performed to generate the population of the next generation.

-

6.

Steps 3 and 4 are repeated for each new generation until a predefined stopping criterion is reached, which is the specified number of successive generations that have no further development in the optimal front.

Performance evaluation

An application example was analyzed using the current model to validate the model computations, demonstrate its capabilities, and highlight the superiority of its results over those presented by similar models in the literature. A concrete bridge project includes five non-typical repetitive activities repeated in four repetitive units. The precedence relationships between consecutive activities are all FS without lag. The quantity of work in each repetitive activity unit is listed in Table 1, and the data on available crew formations for constructing each activity are summarized in Table 2 [28]. The daily indirect cost rate for the project was $2500/day [28]. It is required to select, from all possible alternatives, the optimal number of crew formations to be utilized for each activity and to identify their optimal sequence of work to perform each activity in the project. The current optimization model is utilized to analyze this example to (1) validate the results of the current model; (2) demonstrate the model’s usage and original capabilities to produce a set of non-dominated solutions that represent the optimal trade-offs between project duration and cost; and (3) illustrate the superiority of the solutions generated by the current model over those produced by the model presented by Hyari et al. [28]. First, to validate the computations and results of the current model, the results were compared with those produced by the Hyari et al. [28] model for the same project. This comparison showed that the model identified solutions identical to those produced by the Hyari et al. [28] model (for example, solution C in III). Second, the current model effectively searched for the solution space by identifying a set of 105 Pareto optimal/near-optimal solutions out of the 10,400 feasible solutions discovered in the solution space. Each solution represents a unique resource utilization plan with its own optimal number of crews utilized to perform each activity and their optimal sequence of work among the units assigned to each crew. Third, the current model can provide optimal solutions that are superior to those produced by Hyari et al. [28] as follows:

-

1.

The current model generated a wider range and greater diversity of non-dominated solutions than those provided by Hyari's model. The number of optimal/near-optimal solutions generated by the current model increased by almost ten times compared with those generated by Hyari's model, as shown in Fig. 6a. It should be noted that the solutions obtained by the current model dominate those provided by Hyari et al. [28] in both project duration and project direct cost.

-

2.

As shown in Fig. 6b and Table 3, the current model is capable of providing two solutions (A and B) that achieved further reductions in project duration and project total cost, respectively. First, solution A achieved an 8% decrease in project duration and a 0.34% reduction in project total construction cost compared to solution D provided by Hyari et al. [28]. This superiority was achieved by selecting multiple crew formations to increase the production rate for Foundation and Beams activities, as shown in Table 3. For the foundation activity, two concurrent crews were utilized: Crew 1 was assigned to perform the first three units and Crew 2 was assigned to perform the fourth unit, concurrently. For the Beams activity, three concurrent crews were utilized: Crew 2 was assigned to perform the first two units, Crew 1 to perform the third unit, and Crew 3 to perform the fourth unit, concurrently. Second, compared to solution E provided by Hyari et al. [28], solution B achieved a 0.78% decrease in the total construction cost by selecting crews with the lowest cost rates and a 4% decrease in project duration by utilizing multiple crews concurrently to increase the production rate for construction activities, as shown in Table 3.

Current model results comparison with those of Hyari et al. [28] model:

Such an original approach results in more flexibility in scheduling calculations and an overall improvement in the performance of the current model, whereas existing models utilize fixed output rates in all repetitive units, which is impractical in the case of atypical repetitive activities. The variation in the available trade-offs generated by the current model provides planners with more flexibility in addressing the specific requirements of the project under consideration.

Case study

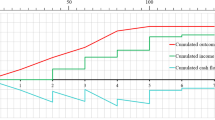

A real-life case study of a highway development and renovation project in Egypt (Fig. 7) was analyzed to illustrate the use of the multi-objective optimization model and highlight its unique capabilities. The project consists of 13 activities repeated in 15 different units with a total length of 30 km. The project activities, precedence relationships among these activities, and corresponding material costs per unit of measurement are listed in Table 4. The quantity of work required for each activity in each unit is listed in Table 5. The required construction crew data are presented in .

Table 6. For example, there are 17 construction crews available to construct activity A, where six crews available from crew formation number 1 (Crew 1), five from crew formation number 2 (Crew 2), and six from crew formation number 3 (Crew 3). The Crews data were provided by highway contractors involved in similar projects. The project’s daily indirect cost rate was 24,250 EGP. The owner specified a 350 days project duration and considered an incentive (bonus/saving) rate of 20,000 EGP per day of early completion and an incentive (penalty) rate of 17,000 EGP per day of late completion to encourage the contractor to minimize the construction time of the project. In addition, a user-specified occupation cost rate of 7000 EGP per day was stipulated for each day of the project. The present model is utilized to schedule the project and generate a set of optimum resource utilization plans that simultaneously minimize project duration and cost. The model generated 46 non-dominated optimal/near-optimal solutions, where each solution represented a unique optimal/near-optimal resource utilization plan, as shown in Fig. 8. Each plan was generated by selecting for each activity: (1) the optimum number of construction crews and their formations and (2) the optimum sequence of work for these crews among different units in the project. As shown in Fig. 8 and Table 7, the range of optimal trade-offs between project duration and cost includes a single solution (S2) that meets the specified deadline (350 days) with a project cost of 927.5 million EGP. The remaining solutions are divided into two groups. The first group (G1) includes the solutions that deliver the project ahead of the specified deadline and have a higher project cost than the solution (S2). For example, solution (S1) represents the extreme solution in this group with a minimum project duration of 292.6 days and the highest project cost of 979 million EGP. This solution (S1) was able to achieve a project duration of 57 days ahead of the specified deadline by selecting the crews with the highest productivity rates to finish activities sooner; however, it increased the cost by 5.5% in comparison with solution (S2). The second group (G2) includes solutions that deliver the project behind the specified deadline with lower project costs. For example, solution (S3) represents the extreme solution in this group with a maximum project duration of 417.7 days and the lowest project cost of 911.5 million EGP. This solution (S3) was able to achieve a 1.7% reduction in project cost by selecting crews with the lowest cost rates to minimize project costs; however, this resulted in a project duration of 68 days behind the specified deadline. In addition, each solution has its advantages and compromises from the contractor’s perspective, which makes it essential to consider the specific priorities and constraints of the project. For example, solution (S1), characterized by the shortest duration but the highest cost, would be an optimal choice for a contractor who values completing the project as quickly as possible. This solution may be suitable when time is essential, and the additional cost can be justified by the urgency or importance preceding the deadline. The contractor might prioritize delivering the project promptly, even if it incurs higher expenses for reasons such as client satisfaction, competitive advantage, time for adjustments, improved project management, and establishing a reputation for reliability and competence. On the other hand, solution (S2) has a slightly higher duration and cost, but meets the stipulated deadline, and could be preferred by a contractor who places equal importance on both time and cost. This solution strikes a balance between meeting the required deadline and managing the expenses. The contractor recognizes the need for timely completion but also considers the financial implications and aims to stay within the budget while maintaining project integrity. Finally, solution (S3) provides the lowest project cost, but the longest project duration may be suitable for the contractor who is willing to maximize profitability by tolerating a longer completion period, which saves construction costs. Additionally, this solution may be appropriate when the project budget is a primary concern for the owner. Ultimately, the preferred or selected solution depends on the contractor's goals, priorities, and constraints. This analysis demonstrates the use of the model and highlights its unique capabilities in (1) harmonizing the parallel work of multiple same/different crews concurrently in each activity, (2) identifying the optimal number of construction crew formations and their optimal sequence of work to minimize project duration and cost, and (3) considering different contractual cost options, such as project incentives (savings/penalties) and project occupational rental costs, which provide more flexibility for planners in scheduling repetitive construction projects.

Conclusion

The present study introduced a multi-objective scheduling optimization model for repetitive construction projects. The model aims to generate optimal resource utilization plans that concurrently minimize the project's duration and cost. The model was implemented in three modules: scheduling, cost, and optimization. The scheduling module was developed to harmonize the concurrent work of multiple same/different crews in each activity, maintaining work continuity while accounting for various precedence relationships. The cost module provides flexibility to planners by incorporating different contractual cost options. The optimization module was designed to provide a set of optimal resource utilization plans by identifying the optimal number of construction crews for each activity and their optimal sequence of work. An application example from the literature was analyzed to evaluate the effectiveness of the model, demonstrating superior results compared to similar models. Notably, the reductions achieved in the total project duration and cost were 8% and 0.78%, respectively. Furthermore, a real-life case study of a highway renovation and development project is examined, demonstrating the practical capabilities of the current model.

The primary contribution of this study is its original methodology, which presents three fundamental enhancements. First, it addresses the challenge of harmonizing the concurrent work of multiple crew formations with same/different productivity rates within each activity. The model considers the specific requirements of each activity and the availability of different crews to maintain crew work continuity constraints, and accounts for different types of precedence relationships. This facilitates efficient management of projects that contain both typical and atypical repetitive activities. Second, in addition to direct and indirect project costs, the model incorporates different contractual cost options such as project incentives, penalties, and occupational rental costs. This feature provides planners with a more realistic representation of the financial aspects associated with the project by selecting the most advantageous cost structure. Third, the model empowers planners with informed decisions, including a diverse set of optimal/near-optimal resource utilization plans that balance project efficiency and financial feasibility. This flexibility is particularly valuable in repetitive construction projects where finding the optimal balance between time and cost is crucial. However, it is essential to acknowledge the limitations of this study and to propose areas for further improvement. These limitations can be summarized as follows: (1) the model strictly enforces crew work continuity for all construction crews without allowing interruptions, while providing the flexibility to introduce selected interruptions may result in minimizing the project duration; and (2) the model does not consider risk and uncertainties due to variations in site conditions, weather, labor productivity, and equipment availability during the construction phase. These limitations will be addressed in future studies.

Data availability

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

Abbreviations

- GAs:

-

Genetic algorithms

- LSM:

-

Linear scheduling method

- LOB:

-

Line of balance

- MCPMWGAs:

-

Modified critical path method with genetic algorithms

- OBL:

-

Opposition-based learning technique

- FS:

-

Finish to start

- FF:

-

Finish to finish

- SS:

-

Start to start

- SF:

-

Start to finish

- NSGA:

-

Non-dominated sorting genetic algorithm

- DEAP:

-

Distributed evolutionary algorithms in Python

- \(I\) :

-

Number of repetitive activities.

- \({N}_{i}\) :

-

The number of all available crews for each activity (\(i\))

- \({J}_{i}\) :

-

The number of repetitive units in activity (\(i\))

- \({M}_{i}\) :

-

The number of crews assigned to perform each activity (\(i\))

- \({s}_{i,m}\) :

-

The sequence of work for each crew variable

- \(\mathrm{TD}\) :

-

Total project duration

- \(\mathrm{TC}\) :

-

Total project cost

- \(\mathrm{DC}\) :

-

Project direct cost

- \({Q}_{i,j}\) :

-

Quantity of work required for activity unit \(\left(i,j\right)\)

- \({\mathrm{MR}}_{i}\) :

-

Material cost rate for activity \(\left(i\right)\)

- \({d}_{i,j}^{{m}_{i}}\) :

-

Duration of activity \(\left(i\right)\) in unit \(\left(j\right)\) utilized by crew \({(m}_{i})\)

- \({L}_{i,j}^{{m}_{i}}\) :

-

Labor cost rate per unit duration of crew \({(m}_{i})\) performing activity unit \(\left(i,j\right)\)

- \({E}_{i,j}^{{m}_{i}}\) :

-

Equipment cost rate per unit duration of crew \({(m}_{i})\) performing activity unit \(\left(i,j\right)\)

- \(\mathrm{IC}\) :

-

Project indirect cost

- \(\mathrm{ICR}\) :

-

Indirect cost rate

- \(\mathrm{PI}\) :

-

Project incentives (bonus or penalty)

- \(\mathrm{SD}\) :

-

Specified duration in the contract

- \(B\) :

-

Bonus rate

- \(P\) :

-

Penalty rate

- \(\mathrm{OC}\) :

-

Occupational rental cost

- \(\mathrm{OR}\) :

-

Occupation cost rate

References

Altuwaim A, El-Rayes K (2018) Minimizing duration and crew work interruptions of repetitive construction projects. Autom Constr 88(December 2017):59–72. https://doi.org/10.1016/j.autcon.2017.12.024

Hassan A, El-Rayes K, Attalla M (2020) Optimizing the scheduling of crew deployments in repetitive construction projects under uncertainty. Eng Constr Archit Manag 28(6):1615–1634. https://doi.org/10.1108/ECAM-05-2020-0304

Vanhoucke M (2006) Work continuity constraints in project scheduling. J Constr Eng Manag 132(1):14–25. https://doi.org/10.1061/(asce)0733-9364(2006)132:1(14)

Abdelkhalek HA, Refaie HS, Aziz RF (2020) Optimization of time and cost through learning curve analysis. Ain Shams Eng J 11(4):1069–1082. https://doi.org/10.1016/j.asej.2019.12.007

Jaskowski P, Biruk S, Lublin (2019) Minimizing the duration of repetitive construction processes with work continuity constraints. https://doi.org/10.3390/computation7010014

Long LD, Ohsato A (2009) A genetic algorithm-based method for scheduling repetitive construction projects. Autom Constr 18(4):499–511. https://doi.org/10.1016/j.autcon.2008.11.005

RSMeans Data (2018) Heavy construction costs with RSMeans Data, 32nd edn. Gordian RSMeans Data, Rockland

Hassan A, El-rayes K, Attalla M (2021) Stochastic scheduling optimization of repetitive construction projects to minimize project duration and cost. Int J Constr Manag. https://doi.org/10.1080/15623599.2021.1975078

Su Y, Lucko G (2016) Linear scheduling with multiple crews based on line-of-balance and productivity scheduling method with singularity functions. Autom Constr 70:38–50. https://doi.org/10.1016/j.autcon.2016.05.011

Duffy GA, Oberlender GD, Seok Jeong DH (2011) Linear scheduling model with varying production rates. J Constr Eng Manag 137(8):574–582. https://doi.org/10.1061/(asce)co.1943-7862.0000320

García-Nieves JD (2019) Multipurpose linear programming optimization model for repetitive activities scheduling in construction projects. Autom Constr 105(August 2018):102799. https://doi.org/10.1016/j.autcon.2019.03.020

Hassan A, El-Rayes K (2019) Quantifying the interruption impact of activity delays in non-serial repetitive construction projects. Constr Manag Econ 38(6):515–533. https://doi.org/10.1080/01446193.2019.1657922

Srisuwanrat C (2009) The Sequence Step Algorithm A Simulation-Based Scheduling Algorithm for Repetitive Projects with Probabilistic Activity Durations. The University of Michigan, Ann Arbor

Lutz JD (1990) Planning of linear construction projects using simulation and line of balance. Ph.D. Dissertation, Purdue University, Lafayette

Damci A (2020) Revisiting the concept of natural rhythm of production in line of balance scheduling. Int J Constr Manag. https://doi.org/10.1080/15623599.2020.1786764

Arditi D, Asce M, Tokdemir OB, Suh K (2002) Challenges in LOB scheduling. J Constr Engi- neering Manag 128(December):545–556

Gouda A, Hosny O, Nassar K (2017) Optimal crew routing for linear repetitive projects using graph theory. Autom Constr 81:411–421. https://doi.org/10.1016/j.autcon.2017.03.007

Arditi BD, Asce M, Albulak Z (1986) Line-of-balance scheduling in pavement construction. J Constr Eng 112(3):411–424

Ammar MA (2019) Optimization of line of balance scheduling considering work interruption. Int J Constr Manag. https://doi.org/10.1080/15623599.2019.1624003

Monghasemi S, Abdallah M (2021) Linear optimization model to minimize total cost of repetitive construction projects and identify order of units. J Manag Eng 37(4):1–15. https://doi.org/10.1061/(asce)me.1943-5479.0000936

Jaskowski P (2020) Scheduling of repetitive construction processes with concurrent work of similarly specialized crews. J Civil Eng Manag 26(6):579–589

Hegazy T, Kamarah E (2008) Efficient repetitive scheduling for high-rise construction. J Constr Eng Manag 134(4):253–264. https://doi.org/10.1061/(asce)0733-9364(2008)134:4(253)

Fan SL, Sun KS, Wang YR (2012) GA optimization model for repetitive projects with soft logic. Autom Constr 21(1):253–261. https://doi.org/10.1016/j.autcon.2011.06.009

Huang Y, Zou X, Zhang L (2016) Genetic algorithm-based method for the deadline problem in repetitive construction projects considering soft logic. J Manag Eng 32(4):04016002. https://doi.org/10.1061/(asce)me.1943-5479.0000426

Hyari K, El-Rayes K (2006) Optimal planning and scheduling for repetitive construction projects. J Manag Eng 22(1):11–19. https://doi.org/10.1061/(asce)0742-597x(2006)22:1(11)

Altuwaim A, El-Rayes K (2018) Optimizing the scheduling of repetitive construction to minimize interruption cost. J Constr Eng Manag 144(7):04018051. https://doi.org/10.1061/(asce)co.1943-7862.0001510

El-Rayes K, Kandil A (2005) Time-cost-quality trade-off analysis for highway construction. J Constr Eng Manag 131(4):477–486. https://doi.org/10.1061/(asce)0733-9364(2005)131:4(477)

Hyari KH, El-Rayes K, El-Mashaleh M (2009) Automated trade-off between time and cost in planning repetitive construction projects. Constr Manag Econ 27(8):749–761. https://doi.org/10.1080/01446190903117793

El Razek RHA, Diab AM, Hafez SM, Aziz RF (2010) Simplified genetic algorithm for solving typical-repetitive construction projects with multi-mode of resources. Measurement 1205–1215

Abd El Razek RH, Diab AM, Hafez SM, Aziz RF (2010) Time-cost-quality trade-off software by using simplified Genetic algorithm for typical-repetitive construction projects. World Acad Sci Eng Technol 61(1):312–321

Aziz RF (2013) Optimizing strategy for repetitive construction projects within multi-mode resources. Alex Eng J 52(1):67–81. https://doi.org/10.1016/j.aej.2012.11.003

Aziz RF (2013) Optimizing strategy software for repetitive construction projects within multi-mode resources. Alex Eng J 52(3):373–385. https://doi.org/10.1016/j.aej.2013.04.002

Tran D, Luong-duc L, Duong M, Le T, Pham A (2018) Opposition multiple objective symbiotic organisms search (OMOSOS ) for time, cost, quality and work continuity tradeoff in repetitive projects. J Comput Des Eng 5(2):160–172. https://doi.org/10.1016/j.jcde.2017.11.008

Altuwaim A, El-Rayes K (2021) Multiobjective optimization model for planning repetitive construction projects. J Constr Eng Manag 147(7):1–12. https://doi.org/10.1061/(asce)co.1943-7862.0002072

El-rayes BK (2001) Optimum planning of highway constrction under A+B bidding method. J Constr Eng Manag 261–269

Verma S, Member GS, Pant M (2021) A comprehensive review on NSGA-II for multi-objective combinatorial optimization problems. J Mag 1:1. https://doi.org/10.1109/ACCESS.2021.3070634

Kandil A, El-Rayes K, El-Anwar O (2010) Optimization research: enhancing the robustness of large-scale multiobjective optimization in construction. J Constr Eng Manag 136(1):17–25. https://doi.org/10.1061/(asce)co.1943-7862.0000140

Mansour AlOtaibi AA, El-Rayes K (2021) Optimizing the renovation scheduling of leased residential buildings to minimize total project Cost.pdf

De Rainville F, Fortin F, Gardner M, Parizeau M, Gagné C (2012) DEAP : a python framework for evolutionary algorithms

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

We confirm that the manuscript has been read and approved by all named authors and that there are no other persons who satisfied the criteria for authorship but are not listed. We further confirm that the order of authors listed in the manuscript has been approved by all of us.

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

For this type of study formal consent is not required.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abdelbasset, E., Hassan, A., Amer, N.H. et al. Optimizing the number of crews working in parallel and their work sequence to minimize project duration and cost for repetitive construction projects. Innov. Infrastruct. Solut. 8, 288 (2023). https://doi.org/10.1007/s41062-023-01233-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01233-3