Abstract

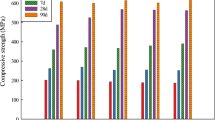

Ordinary Portland Cement (OPC) is an expensive material and has negative effects on environmental health as it increases greenhouse gas emissions. These problems accelerate the search for substitute materials. Although metakaolin (MK) and silica fume (SF) show high potential as substitute materials, they are used at a limited rate in the construction industry. Considering plain Portland Cement may be insufficient in aggressive conditions, it was aimed to increase interest and awareness regarding the application by using two materials together. For this study, a critical substitution ratio (20%), was shared equally between metakaolin (10%) and silica fume (%10). In addition, silica aerogel (SA) (at 1, 2, 3, and 4%) and air-entraining admixture (AEA) (at 0.1, 0.4, 0.7, and 1%) were examined in terms of mechanical and thermal properties for the building construction in sustainable cities. Although these additives bring important advantages, their information is limited, especially in aggressive conditions. The 7 and 28 days compressive and flexural strengths and physical properties were found for 10 series. Also, the freezing–thawing and high-temperature tests were applied, and the scanning electron microscopy (SEM) analyzes were performed. According to the results, metakaolin and silica fume increased flexural strength by 5.67% and compressive strength by 8.07% due to their high pozzolanic properties. Also, 1% silica aerogel strengthened the cement paste and increased the compressive strength by 2%. Also, it maintained this performance after the durability tests. Although 0.1% air-entraining admixture decreased the strength results, it increased the compressive strength by 4% after freezing–thawing.

Similar content being viewed by others

References

Hu L, He Z (2020) A fresh perspective on effect of metakaolin and limestone powder on sulfate resistance of cement-based materials. Constr Build Mater 262:119847. https://doi.org/10.1016/j.conbuildmat.2020.119847

Tang J, Wei S, Li W, Ma S, Ji P, Shen X (2019) Synergistic effect of metakaolin and limestone on the hydration properties of Portland cement. Constr Build Mater 223:177–184. https://doi.org/10.1016/j.conbuildmat.2019.06.059

Subaşı A, Emiroğlu M (2015) Effect of metakaolin substitution on physical, mechanical and hydration process of White Portland cement. Constr Build Mater 95:257–268. https://doi.org/10.1016/j.conbuildmat.2015.07.125

Dinakar P, Sahoo PK, Sriram G (2013) Effect of metakaolin content on the properties of high strength concrete. Int J Concr Struct Mater 7:215–223. https://doi.org/10.1007/s40069-013-0045-0

Ramezanianpour AA, Jovein HB (2012) Influence of metakaolin as supplementary cementing material on strength and durability of concretes. Constr Build Mater 30:470–479. https://doi.org/10.1016/j.conbuildmat.2011.12.050

Weng TL, Lin WT, Cheng A (2013) Effect of metakaolin on strength and efflorescence quantity of cement-based composites. Sci World J. https://doi.org/10.1155/2013/606524

ACI (American Concrete Institute), (1992) ACI 363R–92: State of the art report on high-strength concrete American Concrete Institute Detroit, MI

Sanjuan MA, Argiz C, Gálvez JC, Moragues A (2015) Effect of silica fume fineness on the improvement of Portland cement strength performance. Constr Build Mater 96:55–64. https://doi.org/10.1016/j.conbuildmat.2015.07.092

Singh NB, Kalra M, Kumar M, Rai S (2015) Hydration of ternary cementitious system: Portland cement, fly ash and silica fume. J Therm Anal Calorim 119:381–389. https://doi.org/10.1007/s10973-014-4182-8

Jiang J, Lu Z, Niu Y, Li J, Zhang Y (2016) Investigation of the properties of high-porosity cement foams based on ternary Portland cement-metakaolin-silica fume blends. Constr Build Mater 107:181–190. https://doi.org/10.1016/j.conbuildmat.2015.12.190

Seo J, Park S, Yoon HN, Lee HK (2020) Effect of CaO incorporation on the microstructure and autogenous shrinkage of ternary blend Portland cement-slag-silica fume. Constr Build Mater 249:118691. https://doi.org/10.1016/j.conbuildmat.2020.118691

Bhattacharya M, Harish KV (2018) An integrated approach for studying the hydration of Portland cement systems containing silica fume. Constr Build Mater 188:1179–1192. https://doi.org/10.1016/j.conbuildmat.2018.08.114

Ardalan RB, Joshaghani A, Hooton RD (2017) Workability retention and compressive strength of self-compacting concrete incorporating pumice powder and silica fume. Constr Build Mater 134:116–122. https://doi.org/10.1016/j.conbuildmat.2016.12.090

Rao GA (2003) Investigations on the performance of silica fume-incorporated cement pastes and mortars. Cem Concr Res 33:1765–1770. https://doi.org/10.1016/s0008-8846(03)00171-6

Wu Z, Khayat KH, Shi C (2019) Changes in rheology and mechanical properties of ultra-high performance concrete with silica fume content. Cem Concr Res 123:105786. https://doi.org/10.1016/j.cemconres.2019.105786

Kılıç A, Atiş CD, Yaşar E, Özcan F (2003) High-strength lightweight concrete made with scoria aggregate containing mineral admixtures. Cem Concr Res 33(10):1595–1599. https://doi.org/10.1016/s0008-8846(03)00131-5

Buratti C, Moretti E, Belloni E, Agosti F (2014) Development of innovative aerogel based plasters: preliminary thermal and acoustic performance evaluation. Sustain 6(9):5839–5852. https://doi.org/10.3390/su6095839

de Fátima JM, Soares A, Ilharco LM, Flores-Colen I, de Brito J (2016) Aerogel-based renders with lightweight aggregates: correlation between molecular/pore structure and performance. Constr Build Mater 124:485–495. https://doi.org/10.1016/j.conbuildmat.2016.07.103

Ng S, Jelle BP, Sandberg LIC, Gao T, Wallevik ÓH (2015) Experimental investigations of aerogel-incorporated ultra-high performance concrete. Constr Build Mater 77:307–316. https://doi.org/10.1016/j.conbuildmat.2014.12.064

Kim S, Seo J, Cha J, Kim S (2013) Chemical retreating for gel-typed aerogel and insulation performance of cement containing aerogel. Constr Build Mater 40:501–505. https://doi.org/10.1016/j.conbuildmat.2012.11.046

Strzalkowski J, Garbalinska H (2016) Thermal and strength properties of lightweight concretes with the addition of aerogel particles. Adv Cem Res 28(9):567–575. https://doi.org/10.1680/jadcr.16.00032

Du L, Folliard KJ (2005) Mechanisms of air entrainment in concrete. Cem Concr Res 35(8):1463–1471. https://doi.org/10.1016/j.cemconres.2004.07.026

Lamond JF, Pielert JH (2006) Significance of tests and properties of concrete and concrete-making materials. ASTM international, USA

Pigeon M, Pleau R (2010) Durability of concrete in cold climates. CRC Press. https://doi.org/10.1201/9781482271447

Kim H, Jeon J, Lee H (2012) Workability, and mechanical, acoustic and thermal properties of lightweight aggregate concrete with a high volume of entrained air. Constr Build Mater 29:193–200. https://doi.org/10.1016/j.conbuildmat.2011.08.067

Sengul O, Azizi S, Karaosmanoglu F, Tasdemir MA (2011) Effect of expanded perlite on the mechanical properties and thermal conductivity of lightweight concrete. Energy Build 43(2):671–676. https://doi.org/10.1016/j.enbuild.2010.11.008

Łaźniewska-Piekarczyk B (2012) The influence of selected new generation admixtures on the workability, air-voids parameters and frost-resistance of self compacting concrete. Constr Build Mater 31:310–319. https://doi.org/10.1016/j.conbuildmat.2011.12.107

Aygörmez Y, Canpolat O, Al-mashhadani MM, Uysal M (2020) Elevated temperature, freezing-thawing and wetting-drying effects on polypropylene fiber reinforced metakaolin based geopolymer composites. Constr Build Mater 235:117502. https://doi.org/10.1016/j.conbuildmat.2019.117502

Nayak CB, Taware PP, Jagadale UT, Jadhav NA, Morkhade SG (2021) Effect of SiO2 and ZnO nano-composites on mechanical and chemical properties of modified concrete. Iran J Sci Technol, Trans Civil Eng 2:1–11. https://doi.org/10.1007/s40996-021-00694-9

Kate GK, Nayak CB, Thakare SB (2021) Optimization of sustainable high-strength–high-volume fly ash concrete with and without steel fiber using Taguchi method and multi-regression analysis. Innov Infrastr Solut 6(2):1–18. https://doi.org/10.1007/s41062-021-00472-6

Parlikar AS, Naik CV, Nayak CB (2021) An experimental study on effect of pharmaceutical industrial waste water on compressive strength of concrete. Int J Innov Res Sci, Eng Technol 10(8):11068–11072. https://doi.org/10.15680/IJIRSET.2021.1008038

ASTM C 305 Standard practice for mechanical mixing of hydraulic cement pastes and mortars of plastic consistency. 1999. 3P. ASTM International, United States. https://doi.org/10.1520/C0305-20

ASTM C348—14 Standard test method for flexural strength of hydraulic-cement mortars. (n.d.). Retrieved October 15, 2021. https://doi.org/10.1520/C0348-14

ASTM C109 / C109M - 21 Standard test method for compressive strength of hydraulic cement mortars (Using 2-in. Or [50 mm] Cube Specimens). (n.d.). Retrieved October 28, 2021. https://doi.org/10.1520/C0109_C0109M-21

El-Diadamony H, Amer AA, Sokkary TM, El-Hoseny S (2018) Hydration and characteristics of metakaolin pozzolanic cement pastes. HBRC journal 14(2):150–158. https://doi.org/10.1016/j.hbrcj.2015.05.005

Rais MS, Khan RA (2020) Strength and durability characteristics of binary blended recycled coarse aggregate concrete containing microsilica and metakaolin. Innov Infrastr Solut 5(3):1–13. https://doi.org/10.1007/s41062-020-00365-0

Mehsas B, Siline M, Zeghichi L (2021) Development of supplementary cementitious materials from Algerian kaolin: elaboration of metakaolin and assessment of pozzolanicity. Innov Infrastr Solut 6(2):1–12. https://doi.org/10.1007/s41062-020-00444-2

Moubarak AM, Elwardany H, Taher SED (2021) Optimizing metakaolin and silica-fume in rc beams with/without strengthening. Innov Infrastr Solut 6(2):1–13. https://doi.org/10.1007/s41062-020-00449-x

Khan RA, Haq M (2020) Long-term mechanical and statistical characteristics of binary-and ternary-blended concrete containing rice husk ash, metakaolin and silica fume. Innov Infrastr Solut 5(2):1–14. https://doi.org/10.1007/s41062-020-00303-0

Mushurov M, Canpolat O, Uysal M, Al-mashhadani MM, Aygörmez Y (2018) Investigation of waste products of boron and metakaolin utilizes. J Sustain Constr Mater Technol 3(2):212–220. https://doi.org/10.29187/jscmt.2018.22

Sadrmomtazi A, Tahmouresi B, Saradar A (2018) Effects of silica fume on mechanical strength and microstructure of basalt fiber reinforced cementitious composites (BFRCC). Constr Build Mater 162:321–333. https://doi.org/10.1016/j.conbuildmat.2017.11.159

Topcu IB, Atesin O, Uygunoglu T (2017) Effect of high dosage air-entraining admixture usage on micro concrete properties. Eur J Eng Natural Sci (EJENS) 2(1):1–11

Khamidi MF, Glover C, Farhan SA, Puad NHA, Nuruddin MF (2014) Effect of silica aerogel on the thermal conductivity of cement paste for the construction of concrete buildings in sustainable cities. WIT Trans Built Environ 137:665–674. https://doi.org/10.2495/HPSM140601

Strzałkowski J, Garbalińska H (2016) Thermal and strength properties of lightweight concretes with the addition of aerogel particles. Adv Cem Res 28(9):567–575. https://doi.org/10.1680/jadcr.16.00032

Bostancı L, Ustundag O, Celik Sola O, Uysal M (2019) Effect of various curing methods and addition of silica aerogel on mortar properties. Građevinar 71(08):651–661. https://doi.org/10.14256/JCE.2469.2018

Pilehvar S, Szczotok AM, Rodríguez JF, Valentini L, Lanzón M, Pamies R, Kjøniksen AL (2019) Effect of freeze-thaw cycles on the mechanical behavior of geopolymer concrete and Portland cement concrete containing micro-encapsulated phase change materials. Constr Build Mater 200:94–103. https://doi.org/10.1016/j.conbuildmat.2018.12.057

Allahverdi A, Abadi MMBR, Hossain KMA, Lachemi M (2014) Resistance of chemically-activated high phosphorous slag content cement against freeze–thaw cycles. Cold Regions Sci Technol 103:107–114. https://doi.org/10.1016/j.coldregions.2014.03.012

Basheer L, Kropp J, Cleland DJ (2001) Assessment of the durability of concrete from its permeation properties: a review. Constr Build Mater 15(2):93–103. https://doi.org/10.1016/S0950-0618(00)00058-1

Arslan AA, Uysal M, Yılmaz A, Al-mashhadani MM, Canpolat O, Sahin F, Aygörmez Y (2019) Influence of wetting-drying curing system on the performance of fiber reinforced metakaolin-based geopolymer composites. Constr Build Mater 225:909–926. https://doi.org/10.1016/j.conbuildmat.2019.07.235

Aydın S, Yazıcı H, Baradan B (2008) High temperature resistance of normal strength and autoclaved high strength mortars incorporated polypropylene and steel fibers. Constr Build Mater 22(4):504–512. https://doi.org/10.1016/j.conbuildmat.2006.11.003

Zhang HY, Kodur V, Wu B, Cao L, Qi SL (2016) Comparative thermal and mechanical performance of geopolymers derived from metakaolin and fly ash. J Mater Civ Eng 28(2):1–12. https://doi.org/10.1061/(asce)mt.1943-5533.0001359

Beglarigale A, Yalçınkaya Ç, Yiğiter H, Yazıcı H (2016) Flexural performance of SIFCON composites subjected to high temperature. Constr Build Mater 104:99–108. https://doi.org/10.1016/j.conbuildmat.2015.12.034

Celik A, Yilmaz K, Canpolat O, Al-mashhadani MM, Aygörmez Y, Uysal M (2018) High-temperature behavior and mechanical characteristics of boron waste additive metakaolin based geopolymer composites reinforced with synthetic fibers. Constr Build Mater 187:1190–1203. https://doi.org/10.1016/j.conbuildmat.2018.08.062

Akyuncu V, Uysal M, Tanyildizi H, Sumer M (2019) Modeling the weight and length changes of the concrete exposed to sulfate using artificial neural network. J Constr 17(3):337–353. https://doi.org/10.7764/rdlc.17.3.337

Acknowledgements

This work was supported by the research fund of the Yildiz Technical University, the authors would like to express their sincere gratitude to the scientific research coordination unit for their financial support to the project (Project number: FAP-2021-4020).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Aygörmez, Y. An experimental study on silica fume and metakaolin doped portland cement-based mortars using silica aerogel and air-entraining admixture. Innov. Infrastruct. Solut. 7, 223 (2022). https://doi.org/10.1007/s41062-022-00825-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-022-00825-9