Abstract

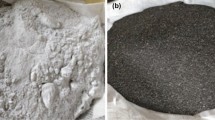

There is a lot of studies going on throughout the world in recycling and reusing waste materials from generated industries. A large portion of the research is devoted to developing cementitious materials that can be utilized instead of regular ordinary portland cement (OPC) and river sand. Many industrial waste by-products such as quartz, metakaolin, ground granulated furnace slag, silica fume and fly ash are being researched for use as cement or fine aggregate replacement in concrete to reduce carbon footprints associated with the building sector. Researchers have been very concerned about using waste copper slag (WCS) as construction materials since it is a non-toxic and innocuous industrial waste. It is expected that WCS would be substituted in concrete with river sand. This work aimed to develop and study the behavior of self-compacting concrete (SCC) properties on fresh SCC (slump flow, V-funnel. L-Box), mechanical, ultrasonic pulse velocity (UPV), rebound hammer (N) at 7, 28, 56, and 90 days of curing age and microstructural properties at (28 days of curing) by replacing cement with fly ash (FA) at (17.85%) and river sand with waste copper slag (WCS) from 0 to 70%. From the results, it is seen that the combination of FA and WCS has shown a significant improvement in all flow and mechanical properties up to 40% WCS in SCC mixes.

Similar content being viewed by others

Code availability

Not applicable.

References

Mendu JK, Pannem RMR (2021) Assessment of mechanical properties of cashew nut shell ash blended concrete. Innov Infrastruct Solut 6:227. https://doi.org/10.1007/s41062-021-00586-x

Raia A, Tahwia A, Raheem AHA et al (2022) Synergistic influence of metakaolin and slag cement on the properties of self-compacting fiber-reinforced concrete. Innov Infrastruct Solut 7:69. https://doi.org/10.1007/s41062-021-00657-z

Kavya Teja BV, Guru Jawahar J, Sashidhar C (2020) Effect of alccofine and fly ash on analytical methods of self-compacting concrete. Innov Infrastruct Solut 5:80. https://doi.org/10.1007/s41062-020-00332-9

Saand A, Ali K, Kumar A et al (2021) Effect of metakaolin developed from natural material Soorh on fresh and hardened properties of self-compacting concrete. Innov Infrastruct Solut 6:166. https://doi.org/10.1007/s41062-021-00534-9

Saini BS, Singh SP (2022) Estimation of flexural fatigue strength of self-compacting concrete made with coarse recycled concrete aggregates. Innov Infrastruct Solut 7:22. https://doi.org/10.1007/s41062-021-00606-w

Sharma R, Khan RA (2018) Influence of copper slag and metakaolin on the durability of self compacting concrete. J Clean Prod 171:1171–1186

Gupta N, Siddique R (2019) Strength and micro-structural properties of self-compacting concrete incorporating copper slag. Constr Build Mater 224:894–908

Sharma R, Khan RA (2017) Fresh and mechanical properties of self compacting concrete containing copper slag as fine aggregates. J Mater Eng Struct 4(1):25–36

Krishna Chaitanya B, Sivakumar I (2021) Influence of waste copper slag on flexural strength properties of self compacting concrete. Mater Today: Proc 42:671–676

Vaishnav Kumar R, Krishna Chaitanya B, Sai Madupu L, Venkata Sairam Kumar N (2021) Evaluation of mechanical and flow properties of crimpled steel fiber in self compacting concrete. Mater Today: Proc 45:4835–4840

Global Construction Aggregates Industry (2020) Market trajectory & analytics. Research and Markets.com

The Freedonia Group, Inc (2021)

Al-Jabri KS, Hisada M, Al-Saidy AH, Al-Oraimi S (2009) Performance of high strength concrete made with copper slag as a fine aggregate. Constr Build Mater 23(6):2132–2140. https://doi.org/10.1016/j.conbuildmat.2008.12.013

International Copper Study Group, ICSG-2015

International Copper Study Group, ICSG-2019

Alter H (2005) The composition and environmental hazard of copper slags in the context of the Basel convention. Resour Conserv Recycl 43(4):353–360

Khanzadi M, Behnood A (2009) Mechanical properties of high-strength concrete incorporating copper slag as coarse aggregate. Constr Build Mater 23(6):2183–2188

Al-Jabri KS, Al-Saidy AH, Taha R (2011) Effect of copper slag as a fine aggregate on the properties of cement mortars and concrete. Constr Build Mater 25(2):933–938

Najimi M, Pourkhorshidi AR (2011) Properties of concrete containing copper slag waste. Mag Concr Res 63(8):605–615. https://doi.org/10.1680/macr.2011.63.8.605

Fadaee M, Mirhosseini RT, Tabatabaei R, Fadaee M (2015) Investigation on using copper slag as part of cementitious materials in self compacting concrete. Asian J Civ Eng (BHRC) 16(3):368–381

Afshoon I, Sharifi Y (2014) Ground copper slag as a supplementary cementing material and its influence on the fresh properties of self-consolidating concrete. IES J Part A: Civ Struct Eng 7(4):229–242

Mishra S (2014) Concrete technology. National Programme on Technology Enhanced Learning (NPTEL), Chennai

Al-Jabri K, Taha R, Al-Hashmi A, Al-Harthy A (2006) Effect of copper slag and cement by-pass dust addition on mechanical properties of concrete. Constr Build Mater 20(5):322–331. https://doi.org/10.1016/j.conbuildmat.2005.01.020

Rajasekar A, Arunachalam K, Kottaisamy M (2019) Assessment of strength and durability characteristics of copper slag incorporated ultra high strength concrete. J Clean Prod 208:402–414

Ambily P, Umarani C, Ravisankar K, Prem PR, Bharatkumar B, Iyer NR (2015) Studies on ultra high performance concrete incorporating copper slag as fine aggregate. Constr Build Mater 77:233–240

Brindha D, Nagan S (2011) Durability studies on copper clag admixed concrete. Asian J Civ Eng (Build Hous) 12(5):563–578

Vijayaraghavan J, Jude AB, Thivya J (2017) Effect of copper slag, iron slag and recycled concrete aggregate on the mechanical properties of concrete. Resour Policy 53:219–225

Lori AR, Hassani A, Sedghi R (2019) Investigating the mechanical and hydraulic characteristics of pervious concrete containing copper slag as coarse aggregate. Constr Build Mater 197:130–142. https://doi.org/10.1016/j.conbuildmat.2018.11.230

Chithra S, Senthil Kumar S, Chinnaraju K (2016) The effect of colloidal nano-silica on workability, mechanical and durability properties of high-performance concrete with copper slag as partial fine aggregate. Constr Build Mater 113:794–804

Mithun B, Narasimhan M (2016) Performance of alkali activated slag concrete mixes incorporating copper slag as fine aggregate. J Clean Prod 112:837–844. https://doi.org/10.1016/j.jclepro.2015.06.026

Wu W, Zhang W, Ma G (2010) Optimum content of copper slag as a fine aggregate in high strength concrete. Mater Des 31(6):2878–2883. https://doi.org/10.1016/j.matdes.2009.12.037

Wang CL, Laiw JC (1989) Properties of concrete using copper slag as a substitute for fine aggregate. Spec Publ 144:1677–1696

Construction Aggregates 101 (2021). https://www.aem.org/news/construction-aggregates-101-what-they-are-and-why-they-matter

IS: 12269:1987. Indian Standard Ordinary Portland cement, 53 Grade-Specification. Bureau of Indian Standard, and New Delhi

IS: 383-1970. Specification for coarse and fine aggregates from natural sources for concrete. Bureau Of Indian Standard, New Delhi

IS 9103:1999. Indian Standard Concrete admixtures-specification (first revision). Bureau of Indian Standard, New Delhi

EFNARC (2002) Specification and guidelines for self-compacting concrete

EFNARC (2005) The European guidelines for self-compacting concrete

IS 10262:2019. Concrete Mix, proportioning guidelines (first revision). Bureau of Indian Standard, New Delhi

ACI-237R-07 (2007) Self-consolidating concrete. ACI Committee 237, USA

IS 516:2004. Methods of tests for strength of concrete. Bureau of Indian Standard, New Delhi

IS 5816:1999. Indian standard splitting tensile strength of concrete-method of test (first revision). Bureau of Indian Standard, New Delhi

IS: 13311 (Part-1):1992. Non-destructive testing of concrete-methods of test- part 1 ultrasonic pulse velocity. Bureau of Indian Standard, New Delhi

IS: 13311 (Part 2):1992. Non-destructive testing of concrete-methods of test, part 2 rebound hammer. Bureau Of Indian Standard, New Delhi

dos Anjos M, Sales A, Andrade N (2017) Blasted copper slag as fine aggregate in Portland cement concrete. J Environ Manage 196:607–613

Sharifi Y, Afshoon I, Asad-Abadi S, Aslani F (2020) Environmental protection by using waste copper slag as a coarse aggregate in self-compacting concrete. J Environ Manag 271:111013

Mavroulidou M (2017) Mechanical properties and durability of concrete with water cooled copper slag aggregate. Waste Biomass Valorization 8(5):1841–1854. https://doi.org/10.1007/s12649-016-9819-3

You N, Liu Y, Gu D, Ozbakkaloglu T, Pan J, Zhang Y (2020) Rheology, shrinkage and pore structure of alkali-activated slag-fly ash mortar incorporating copper slag as fine aggregate. Constr Build Mater 242:118029

Mahesh Babu K, Ravitheja A (2019) Effect of copper slag as fine aggregate replacement in high strength concrete. Mater Today: Proc 19:409–414. https://doi.org/10.1016/j.matpr.2019.07.626

Hooton R, Al-Jabri K, Taha R, Al-Ghassani M (2002) Use of copper slag and cement by-pass dust as cementitious materials. Cement Concr Aggreg 24(1):7

Sharifi Y, Afshoon I, Firoozjaei Z, Momeni A (2016) Utilization of waste glass micro-particles in producing self-consolidating concrete mixtures. Int J Concr Struct Mater 10(3):337–353. https://doi.org/10.1007/s40069-016-0141-z

Achudhan KV, Vandhana K (2018) Effect of copper slag in structural behaviour of reinforced concrete beams. Mater Today: Proc 5(2):6878–6887

Bhoi AM, Patil YD, Patil HS, Kadam MP (2018) Feasibility assessment of incorporating copper slag as a sand substitute to attain sustainable production perspective in concrete. Adv Mater Sci Eng 2018:1–11

Ganesh Prabhu G, Hyun JH, Kim YY (2014) Effects of foundry sand as a fine aggregate in concrete production. Constr Build Mater 70:514–521

Singh G, Siddique R (2016) Strength properties and micro-structural analysis of self-compacting concrete made with iron slag as partial replacement of fine aggregates. Constr Build Mater 127:144–152

Vivek S, Dhinakaran G (2017) Fresh and hardened properties of binary blend high strength self compacting concrete. Int J Eng Sci Technol 20(3):1173–1179. https://doi.org/10.1016/j.jestch.2017.05.003

Singh N, Singh S (2018) Evaluating the performance of self compacting concretes made with recycled coarse and fine aggregates using non-destructive testing techniques. Constr Build Mater 181:73–84

Chithra S, Kumar SS, Chinnaraju K, Alfin Ashmita F (2016) A comparative study on the compressive strength prediction models for high performance concrete containing nano silica and copper slag using regression analysis and artificial neural networks. Constr Build Mater 114:528–535

Tixier R, Devaguptapu R, Mobasher B (1997) The effect of copper slag on the hydration and mechanical properties of cementitious mixtures. Cem Concr Res 27(10):1569–1580

Sreenivasulu C, Guru Jawahar J, Sashidhar C (2020) Effect of copper slag on micro, macro, and flexural characteristics of geopolymer concrete. J Mater Civ Eng 32(5):04020086. https://doi.org/10.1061/(ASCE)mt.1943-5533.0003157

Funding

No.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Chaitanya, B.K., Sivakumar, I. Flow-behaviour, microstructure, and strength properties of self-compacting concrete using waste copper slag as fine aggregate. Innov. Infrastruct. Solut. 7, 181 (2022). https://doi.org/10.1007/s41062-022-00766-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-022-00766-3