Abstract

The use of sodium silicate solution for geopolymerisation has heavy impact on the environment and its cost of production is also high. The present research was undertaken to minimize the use of the alkaline activator and assess the effect of molarity of sodium hydroxide on the properties of red mud based geopolymer mortar and based on the results to synthesize sustainable first-class bricks that could cater to structural applications. Red mud-GGBS (ground granulated blast furnace slag) binder was synthesized with varying red mud percentage and molarity. The maximum strength was obtained at 4 M alkaline solution at 40% red mud. The strength of the paste was found to be significant even at a molarity of 2 M. To utilize the red mud to maximum strength, 50% red mud at 2 M molarity was used for further investigation on mortar. The results show that the decrease in the ratio of sodium silicate to sodium hydroxide from 2.5 to 1.5 improved the compressive strength of the geopolymer mortar. Microscopic and mineralogical studies through X-ray diffraction (XRD), scanning electron microscopy (SEM), and Fourier transform infrared spectroscopy (FTIR) were conducted on the mortar samples to analyze the result of compression testing. Bricks cast from the blend of red mud and GGBS with 50% red mud at low molarity exhibited excellent mechanical properties and found suitable to be used for all structural applications.

Graphical Abstract

Similar content being viewed by others

Data Availability

Not applicable.

References

Vigneshwaran S, Uthayakumar M, Arumugaprabu V (2020) Potential use of industrial waste-red mud in developing hybrid composites: A waste management approach. J Clean Prod 276:124278. https://doi.org/10.1016/j.jclepro.2020.124278

Ding X, Lu X, Zhao C, Yang G, Li N (2013) Measurement of natural radioactivity in building materials used in Urumqi, China. Radiat Prot Dosimetry 155:. https://doi.org/10.1093/rpd/nct002

Sas Z, Sha W, Soutsos M, Doherty R, Bondar D, Gijbels K, Schroeyers W (2019) Radiological characterisation of alkali-activated construction materials containing red mud, fly ash and ground granulated blast-furnace slag. Sci Total Environ 659:1496–1504. https://doi.org/10.1016/j.scitotenv.2019.01.006

Guo B, Pan D, Liu B, Volinsky AA, Fincan M, Du J, Zhang S (2017) Immobilization mechanism of Pb in fly ash-based geopolymer. Constr Build Mater 134:123–130. https://doi.org/10.1016/j.conbuildmat.2016.12.139

Zhang J, Provis JL, Feng D, van Deventer JSJ (2008) The role of sulfide in the immobilization of Cr(VI) in fly ash geopolymers. Cem Concr Res 38:681–688. https://doi.org/10.1016/j.cemconres.2008.01.006

El-Eswed BI, Yousef RI, Alshaaer M, Hamadneh I, Al-Gharabli SI, Khalili F (2015) Stabilization/solidification of heavy metals in kaolin/zeolite based geopolymers. Int J Miner Process 137:34–42. https://doi.org/10.1016/j.minpro.2015.03.002

Singh S, Aswath MU, Ranganath RV (2018) Effect of mechanical activation of red mud on the strength of geopolymer binder. Constr Build Mater 177:91–101. https://doi.org/10.1016/j.conbuildmat.2018.05.096

Sofi M, van Deventer JSJ, Mendis PA, Lukey GC (2007) Engineering properties of inorganic polymer concretes (IPCs). Cem Concr Res 37:251–257. https://doi.org/10.1016/j.cemconres.2006.10.008

Al-azzawi M (2018) Effects of fly ash characteristics on the mix proportion of the fly ash based geopolymer concrete A thesis submitted in fulfilment by Mustafa Sameer Abdulkareem Al-Azzawi

Zhang M, El-Korchi T, Zhang G, Liang J, Tao M (2014) Synthesis factors affecting mechanical properties, microstructure, and chemical composition of red mud–fly ash based geopolymers. Fuel 134:315–325. https://doi.org/10.1016/j.fuel.2014.05.058

Singh S, Aswath MU, Das Biswas R, Ranganath RV, Choudhary HK, Kumar R, Sahoo B (2019) Role of iron in the enhanced reactivity of pulverized Red mud: Analysis by Mössbauer spectroscopy and FTIR spectroscopy. Case Stud Construct Mater 11:e00266. https://doi.org/10.1016/j.cscm.2019.e00266

Reddy Y, Somasundaram K (2020) Effect of red mud proportion on the strength and microstructure of ferrosialate based geopolymer mortar. Indian J Eng Mater Sci 27:554–563

Singh S, Thakur A (2021) Red mud based binder: A sustainable material for removal of chromium (VI) from water. Mater Today Proc 46:2955–2959. https://doi.org/10.1016/j.matpr.2020.12.421

Duxson P, Provis JL, Lukey GC, van Deventer JSJ (2007) The role of inorganic polymer technology in the development of ‘green concrete.’ Cem Concr Res 37:1590–1597. https://doi.org/10.1016/j.cemconres.2007.08.018

Puertas F, Torres-Carrasco M (2014) Use of glass waste as an activator in the preparation of alkali-activated slag. Mechanical strength and paste characterisation. Cem Concr Res 57:95–104. https://doi.org/10.1016/j.cemconres.2013.12.005

Rakhimova NR, Rakhimov RZ (2019) Toward clean cement technologies: A review on alkali-activated fly-ash cements incorporated with supplementary materials. J Non Cryst Solids 509:31–41. https://doi.org/10.1016/j.jnoncrysol.2019.01.025

Mendes BC, Pedroti LG, Vieira CMF, Carvalho JMF, Ribeiro JCL, Albuini-Oliveira NM, Andrade IKR (2022) Evaluation of eco-efficient geopolymer using chamotte and waste glass-based alkaline solutions. Case Stud Constructi Mater 16:e00847. https://doi.org/10.1016/j.cscm.2021.e00847

Habert G, d’Espinose de Lacaillerie J-B, Roussel N (2011) An Environmental Evaluation of Geopolymer Based Concrete Production: Reviewing Current Research Trends. J Clean Prod 19:1229–1238. https://doi.org/10.1016/j.jclepro.2011.03.012

Varma DN, Singh SP (2023) A Review on Waste Glass-based Geopolymer Composites as a Sustainable Binder. SILICON 15:7685–7703. https://doi.org/10.1007/s12633-023-02629-7

Tchakoute Kouamo H, Rüscher C, Hinsch M, Djobo N, Kamseu E, Leonelli C (2017) Utilization of sodium waterglass from sugar cane bagasse ash as a new alternative hardener for producing metakaolin-based geopolymer cement. Chemie der Erde - Geochemistry 77:. https://doi.org/10.1016/j.chemer.2017.04.003

Wang S-D, Scrivener KL (2003) 29Si and 27Al NMR study of alkali-activated slag. Cem Concr Res 33:769–774. https://doi.org/10.1016/S0008-8846(02)01044-X

Rajan HS, Kathirvel P (2021) Sustainable development of geopolymer binder using sodium silicate synthesized from agricultural waste. J Clean Prod 286:124959. https://doi.org/10.1016/j.jclepro.2020.124959

Kaur M, Singh J, Kaur M (2018) Microstructure and strength development of fly ash-based geopolymer mortar: Role of nano-metakaolin. Constr Build Mater 190:672–679. https://doi.org/10.1016/j.conbuildmat.2018.09.157

Nuaklong P, Wongsa A, Sata V, Boonserm K, Sanjayan J, Chindaprasirt P (2019) Properties of high-calcium and low-calcium fly ash combination geopolymer mortar containing recycled aggregate. Heliyon 5:e02513. https://doi.org/10.1016/j.heliyon.2019.e02513

Sajjad U, Sheikh MN, Hadi MNS (2021) Experimental study of the effect of graphene on properties of ambient-cured slag and fly ash-based geopolymer paste and mortar. Constr Build Mater 313:125403. https://doi.org/10.1016/j.conbuildmat.2021.125403

Mudgal M, Singh A, Chouhan RK, Acharya A, Srivastava AK (2021) Fly ash red mud geopolymer with improved mechanical strength. Clean Eng Technol 4:100215. https://doi.org/10.1016/j.clet.2021.100215

Sowmyashree T, Muralidhara S, Sharif A, Mohammed V (2023) An Experimental Study on Red Mud Based Geo Polymer Mortar with GGBS, M Sand and Metakaolin BT - Advances in Construction Materials and Management. In: Singh SB, Delhi VSK (eds) Vilventhan A. Springer Nature Singapore, Singapore, pp 305–315

Monteiro SN, Vieira CMF (2014) On the production of fired clay bricks from waste materials: A critical update. Constr Build Mater 68:599–610. https://doi.org/10.1016/j.conbuildmat.2014.07.006

Goel G, Vasić MV, Katiyar NK, Kirthika SK, Pezo M, Dinakar P (2021) Potential pathway for recycling of the paper mill sludge compost for brick making. Constr Build Mater 278:122384. https://doi.org/10.1016/j.conbuildmat.2021.122384

LD M, Sameer, Sonal K (2014) Factsheets about brick kilns in South and Southeast Asia. 1–40

Al MS et (2012) Brick Kilns Performance Assessment A Roadmap for Cleaner Brick Production in India, Analysis. 164:

Murmu AL, Patel A (2018) Towards sustainable bricks production: An overview. Constr Build Mater 165:112–125. https://doi.org/10.1016/j.conbuildmat.2018.01.038

Singh S, Aswath MU, Ranganath RV (2020) Performance assessment of bricks and prisms: Red mud based geopolymer composite. Journal of Build Eng 32:101462. https://doi.org/10.1016/j.jobe.2020.101462

Mohammed B, Liew MS, Alaloul W, Al-Fakih A, Ibrahim W, Adamu M (2018) Development of rubberized geopolymer interlocking bricks. Case Studies in Construction Materials 8:401–408. https://doi.org/10.1016/j.cscm.2018.03.007

Arıöz Ö, Kilinç K, Tuncan M, Tuncan A, Kavas T (2011) Physical, Mechanical and Micro-Structural Properties of F Type Fly-Ash Based Geopolymeric Bricks Produced by Pressure Forming Process. Advances in Sci Technol 69:69–74

Ahmari S, Zhang L (2012) Production of eco-friendly bricks from copper mine tailings through geopolymerization. Constr Build Mater 29:323–331. https://doi.org/10.1016/j.conbuildmat.2011.10.048

BIS (Bureau of Indian Standards), Coarse and Fine Aggregate for Concrete- Specification. IS 383:2016, New Delhi, India BIS (2016) 1–21

BIS, Preparation and Use of Masonry Mortar. Bur Indian Stand IS 2250, New Delhi (1981)

BIS, IS 1727 (1967): Methods of test for pozzolanic materials, (1968)

1077:1992, Building Common Burnt Clay Building Bricks- Specifications. Bur Indian Stand (1992)

BIS, IS 3495 Parts 1–4 : Methods of Tests of Burnt Clay building brick, (1992) 1–7.

BIS, Indian Standard SPECIFICATION FOR ACID-RESISTANT BRICKS IS: 4860 :1968, (1968)

Das SK, Shrivastava S (2021) Influence of molarity and alkali mixture ratio on ambient temperature cured waste cement concrete based geopolymer mortar. Constr Build Mater 301:124380. https://doi.org/10.1016/j.conbuildmat.2021.124380

Li Z, Liu X, Gao Y, Zhang J (2023) Study on the hardening mechanism of Bayer red mud-based geopolymer engineered cementitious composites. Constr Build Mater 392:131669. https://doi.org/10.1016/j.conbuildmat.2023.131669

Yip CK, Lukey GC, Provis JL, van Deventer JSJ (2008) Effect of calcium silicate sources on geopolymerisation. Cem Concr Res 38:554–564. https://doi.org/10.1016/j.cemconres.2007.11.001

Dehghani A, Aslani F, Ghaebi Panah N (2021) Effects of initial SiO2/Al2O3 molar ratio and slag on fly ash-based ambient cured geopolymer properties. Constr Build Mater 293:123527. https://doi.org/10.1016/j.conbuildmat.2021.123527

Giannopoulou I, Panias D (2007) Structure, Design and Applications of Geopolymeric Materials

Kumar S, Kumar R, Mehrotra SP (2010) Influence of Granulated Blast Furnace Slag on the Reaction, Structure and Properties of fly ash Based Geopolymer. J Mater Sci 45:607–615. https://doi.org/10.1007/s10853-009-3934-5

Provis JL, Van Deventer JSJ (2009) 1 - Introduction to geopolymers. In: Provis JL, van Deventer JSJBT-G (eds) Woodhead Publishing Series in Civil and Structural Engineering. Woodhead Publishing, 1–11

Huang X, Huang T, Li S, Muhammad F, Xu G, Zhao Z, Yu L, Yan Y, Li D, Jiao B (2016) Immobilization of chromite ore processing residue with alkali-activated blast furnace slag-based geopolymer. Ceram Int 42:9538–9549. https://doi.org/10.1016/j.ceramint.2016.03.033

Duan P, Yan C, Zhou W (2017) Compressive strength and microstructure of fly ash based geopolymer blended with silica fume under thermal cycle. Cem Concr Compos 78:108–119. https://doi.org/10.1016/j.cemconcomp.2017.01.009

Luo Z, Hao Y, Mu Y, Tang C, Liu X (2022) Solidification/stabilization of red mud with natural radionuclides in granular blast furnace slag based geopolymers. Constr Build Mater 316:125916. https://doi.org/10.1016/j.conbuildmat.2021.125916

Chen Y, Dolado J, li Z, Yin S, Yu Q, Kostiuchenko A, Ye G (2022) A molecular dynamics study of N‐A‐S‐H gel with various Si/Al ratios. Journal of the American Ceramic Society 105:. https://doi.org/10.1111/jace.18597

Bradtmüller H, Villas-Boas MC, Zanotto ED, Eckert H (2020) Structural aspects of the glass-to-crystal transition in sodium-calcium silicate glasses. J Non Cryst Solids 535:119844. https://doi.org/10.1016/j.jnoncrysol.2019.119844

Li J, Tao Y, Zhuang E, Cui X, Yu K, Yu B, Boluk Y, Bindiganavile V, Chen Z, Yi C (2022) Optimal amorphous oxide ratios and multifactor models for binary geopolymers from metakaolin blended with substantial sugarcane bagasse ash. J Clean Prod 377:134215. https://doi.org/10.1016/j.jclepro.2022.134215

Ge X, Hu X, Shi C (2022) Mechanical properties and microstructure of circulating fluidized bed fly ash and red mud-based geopolymer. Constr Build Mater 340:127599. https://doi.org/10.1016/j.conbuildmat.2022.127599

Lu B, Huo Z, Xu Q, Hou G, Wang X, Liu J, Hu X (2023) Characteristics of CSH under carbonation and its effects on the hydration and microstructure of cement paste. Constr Build Mater 364:129952. https://doi.org/10.1016/j.conbuildmat.2022.129952

Luo Z, Zhi T, Liu L, Mi J, Zhang M, Tian C, Si Z, Liu X, Mu Y (2022) Solidification/stabilization of chromium slag in red mud-based geopolymer. Constr Build Mater 316:125813. https://doi.org/10.1016/j.conbuildmat.2021.125813

Guo X, Zhao H, Qiang X, Ouyang C, Wang Z, Huang D (2023) Facile construction of agar-based fire-resistant aerogels: A synergistic strategy via in situ generations of magnesium hydroxide and cross-linked Ca-alginate. Int J Biol Macromol 227:297–306. https://doi.org/10.1016/j.ijbiomac.2022.12.164

Ngo T-P, Bui Q-B, Phan VT-A, Tran H-B (2022) Durability of geopolymer stabilised compacted earth exposed to wetting–drying cycles at different conditions of pH and salt. Constr Build Mater 329:127168. https://doi.org/10.1016/j.conbuildmat.2022.127168

Du C, Yang Q (2021) Experimental study of the feasibility of using calcium carbide residue as an alkaline activator for clay-plant ash geopolymer. Constr Build Mater 301:124351. https://doi.org/10.1016/j.conbuildmat.2021.124351

Gómez-Casero MA, Moral-Moral FJ, Pérez-Villarejo L, Sánchez-Soto PJ, Eliche-Quesada D (2021) Synthesis of clay geopolymers using olive pomace fly ash as an alternative activator. Influence of the additional commercial alkaline activator used. J Market Res 12:1762–1776. https://doi.org/10.1016/j.jmrt.2021.03.102

Kaya M, Koksal F, Gencel O, Munir MJ, Kazmi SMS (2022) Influence of micro Fe2O3 and MgO on the physical and mechanical properties of the zeolite and kaolin based geopolymer mortar. J Build Eng 52:104443. https://doi.org/10.1016/j.jobe.2022.104443

Yu P, Kirkpatrick R, Poe B, McMillan P, Cong X (2004) Structure of Calcium Silicate Hydrate (C-S-H): Near-, Mid-, and Far-Infrared Spectroscopy. J Am Ceram Soc 82:742–748. https://doi.org/10.1111/j.1151-2916.1999.tb01826.x

Sarangapani G, Reddy BV, Jagadish KS (2002) Structural characteristics of bricks, mortars and masonry. J Struct Eng 29:101–107

Funding

The work has not received any outside funding.

Author information

Authors and Affiliations

Contributions

Smita Singh: conceptualization, methodology, investigation, writing original draft. Aswath M.U.: conceptualization, project administration, supervision, validation & editing. Tanushree B.S.: methodology, investigation, data curation, visualization.

Corresponding author

Ethics declarations

Consent for publication

All of the authors confirm the consent for Publication.

Research involving human participants and/or animals

This article does not contain any studies involving animals or human participants performed by any of the authors.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Red mud-based binder exhibited 53.8 MPa strength at 2 M molar solution with 30% red mud.

• Red mud mortar was synthesized using low molar sodium hydroxide solution.

• Effect of change in sodium silicate to sodium hydroxide ratio was investigated.

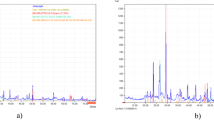

• Results were analysed with SEM, XRD and FTIR test.

• Bricks at low molarity had compressive strength of 33.7 MPa and flexural strength of 2.75 MPa.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Singh, S., Aswath, M.U. & S, T.B. Effect of silica on the properties of red mud based geopolymer mortar for synthesis of sustainable bricks. J Build Rehabil 9, 67 (2024). https://doi.org/10.1007/s41024-024-00424-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41024-024-00424-4