Abstract

The construction sector contributes significantly to the production of greenhouse gases and thus to climate change. This study aims to quantify the environmental performance of selected bearing constructions with special regard to their climate change contribution and resource depletion. Environmental impacts were assessed using environmental indicators, such as global warming potential and abiotic, water and natural resource depletion. The material composition of the wall structures consisted of aerated concrete blocks, ranging from 300 to 375 mm, with different thermal-insulation materials (expanded polystyrene with graphite, and rock wool) and variable interior and exterior plaster. The evaluation was based on life cycle assessment (LCA) methodology within the ‘‘cradle to gate” boundaries. The calculated values of global warming potentials per square metre of wall construction ranged from 234.16 to 283.46 kg CO2 eq for the 20-year time span, from 213.02 to 255.20 kg CO2 eq for the 100-year time span and from 190.40 to 229.90 kg CO2 eq for the 500-year time span. The average water consumption was identified as 3.97 m3, and the abiotic depletion was identified as 1.41 kg Sbeq per square metre of the wall structure. The lowest environmental impact in all environmental categories evaluated was found for a structure with aerated concrete with a thickness of 300 mm with graphite polystyrene thermal insulation and with silicone outdoor plaster. Using a suitable material composition of the wall structure, up to a 20% reduction in greenhouse gas emissions can be achieved while maintaining the same thermal parameters of the structure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Unprecedented modernisation characterised by population explosion, urbanisation and economic development is a major contributor to environmental pollution and resource depletion [1, 2]. One of the major challenges facing humanity in this century is climate change, which has significant global consequences for individual aspects, such as human health, the environment and the economy. These consequences are manifested in the form of elevated temperature and in the form of storms, cyclones and hurricanes, which are caused by stronger precipitation and rising sea level [3, 4]. Carbon dioxide (CO2) gas is considered to be the most serious greenhouse gas caused by pollution predominantly from fossil energy sources and accounts for up to 76% of total greenhouse gases [5]. One of the major contributors to greenhouse gases is the construction sector, which plays an important role in the environment [6].

In recent years, the construction sector has become a major problem and the best tool to mitigate climate change and is responsible for 30% of the total greenhouse gas emissions that are released into the atmosphere annually [7]. In addition, the construction sector is a main consumer of raw materials and energy, and it generates a large amount of waste [8]. In OECD (Organization for Economic Co-operation and Development) countries, the construction sector utilises processes, such as the extraction of raw materials and transportation between all stages that consume from 25 to 45% of the total energy used [9]. Worldwide, the construction sector is responsible for 40% of global energy consumption, according to the IPCC (Intergovernmental Panel on Climate Change) report [10]. The depletion of resources, such as abiotic, water and natural resources, is also closely linked to the construction sector, which has a multiplier effect on human natural systems and negative consequences for sustainable development. Therefore, sustainable management of these resources is important [11].

The appropriate choice of building material is one of the options that can be achieved at the design stage to reduce energy consumption and associated greenhouse gas production, as well as the other negative environmental impacts mentioned. Wall structures in traditional residential houses represent up to 25% of the total area of the building and thus can contribute significantly to the overall negative environmental impacts of materials in the building [12, 13]. As reported in [13], in masonry residential buildings, bulk materials represent a group with significant weight (14.2%) and volume (9.7%) but with a low share of the overall environmental load (0.3–1.3%) when evaluating greenhouse gas emissions, acidification potential and embodied energy in materials. Autoclaved aerated concrete (AC), as a lightweight porous building material that offers advantages in the form of sound, thermal and fire insulation, as well as energy demands [14], is a widely used building material in the construction industry [15] and represents a preferable material in central European countries. However, concrete, which primarily consists of cement, water and aggregates, is associated with several negative impacts on the environment. Cement production is material and energy intensive and produces a large amount of greenhouse gases. In addition, the extraction of aggregates contributes to the depletion of raw material resources. In residential buildings, concrete represents a relatively high volume and weight of material used (34.3–63%) and thus is responsible for high environmental impacts [16, 17]. Concrete can contribute to the overall impact of materials in masonry residential buildings on greenhouse gas emissions by 41.2% [13], having a higher impact than steel [18]. Ceramic materials are usually also largely represented in wall construction (with 17.1% by volume and 11.2% by weight on average) and have several negative impacts connected to material and energy consumption. Their share of the total impact of buildings on greenhouse gas emissions, acidification potential and embodied energy can range from 13.3 to 20.2% [13]. Thermal insulation materials improve the energy efficiency of buildings and thus reduce heat for heating and cooling [60]. Therefore, they also indirectly contribute to reducing the amount of fossil fuels and to reducing greenhouse gas and acidifying gas emissions produced during the operation of buildings. However, the production of insulation materials is also associated with a certain environmental burden in the form of energy consumption and the carbon footprint. Thermal insulation materials represent a relatively high volume percentage in wall constructions and can contribute significantly to the overall environmental load of buildings. As reported in [19], organic-based insulation materials exhibit a higher impact on greenhouse gas emissions and embodied energy than inorganic insulation materials. In contrast, wood materials have a negative contribution on greenhouse gas emissions, which can significantly reduce the overall global warming potential [20] and primary energy during the production stage [21]. The environmental design for building material construction should include the best environmental combination of available (local) materials on the market to help the construction sector reduce climate change and other related environmental loads [22].

At present, a whole range of methods is used to assess the environmental suitability and environmental selection of building materials. The environmental suitability of materials can be assessed at different levels with varying degrees of precision, depending on the particular purpose and scope of the study. In general, there are three approaches to building material environmental evaluation. (i) Environmental assessment and labelling of type I is an independent assessment by a third party, the principles of which are in the standard ISO 14024. This type is generally known as an eco-labelling process and is widely used. (ii) Environmental assessment of type II is based on the environmental properties of the product, e.g. by producer, and the principles are standardised in ISO 14021. (iii) Environmental assessment of type III is based on the assessment of the entire life cycle of a product, the principles of which are standardised in the standard ISO 14025. Life cycle assessment (LCA) is a state-of-the-art tool that has been developed to assess the environmental impacts of a product during its life effectively and in complexity [23]. The LCA method is one of the most commonly used methods for the environmental evaluation of building materials, which includes the existing and potential environmental impact evaluations of materials within their life cycle. This life cycle includes processes such as raw material extraction, production of the building product including packaging and distribution, application of the building product to the building, usage and, at the very end, final treatment such as recycling, reusing, energy recovery or disposal. LCA can be defined as a set of all inputs in the form of resources and outputs and the potential environmental impacts of a product system, as well as their processes and design throughout its life cycle (ISO) (2006). The LCA study, based on ISO 14040 (2006), consists of four main steps: goal and scope definition, life cycle inventory (LCI), life cycle impact assessment (LCIA) and interpretation [24, 25]. More detailed information on the LCA of construction products is given in standard EN 15804 and relevant standards for individual categories of construction products (PCR, product category rules).

Assessment of the environmental parameters of building materials, structures and entire buildings based on the LCA approach was recently presented by many authors [26,27,28,29,30]. Table 1 presents the research papers on the Web of Science database when using the selected key words regarding the buildings and building materials and LCA.

For the building industry, most LCA studies have focussed on expressing the environmental impacts of construction materials and buildings by midpoint indicators in the categories of global warming potential (GWP), primary or embodied energy and acidification potential (AP) (embodied acidification gas emissions). The IPCC (Intergovernmental Panel on Climate Change) GWP methods evaluate the long effect of greenhouse gas emissions in the atmosphere within a time horizon of 20, 100 and 500 years (IPCC GWP 20a, IPCC GWP 100a, and IPCC GWP 500a, respectively) [31]. This indicates that these methods expressed the emissions of greenhouse gases produced in kilograms equivalent to CO2 over 20-, 100- and 500-year time horizons, respectively [32]. The characterisation model for the global warming potential (IPCC GWP) does not take into account these factors: the range of indirect effects given by the IPCC; radiative forcing due to emissions of NOx, water, sulphate, etc. in the lower stratosphere and upper troposphere; and indirect formation of dinitrogen monoxide from nitrogen emissions. The neglected factors are related to a low confidence in quantitative estimates of the radiative forcing due to these indirect effects [33]. For water, the water vapour in the atmosphere is controlled mostly by air temperature rather than by emissions. Therefore, water is considered a feedback agent and is not calculated as radiative forcing from anthropogenic emissions. Most authors have used the global warming potential indicator over a period of 100 years (GWP100) to compare the effects on global warming [34,35,36]. In general, the GWP indicator can be calculated by several midpoint methods.

Several authors also assessed the water footprint of buildings [37, 38]. Hosseinian [39] found that the water footprint of concrete structures is less than that of steel structures, and Sameer [40] mentioned that ultrahigh-performance concrete performed better than conventional concrete regarding the water footprint. In the literature, however, there are very few data that pertain to construction and the water footprint, depletion of raw material resources and global warming potential at the same time.

This article provides a life cycle assessment of masonry-bearing construction with particular regard to its share of climate change. In addition, the depletion of water and raw material resources connected to these structures was analysed, and mutual connections among the indicators mentioned were investigated. The objective was to determine whether material variation could reduce not only the global warming potential but also water and resource consumption. The novelty of this paper lies in evaluating the water footprint and raw material resource depletion relating to designed wall construction and correlating these environmental factors to the global warming potential. This paper compares the impacts of wall construction on climate change not only on the usual 100-year timespan but also on shorter, 20 years, and longer, 500 years, horizons.

2 Materials and Methods

2.1 Material Composition of Wall Structures

Cradle-to-gate LCA was performed to assess 24 compositions of wall structures of aerated concrete blocks of overall variable thickness. To ensure relevance in the environmental evaluation of various wall material alternatives, a key parameter was chosen that captures the properties of these structures, the heat transfer coefficient U. All analysed wall structures had the same value of the heat transfer coefficient U = 0.21 ± 0.05 W/(m2 × K). This value is recommended for wall structures and is used to classify buildings in terms of their energy efficiency [41].

The main materials of wall structures from the outer to the inner layer were designed as follows: finish coat, exterior primer, adhesive, thermal-insulation materials, adhesive mortar, aerated concrete block and interior plaster (Fig. 1).

The thickness and type of materials (concrete and thermal insulation) were designed so that the structure meets the specified value of the U heat transfer coefficient. The U heat transfer coefficient was calculated by Svoboda Software, version 2009, according to ISO 6946:2017 [59], including design values of the thermal conductivity coefficient of each layer of the structure. Four types of aerated concrete blocks were considered: AC 300A (thickness 300 mm) and AC 375A (thickness 375 mm) with a bulk density of 400 kg/m3 and AC 300B (thickness 300 mm) and AC 375 B (thickness 375 mm) with a bulk density of 500 kg/m3.

As thermal insulation for the external walls, two types of insulation material were selected: mineral wool and expanded polystyrene (EPS). For the expanded polystyrene, four variations of various thicknesses were evaluated in combination with AC: EPS 28 and EPS 30 with bulk densities of 28 and 30 kg/m3, respectively, and EPSG 15 (intensified graphite polystyrene with a density of 15 kg/m3) and EPSG 20 (intensified graphite polystyrene with a density of 20 kg/m3). Two alternatives of mineral wool (MW) of two different densities 115 (MW 115) and 150 kg/m3 (MW 150) were under consideration in the material composition of the wall structures. The choice of insulation materials and their thicknesses, as well as the overall material composition, corresponded to the commonly available and generally used materials on the central European market and built in the majority of family houses [42].

Lime-cement plasters, which are among the most widely used plasters, were used to treat all internal surfaces. Lime plaster can contribute to better quality of the indoor air by absorbing carbon dioxide and regulating humidity [43]. In addition, lime plaster has a high pH and could act as a fungicide preventing mould growth. For exterior treatment, silicone plasters based on organic silicone resins were chosen for all wall alternatives because of their hydrophobicity and excellent adhesion [44]. Reinforcing fibreglass mesh was also included in the calculations.

The designation of the structures investigated and their material composition are given in Table 2.

2.2 LCA

2.2.1 Goal and Scope Definition

LCA analysis was performed to compare the environmental impacts of several alternatives of the material composition of masonry perimeter walls. Midpoint indicators for global warming, depletion of raw material resources and water footprint were chosen to compare the environmental burden. The assessment was carried out within the cradle-to-gate system boundaries, according to the standard for environmental impact assessment of building materials, EN 15804. In accordance with this standard, the product stage of the life cycle of the wall structure was taken into account, including raw material extraction and processing, transport to the manufacturer, and manufacturing all materials for the wall structure, including the provision of all materials, products and energy. Transportation between the “gate-to-building site”, construction work, operational phase, and dismantling were not part of the system. Processes of the end of life of the materials were not included.

The service life of the wall structure was considered to be 50 years, while for external and internal plasters, the service life was shorter (25 years); therefore, their impacts were counted twice.

The functional unit for addressing the LCA methodology selected for this analysis was defined as 1 m2 of the wall structure of variable thickness; however, the same function was represented by the same thermal properties expressed by the same value of the heat transfer coefficient U.

2.2.2 Life Cycle Inventory Analysis

Life cycle inventory analysis (LCI) was focussed on all environmental inputs and outputs that are associated with materials in wall construction. The data used originated from the Ecoinvent database [45].

The processes included in the calculation are specified in Table 3:

Electricity included the main processes of electricity production in Slovakia, the transmission network, and direct SF6 emissions to air. Electricity losses during medium-voltage transmission and transformation from high voltage were accounted for. The production volume was 23 TW h. Assumptions for the transmission network, losses, and emissions were based on Swiss data.

2.2.3 Life Cycle Impact Assessment

In this study, SimaPro 8.5.0.0 software was used to identify the environmental performance of building construction. This software enabled the calculation of environmental impacts using the various methods available in this version [46].

The IPCC (Intergovernmental Panel on Climate Change) impact assessment methods were used to identify the contribution of the structures to climate change by calculating the global warming potential (GWP) over time horizons of 20, 100 and 500 years. Biogenic CO2 uptake was considered a negative impact, and CO2 formation from CO emissions was also included in the calculations [32].

To evaluate the contribution of the analysed structures to resource deletion, CML (Centrum voor Milieukunde Leiden) according to [25], BEES (Building for Environmental and Economic Sustainability) according to [47] and ReCiPe [48] methods were applied. The CML method was used to calculate the extraction of metals, minerals and fossil fuels similarly to [49] in connection to the wall structures. The abiotic depletion factor (ADF) was determined in kg antimony equivalents/kg extraction based on concentration reserves and the rate of deaccumulation [50].

In addition to the CML method, the natural resource depletion was calculated by the BEES method. This method included up-to-date data on the environmental and economic properties of construction products [51].

The ReCiPe midpoint method in SimaPro software was chosen for appraising and comparing selected structures based on the water depletion indicator in accordance with [52]. However, as mentioned in [53], the results between different methods vary significantly, and there is a need for a standardised methodology regarding the LCA-based water footprint. The contribution of the analysed structures to water depletion was expressed in cubic metres per functional unit.

3 Results and Discussion

3.1 Contribution of the Wall Structures to Climate Change

The average values of the calculated GWPs for the 24 structures of the assessed bearing walls are given in Fig. 2. The GWP in the 20-year time span ranged from 234.16 to 283.46 kg CO2 eq/m2, from 213.02 to 255.20 CO2 eq/m2 for the 100-year time span and from 190.40 to 229.90 CO2 eq/m2 for 500-year time span (Fig. 2). The average contribution of aerated concrete structures to climate change, expressed using the global warming potential, was 256.53, 233.03 and 209.49 CO2 eq/m2 for 20-, 100- and 500-year horizons, respectively.

The largest difference in absolute numbers between the lowest and highest GWP (49.30 kg CO2 eq per 1 m2) was found for a time horizon of 20 years. This corresponded to a percentage difference of 21.05%. Similar differences between the best and worst GWP results were also observed for the time horizons of 100 (19.8%) and 500 years (20.74%). Thus, considering all three time perspectives, the difference between the lowest and highest GWP values fluctuated by 20%. This indicates that a suitable material composition of the wall structure can achieve up to a 20% reduction in greenhouse gas emissions while maintaining the same thermal parameters of the structure. González and Navarro reported that the selection of low impacted building materials can mitigate greenhouse gases by up to 30% [54]. As mentioned in [55], by choosing appropriate materials, the emissions of greenhouse gases can be reduced by more than 100 tons per year.

The values of GWPs per square metre of the wall structure decreased with increasing time horizon. However, the negative effects on climate change to which wall structures contribute would have only an 11% lower impact over the 500-year horizon than on the 100-year time horizon, which is most commonly used in climate change assessments. This finding confirms the long-term negative impacts of greenhouse gases and points to the potential for the right choice of materials in relation to climate change mitigation. The differences in the obtained values of GWP100 of the particular wall structures are given in Tables 4 and 5.

The differences in GWP values for AC 300 structures with the same thickness of core wall material were 0.3–12.9% (Table 4), whereas for the AC 375 structures, the differences varied in an almost similar interval from 0.2 to 12.2%. However, as already mentioned, when comparing the obtained GWP values of all structures together, the highest percentage difference between the evaluated material alternatives of wall structures reached the value of 19.8%.

Furthermore, the influence of the main parameters of the wall structures on the obtained GWP, the overall weight of materials per square metre and the overall thickness were analysed. Figure 3 shows the comparison of the calculated global warming potentials of the individual wall structures and their thicknesses and weights.

The overall thickness of the wall structure should not represent an indicator to evaluate the share of the structure with global warming. As seen in Fig. 2, different GWP values were found for structures with the same overall thickness. However, for a group of structures with equally thick AC blocks, a relationship was observed between the GWP and the overall thickness of the structure, with correlation coefficients R = 0.89 and R = 0.92 for AC blocks 300 mm thick and 375 mm thick, respectively.

A similar conclusion can be drawn from the results of the study of the relationship between GWP and the total weight of materials per square metre of the structure. Although the total weights of the materials in 1 m2 of the wall structure were almost the same, the contributions of these structures to the global warming expressed by GWP were different. For example, the difference between the weights of structures S1, which contained EPS insulation, and S5, which contained EPSG insulation, was only 0.8% (155.2 kg/m2 for S1 and 154.0 kg/m2 for S5), but the difference in the calculated GWP100 values was more than five times higher (4.2%).

The type of insulation material was identified to be the most important factor in assessing the environmental impact within a group of structures with an equally thick AC layer. The best results and thus the lowest impacts on climate change were found for structures with insulation materials of intensified graphite polystyrene EPSG (213.0 kg CO2 eq/m2 for AC 300 and 224.0 kg CO2 eq/m2 for AC 375), followed by EPS (218.2 kg CO2 eq/m2 for AC 300 and 228.1 kg CO2 eq/m2 for AC 375) and mineral wool (218.8 kg CO2 eq/m2 for AC 300 and 228.5 kg CO2 eq/m2 for AC 375). The EPS and mineral wool insulations proved to have very similar environmental loads when applied in the analysed wall structures. Intensified graphite polystyrene EPSG is a thermal-insulation material with graphite particles added in the production process, which can increase the efficiency of insulation due to graphite flakes that reflect and absorb radiation energy [56]. The lower environmental impacts of EPSG are related to the fact that thinner insulation was sufficient to achieve the same U value of the wall structure and thus less EPS could be applied. The use of such a more effective insulating material makes it possible to reduce the thickness of the structure, as well as the total amount of materials used, which not only reduces greenhouse gas emissions but also reduces other environmental impacts that are not discussed here, e.g. in the case of polystyrene, the toxicity potential. However, the mineral wool constructions did not perform significantly better than the EPS constructions, which is not entirely consistent with [19], where it was stated that insulating materials based on organic compounds have more serious impacts than mineral-insulating materials.

The best alternative of the material composition of the wall structure, having the lowest GWP values, was the S5 structure (300-mm-thick aerated concrete block with a density of 400 kg/m3 with the thermal insulation of graphite polystyrene EPSG with a bulk density of 28 kg/m3 and silicone plaster). The highest GWP values were found for the S16 structure (375-mm-thick aerated concrete block with a density of 500 kg/m3, EPS with a density of 30 kg/m3 and silicone plaster), which can, therefore, be considered the structure with the greatest contribution to climate change. The S9 wall structure with thermal insulation from mineral wool achieved similar GWP values as the best S5 wall structure.

3.2 Resource Depletion

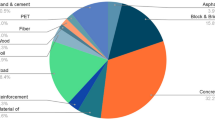

Figure 4 shows the results calculated to assess the contribution of the individual wall structures to water and resource depletion.

The average water consumption related to the wall structures was 3.97 m3 per square metre of the structure (Fig. 4). The calculated values of the structures ranged in a closer interval (3.8–4.14 m3), as was observed for the other environmental indicators since the difference between the lowest and highest consumption was approximately 7.8%, while for GWP, it was approximately 20%. This finding points to the fact that alternation in material composition more significantly affects greenhouse gas emissions than water consumption. For raw material depletion, the abiotic depletion indicator ranged from 1.29 to 1.55 kg Sbeq with an average value of 1.41 kg Sbeq per square metre of the structure, and the natural resource depletion indicator ranged from 3.1–3.8 × 102 MJ, reaching an average of 3.36 × 102 MJ per square metre of the structure (Fig. 4). The differences between the lowest and highest scores for natural resource depletion (23.56%) were comparable to those for abiotic depletion (20.10%) and fluctuated by approximately 20%, similar to the GWP indicators. Mequignon [57] reported different values for the various materials, and the values for AC varied depending on the lifespan from 0.27 to 1 kg Sbeq per square metre.

Interestingly, although different calculation methods and characterisation models were used to calculate the environmental impacts related to resource depletion and global warming potentials, the S5 material composition of the wall structure again achieved the lowest values for water consumption and abiotic depletion (Fig. 5).

For the natural resource depletion indicator, the lowest value was found for the S9 structure, where mineral wool instead of graphite polystyrene was used as thermal insulation. Being the best in three of the four environmental indicators, the S5 material alternative proved to have the best environmental performance. As the S5 structure achieved the best results in three of the four environmental indicators, it can be considered the best of the material alternatives to wall structures that have been evaluated in this work. This is related to the optimal combination of thicknesses of the materials used while maintaining the same thermal-technical parameters of the structure.

Moreover, the potential correlation between the environmental indicators was investigated. Figure 6 presents the relationships observed.

The correlations among the particular environmental indicators: a GWP100 versus water depletion, b GWP100 versus abiotic depletion, c GWP100 versus natural resource depletion, d water versus abiotic depletion, e water versus natural resource depletion, and f abiotic versus natural resource depletion

As shown in Fig. 4, the correlations were examined depending on the different environmental categories. The correlation coefficients R obtained are given in Table 6. Individual potential correlations were evaluated on the basis of the values of the correlation coefficients given in [58].

The lowest dependence was found between the depletion of natural resources and water depletion, and a medium correlation was observed between natural resource depletion and GWP100 (0.68) and between abiotic and water depletion (0.56). The other relationships, namely between GWP100 and water depletion (0.85), GWP100 and abiotic depletion (0.84) and between natural resource and abiotic depletion (0.91), had a significant correlation. These dependences were high, although various LCA methods were used to calculate the negative effects in the individual environmental categories, which differed in their characterisation models. The findings revealed that the wall structures that had the highest potential contribution to climate change also had the most significant negative impacts on water consumption and depletion of material resources, which were consistent with [40]. This indicates that there was a linear correlation between the impact of the material composition of the structure on climate change and resource depletion. As mentioned in [57], natural resource depletion also depends on the lifespan of buildings.

The results of this study indicate that the environmentally optimal material composition of structures can reduce significantly negative impacts, such as the greenhouse effect and the consequent impacts on climate change, as well as minimise the consumption of water and raw materials. The choice of a suitable material composition of the structure with regard to its environmental load while maintaining the same functional properties gives designers a potential tool to contribute to sustainability in construction. The choice of materials should not only be based on price, but the environmental aspect must be added to the technical and economic aspects of decision-making. Here, however, it is necessary to provide designers with practical and scientifically based information on the materials used, in regard to the construction designed. Therefore, the technical design should include a calculation of the environmental impacts of the material variants of the proposed structures.

4 Conclusion

It is well known that the construction sector has the potential to reduce its negative impact on the environment. Recently, much attention has been given to the design of buildings in terms of reducing operational energy and thus reducing greenhouse gas emissions during the use of the buildings. However, in the design of passive or zero-energy buildings, the embodied energy and embodied CO2 emissions in the materials utilised in structures in connection with climate change will also play an increasingly important role. This paper analysed common types of masonry wall structures using aerated concrete blocks of variable thickness and thermal insulations, with special regard to their contribution to climate change and resource depletion. The results of this study facilitated the following conclusions:

-

The reduction in the global warming potential of structures can be reached by even small material alterations. A decrease of up to 20% in GWP100 was noticed while maintaining the functionality and the same thermal-technical parameter (U = 0.21 ± 0.05 W/(m2 × K)) of the wall structure.

-

The lowest impact on climate change and water material depletion was observed for a structure with a 300-mm-thick aerated concrete block with a density of 400 kg/m3 with 20 mm graphite polystyrene thermal insulation (EPSG) and silicone plaster.

-

It was confirmed that the type of materials used plays a more important role and affects the GWP more than the total weight of the materials in the structure or its total thickness.

-

The optimisation and selection of materials based on the scientific estimation of environmental impacts should be considered in building design.

-

Based on the results, the optimal choice of material composition of the building structure not only mitigates climate change but also saves water by 7.8% and raw material resources by 23.6%. However, the alternation in material composition more strongly affected greenhouse gas emission reduction than water consumption.

Finally, it should be noted that different software may include different characterisation models, and it is often difficult to compare the obtained numbers of the results calculated. Therefore, this study was not focussed on the presentation of absolute numbers or the preference of some specific materials but on the comparison of several material compositions of structures and analysis of whether a small variation in material characteristics will affect the overall impacts on global warming and resource depletion.

References

Jia X, O’Connor D, Hou D, Jin Y, Li G, Zheng C, Yong SO, Dan Tsang CW, Luo J (2019) Groundwater depletion and contamination: Spatial distribution of groundwater resources sustainability in China. Sci Total Environ 672:551–562. https://doi.org/10.1016/j.scitotenv.2019.03.457

Hazarika N, Nitivattananon V (2016) Strategic assessment of groundwater resource exploitation using DPSIR framework in Guwahati city, India. Habitat Int 51:79–89. https://doi.org/10.1016/j.habitatint.2015.10.003

Younger M, Morrow-Almeida HR, Vindigni SM, Dannenberg AL (2008) The built environment, climate change, and health: opportunities for co-benefits. Am J Prev Med 35(5):517–526. https://doi.org/10.1016/j.amepre.2008.08.017

De Wilde P, Coley D (2012) The implications of a changing climate for buildings. Build Environ 55:1–7. https://doi.org/10.1016/j.buildenv.2012.03.014

Quadrelli R, Peterson S (2007) The energy–climate challenge: recent trends in CO2 emissions from fuel combustion. Energy Policy 35(11):5938–5952. https://doi.org/10.1016/j.enpol.2007.07.001

Thomas R (2005) Environmental design. An introduction for architects and engineers. Taylor & Francis, London

Li H, Deng Q, Zhang J, Xia B, Skitmore M (2019) Assessing the life cycle CO2 emissions of reinforced concrete structures: four cases from China. J Clean Prod 210:1496–1506. https://doi.org/10.1016/j.jclepro.2018.11.102

Dimoudi A, Tompa C (2008) Energy and environmental indicators related to construction of office buildings. Resour Conserv Recycl 53(1–2):86–95. https://doi.org/10.1016/j.resconrec.2008.09.008

Asif M, Muneer T, Kelley R (2007) Life cycle assessment: a case study of a dwelling home in Scotland. Build Environ 42(3):1391–1394. https://doi.org/10.1016/j.buildenv.2005.11.023

IPCC (2007) Summary for policymakers. In: Solomon S, Qin D, Manning M, Chen Z, Marquis M, Averyt KB, Tignor M, Miller HL (eds) Climate change 2007: the physical science basis. Contribution of working group I to the fourth assessment report of the intergovernmental panel on climate change. Cambridge University Press, Cambridge

Megdal SB (2018) Invisible water: the importance of good groundwater governance and management. NPJ Clean Water 1(1):1–5. https://doi.org/10.1038/s41545-018-0015-9

Ingrao C, Scrucca F, Tricase C, Asdrubali F (2016) A comparative life cycle assessment of external wall-compositions for cleaner construction solutions in buildings. J Clean Prod 124:283–298. https://doi.org/10.1016/j.jclepro.2016.02.112

Estokova A, Porhincak M (2012) Reduction of primary energy and CO2 emissions through selection and environmental evaluation of building materials. Theor Found Chem Eng 46(6):704–712. https://doi.org/10.1134/S0040579512060085

Bergmans J, Nielsen P, Snellings R, Broos K (2016) Recycling of autoclaved aerated concrete in floor screeds: sulfate leaching reduction by ettringite formation. Constr Build Mater 111:9–14. https://doi.org/10.1016/j.conbuildmat.2016.02.075

Liu Q, Li B, Xiao J, Singh A (2020) Utilization potential of aerated concrete block powder and clay brick powder from C&D waste. Constr Build Mater 238:117721. https://doi.org/10.1016/j.conbuildmat.2019.117721

Sabău M, Bompa DV, Silva LFO (2021) Comparative carbon emission assessments of recycled and natural aggregate concrete: environmental influence of cement content. Geosci Front 12(6):101235. https://doi.org/10.1016/j.gsf.2021.101235

Ingrao C, Giudice AL, Tricase C, Mbohwa C, Rana R (2014) The use of basalt aggregates in the production of concrete for the prefabrication industry: environmental impact assessment, interpretation and improvement. J Clean Prod 75:95–204. https://doi.org/10.1016/j.jclepro.2014.04.002

Hawkins W, Cooper S, Allen S, Roynon J, Ibell T (2021) Embodied carbon assessment using a dynamic climate model: case-study comparison of a concrete, steel and timber building structure. Structures 33:90–98. https://doi.org/10.1016/j.istruc.2020.12.013

Hill C, Norton A, Dibdiakova J (2018) A comparison of the environmental impacts of different categories of insulation materials. Energy Build 162:12–20. https://doi.org/10.1016/j.enbuild.2017.12.009

Gerilla GP, Teknomo K, Hokao K (2007) An environmental assessment of wood and steel reinforced concrete housing construction. Build Environ 42:2778–2784. https://doi.org/10.1016/j.buildenv.2006.07.021

Buchanan AH, Levine SB (1999) Wood-based building materials and atmospheric carbon emissions. Environ Sci Policy 2:427–437. https://doi.org/10.1016/S1462-9011(99)00038-6

Balasbaneh AT, Marsono AKB (2017) Strategies for reducing greenhouse gas emissions from residential sector by proposing new building structures in hot and humid climatic conditions. Build Environ 124:357–368. https://doi.org/10.1016/j.buildenv.2017.08.025

Grant A, Ries R, Kibert C (2014) Life cycle assessment and service life prediction: a case study of building envelope materials. J Ind Ecol 18(2):187–200. https://doi.org/10.1111/jiec.12089

Pennington DW, Potting J, Finnveden G, Lindeijer E, Jolliet O, Rydberg T, Rebitzer G (2004) Life cycle assessment Part 2: current impact assessment practice. Environ Int 30(5):721–739. https://doi.org/10.1016/j.envint.2003.12.009

Guinée JB, Gorrée M, Heijungs R, Huppes G, Kleijn R, de Koning A, van Oers L, Wegener Sleeswijk A, Suh S, Udo de Haes HA, de Bruijn H, van Duin R, Huijbregts MAJ (2002) Handbook on life cycle assessment. Operational guide to the ISO standards. Part III: scientific background. Kluwer Academic Publishers, Dordrecht, p 692

Oladazimi A, Mansour S, Hosseinijou SA (2020) Comparative life cycle assessment of steel and concrete construction frames: a case study of two residential buildings in Iran. Buildings 10(3):54. https://doi.org/10.3390/buildings10030054

Echarri-Iribarren V, Echarri-Iribarren F, Rizo-Maestre C (2019) Ceramic panels versus aluminium in buildings: energy consumption and environmental impact assessment with a new methodology. Appl Energy 233:959–974. https://doi.org/10.1016/j.apenergy.2018.08.091

Leskovar VŽ, Žigart M, Premrov M, Lukman RK (2019) Comparative assessment of shape related cross-laminated timber building typologies focusing on environmental performance. J Clean Prod 216:482–494. https://doi.org/10.1016/j.jclepro.2018.12.140

Abouhamad M, Abu-Hamd M (2021) Life cycle assessment framework for embodied environmental impacts of building construction systems. Sustainability 13(2):461. https://doi.org/10.3390/su13020461

Ingrao C, Messineo A, Beltramo R, Yigitcanlar T, Ioppolo G (2018) How can life cycle thinking support sustainability of buildings? Investigating life cycle assessment applications for energy efficiency and environmental performance. J Clean Prod 201:556–569. https://doi.org/10.1016/j.jclepro.2018.08.080

Neves TI, Uyeda CA, Carvalho M, Abrahão R (2018) Environmental evaluation of the life cycle of elephant grass fertilization—Cenchrus purpureus (Schumach.) Morrone—using chemical fertilization and biosolids. Environ Monit Assess 190(1):30. https://link.springer.com/article/. https://doi.org/10.1007/s10661-017-6406-4

Goedkoop MJ, Heijungs R, Huijbregts MAJ, De Schryver AM, Struijs J, Van Zelm R (2009) ReCiPe 2008: a life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level; First edition Report I: Characterisation. http://www.lcia-recipe.net.

Myhre GD, Shindell D, Bréon FM, Collins W, Fuglestvedt J, Huang J, Koch D, Lamarque JF, Lee D, Mendoza B, Nakajima T, Robock A, Stephens G, Takemura T, Zhang H (2014) Anthropogenic and natural radiative forcing. In: Stocker TF, Qin D, Plattner GK, Tignor M, Allen SK, Boschung J, Nauels A, Xia Y, Bex V, Midgley PM (eds) Climate change 2013—the physical science basis. Cambridge University Press, Cambridge, pp 659–740

Petrovic B, Myhren JA, Zhang X, Wallhagen M, Eriksson O (2019) Life cycle assessment of building materials for a single-family house in Sweden. Energy Proced 158:3547–3552. https://doi.org/10.1016/j.egypro.2019.01.913

Sedláková A, Vilčeková S, Burák D, Blichová Ž, Moňoková A, Doroudiani S (2020) Environmental impacts assessment for conversion of an old mill building into a modern apartment building through reconstruction. Build Environ 172:1–13. https://doi.org/10.1016/j.buildenv.2020.106734

Pujadas-Gispert E, Vogtländer JG, Moonen SPG (2021) Environmental and economic optimization of a conventional concrete building foundation: selecting the best of 28 alternatives by applying the Pareto front. Sustainability 13(3):1496. https://doi.org/10.3390/su13031496

Chang Y, Huang Z, Ries RJ, Masanet E (2016) The embodied air pollutant emissions and water footprints of buildings in China: a quantification using disaggregated input–output life cycle inventory model. J Clean Prod 113:274–284. https://doi.org/10.1016/j.jclepro.2015.11.014

Novotny V (2010) Water and energy footprints of the cities of the future. Water Pract Technol 5(4):wpt2010074. https://doi.org/10.2166/wpt.2010.074

Hosseinian SM, Ghahari SM (2021) The relationship between structural parameters and water footprint of residential buildings. J Clean Prod 279:123562. https://doi.org/10.1016/j.jclepro.2020.123562

Sameer H, Bringezu S (2019) Life cycle input indicators of material resource use for enhancing sustainability assessment schemes of buildings. J Build Eng 21:230–242. https://doi.org/10.1016/j.jobe.2018.10.010

Fokaides PA, Kalogirou SA (2011) Application of infrared thermography for the determination of the overall heat transfer coefficient (U-Value) in building envelopes. Appl Energy 88(12):4358–4365. https://doi.org/10.1016/j.apenergy.2011.05.014

Pavel CC, Blagoeva DT (2018) Competitive landscape of the EU’s insulation materials industry for energy-efficient buildings. EUR 28816 EN, Publications Office of the European Union, Luxembourg. https://doi.org/10.2760/750646

Liuzzi S, Hall MR, Stefanizzi P, Casey SP (2013) Hygrothermal behaviour and relative humidity buffering of unfired and hydrated lime-stabilised clay composites in a Mediterranean climate. Build Environ 61:82–92. https://doi.org/10.1016/j.buildenv.2012.12.006

Tulliani JM, Formia A, Sangermano M (2011) Organic-inorganic material for the consolidation of plaster. J Cult Herit 12(4):364–371. https://doi.org/10.1016/j.culher.2011.04.001

Frischknecht R, Jungbluth N, Althaus HJ, Doka G, Dones R, Hischier R, Hellweg S, Humbert S, Margni M, Nemecek T, Spielmann M (2007) Implementation of Life cycle impact assessment methods: data v2.0. ecoinvent report No. 3, Swiss centre for Life Cycle Inventories, Dübendorf, Switzerland

SimaPro database manual methods library. Pré Sustainability B.V. web. https://simapro.com/wp-content/uploads/2021/07/DatabaseManualMethods920.pdf. Accessed 5 Oct 2021

Lippiatt BC, Greig AL, Lavappa PD (2010) BEES online: life cycle analysis for building products. National Institute of Standards and Technology (NIST) Web. https://www.nist.gov/publications/bees-online-life-cycle-analysis-building-products. Accessed 5 Oct 2021

Huijbregts MAJ, Steinmann ZJN, Elshout PMF et al (2016) ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int J Life Cycle Assess 22:138–147. https://doi.org/10.1007/s11367-016-1246-y

Van Caneghem J, Vermeulen I, Block C, Cramm P, Mortier R, Vandecasteele C (2010) Abiotic depletion due to resource consumption in a steelwork assessed by five different methods. Resour Conserv Recycl 54(12):1067–1073. https://doi.org/10.1016/j.resconrec.2010.02.011

Dincer I, Colpan CO, Kizilkan O (2017) Exergetic, energetic and environmental dimensions. Academic Press, London

Sackey S, Kim BS (2018) Environmental and economic performance of asphalt shingle and clay tile roofing sheets using life cycle assessment approach and topsis. J Constr Eng Manag 144(11):04018104. https://doi.org/10.1061/(ASCE)CO.1943-7862.0001564

Lamnatou C, Motte F, Notton G, Chemisana D, Cristofari C (2018) Building-integrated solar thermal system with/without phase change material: life cycle assessment based on ReCiPe, USEtox and ecological footprint. J Clean Prod 193:672–683. https://doi.org/10.1016/j.jclepro.2018.05.032

Jeswani HK, Azapagic A (2011) Water footprint: methodologies and a case study for assessing the impacts of water use. J Clean Prod 19(12):1288–1299. https://doi.org/10.1016/j.jclepro.2011.04.003

Gonzalez M, Navarro J (2006) Assessment of the decrease of CO2 emissions in the construction field through the selection of materials: practical case study of three houses of low environmental impact. Build Environ 41:902–909. https://doi.org/10.1016/j.buildenv.2005.04.006

Shukla A, Tiwari GN, Sodha MS (2009) Embodied energy analysis of adobe house. Renew Energy 34(3):755–761. https://doi.org/10.1016/j.renene.2008.04.002

Lakatos A et al (2018) Thermal characterization of different graphite polystyrene. Int Rev Appl Sci Eng 9(2):163–168. https://doi.org/10.1556/1848.2018.9.2.12

Mequignon M, Haddou HA (2015) Impact of the lifespan of building external walls on depletion of natural resources. IFAC-Pap 48(3):351–356. https://doi.org/10.1016/j.ifacol.2015.06.106

Shahriari F (2018) The Relationship between Iranian EFL instructors’ multiple intelligence ability and reflective teaching. Rev Romaneasca Pentru Educ Multidimens 10(1):97–109. https://doi.org/10.18662/rrem/39

ISO 6946 (2017) Building components and building elements—thermal resistance and thermal transmittance—calculation methods

Papadopoulos AM, Giama E (2007) Environmental performance evaluation of thermal insulation materials and its impact on the building. Build Environ 42(5):2178–2187. https://doi.org/10.1016/j.buildenv.2006.04.012

Funding

This research was conducted within the solution of the grant financed by the Scientific Grant Agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic and the Slovak Academy of Sciences VEGA (Grant No. 1/0230/21).

Author information

Authors and Affiliations

Contributions

AE: conceptualisation, supervision, and writing–review and editing; MW: methodology, software, and writing–original draft. MO: interpretation of the results, validation, and data curation.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Data Availability

The data presented in this study are available on request from the corresponding author.

Consent to Participate

All the authors declare their consent to participate on the manuscript.

Consent for Publication

All the authors have read and agreed to the submitted version of the manuscript.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Eštoková, A., Wolfová Fabiánová, M. & Ondová, M. Concrete Structures and Their Impacts on Climate Change and Water and Raw Material Resource Depletion. Int J Civ Eng 20, 735–747 (2022). https://doi.org/10.1007/s40999-022-00701-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-022-00701-8