Abstract

The binder in hot-mix asphalt (HMA) is aged (oxidized) in a short-time period during haul-and-queue in the field. Since the oxidative aging of asphalt is a complex chemical process, it is difficult to define the asphalt aging as a function of limited variables. When comparing the same types of asphalt mixes, however, the mix temperature (T) and time (t) kept at the T will be the primary source of variation affecting aging levels of the binder in the mix. Since the binder aging level is not easy to estimate without measuring a physical property, this study concentrated on developing an aging quantity (AQ) model for estimating aging levels of the binder in the mix based on T and t. The loose asphalt mixes were artificially short-term aged at various Ts for different t; 130, 160, and 180 °C for 1, 2, 4, and 8 h. The absolute viscosity (AV) values, which represent aging levels of the recovered binder after each short-term aging (SA) of normal dense-graded mix, were used for regression with AQ values computed by the AQ model. The best-fit AQ model was selected by trial-and-error regression iterations between measured AV and computed AQ. The AQ was then used to estimate AV (EAV) of the aged asphalts in various normal asphalt mixes. It was found that the AQ was useful for estimating AV of the binder in the SA-treated mix, and the EAV by AQ showed an excellent correlation with the measured AV with R2 > 0.99. Therefore, it was possible to conclude that the AQ could be used to predict aging level of various short-term-aged normal asphalt mixes if the materials sources were limited.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Short-term aging (SA) of binders in hot-mix asphalt (HMA) is known to take place during haul-and-queue in a truck. Since the oxidation is expedited by heat and intensified by time, the binder aging is primarily dependent on the mixture temperature (T) and delivery time (t), although many other factors are related. It was demonstrated that the binder SA was induced further if the HMA was produced at a higher temperature and kept for a longer time at an elevated temperature [1, 2]. If the temperature is at a lower level, like warm-mix asphalt (WMA), SA will not be intensified even if the time is extended. However, since the oxidation of asphalt is a complex chemical process, it is difficult to define the asphalt aging as a function of only those two factors (T and t). Nevertheless, if the same types of asphalt mixtures are considered, the main source of variation for aging will be from the exposed T and t.

According to laboratory studies, the absolute viscosity of 407 Pa s, on average, was measured from the recovered binders of normal dense-graded asphalt mixes after SA for one hour (1-h) at 160 °C in the laboratory [3, 4]. This viscosity level was approximately twice the viscosity (198 Pa s) of the original binder used for these mixes, and identical to 405 Pa s [3], which was measured after a rolling thin film oven (RTFO) run of the same binder. The RTFO procedure (85 min at 163 °C) was used to make a simulated short-term aging of the binder, which is identical to the binder in the mix under the normal short-term aging condition [5]. However, after short-term aging of the same mix for 2-h at 180 °C, the viscosity of recovered binder was increased to 1944 Pa s, approximately 5 times the viscosity (407 Pa s) of the mix after 1-h SA at 160 °C, and 10 times the viscosity (198 Pa s) of the original binder [3].

Although quantifying aging by numerical function is complex due to various factors involved, the results showed the remaining source of variation governing aging seemed to be those two variables for the case of the same materials. Therefore, if the aging quantity is estimated by a model as a function of these two variables for the same mix, it is possible to represent the binder aging level as a numerical value.

Generally, the current aging level is estimated by measuring a conventional physical property, such as viscosity or stiffness index from the recovered binder, even though gel-permeation chromatography (GPC) and Fourier transform infrared spectroscopy (FTIR) can be applied for aging estimation [2, 6,7,8,9]. Significant time and effort are needed for recovering binder from the mix, as well as testing physical property using the recovered binder. If the aging level can be quantitatively assessed by a numeric value, it will be useful in assessing the aging level of the mix’s binder without any property testing [10, 11]. Therefore, this study focused on aging quantity (AQ) modeling using experimental short-term aging data for the normal HMA and WMA mixes. As with many types of asphalt mixes, this study was applied to normal dense grade asphalt mixtures, which are most widely used for surface-course asphalt pavement. The binder was limited to normal asphalt (without polymer) to prevent sources of variation. Since the absolute viscosity (AV), measured by ASTM D2171 [12], is the most widely used property for asphalt aging estimation, the AV was utilized as an aging index in this study. To achieve a proper aging model, the two independent variables, t and T, should be quantified numerically in a function, which should manage the variation between AV and AQ properly for given t and T.

The objective of this study was to develop an AQ model, which can be utilized for the binder aging estimation of the aged mix, by employing a numerical function using the short-term aging time and temperature. The purpose of this paper is to present methodologies used in the course of this study for developing an AQ model using normal asphalt mixtures. Once the AQ model is successfully developed, it can be applied for estimating the binder aging level of short-term-aged normal asphalt mixes without physical property testing. Although this study only used normal asphalt dense-graded mixes, this aging assessment idea may be applied in the same way for other mixes, that use other grade normal asphalt binders.

2 Materials and Methods

2.1 Materials

A PG 64-22 asphalt binder, which is also classified as AC-20 viscosity grade and 60–80 penetration grade in Korea, was used as the base asphalt with two granite aggregates in this study. The stiffness index (G*/sin δ), absolute viscosity (AV), and penetration (PEN) values are shown in Table 1 by conditions. K-pearl, a WMA additive that is known to be a paraffin-wax based compound, was used by 1.7 wt. % of binder. Two granite-based 13 mm aggregates, granite screenings passing #8 sieve (2.36 mm) and a limestone powder, were used as the coarse aggregate, fine aggregate, and mineral filler, respectively. The two aggregate gradations confirming WC-1 dense-graded asphalt (DGA) gradation specifications (Fig. 1) were prepared for surface course asphalt pavement mixes based on the Korean mix-design guide [13].

Two aggregate gradations confirming upper and lower limits of WC-1 gradation [13]

2.2 Methods

Two dense-graded HMA mixes (Mix I and II) were prepared by mix-design for the surface course mixture using the normal asphalt and two aggregates in accordance with the Korean mix-design guide [13]. The HMA mixture, which was blended for 1 min using a paddle mixer, was short-term aged for 1-h at 160 °C before compaction for 100-mm diameter specimen using a gyratory compactor. Mix design was performed to determine optimum asphalt content (OAC) based on four properties specified by Korean Guide [13]: air void ratio, strength against deformation (SD), voids filled with asphalt (VFA), and voids in mineral aggregates (VMA). The specification limits of the air void ratio, SD, VFA and VMA were 4%, ≥ 3.2 MPa, 65 ~ 80%, and ≥ 14%, respectively, for surface course of secondary class highways [13]. The WMA mixtures satisfied the specification limits of the four properties with slight modification of OACs of the HMA mixes, as shown in Table 2.

The fresh HMA and WMA mixes at the OAC were prepared for short-term aging (SA) by blending for 1 min using a paddle mixer. The SA was conducted for each mix in loose state in an open canister (Fig. 2), which was kept in a drying oven at three different temperatures for 3 and 4 times without air blowing (Table 2). One hour (1-h), 2-h, and 4-h were used for SA of the mixes at 130 and 180 °C. In addition to 1-h, 2-h, and 4-h, the 8-h was applied for the mix at 160 °C. The 1-h, 2-h, and 4-h were considered the optimistic time, the most likely time and the pessimistic (worst) time of SA, respectively, for the field paving project. Although the 4-h delay was assumed to be the longest time before feeding to the paver for the normal paving operation, 8-h was assumed to be the maximum time for carry-on mix in an insulated chamber for repair work in this study. Therefore, 160 °C mix was used for 8-h SA under the assumption that the normal HMA mix maintained at 160 °C was used for repair work.

Although the field mix is an average of 160 °C in normal season, SA temperatures of 160 °C and 180 °C were chosen based on the assumption that the use of elevated temperature (180 °C on average) would be normal practice in Korea’s winter season. The average represents the average temperature of the mixture in the truck from the starting point at the mixing plant to the end of haul-and-queue point at the job site. The SA at 130 °C, which is 30 °C lower than the normal HMA, was used for the WMA mix.

The AV was measured by ASTM D2171 [12] from the binder recovered from each SA-treated mix by the Abson method [14]. The AV was also measured from the binder recovered from the fresh mix (before SA) after mixing for one minute at 160 °C to examine the AV level immediately after mixing. Figure 3 shows the equipment used for the Abson recovery in this study.

3 Results and Discussions

3.1 Aging Measured by Absolute viscosity (AV)

Table 3 shows AV values, which were measured from the binder recovered from the mixture after each short-term aging (SA). Mix I showed somewhat lower AV values than Mix II at the same condition. The difference in optimum asphalt content (OAC) was considered to be the cause of the difference in AV level with the higher OAC mix (Mix I) showing the lower AV. Just after mixing for 1 min at 160 °C, the binder viscosity had not changed much from the original value (190.5 Pa s), as shown in Table 1. Therefore, mixing for a short time (1 min in this study) was found to have little effect on binder aging.

However, after SA for 1-h at 160 °C, the binder AV had clearly changed from its original value. The AV of the mix after 1-h SA at 160 °C was 441 Pa s, on average, which was 2.3 times higher than the AV value of the original binder. This AV level was identical to the AV (421.3 Pa s) of the RTFO binder, as shown in Table 1. Therefore, the SA for 1 h at 160 °C was designated as the normal short-term aging (NSA) [15] for comparison purposes in this study.

It was found that doubling the time from 2-h to 4-h and 4-h to 8-h at 160 °C induced more than twice the viscosity increase in each time step as shown in the AV ratio in Table 3. However, by doubling the time from 1-h to 2-h at 160 °C, the AV increase ratio was less than twice (1.51). For the same time step increase at 180 °C, much more significant increases were observed; i.e., approximately 4 times from 1-h to 2-h and 2-h to 4-h, as shown in Table 3 and Fig. 4. The temperature difference from 160 °C to 180 °C is only 20 °C (12.5% higher), but its impact on aging was much greater than expected when the mix was kept for over 2-h. It is important to note that the SA at 180 °C induced a much higher viscosity escalation than the SA at 160 °C for the same time from 2-h or longer.

Aging of the WMA mix was much lower than the two HMA temperatures, however, showing a minor AV increase for the same time step increment. The 2-h SA at 130 °C was slightly lower than the AV of the mix by 1-h SA at 160 °C. Four-hour SA of the WMA mix was found to show still lower AV than those of 1-h SA at 180 °C and 2-h SA at 160 °C. Therefore, the WMA mix demonstrated a great advantage in aging control, without problems of significant aging due to the time increase (i.e., traffic delay in the field).

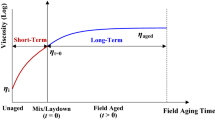

Figure 4, which was created using the ratios of AV compared to the AV of NSA (SA for 1-h at 160 °C), illustrates how much the temperature and time differences induced AV change. Since the trend of increments clearly appeared to follow a typical exponential function form, \(y = ae^{{bx}}\), it is implied that if the values in horizontal axis can be quantified numerically in order, it might be possible to estimate binder aging by the exponential function model.

3.2 AQ Modeling

It is a well-known fact that asphalt binders become harder due to the mixture SA, and many researchers evaluated performance of asphalt mixtures through modeling in relation to asphalt age-hardening. Liu et al. [16] compared the effects of loading frequency and aging degree for the asphalt fatigue properties using the tensile fatigue test. One-day-aged asphalt concrete was found to show better fatigue performance than unaged asphalt concrete, and asphalt concrete aged over 1-day showed deteriorated fatigue performance. Zang et al. [17] suggested a new short-term aging model for binders that focused on the viscosity and rheological activation energy, and was calculated from the conventional properties such as penetration, kinematic viscosity, AV, and viscosity-temperature susceptibility (VTS) values of unaged asphalt binders. According to this aging model, the rheological activation energy of asphalt was increased linearly proportional to SA, and provided accurate viscosity predictions in both lab and field short-term aging. Additionally, Chen and Haung [18] proposed an aging model to predict changes in binder properties during field age hardening. This model allowed for engineers to quantify two characteristics of binder aging the aging rate and the ultimate degree of changes in binder properties due to long-term aging. Garrick [19] evaluated the logistic function for quantifying two essential characteristics of asphalt aging: the rate of aging and ultimate degree of change in asphalt properties due to aging. The model was comparable to experimental data from a variety of pavement-aging studies, including the relative effects on the aging process of factors such as asphalt type, void level, and climate. Zhang et al. [20] developed a new long-term aging model to predict field-aged viscosity of pavement binder using two-stage aging kinetics to capture oxidation mechanism of long-term aging. They incorporated primary structure coating thickness to quantify the effects of mixture morphology on long-term aging. However, those researches studied the modeling of asphalt aging in relation to properties of mixture or long-term pavement performance, not just assessing aging in numerical quantity itself as this study was focused on.

This study intended to develop an AQ model using SA time and temperature of asphalt mixes. The x-axis values should be quantified as the AQ, which can be arranged according to AV level in order. As a simple example of AQ quantification, if t and T are simply multiplied, the AQ of 1-h SA at 160 °C is calculated as 9,600 (60 min × 160 °C). For the case of direct multiplication of the two values, however, the quantified AQ values were not comparable to the AV values, as shown by the regression curve in Fig. 5 (R2 = 0.639).

Due to high variations between measured AV and computed AQ, a more sophisticated model was needed, and many forms of numerical functions were evaluated by trial-and-error iterations. Initially, the AQ was computed using an exponential form because the changing pattern of binder AV by aging time increase in temperature was observed to follow an exponential form as shown in Fig. 4 and in earlier studies [10, 15]. The form of exponential equation is f(t, T) = AeBx, in which value A was found to be related more with time, and B related with the temperature of SA. The main function of the model is to reduce the variation between AV and AQ properly to fit to the regression curve.

For the constant A and B, three forms were investigated, respectively; A = at, at or ta, and B = bT, bT or Tb using trial-and-error regression iterations between AV and AQ. The most appropriate form was found to be AQ = ta ebT. Selected constants a and b for the best model are shown in the AQ equation in Table 4, which shows the best model for each function investigated in this study. The highest R2 was observed to be 0.9805 from the exponential model of AQ = t0.7436 e0.0334T.

To find a better model, which might show higher R2 value than 0.9805, an approach was made using the power form for AQ computation; f(t, T) = AxB. For constant A and B, A = at, at or ta and B = bT, bT or Tb were also investigated using trial-and-error regression iterations between AV and AQ. The most appropriate form was found to be AQ = (at)bT. Selected constants a and b for the model are shown in the AQ equation in Table 4. The highest R2 was observed to be 0.9844 from the power model of AQ = (8.75t)0.0042T. This R2 value is 0.0039 higher than that of the exponential model.

Further investigation was performed to find a more favorable model, which might show a better R2 than 0.9844. Another approach was made using a natural logarithm form for AQ computation; f(t,T) = A ln(Bx). Initially, A ln(Bx) and ln(A)Bx were investigated. For the constant A and B, three forms were also investigated, respectively; A = a.t, at or ta, and B = bT, bT or Tb using trial-and-error regression iterations between AV and AQ. The most appropriate form was found to be AQ = ln (at)bT. Selected constants a and b for the model are shown in the AQ equation in Table 4. The highest R2 was observed to be 0.9903 from the logarithm model of AQ = 10 ln(0.5689t)0.01949T. Since this R2 was higher than any others, this model was selected as a final model in this study, as shown in Eq. (1). Figure 6 shows a regression curve between AV means in Table 3 and AQ computed using this model. The final model showed a great fitting effect as shown step by step in Figs. 5, 7a–d, by changing AQ model and constants a and b. The widely spread data points were almost perfectly fitted to the regression line.

in which, AQ = aging quantity (min.oC), t = SA time (min), and T = SA temperature (oC).

To show a more detailed procedure for selecting a final AQ model, several steps of trial-and-error iterations for selecting a better-fit model in regression were briefly shown in Table 5 and Fig. 7 by changing the constant a and b. Referring to earlier study, initial input values used for a and b were 0.5 and 0.1, respectively. First AQ values were computed using corresponding t and T by the AQ model shown in Fig. 7a, and a regression was performed using the mean AV values (Table 3) and the computed AQ values.

The next step was performed using a = 0.6 and b = 0.05 for selecting a better model, as shown in Fig. 7b, which was followed with several more steps by changing a and b values, as shown in Fig. 7c and d. The best-fit a and b were determined based on the highest R2 value (0.990307651 ≒ 0.9903) of the regression, as shown in the last step in Table 5, and Fig. 6.

The AQ values computed by Eq. (1) are numerical values quantified using the data in Table 3 which were arranged in the horizontal axis of Fig. 4 by AV ratio. The regression between the mean AV and AQ is a correlation analysis between a physical property (AV) and the numerical value (AQ) of agedness quantified using aging time and temperature. Therefore, the AQ can be used to estimate the AV, because the AV is function of AQ, or AV = f(AQ). As shown in Fig. 6, the regression curve showing AV increase by AQ increase is similar to the curve in Fig. 4. Therefore, as initially hypothesized, the AV changing pattern by the AQ (the x-axis value) increase was proved to follow an exponential model. By replacing x with AQ and y with AV in y = 218.756 e0.001425x; therefore, the AV can be estimated using the Eq. (2). The estimated AV (EAV) is the viscosity predicted by AQ, which is a function of t and T for SA, without actual property testing.

To verify the validity of the developed AQ model, 22 data sets from WMA and HMA mixes in earlier studies [6, 15, 21,22,23] were collected and used to calculate EAV based on the AQ. Those mixes were prepared using the same class binder (PG64-22 and AC-20) for dense-graded surface course asphalt mix. AQ values computed by Eq. (1) for the given T and t are shown in Table 6 together with the AV (from previous studies), and the EAV values computed by Eq. (2). A regression analysis was performed between measured AV and estimated AV values in Table 6, and the result is shown in Fig. 8. The two values showed an excellent correlation with R2 = 0.9977. Since the measured AV and estimated AV were found to have an excellent correlation (R2 > 0.99), the AQ model can be considered a proper numerical function for quantifying aging (agedness) of asphalt in normal mixes using t and T of SA.

Relation of Absolute Viscosity (AV) and Estimated AV (EAV) by Eq. (2)

Therefore, this study ultimately developed a highly reliable estimation model for asphalt aging in a numerical quantity for normal asphalt mixes. The superiority of this model is to estimate AV based on the numerical AQ value, which is a function of “simple” time and temperature of the mix’s SA without any property testing. Since this is a highly reliable estimation model for asphalt aging in a numerical quantity for normal asphalt mixes, it can be applicable for field mix aging control. However, since the interpolation should be limited within the AQ value range used in Table 5, AQ range for field mix should be limited within the same range for reliable AV estimation.

3.3 Application of AQ

For further evaluation, an application of AQ was made for reviewing current SA specifications, based on AQ and EAV values computed using Eqs. (1) and (2), respectively. Two specifications, which regulated the laboratory SA conditions at different t and T were examined. One was Korean Guide [13], which specified SA for 1-h at compaction T, and the other was Australia/New Zealand standards [24], which regulated SA for 1 h at 150 °C. The compaction temperature for Korean guide was 140 °C, which was calculated based on 280 ± 30 cSt of kinematics viscosity of the binder used in this study [13, 22].

To evaluate these specifications in terms of EAV, the binder aging level after the RTFO result was introduced for normal (unmodified) binders. It was assumed that the proper SA of a normal mix will have to show a similar binder AV level to the AV of the RTFO-treated binder if the same grade binder is used. In this study, the AV of the RTFO-treated binder was 421.3 Pa s (Table 1).

According to the ASTM D3381 [25], the AV grade range (R) is given by the mean \((\bar{x})\) plus or minus 20% of the mean, or \(R = \bar{x} \pm 0.2\bar{x}\). Therefore, since the AV sample range will be R = 421.3 \(\pm\) 0.2 \(\times\) 421.3 = 337.0 ~ 505.6, or R = 505.6 − 337.0 = 168.6. Assuming normal distribution, the interval defined by the mean plus or minus 3 standard deviation (s) (\(\bar{x} \pm 3s\)) should contain 99.7% of the samples [26, 27]. The total range is 6 s and therefore s can be approximated as 1/6 of the range. In this case, the mean \(\bar{x}~\) is 421.3 and the standard deviation s is 28.1 (= 168.6/6). However, since the AV is measured by the average of a minimum of 3 samples, the range of 3 sample mean should be \(\bar{x} \pm 3s/\sqrt 3 = {\text{ }}421.3 \pm {\text{ }}3\left( {28.1} \right)/~\sqrt 3 = 421.3 \pm {\text{ }}48.7\), or 372.6 ~ 477.0 Pa s, or more practically, 373 ~ 470 Pa s. The EAV in this range can be suggested as proper AV values, which will be induced by the normal SA (NSA) if the same asphalt, used in this study, is considered.

The EAV values, which were computed using AQ based on t and T of each specification, are shown in Table 7. The EAV was computed using the AQ obtained by t from 30 to 240 min (4 h). The temperature of the HMA mix in the haul truck was assumed to range from a minimum of 150 °C up to 180 °C. However, since the Korean Guide specifies a lower temperature (140 °C), and this study used WMA, the temperatures from 130 °C were used in Table 7. The EAVs in the shaded boxes represent the values within 373 ~ 470 Pa s range. The observed proper SA ranges are from 120 min at 130 °C to 30 min at 180 °C in a 5 °C T step.

The EAV value, which was computed based on 1-h SA at 140 °C by the Korean Guide [13], was out of the AV range, as denoted by superscript of “a” with a bold letter. However, the EAV by 1-h SA at 150 °C by the Australia/New Zealand guide [24] was within the AV range, as denoted by superscript of “b” with a bold letter.

Although the EAV values by SA for 120 min (2-h) at 140 °C are within the suggested AV range according to Table 7, the HMA mix cannot be kept in the truck in the field for 2-h at 140 °C, which is considered WMA temperature level. Because of the necessity to maintain compaction temperatures due to the rapid cooling after spreading by pavers, these temperature levels are not allowed for HMA in the field. Since the lab SA is a simulation process for making a field-conditioned mix in the lab, it should follow the field SA process as much as possible. Therefore, the SA specifications with temperatures lower than the HMA range was found to be unrealistic for lab SA procedures.

According to the above examination, it was shown that the aging level could be estimated using AQ without measuring viscosity. In addition to these examples, the aging level of any field SA mix can be estimated by instant calculation in terms of EAV. For example, if a normal dense-graded asphalt mixture using a PG64-22 binder was paved after haul-and-queue for 90 min at 170 °C on average, the AQ of 936.5 (minoC) can be obtained by AQ = 10ln(0.5689 × 90)0.01949(170) using Eq. (1). The EAV calculated using Eq. (2) is 830.9 (Pa s) [= 218.756e(0.001425×936.5)], which is out of the 373 ~ 470 Pa s range. Because the binder in the paved mix was aged over the proper aging level, and approximately twice the average of proper aging level (421 Pa s), it is possible that any SA condition can be judged by the suggested EAV through AQ without actual AV testing.

It is also possible to use AQ itself as an aging index. For example, since the mean EAV of 421 Pa s was approximately achieved by SA by 52 min at 161 °C and 63 min at 154 °C using Eqs. (1) and (2), the AQ computed using those aging conditions is 460 min oC on average. For proper AV of 373 ~ 470 Pa s, the AQ range was computed as 375 ~ 537 min oC. Therefore, the AQ value itself can be introduced as an aging index of asphalt binder in the aged mix after further studies for practical application are done in the future.

This novel study was performed to introduce the AQ for estimating an aging level in terms of EAV value and demonstrated examples of applications of the developed AQ model. Future studies may investigate other properties related to binder aging, such as stiffness index. However, the argument stressed in this study is not to specify proper EAV range or suggest constants in the developed model, but to present methodology showing the possibility of estimating aging levels using the numerical value without property testing.

Since this study developed a quantified agedness, accumulated by the time at a temperature, this concept might be similar to the concept of “maturity” of cement concrete curing. Although it is recognized that defining asphalt aging in quantity is a complex problem due to the many variations involved, this is a beginning effort in developing a procedure for identifying aging in quantity using limited materials. Therefore, further study with many other materials may be needed for generalization of the current concepts.

4 Conclusions

To estimate aging level numerically using short-term aging (SA) time (t) and temperature (T) of asphalt mixes, a binder aging quantity (AQ) model was developed based on the best-fit R2 in regression between absolute viscosity (AV) and computed AQ values. Since this study used dense-graded HMA and WMA mixes with normal asphalt binders, the developed AQ model was validated using the data from the same type of mixes from previous studies.

The model was developed as AQ = ln (at)bT form, and the AQ was applied for estimating binder aging levels (in terms of AV) of SA-treated mixes. The estimated AV (EAV) was found to have an excellent correlation with the measured AV with R2 > 0.99. Therefore, it was possible to show that the AQ model could be developed and the AQ could be applied to estimate the asphalt aging level of binder in the SA-treated normal asphalt mixes without property testing.

Since the AQ model developed was applicable to estimate the AV of the binder in short-term aged mixes, it was concluded that the AQ could be a useful implement to estimate AV of the binder in SA-treated normal dense-graded asphalt mixes before AV testing. The superiority of this model is to estimate AV based on the AQ value, which is a function of “simple” t and T of the mix’s SA without any property testing. Since EAV can be computed using only t and T in the AQ model, the proper SA conditions can be suggested based on the AV level of the RTFO-run binder as a standard SA for normal asphalt mixes.

However, since this study used only PG64-22 (AC-20 and pen 60–80) binder with dense-graded HMA and WMA mixes, the conclusion reached in this study is tentative, and as good as the assumption upon which these findings were reached. The objective stressed in this study is not to specify the numbers in the AQ model or give a specific EAV range, but to present the methodology for estimating aging in numerical quantities.

Although, it is recognized that defining aging is a complex issue due to various factors involved, it is a unique effort in developing a procedure for identifying aging in numeric value. Therefore, further studies using other materials may be needed for generalization of the current concept.

References

Jeong S, Xiao F, Kim YS, Kim KW (2017) Evaluation of age retardation effect of antioxidant in dense-graded asphalt (DGA) mixture using large molecular size. Constr Build Mater 149:459–466. https://doi.org/10.1016/j.conbuildmat.2017.05.094

Kim S, Lee SH, Kwon O, Han JY, Kim YS, Kim KW (2016) Estimation of service life reduction of asphalt pavement due to short-term ageing measured by GPC from of asphalt mixture. Road Mater Pavement Des 17(1):153–167. https://doi.org/10.1080/14680629.2015.1066704

Kim S, Shen J, Lee SJ, Kim YS, Kim KW (2019) Examination of physical property degradation due to severe short-term aging and effect of hydrated lime as antioxidant in asphalt mixture. Road Mater Pavement Des 20(7):1638–1652. https://doi.org/10.1080/14680629.2018.1473281

Han JY, Kim H, Kim YS, Yun J, Kim S, Kim KW (2015) Aging characterization of SMA and dense-graded asphalt mixture using gel-permeation chromatography. New Front Road Airpt Eng. https://doi.org/10.1061/9780784414255.014

Asphalt Institute (2003) Superpave: performance graded asphalt binder specification and testing. Superpave series no. 1 (SP-1). Asphalt Institute, Lexington (ISBN-13: 978-1934154168)

Kim KW, Kim KA, Doh YS, Amirkhanian SN (2006) Estimation of RAP’s binder viscosity using GPC without binder recovery. J Mater Civ Eng 18(4):561–567. https://doi.org/10.1061/(ASCE)0899-1561(2006)18:4(561)

Jennings PW, Pribanic JAS, Smith J, Mendes TM (1988) Predicting the performance of the Montana test sections by physical and chemical testing. Transp Res Rec 1171:59–65

Kim KW, Burati JL Jr (1993) Use of GPC chromatogram to characterize aged asphalt cement. J Mater Civil Eng 5(1):41–52. https://doi.org/10.1061/(ASCE)0899-1561(1993)5:1(41)

Nivitha MR, Prasad E, Krishnan JM (2016) Ageing in modified bitumen using FTIR spectroscopy. Int J Pavement Eng 17(7):565–577. https://doi.org/10.1080/10298436.2015.1007230

Kim YS, Dong BS, Kim S, Jo JW, Kim KW (2018) Prediction of short-term aging level by aging quantity model using time and temperature of hot-mix asphalt. Proc Int Conf Road Rail Infrastruct. https://doi.org/10.5592/CO/CETRA.2018.726 (ISSN 1848-9850)

Prapaitrakul N, Han R, Jin X, Glover CJ (2009) A transport model of Asphalt binder oxidation in pavements. Road Mater Pavement Des 10:95–113. https://doi.org/10.1080/14680629.2009.9690238

ASTM D2171, D2171M-18 (2018) Standard test method for viscosity of asphalts by vacuum capillary viscometer. ASTM International, West Conshohocken. https://doi.org/10.1520/D2171_D2171M-18

Ministry of Land, Infrastructure and Transport (2016) Guidelines for asphalt concrete pavement construction. Korea Construction Standard Center, Republic of Korea. https://kcsc.re.kr/Cstd/Detail2/1269

ASTM D1856–21 (2021) Standard test method for recovery of asphalt from solution by Abson method. ASTM International, West Conshohocken. https://doi.org/10.1520/D1856-21

Kim S, Jeong SH, Kim KW (2020) Evaluation of existing short-term aging procedure for hot-mix asphalt mixture and related suggestions. Int J Highw Eng 22(3):1–11. https://doi.org/10.7855/IJHE.2020.22.3.001

Liu C, Lv S, Peng X, Zheng J, Yu M (2020) Analysis and comparison of different impacts of aging and loading frequency on fatigue characterization of Asphalt concrete. J Mater Civil Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003317

Zhang D, Birgisson B, Luo X, Onifade I (2019) A new short-term aging model for asphalt binders based on rheological activation energy. Mater Struct 52:68. https://doi.org/10.1617/s11527-019-1364-7

Chen JS, Huang LS (2000) Developing an aging model to evaluate engineering properties of asphalt paving binders. Mater Struct 33(9):559–565. https://doi.org/10.1007/BF02480536

Garrick NW (1995) Nonlinear differential equation for modeling asphalt aging. J Mater Civil Eng. https://doi.org/10.1061/(ASCE)0899-1561(1995)7:4(265)

Zhang D, Birgisson B, Luo X, Onifade I (2019) A new long-term aging model for asphalt pavements using morphology-kinetics based approach. Constr Build Mater 229:1–11. https://doi.org/10.1016/j.conbuildmat.2019.117032

Kim Y, Yun J, Jeong S, Kim KW (2016) Analysis of binder aging levels in asphalt mixture caused by short-term aging conditions using the GPC technique. Int J Highw Eng 18(3):1–9. https://doi.org/10.7855/IJHE.2016.18.3.001

Lee MS, Kim S, Kim KW (2012) Estimation of optimum compaction temperature for PMA and WMA mixtures by volumetric property evaluation. J Test Eval 40(3):463–475. https://doi.org/10.1520/JTE103943

Kim S, Kim Y, Kim KW (2020) Estimation of significant binder aging due to the use of different anti-stripping additives in polymer and CRM asphalt mixtures using GPC. J Test Eval 48(3):463–475. https://doi.org/10.1520/JTE20190129

AS/NZS 2891.2.1. (2014) Methods of sampling and testing asphalt method 2.1: sample preparation-mixing, quartering and conditioning of asphalt in the laboratory. Standards Australia Limited, GPO Box 476, Sydney, NSW 2001 and Standards New Zealand, Private Bag 2439, Wellington 6140. ISSN 978-1-77551-626-2

ASTM D3381, D3381M-13 (2013) Standard specification for viscosity-graded asphalt cement for use in pavement construction. ASTM International, West Conshohocken. https://doi.org/10.1520/D3381_D3381M-13

Gant E, Leavenworth R (1996) Statistical quality control. McGraw-Hill Inc, New York (ISBN-10: 0078443547, ISBN-13: 978-0078443541)

Doh YS, Amirkhanian SN, Thodesen C, Bridges W, Kim KW (2010) Evaluation of statistical validity of some asphalt binder grade systems. J Test Eval 38(6):667–673. https://doi.org/10.1520/JTE102389

Funding

This study was supported by 2016 research grant from Kangwon National University (KNU) (No. 52016 0138), and partially supported by PPI (Public Procurement of Innovation) Program To Solve Social Issues through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (No. 2019M3E8A1067629), using the facilities of the Advanced Construction Research Center at Kangwon National University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

An, S., Jo, Y., Park, T. et al. Modeling of Asphalt Aging Based on Short-Term Aging Temperature and Time of Normal Asphalt Mixture for Quantifying Binder Aging. Int J Civ Eng 20, 15–25 (2022). https://doi.org/10.1007/s40999-021-00651-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-021-00651-7