Abstract

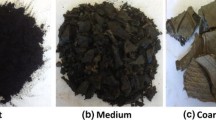

This paper discusses the assessment of optimum mix proportions of aggregates and tire chips based on shear strength and index properties (unit weight and specific gravity) for applications in granular piles/stone columns. Tire chips of cubical size 10 mm × 10 mm × 10 mm and aggregates passing through 12.5 mm, but retained on 10 mm were used. The aggregates and tire chips were mixed using the volumetric mix proportions (aggregates: tire chips) (%) of 100:0, 75:25, 50:50, 25:75 and 0:100. Large direct shear tests under normal stresses of 50, 100, and 150 kPa were performed on these mix proportions. The optimum mixing ratio is a function of void ratio and shear strength of mixture. Based on findings from experiments, the optimum content of tire chips has been found to be 25% by weight, which is equivalent to 44.4% by volume. The results from unit weight and specific gravity tests indicate that the void ratio of the mixture decreased up to the tire chips content of 50% and again increased with 100% content by weight. The results from large direct shear tests have shown that the percentage decrease in shear strength of aggregates due to addition of 25% tire chips by weight is 4.6%. Also, the angle of internal friction slightly decreased by 3° and cohesion value increased by 3.1 kPa due to addition of 25% tire chips by weight. The addition of tire chips enables the aggregate to become ductile in nature, and its dilation value and shear modulus values are decreased. The bearing capacity of granular pile has been defined in terms of improvement factor and loss of improvement is found to be only 12%, but replacement of aggregate with 25% tire chips by weight is the best solution in terms of cost-effectiveness and sustainability.

Similar content being viewed by others

Abbreviations

- ϲ :

-

Undrained cohesion of mix proportion (kPa)

- e :

-

Void ratio (dimensionless)

- E c :

-

Elastic modulus of the soil (kPa)

- F mp :

-

Influence factor for any mix proportion (dimensionless)

- G :

-

Specific gravity from laboratory (dimensionless)

- G m (cal) :

-

Specific gravity from formula (dimensionless)

- G 50 :

-

Secant shear modulus of mixture (MPa)

- I D :

-

Relative density (dimensionless)

- k p :

-

Passive coefficient (dimensionless)

- \(k_{{{\text{pa}}}}\) :

-

Passive coefficient for a granular pile with 100% aggregates

- \({k}_{{p}_{mp}}\) :

-

Passive coefficient for a granular pile with any mix proportion

- p t :

-

Tire chips (%)

- \({q}_{u}\) :

-

Ultimate load carrying capacity of granular/stone column (kPa)

- \({{q}_{u}}_{ag}\) :

-

Ultimate bearing capacity of granular pile with 100% aggregates (kPa)

- \({q}_{{u}_{mp}}\) :

-

Ultimate bearing capacity of granular pile with any mix proportion (kPa)

- τ :

-

Shear stress (kPa)

- V m :

-

Volume of mold (m3)

- V s :

-

Volume of solids (m3)

- V v :

-

Volume of voids (m3)

- W ag :

-

Weight of aggregates in mixture (kg)

- W m :

-

Weight of aggregates and tire chips mixture (kg)

- W tc :

-

Weight of tire chips in mixture (kg)

- ϕ :

-

Angle of internal friction of mix proportion (°)

- ψ :

-

Dilatancy angle (°)

- σ :

-

Normal stress (kPa)

- ∂y :

-

Incremental vertical deformation (mm)

- ∂x :

-

Incremental shear deformation (mm)

- ε :

-

Shear strain (mm)

- σ ro :

-

Initial effective radial stress (kPa)

- \(\mu\) :

-

Poisson’s ratio (dimensionless)

- γ d :

-

Dry unit weight at 70% relative density (kN/m3)

- γ dmax :

-

Maximum dry unit weight (kN/m3)

- γ dmin :

-

Minimum dry unit weight (kN/m3)

- 100% AG + 0% TC:

-

100% Aggregates + 0% tire chips

- 75% AG + 25% TC:

-

75% Aggregates + 25% tire chips

- 50% AG + 50% TC:

-

50% Aggregates + 50% tire chips

- 25% AG + 75% TC:

-

25% Aggregates + 75% tire chips

- 0% AG + 100% TC:

-

0% Aggregates + 100% tire chips

References

Ahmed I (1993) Laboratory Study on Properties of Rubber-Soils. Publication FHWA/IN/JHRP-93/04. Joint Highway Research Project. Indiana Department of Transportation and Purdue University, (May), p 394

Ahn I, Cheng L (2017) Seismic analysis of semi-gravity RC cantilever retaining wall with TDA back fill. Front Struct Civ Eng 11(4):455–469. https://doi.org/10.1007/s11709-017-0392-z

Ambily AP, Gandhi SR (2007) Behavior of stone columns based on experimental and FEM analysis. J Geotech Geoenviron Eng 133(4):405–415. https://doi.org/10.1061/(ASCE)1090-0241(2007)133:4(405)

Anvari SM, Shooshpasha I, Kutanaei SS (2017) Effect of granulated rubber on shear strength of fine-grained sand. J Rock Mech Geotech Eng 9(5):936–944. https://doi.org/10.1016/j.jrmge.2017.03.008

Ayothiraman R, Soumya S (2015) Model tests on the use of tyre chips as aggregate in stone columns. Proc Inst Civ Eng Ground Improv 168(3):187–193. https://doi.org/10.1680/grim.13.00006

Bali Reddy S, Pradeep Kumar D, Murali Krishna A (2016) Evaluation of the optimum mixing ratio of a sand–tire chips mixture for geoengineering applications. J Mater Civ Eng 28(2):1–7. https://doi.org/10.1061/(asce)mt.1943-5533.0001335

Balunaini U, Sungmin Yoon MP (2009) Tire shred backfill in mechanically. (August): 169

Cecich V, Gonzales L, Hoisaeter A, Williams J, Reddy K (1996) Use of shredded tires as lightweight backfill material for retaining structures. Waste Manag Res 14(5):433–451. https://doi.org/10.1006/wmre.1996.0043

Choobbasti AJ, Vafaei A, Kutanaei SS (2015) Mechanical properties of sandy soil improved with cement and nanosilica. Open Eng 5(1):111–116. https://doi.org/10.1515/eng-2015-0011

D3080., A. 2012. “Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions.” Annual Book of ASTM Standards; ASTM:West Conshohocken, PA, USA, 1–9.

D6270, A (2017) Standard practice for use of scrap tires in civil engineering applications; Annual Book of ASTM Standards,ASTM: West Conshohocken, PA, USA, pp 1–21. https://doi.org/10.1016/S0169-7722(00)00084-X.

Das BM (2014) Advanced soil mechanics, 4th edn. CRC Press, Boca Raton

El Naggar H, Zahran K, Moussa A (2021) Effect of the particle size on the TDA shear strength and stiffness parameters in large-scale direct shear tests. Geotechnics 1(1):1–17. https://doi.org/10.3390/geotechnics1010001

Foose GJ, Benson CH, Bosscher PJ (1996) Sand reinforced with shredded waste tires. J Geotech Eng 122(9):760–767. https://doi.org/10.1061/(asce)0733-9410(1996)122:9(760)

Frikha W, Bouassida M, Canou J (2015) Parametric study of a clayey specimen reinforced by a Granular Column. Int J Geomech. https://doi.org/10.1061/(asce)gm.1943-5622.0000419

Gary, B., J. F. Craig, and P. J. Bosscher. 1996. “Sand Reinforced With Shredded Waste Tires By Gary.” 122(1994): 760–767.

Ghazavi M, Nazari Afshar J (2013) Bearing capacity of geosynthetic encased stone columns. Geotext Geomembr 38:26–36. https://doi.org/10.1016/j.geotexmem.2013.04.003

Gong H, Song W, Huang B, Shu X, Han B, Wu H, Zou J (2019) Direct shear properties of railway ballast mixed with tire derived aggregates: experimental and numerical investigations. Construc Build Mater 200:465–473. https://doi.org/10.1016/j.conbuildmat.2018.11.284

Greenwood DA (1970) Mechanical improvement of soils below ground surface

Hugher J, Withers NJ (1974) Reinforcing of soft cohesive soils with stone columns. Ground Eng 7(3)

Humphrey DN (1999) Civil engineering application of tire shreds.

IS 15284 (part 1) (2003) Design and construction for ground improvement-guidelines. Bureau of Indian Standards, New Delhi, vol 15284, pp 1–20

IS 2386- Part III (1963) Method of test for aggregate for concrete. Part III- specific gravity, density, voids, absorption and bulking. Bureau of Indian Standards, New Delhi, (Reaffirmed 2002)

Kaushik MK, Kumar A, Bansal A, Kaushik MK, Kumar A, Bansal A (2016) Performance assessment of tire chips—gravel mixes as leachate drainage layer material. Int J Geotech Eng. https://doi.org/10.1179/1939787914Y.0000000086

Li L, Yang J, Xiao H, Zhang L, Hu Z, Liu Y (2020) Behavior of tire-geogrid—reinforced retaining wall system under dynamic behavior of tire-geogrid—reinforced retaining wall system under dynamic vehicle load. Int J Geomech. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001566

Lo Presti D (2013) Recycled tyre rubber modified bitumens for road asphalt mixtures: a literature review. Constr Build Mater 49:863–881. https://doi.org/10.1016/j.conbuildmat.2013.09.007

Mahgoub A, El Naggar H (2019) Using TDA underneath shallow foundations: simplified design procedure. Int J Geotech Eng. https://doi.org/10.1080/19386362.2019.1690415

Malarvizhi SN (2007) Comparative study on the behavior of encased stone column and conventional stone column. Soils Found 47(5):873–885. https://doi.org/10.3208/SANDF.47.873

Mashiri MS, Vinod JS, Sheikh MN, Tsang HH (2015) Shear Strength and Dilatancy Behaviour of Sand-Tyre Chip Mixtures. Soils Found 55(3):517–528. https://doi.org/10.1016/j.sandf.2015.04.004

Mazumder T, Rolaniya AK, Ayothiraman R (2018) Experimental study on behaviour of encased stone column with tyre chips as aggregates. Geosynth Int 25(3):259–270. https://doi.org/10.1680/jgein.18.00006

Medina LE, Costa PA (2020) Use of tyre-derived aggregate as backfill material for wave barriers to mitigate railway-induced ground vibrations.

Meles D, Bayat A, Shafiee MH, Nassiri S, Gul M, Meles D, Bayat A, Shafiee MH, Nassiri S (2014) Investigation of tire derived aggregate as a fill material for highway embankment. Int J Geotech Eng. https://doi.org/10.1179/1939787913Y.0000000015

Moussa A, Asce SM, El Naggar H, Ph D, Eng P, Asce M (2021) Dynamic characterization of tire derived aggregates. J Mater Civil Eng 33(2000):1–11. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003583

Murugesan S, and Rajagopal K (2009) Investigations on the behaviour of geosynthetic encased stone columns. In: Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering. The Academia and Practice of Geotechnical Engineering, pp 2411–2414

Pradeep M, Choudhary AK, Choudhary AK, and Shukla SK (2021) An experimental study on improving the performance of silty soil by encased granular column using shredded tire chips. Lecture Notes in Civil Engineering, 136 LNCE: 509–521. Springer, Singapore. https://doi.org/10.1007/978-981-33-6444-8_46.

Reddy SB, Krishna AM (2019) Sand-scrap tyre chip mixtures for improving the dynamic behaviour of retaining walls. Int J Geotech Eng. https://doi.org/10.1080/19386362.2019.1652969

Sarokolayi LK, Beitollahi A, Abdollahzadeh G, Amreie STR, Kutanaei SS (2015) Modeling of ground motion rotational components for near-fault and far-fault earthquake according to soil type. Arab J Geosci 8(6):3785–3797. https://doi.org/10.1007/s12517-014-1409-8

Shariatmadari N, Zeinali SM, Mirzaeifar H, Keramati M (2018) Evaluating the effect of using shredded waste tire in the stone columns as an improvement technique. Constr Build Mater 176:700–709. https://doi.org/10.1016/j.conbuildmat.2018.05.090

Sparkes J, Eng P, El Naggar H, Ph D, Eng P, Asce M, Valsangkar A, Ph D, Eng P, Asce M (2019) Compressibility and shear strength properties of tire-derived aggregate mixed with lightweight aggregate. J Pipeline Syst Eng Pract 10(1):1–9. https://doi.org/10.1061/(ASCE)PS.1949-1204.0000354

Tweedie JJ, Humphrey DN, Sandford TC (1998) Tire shreds as lightweight retaining wall backfill: active conditions. J Geotech Geoenviron Eng 124(11):1061–1070. https://doi.org/10.1061/(ASCE)1090-0241(1998)124:11(1061)

Xiao M, Asce M, Bowen J, Graham M, Larralde J, Asce M (2012) Comparison of seismic responses of geosynthetically reinforced walls with tire-derived aggregates and granular backfills. (November): 1368–1377. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000514

Yoo C, Abbas Q (2020) Laboratory investigation of the behavior of a geosynthetic encased stone column in sand under cyclic loading. Geotext Geomembr 48(4):431–442. https://doi.org/10.1016/j.geotexmem.2020.02.002

Zahran K, El Naggar H (2020) Effect of sample size on TDA shear strength parameters in direct shear tests. Transp Res Rec 2674(9):1110–1119. https://doi.org/10.1177/0361198120934482

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pradeep, N.M., Kumar, S. & Shukla, S.K. Evaluation of Strength Behavior of Aggregates Mixed with Tire Chips in Granular Piles. Iran J Sci Technol Trans Civ Eng 48, 81–96 (2024). https://doi.org/10.1007/s40996-023-01155-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40996-023-01155-1