Abstract

In this work, a simulation-based thermal management model for metal parts produced through powder bed fusion (PBF) is proposed. PBF is an additive manufacturing technique that employs a high-energy beam to selectively melt and fuse powder particles layer by layer. The productivity and efficiency of PBF processes can be significantly increased using multi-laser systems with larger build volumes. However, this approach affects the parts thermal history, which can significantly impact their mechanical properties, microstructure, and defects. To address this issue, an algorithm has been developed to calculate adaptive cooling times reaching predefined temperatures at the end of each layer. The algorithm is used in a fast thermal process simulation using layer lumping. The simulation model is applied to a modern multi-laser machine, and the effectiveness of the adaptive cooling times and minimal layer times is evaluated. The results indicate that lower maximum temperatures can be achieved in less manufacturing time with adaptive cooling times than with minimal layer times. However, the significant increase in manufacturing time highlights the need for active cooling systems to utilize multi-laser machines fully. In summary, this paper presents a significant contribution to the field of additive manufacturing, emphasizing the importance of thermal management in ensuring the quality and performance of metal parts produced through PBF.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction and motivation

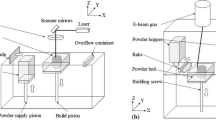

The global revenue for additively manufactured products and services is growing, as shown on the website of the 2023 Wohler’s report [1]. Additive manufacturing (AM) is described as the driving force in the manufacturing segment of the fourth industrial revolution [2]. The most widely used AM process for metals (M) is the PBF process [3], where a high-energy beam, e.g., a laser beam—(LB), selectively melts powder particles layer upon layer. Multi-laser systems with larger build volumes have been developed and commercialized to increase the productivity and efficiency of PBF-LB/M. For example, Kasprowicz et al. [4] compared the exposure times of a twin-laser and a quad-laser system. They found that the exposure time could be reduced by 50% for a twin laser and 67% for a quad-laser system compared to a single-laser system. The latest machines, such as the NXG XII 600 from SLM solutions, can use 12 lasers simultaneously, which offers enormous potential for further reducing manufacturing times [5].

However, reducing the manufacturing time of a part reduces the layer time (LT), which is the time interval between the start of one layer and the start of the next layer. A significant drop in LT can affect the part negatively. For instance, an increase in defects and grain size was reported for parts made of steel of type 316L when reducing the LT [6]. Shortening the LT from 116 to 18 s also significantly increases the maximum temperature per layer [7]. Even without changing the LT, differences in the material properties and microstructure of an Inconel 718 specimen can be determined in the build direction, with the finest microstructure and the highest yield stress being found at the very bottom of the specimen [8, 9].

The potential heat-up due to shorter LT and the change in microstructure with the build height indicates the necessity of thermal management systems in PBF-LB/M, such as closed-loop systems. Closed-loop monitoring and inspection systems need to be developed by creating a correlation of process parameters, measurable variables, and process output [10]. However, the development of closed-loop systems faces practical challenges, such as delays between sensors and control actions and noise in the observed data [11]. Even the methods of reinforced learning have significant drawbacks as they are difficult to train, and it is even more difficult to obtain the required amount of data [11]. Alternatively, thermal management can be achieved by developing white-box models that can simulate the PBF-LB/M process and create digital parallel systems/digital twins of the AM process [11].

Such process simulations, which can be used in a white-box model, vary in complexity and computational effort [12]. When it comes to the thermal management of parts, the simulation should be able to calculate the thermal history (heat flow) on a part scale within an acceptable time frame. Layer-by-layer process simulation can be used for rapid detection of heat accumulation, often in combination with the simultaneous activation of multiple layers, so-called layer lumping [13, 14].

In this work, a layer-by-layer process simulation is developed to calculate adaptive cooling times to achieve predefined temperatures at the end of each layer. Layer lumping is compared to a layer activation with a separate cooling calculation for the recoating procedure. The effectiveness of the adaptive LT and the minimum LT a is compared.

2 Methods

2.1 Simulation model

The simulation is used to solve the enthalpy-based transient nonlinear heat conduction problem

on the layer-dependent domain \({\Omega }_{l}\) and layer-dependent boundary conditions for convection and radiation. Convection on the top surface is considered to respect the gas flow by

\({T}_{\infty }\) is the ambient temperature of the system and \(\gamma\) the convection coefficient.

Radiation is implemented using the Stefan-Boltzmann law

\({\sigma }_{B}\) is the Stefan–Boltzman–Constant and \(\varepsilon\) the emissivity value.

An additional convection boundary condition is considered on the bottom of the build platform and the sides of the calculation domain to consider the heat transfer from the build chamber into the machine

\(\widetilde{\gamma }\) is the corresponding convection coefficient.

Equation (1) is solved by the finite element method. Therefore, the variational formulation is formulated based on the temperature \(T\) and the enthalpy \(H\) with \(H=H\left(T\right)\). The so-called “relaxed linearization” is used to calculate the update of the temperature field \(\Delta {T}^{l}\) and, subsequentially, the update of the enthalpy field \(\Delta {H}^{l}\) to solve the implicit time steps of the transient nonlinear heat conduction problem [15].

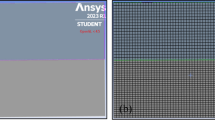

The flowchart of the simulation is shown in Fig. 1. The mesh is created based on the stereolithography tessellation language (STL) file with a set simulation layer height and element width. An h-refinement and hexahedron elements with eight nodes are used for the mesh. Powder and build platform elements have an adaptive size, while in the part elements, the size is constant. The diameter of powder and build platform elements increases with the distance to the part.

The part elements are stored in layer containers and will be activated when the summed layer height loaded from the common layer interface (CLI) file reaches the same height as the elements of the layer container. The combined process layers are referred to as batches. A batch activation combines the time step of exposure and cooling during the recoating in a single time step. The layer height and the number of process layers in a batch can be set independently. Therefore, a batch or layer activation can occur without new elements being activated. In that case, the last layer of elements is reactivated.

If the simulation is started with an interpass layer temperature (ILT), the first layer of a loaded batch of process layers from the CLI will be activated. For the activation, the summed hatching time

and energy density

is calculated from the CLI. \({d}^{h}\) is the distance of the hatch \(h\), \({v}^{h}\) the speed, \({P}^{h}\) the power, and \(\eta\) the efficiency. The energy density per time unit

is inserted in the elements of the currently active layer container.

The right-hand side, the updated stiffness and mass matrix and the surfaces of the convection and radiation boundary conditions are then recalculated.

The temperature field from solving the system is the average temperature directly after the hatching of the layer. A cooldown is calculated for the recoating time \({t}^{r}\) and an additional cooldown until the interpass layer temperature is reached. The additional cooling time \({t}^{c}\) is saved. During the next cycle, the remaining layers of the loaded batch are activated at once. The activation energy density \({E}_{VT}^{b}\) for that activation corresponds to the summed power and hatching time over the remaining layers and the summed recoating time \({t}^{r}\) and additional cooling time \({t}^{c}\)

The next iteration starts with a new batch of layers read from the CLI file, while the cooling time \({t}^{c}\) is set to zero.

2.2 Material and process

The material properties of Inconel 718 are suggested thermo-mechanical material properties from Agazhanov et al. [16], and the density is taken from [17]. The graphs for heat conductivity, density, and specific heat capacity are shown in Fig. 2.

The assumed scanning parameters are taken from [18] and are listed in Table 1. Parameters such as focus diameter are important for manufacturing but cannot be taken into account in a layer activation simulation.

This work focuses on managing the thermal balance during the additive manufacturing process. Modern machines with multiple lasers could reduce layer times to such an extent that critical heating of the parts would have to be accepted. SLM Solutions advertises that the NXG XII 600 is up to 20 times faster than a conventional single-laser system thanks to the use of twelve 1000 W lasers [5]. The possible energy input per time with such a system is tremendous. Therefore, the system is chosen to be modelled by the simulation. The build volume of the NXG XII 600 is 600 mm by 600 mm by 600 mm. The build platform thickness in the simulation is set to 30 mm.

All parameters used in the simulation can be seen in Table 2. It should be noted that these values are not calibrated for the given system. The convection coefficient of the gas flow is \(10\) W/(m2K), which is at the lower end of a forced convection [19] and might be higher in a system with an optimized gas flow as in the NXG XII [5]. The recoating time is added to the implicit time step in the batch activation or cooldown phase. The recoating time is also used to increase the LT of the current layer to respect the exposure time of other parts on the build platform.

The specimens simulated in this work are shown in Fig. 3. The first specimen is a cylinder with a radius of 10 mm and a height of 84 mm. The second one is a hollow double-cone structure. The total height is 80 mm, the maximum radius is 50 mm, and the minimum is 10 mm. The wall thickness measures 5 mm. The structure is designed to provoke a heat accumulation in the second inverted cone. The inserted heat of each layer has to pass the smaller cross-sectional area of the previous layer. Thus, the heat flux towards the build platform is reduced and cannot compensate for the heat input. However, the angle of all overhang regions is 45°, which can easily be manufactured by most machines. Therefore, the double cone specimen is interesting for investigating the thermal management in multi-laser machines.

3 Results

3.1 Investigation of the simulation method

Layer Lumping The batch activation of a single process layer (batch 1) and the layer activation with separate cooling are compared for the double-cone specimen (Fig. 3b). Figure 4 shows the maximum temperature over time for both methods. The moving average over 20 time steps from the layer + cooling graph is also presented (dotted orange). The temperature curves of the batch activation (blue curve) and the moving average align well. The combined energy activation leads to an average temperature during that time step. However, the average and batch temperature curves may show small deviations (shortly before 300 min) but agree well thereafter. That indicates the method is robust, and slight deviations do not lead to error propagation.

Another important observation is the stepwise nature of the temperature curves. The maximum temperature from the layer activation with cooling increases and reaches the plateau. The temperature increases again after a constant time interval until the next plateau is reached. The stepwise increase in temperature is an artifact of the independent element layer height and height of batch activation. The finite elements are 1 mm high, while the process layer height is only 30 µm. The energy density is calculated by dividing the summed energy \({E}^{l}\) by the volume of the finite element layer. The resulting maximum temperatures will be lower than expected because the inserted energy (Eqs. (6) and (7)) is distributed over a bigger volume. The element layer needs to heat-up to give more accurate temperature predictions. Correcting the energy density introduced in order to achieve more realistic peak temperatures within the first layer increases the energy input artificially and distorts the energy balance of the system.

Different numbers of lumped layers in the batch activation are compared in Fig. 5. The number behind batch refers to the number of process layers lumped together. The data for batch 1 (blue) are the same as in batch 1 in Fig. 4.

The curve batch 10 (green) agrees very well with batch 1. However, the curve for batch 30 (yellow) appears to be different. It intersects the curve of batch 1 several times but shows some visible differences, especially in the first 50 min of the simulation. While the curve for batch 1 shows the artifact from the independent element height and batch height, this is not the case for the curve for batch 30. Here, the element height of 1 mm and the batch height of \(30\) µm \(\cdot 30=0.9\) mm match better. Therefore, the simulation artifact is not visible. The temperature at the evaluated time steps is still in good agreement for all three batch sizes. Visible deviations are only from the linear interpolation between the evaluated time steps.

The temperature curves agree well even between different activation methods: directly calculating the cooling phase and heavy layer lumping.

3.2 Sensitivity of build platform thickness

The simulation of a double-cone (Fig. 3b) on the build platform of an SLM NXG XII 600 is investigated. The system can utilize 12 lasers. Therefore, a shortened LT is assumed by setting the recoating time \({t}^{r}=15 \text{s}\) in the simulation. The thickness of the build platform is varied and maximum temperatures over time are compared in Fig. 6.

At first glance, there is no noticeable difference between thicknesses of 10–90 mm. However, a significant difference becomes visible when comparing the first 200 min of the simulation. In the first time step (ca. 50 min), the maximum temperature drops from 178 to 135 °C when the thickness of the build platform is increased from 10 to 90 mm. In contrast, the temperature difference for the inverted cone structure is only 1 °C between the lowest and highest build platform thickness. Therefore, the possibility of cooling the system with a bigger heat capacity of the build platform by increasing the volume is limited. An effect is only noticeable in the first few layers. In particular, if the geometry has features that lead to heat accumulation, the effect of the increased build platform thickness is neglectable.

3.3 Sensitivity of layer time

The influence of the layer time is investigated, and the sensitivity is shown in Fig. 7 by comparing different maximum temperatures over time for different recoating times set from 5 to 180 s. 120 to 180 s are typical layer times for single-laser machines. Multiple lasers can drastically reduce the layer time by manufacturing multiple parts in parallel, as shown by the low recoating times of 5 s and 30 s.

The heat-up of the cylinder specimen is very sensitive to the set recoating time, which represents different LT. In a conventional single-laser machine, heat-up is shown with a recoating time of 180 s. The temperature reached in the last layer is only 155 °C. Despite the height of 84 mm, no problematic heat-up could be simulated for LTs of single-laser machines. In contrast, a critical heat-up of the specimen is simulated with reduced LTs. At a recoating time of 30 s, the calculated peak temperature in the last layer is above 415 °C. 5 s recoating time leads to an even more drastic temperature increase over 800 °C. The simulated heat-up exhibits the same tendencies as in the study by Mohr et al. for steel of type 316L [7].

However, it must be noted that the boundary conditions of the simulation are not calibrated. The calculated temperatures could be under- or overestimations. Still, the system's sensitivity regarding the layer time indicates the necessity to control the energy balance of multi-laser machines more carefully than in the past for single-laser machines.

3.4 Comparison of layer time models

Integration of interpass layer temperatures The ILT algorithm described in the method section leads to a strong oscillation of the calculated temperatures, as seen in Fig. 8. The ILT is set to 200 °C, and the calculated curve is represented in yellow. When the calculated temperature first exceeds the ILT, a single layer is activated, and the additional cooling time is calculated. The batch activation can overheat the system compared to a single-layer activation with ILT. If the ILT algorithm would trigger on layer 91 for a single-layer activation, it would trigger on layer 120 for a batch 30 activation. The cooling time is calculated from an already overheated system. The resulting cooling time in the subsequent batch activation will lead to a cooldown of the system below the ILT. This is followed by a batch activation that does not trigger the ILT algorithm. This causes the system to overheat again, which leads to an oscillation of over- and undercompensation.

Maximum temperatures obtained by temperature simulation of a PBF-LB/M part. No additional layer time in black (default), interpass layer temperature in yellow, and adaptive layer time in red obtained from the interpass layer temperature. The time graphs have the same color code and are represented by dashed-dotted lines

The LTs and layer heights are exported and used as input for a new simulation using only a batch activation. The additional layer times are taken from the exported list. The LTs of two calculation steps (overheated and undercooled batch) are averaged to compensate for the oscillation. The simulated temperature curve is shown in red. Still, the adaptive cooling times are too high, and the system is cooled down even under 100 °C.

The overcompensation can be reduced by smoothing the cooling time calculated in the simulation with the ILT algorithm. The smoothing is done by taking the average of the current cooling time from the single-layer activation and the cooling time during the last batch activation. Taking the average cooling times over two batch activations creates an inertia of adaptive layer times. The temperature curve from the simulation with the ILT algorithm and smoothing is shown in Fig. 9 in yellow. The oscillation is vastly reduced.

Maximum temperatures obtained by temperature simulation of a PBF-LB/M part. No additional layer time in black (default), interpass layer temperature with a smoothing correction (yellow), and adaptive layer time (red) from the smoothed interpass layer temperature. The time graphs have the same color code and are represented by dashed-dotted lines

The layer times are again exported, and the average of two batch activations is taken. The batch activation using the calculated adaptive layer times is shown in red. The average of the simulated maximum temperature over all layers with adaptive layer times is

The error is the standard deviation.

The smoothed ILT algorithm can calculate adaptive layer times controlling the temperature during the additive manufacturing process.

3.5 Comparison to a minimal layer time

Minimal layer times are another algorithm already used in additive manufacturing processes to control heat-up in parts. The algorithm should compensate for the heat-up when the exposed area in a layer is drastically reduced. The layer time has a very high impact on the heat-up of a system, as seen in Fig. 7. However, minimal layer time does not consider geometric features that lead to heat-up. Usually, the layers with the less exposed area are not necessarily the critical layers. The following layers have an increased volume. Moreover, the heat inserted with that volume needs to be conducted through the small cross-sectional area of the previous layers. The resulting heat-up is not compensated by a minimal layer time.

Figure 10 shows the maximum temperatures over time for the simulation of the double-cone specimen with the default build-up (black), a minimal layer time of 25 s (red), a minimal layer time of 60 s (yellow), an ILT of 400 °C (grey-solid) and an ILT of 200 °C (grey-dotted). The minimal layer time of 25 s mostly leads to a reduced temperature in the middle region of the double-cone, which corresponds to the local minimum in the middle of the curve. The temperatures increase drastically when the minimal layer time is no longer triggered. The temperature in the last layer is roughly the same as in the default curve.

Increasing the minimal layer time to 60 s will always add extra layer time to the process. Therefore, even the temperatures in the last layers are affected. However, the ILT of 400 °C has a lower temperature in the final layers and less manufacturing time. Therefore, the ILT algorithm controls the temperatures during the additive manufacturing process simulation more efficiently than a minimal layer time.

Reducing the ILT to 200 °C leads to a significant increase in the manufacturing time by 360% from ca. 21 to 75 h. The desired ILT might be lower to achieve constant thermal conditions in each layer. The calculated time increase using the ILT indicates that advanced cooling methods might be necessary to exploit the maximum potential of multi-laser machines.

4 Conclusion and outlook

In this work, an algorithm is proposed to calculate adaptive layer times using a macroscopic temperature simulation of the PBF-LB/M process. The simulation method is investigated by sensitivity analysis and comparing single-layer and batch activation. The temperature curves from the adaptive layer times were then compared to the default manufacturing process and minimal layer times.

Main findings are.

-

The ILT algorithm can control temperatures in parts with overhang regions and geometrical features that lead to heat accumulation. The ILT leads to better temperature management compared to minimal layer times.

-

Single-layer activation and separate calculation of the cooling during the recoating process are equivalent to the layer lumping of at least up to 30 layers.

-

The potential reduction of manufacturing time from multi-laser machines might be negated by the necessary waiting time to avoid heat accumulation. Therefore, advanced cooling methods are required to boost PBF-LB/M machines' productivity further.

In the future, the simulation results have to be validated by experiments. For that purpose, the simulation needs to be calibrated for the machine and for the process, and the simulations need to be redone with the ILT algorithm. The calculated adaptive layer times can then be used in a manufacturing process. Thermography should be used to validate the reduced heat and compare it to a manufacturing process with minimal layer time.

Data availability

The data supporting the findings of this study are available from the corresponding author upon request.

References

Wohlers Associates (2023) Wohlers Report 2023. [Online]. https://wohlersassociates.com/product/wr2023/. Accessed 14 Dec 2023

Mahamood RM, Jen TC, Akinlabi SA, Hassan S, Abdulrahman KO, Akinlabi ET (2021) Chapter 6—role of additive manufacturing in the era of Industry 4.0. In: Additive Manufacturing : Woodhead Publishing Reviews: Mechanical Engineering Series. Manjaiah M, Raghavendra K, Balashanmugam N, Davim JP (eds) Woodhead Publishing, 2021, pp. 107–126. [Online]. https://www.sciencedirect.com/science/article/pii/B9780128220566000035

T. T. Wohlers et al., Wohlers Report 2022: 3D Printing and Additive Manufacturing Global State of the Industry: Wohlers Associates, 2022. [Online]. Available: https://books.google.de/books?id=CyUGzwEACAAJ

Kasprowicz M, Pawlak A, Jurkowski P, Kurzynowski T (2023) Ways to increase the productivity of L-PBF processes. Arch Civil Mech Eng 23(3):211. https://doi.org/10.1007/s43452-023-00750-3

SLM Solutions, Introducing the NXG XII 600. [Online]. https://www.slm-pushing-the-limits.com. Accessed 13 Dec 2023

Mohr G, Altenburg SJ, Hilgenberg K (2020) Effects of inter layer time and build height on resulting properties of 316L stainless steel processed by laser powder bed fusion. Addit Manuf 32:101080. https://doi.org/10.1016/j.addma.2020.101080

Mohr G et al (2021) Process Induced Preheating in Laser Powder Bed Fusion Monitored by Thermography and Its Influence on the Microstructure of 316L Stainless Steel Parts. Metals. https://doi.org/10.3390/met11071063

Wang X, Keya T, Chou K (2016) Build height effect on the Inconel 718 parts fabricated by selective laser melting. Proc Manuf 5:1006–1017. https://doi.org/10.1016/j.promfg.2016.08.089

Zhang B et al (2020) Mechanical properties and microstructure evolution of selective laser melting Inconel 718 along building direction and sectional dimension. Mater Sci Eng, A 794:139941. https://doi.org/10.1016/j.msea.2020.139941

Chua ZY, Ahn IH, Moon SK (2017) Process monitoring and inspection systems in metal additive manufacturing: status and applications. Int J Precis Eng Manuf-Green Technol 4:235–245

Fang Q et al (2022) Process monitoring, diagnosis and control of additive manufacturing. IEEE Trans Autom Sci Eng 21:1041–1067

Lindgren L-E, Lundbäck A (2018) Approaches in computational welding mechanics applied to additive manufacturing: review and outlook. Comptes Rendus Mécanique 346(11):1033–1042. https://doi.org/10.1016/j.crme.2018.08.004

Ranjan R, Ayas C, Langelaar M, van Keulen F (2020) Fast detection of heat accumulation in powder bed fusion using computationally efficient thermal models. Materials. https://doi.org/10.3390/ma13204576

Illies O, Li G, Jürgens J-P, Ploshikhin V, Herzog D, Emmelmann C (2018) Numerical modelling and experimental validation of thermal history of titanium alloys in laser beam melting. Proc CIRP 74:92–96. https://doi.org/10.1016/j.procir.2018.08.046

Nedjar B (2002) An enthalpy-based finite element method for nonlinear heat problems involving phase change. Comput Struct 80(1):9–21. https://doi.org/10.1016/S0045-7949(01)00165-1

Agazhanov AS, Samoshkin DA, Kozlovskii YM (2019) Thermophysical properties of Inconel 718 alloy. J Phys Conf Ser 1382(1):12175. https://doi.org/10.1088/1742-6596/1382/1/012175

Hernando Arriandiaga I, Renderos M, Cortina M, Ruiz J, Arrizubieta J, Lamikiz A (2018) Inconel 718 laser welding simulation tool based on a moving heat source and phase change. Procedia CIRP 74:674–678. https://doi.org/10.1016/j.procir.2018.08.045

Huo Y, Hong C, Li H, Liu P (2020) Influence of different Processing Parameter on distortion and Residual Stress of Inconel 718 Alloys Fabricated by Selective Laser Melting (SLM). Mater Res 23. https://doi.org/10.1590/1980-5373-MR-2020-0176

L. L. Engineers Edge LL (2023) Convective Heat Transfer Coefficients Table Chart. [Online]. Available: https://www.engineersedge.com/heat_transfer/convective_heat_transfer_coefficients__13378.htm. Accessed 13 Dec 2023

Acknowledgements

The research project IFG 22690 N “Reduktion des in-situ Verzugs under Konturüberhöhung durch material- und geometriespezifische Parameteranpassung im PBF-LB/M-Prozess” is supported by the Federal Ministry of Economic Affairs and Climate Action the German Federation of Industrial Research Associations (AiF) as part of the program for promoting industrial cooperative research (IGF) on the basis of a decision by the German Bundestag. The project is carried out at the research institutes ISEMP and HAM.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Behrens, C., Ostermann, N., Sehrt, J.T. et al. Temperature control by simulated adaptive layer times in powder bed fusion processes. Prog Addit Manuf 9, 705–713 (2024). https://doi.org/10.1007/s40964-024-00669-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-024-00669-y