Abstract

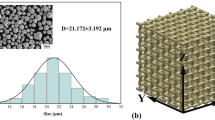

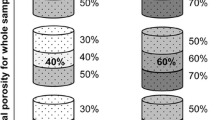

Open-cell titanium lattice structures produced by selective laser melting (SLM) are attractive for creation of patient-specific implants with high level of bone ingrowth. In this work, irregular SLM lattice structures made of titanium (cp-Ti) with an average beam thickness of 300 μm and an average porous size of 600 μm were investigated. Optimal processing conditions of SLM for obtaining irregular open-cell cp-Ti lattice structures with mechanical and porous geometry close to human cancellous bone were developed. It was observed that the main parameter of SLM affected on beam thickness is volumetric energy density. Influence of orientation of cubic samples on the construction platform (on the plane, on the edge or on the corner) on properties of lattice structures was investigated. The corner orientation was found to be optimal. It was shown that chemical etching is effective post-treatment method for obtaining required beam thickness and removing the attached powder particles. Optimal chemical etching conditions are the following: etching solution contains 30 mL HNO3 + 45 mL HF + 120 mL water, etching time is 10 s. The elastic modulus and the elastic limit of etched lattice samples are 1.4–1.9 GPa and 44–51 MPa, respectively, which correlates with characteristics of human cancellous bone. Compression of samples during mechanical tests occurred without beams destruction. Corrosion characteristics of obtained etched and non-etched lattice structures in Hank's Balanced Salt Solution (HBSS) have been improved compared with cp-Ti bulk samples. The biological and medical tests of the obtained samples will be carrying out to determine biocompatibility, influence on the growth of bone tissue, permeability, etc.

Similar content being viewed by others

References

Alabort E, Barba D, Reed RC (2019) Design of metallic bone by additive manufacturing. Scripta Mater 164:110–114

Sumner DR (2015) Long-term implant fixation and stress-shielding in total hip replacement //. J Biomech 48(5):797–800

Ryan G, Pandit A, Panagiotis AD (2006) Fabrication methods of porous metals for use in orthopaedic applications //. Biomaterials 27(13):2651–2670

Maconachie T, Leary M, Lozanovski B, Zhang X, Qian Ma, Faruque O, Brandt M (2019) SLM lattice structures: properties, performance, applications and challenges. Mater Des 183:108137

Zadpoor AA (2019) Mechanical performance of additively manufactured meta-biomaterials //. Acta Biomater 85:41–59

Mullen L, Stamp RC, Brooks WK, Jones E, Sutcliffe CJ (2009) Selective Laser Melting: a regular unit cell approach for the manufacture of porous, titanium, bone in-growth constructs, suitable for orthopedic applications. J Biomed Mater Res B Appl Biomater 89(2):325–334. https://doi.org/10.1002/jbm.b.31219

Van Bael S, Kerckhofs G, Moesen M, Pyka G, Schrooten J, Kruth JP (2011) Micro-CT-based improvement of geometrical and mechanical controllability of selective laser melted Ti6Al4V porous structures. Mater Sci Eng, A 528(24):7423–7431

Pyka G, Kerckhofs G, Papantoniou I, Speirs M, Schrooten J, Wevers M (2013) Surface roughness and morphology customization of additive manufactured open porous Ti6Al4V structures. Materials 6:4737–4757

McMillan M, Leary M, Brandt M (2017) Computationally efficient finite difference method for metal additive manufacturing: a reduced-order DFAM tool applied to SLM. Mater Des 132:226–243

Mazur M, Leary M, McMillan M, Sun S, Shidid D, Brandt M (2019) 5 - Mechanical properties of Ti6Al4V and AlSi12Mg lattice structures manufactured by Selective Laser Melting (SLM). In: Brandt M (ed) Woodhead Publishing Series in Electronic and Optical Materials, Laser Additive Manufacturing. Woodhead Publishing, pp 119–161

Amin YS, Ahmadi SM, Wauthle R, Pouran B, Schrooten J, Weinans H, Zadpoor AA (2015) Relationship between unit cell type and porosity and the fatigue behavior of selective laser melted meta-biomaterials. J Mech Behav Biomed Mater 43:91–100

Ahmadi SM, Campoli G, Amin YS, Sajadi B, Wauthle R, Schrooten J, Weinans H, Zadpoor AA (2014) Mechanical behavior of regular open-cell porous biomaterials made of diamond lattice unit cells. J Mech Behav Biomed Mater 34:106–115

Ataee A, Li Y, Brandt M, Wen C (2018) Ultrahigh-strength titanium gyroid scaffolds manufactured by selective laser melting (SLM) for bone implant applications. Acta Mater 158:354–368

Zadpoor AA (2015) Bone tissue regeneration: the role of scaffold geometry. Biomater Sci 3(2):231–245

Tancogne-Dejean T, Diamantopoulou M, Gorji MB, Bonatti C, Mohr D (2018) 3D Plate-lattices: an emerging class of low-density metamaterial exhibiting optimal isotropic stiffness. Adv Mater 30(45):1803334

GOST 26492–85. Titanium and titanium alloys rolled bars. Specifications. Approved: USSR State Committee for Standards 3/25/1985, p 32

Acknowledgements

The authors wish to acknowledge the financial support of the Ministry of Education and Science of the Russian Federation in the framework of Increase Competitiveness Program of NUST «MISIS», contract № K2-2019-012, К2A-2019-034.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bautin, V.A., Bardin, I.V., Yudin, A.V. et al. Development of selective laser melting irregular open-cell titanium lattice structure to mimic the human cancellous bone. Prog Addit Manuf 7, 1287–1295 (2022). https://doi.org/10.1007/s40964-022-00303-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-022-00303-9