Abstract

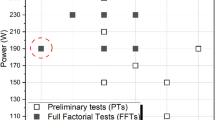

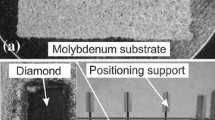

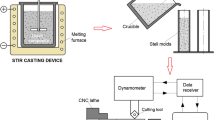

This study aims to assess the influence of the Mn to S ratios on the machinability and tensile behavior of GG20-gray cast iron brake drums. The effect of various Mn and S contents on microstructural characteristics such as type, size, and aspect ratio of graphite particles, interlamellar spacing of pearlite, and the distribution factor, size, and volume fraction of MnS were investigated. The microstructural results showed that a decrease in the Mn/S ratio to 5.1 and a decrease in the Ti/S ratio to under 0.11 promote the lengthy A-type graphite formation. Meanwhile, with the %Mn × %S value of about 0.08, the best uniform distribution of MnS inclusions has been obtained (about 55% of MnS inclusions are near A-type graphite flakes in the P1 specimen with %Mn × %S about 0.08 and Mn/S value of 5.1). Good machining in terms of less wear of the cutting tool and easier fragmentation of the chip in the sample with Mn/S value of 1.5 (0.65% Mn and 0.128% Sulfur) due to having more MnS inclusions, as well as a larger grain size graphite and its high aspect ratio have been obtained. The minimum tensile strength has been calculated to be 193MPa in the specimen with Mn/S value of 3.5 (0.55% manganese and 0.156% sulfur) due to the effects of higher sulfur content on changing the morphology of graphite to a higher aspect ratio. Meanwhile, at the same content of Mn (almost 0.55 wt%), further reduction of sulfur results in promoting E and D types of graphite in the microstructure.

Graphic Abstract

Similar content being viewed by others

Abbreviations

- ISO M:

-

Stainless steel

- HC:

-

Coated cemented carbide

- CVD:

-

Chemical vapor deposition

- WC:

-

Tungsten carbide

- MF:

-

M: medium turning, F: finishing

- CN1204:

-

CN: shape of insert, 1204: size of insert

References

A. Yella, A. Chaudhary, S. Sundar, Development and comparative evaluation of various fault detection algorithms for a drum brake using artificial neural networks and a physics-based model. Eng. Appl. Artif. Intell. 124, 106565 (2023)

O.F. Abraham, D.T. Oloruntoba, A.D. Damilola, K.I. Fesomade, M.C. Ugoh, A.O. Damilola, Electrochemical and weight loss studies of the corrosion profiles of gray cast iron under the influence of water hyacinth plant extract in 0.5 M NaOH. Chem. Data Collect. 42, 100951 (2022)

D. Yu, T. Zhou, H. Zhou, H. Bo, H. Lu, Non-single bionic coupling model for thermal fatigue and wear resistance of gray cast iron drum brake. Opt. Laser Technol. 111, 781–788 (2019)

X.B. Huang, Y.G. Ye, X.Q. Shen, X. Chang, The mechanical properties of gray cast iron and metallographic structure effect on the chip shape. Adv. Mater. Res. 339, 200–203 (2011)

A.A. Pereira, L. Boehs, W.L. Guesser, The influence of sulfur on the machinability of gray cast iron FC25. J. Mater. Process. Technol. 179(1–3), 165–171 (2006)

S.E. Bilim, M. Rafighi, S. Dengiz, Machinability of GG25 gray cast iron using carbide inserts. Mater. Today Proc. 10(136), 1–9 (2023)

C. Burke, D. Moore, J. Parolini, K. Rundman, D. Waarala, Machinability of gray cast iron: a drilling study. AFS Trans. 106, 567–575 (1999)

R. Voigt, R. Marwanga, P. Cohen, Machinability of gray iron—mechanics of chip formation. Int. J. Cast Met. Res. 11(6), 567–572 (1999)

J. Brion, B. Sander, G. Pierson, J. Lepage, J. Von Stebut, Mechanisms of built-up layer formation on turning tools: influence of tool and workpiece. Wear 154(2), 225–239 (1992)

X. Fang, D. Zhang, An investigation of adhering layer formation during tool wear progression in turning of free-cutting stainless steel. Wear 197(1–2), 169–178 (1996)

G. Poulachon, M. Dessoly, J. Lebrun, C. Le Calvez, V. Prunet, I. Jawahir, Sulphide inclusion effects on tool-wear in high productivity milling of tool steels. Wear 253(3–4), 339–356 (2002)

A. Sahm, E. Abele, H. Schulz, Machining of compacted graphite iron (CGI). Materialwissenschaft und Werkstofftechnik: Entwicklung, Fertigung, Prüfung, Eigenschaften und Anwendungen technischer Werkstoffe 33(9), 501–506 (2002)

E.Y. Salawu, A.O. Elvis, O.O. Ajayi, S.O. Ongbali, S.A. Afolalu, Particle size distribution analysis of carburized HT250 gray cast iron using ImageJ. Mater. Today Proc. 1–13 (2023). https://doi.org/10.1016/j.matpr.2023.08.321

A. Diószegi, V. Fourlakidis, I.L. Svensson, Fracture mechanics of gray cast iron, in Materials Science Forum, Trans Tech Publ, 2010, pp. 517–522

E. John, J. Boxall, R. Collins, E. Bowman, L. Susmel, Multiaxial fatigue of water pipe grey cast iron. Int. J. Fatigue 178, 108002 (2024)

S. Tooptong, K.-H. Park, S.-W. Lee, P.Y. Kwon, A preliminary machinability study of flake and compacted graphite irons with multilayer coated and uncoated carbide inserts. Procedia Manuf. 5, 644–657 (2016)

Q. Li, Y. Zhang, Y. Zhang, H. Liu, H. Ren, Y. Zhong, X. Huang, W. Huang, Influence of Sn and Nb additions on the microstructure and wear characteristics of a gray cast iron. Appl. Phys. A 126, 1–8 (2020)

X. Teng, J. Pang, F. Liu, C. Zou, C. Gao, S. Li, Z. Zhang, Fatigue strength optimization of gray cast iron processed by different austempering temperatures. Int. J. Fatigue 175, 107831 (2023)

W. Xu, M. Ferry, Y. Wang, Influence of alloying elements on as-cast microstructure and strength of gray iron. Mater. Sci. Eng. A 390(1–2), 326–333 (2005)

Z. Taşliçukur, G.S. Altuğ, Ş. Polat, Ş.H. Atapek, E. Türedi, Characterization of microstructure and fracture behavior of GG20 and GG25 cast iron materials used in valves, in Proceedings of the 21st International Conference on Metallurgy and Materials, Brno, Czech Republic, 2012, pp. 23-–25.

P. Tonolini, L. Montesano, A. Pola, E. Landriani, M. Gelfi, The effect of laser-cladding on the wear behavior of gray cast iron brake disc. Procedia Struct. Integr. 33, 1152–1161 (2021)

V. Fourlakidis, J.C. Hernando, D. Holmgren, A. Diószegi, Relationship between thermal conductivity and tensile strength in cast irons. Inter Metalcast 17, 2862–2867 (2023). https://doi.org/10.1007/s40962-023-00970-6

Y. Lin, J. Ma, D. Lai, J. Zhang, W. Li, S. Li, S. He, Multi-response optimization of process parameters in nitrogen-containing gray cast iron milling process based on application of non-dominated ranking genetic algorithm. Heliyon 8(11), e11629 (2022)

J. Chander, T.S. Bedi, A.S. Rana, Sustainable machinability of cast iron material by optimizing Mn and S configurations. Mater. Today Proc. 1–7 (2023). https://doi.org/10.1016/j.matpr.2023.02.084

J. Agunsoye, E. Ochulor, S.I. Talabi, S. Olatunji, Effect of manganese additions and wear parameter on the tribological behaviour of NFGrey (8) cast iron. Tribol. Ind. 34(4), 239 (2012)

R. Srivastava, B. Singh, K.K. Saxena, Influence of S and Mn on mechanical properties and microstructure of grey cast iron: an overview. Mater. Today Proc. 26, 2770–2775 (2020)

R. Gundlach, M. Meyer, L. Winardi, Influence of Mn and S on the properties of cast iron part III—testing and analysis. Inter Metalcast 9, 69–82 (2015). https://doi.org/10.1007/BF03355617

E. Moumeni, D.M. Stefanescu, N.S. Tiedje, P. Larrañaga, J.H. Hattel, Investigation on the effect of sulfur and titanium on the microstructure of lamellar graphite iron. Metall. Mater. Trans. A 44, 5134–5146 (2013)

H. Ghanbari, M. Ketabchi, E. Damavandi, Effect of chemical composition and microstructure on the crack growth and machinability of GG20 gray cast iron for brake drum application. Mach. Sci. Technol. 26(6), 977–1002 (2022)

S. Nourouzi, E. Damavandi, S.M. Rabiee, Microstructural and mechanical properties of Al-Al2O3 composites focus on experimental techniques. Int. J. Microstruct. Mater. Prop. 11(5), 383–398 (2016)

H.M. Muhmond, H. Fredriksson, Relationship between inoculants and the morphologies of MnS and graphite in gray cast iron. Metall. Mater. Trans. B 44, 283–298 (2013)

X. Zhang, L. Zhang, W. Yang, Y. Dong, Characterization of MnS particles in heavy rail steels using different methods. Steel Res. Int. 88(1), 1600080 (2017)

K.V. Makarenko, A.A. Nikitin, A.S. Parenko, Fractographic Analysis of Fractures of Graphitized Cast Iron using Optical Microscopy, vol. 2763, 2020, pp. 315–318

S. Brauer, W. Whittington, K. Johnson, B. Li, H. Rhee, P. Allison, C. Crane, M. Horstemeyer, Strain rate and stress-state dependence of gray cast iron. J. Eng. Mater. Technol. 139(2), 021013 (2017)

G.W. Powell, The fractography of casting alloys. Mater Charact 33(3), 275–293 (1994)

E. Damavandi, A. Kolahdooz, Y. Shokoohi, S.A.L. Rostami, S.M. Tabatabaei, Multi-objective parameter optimisation to improve machining performance on deep drilling process. Int. J. Mach. Mach. Mater. 23(5–6), 500–513 (2021)

A.P. Rifai, H. Aoyama, N.H. Tho, S.Z.M. Dawal, N.A. Masruroh, Evaluation of turned and milled surfaces roughness using convolutional neural network. Measurement 161, 107860 (2020)

M.N. Derani, M.M. Ratnam, The use of tool flank wear and average roughness in assessing effectiveness of vegetable oils as cutting fluids during turning—a critical review. Int. J. Adv. Manuf. Technol. 112, 1841–1871 (2021)

U. Şeker, I. Ciftci, H. Hasirci, The effect of alloying elements on surface roughness and cutting forces during machining of ductile iron. Mater. Des. 24(1), 47–51 (2003)

N. Camuşcu, Effect of cutting speed on the performance of Al2O3 based ceramic tools in turning nodular cast iron. Mater. Des. 27(10), 997–1006 (2006)

J.A.G. de Sousa, W.F. Sales, A.R. Machado, A review on the machining of cast irons. Int. J. Adv. Manuf. Technol. 94, 4073–4092 (2018)

J. Ren, F. Ren, F. Li, L. Cui, Y. Xiong, A.A. Volinsky, Effects of microstructure, mechanical and physical properties on machinability of graphite cast irons. Metals 10(2), 285 (2020)

S. Dawson, Process control for the production of compacted graphite iron, in 106th AFS Casting Congress, Kansas City, 2002, pp. 4–7

W.L. Guesser, F.S. Pereira, L. Boehs, Surface changes during turning of grey cast iron. Int. J. Mach. Mach. Mater. 18(3), 313–324 (2016)

T. Sarkar, G. Sutradhar, Investigation on mechanical properties and wear behavior of Cu-alloyed austempered gray cast iron (AGI). Sādhanā 43, 1–11 (2018)

A. Fay, Influence of inoculation on cast iron machinability: Case studies. China Found. 17(2), 150–157 (2020)

B. Li, An experimental investigation of dry cutting performance for machining gray cast iron with carbide coating tool. Int. J. Adv. Manuf. Technol. 71, 1093–1098 (2014)

B.C.M. Reis, A.J. dos Santos, N.F.S. Pereira, D.J. do Carmo, G.L. de Faria, M.A. Câmara, P.E. de Faria, A.M. Abrao, Effect of Nb addition on the machinability of a pearlitic gray cast iron. J. Mater. Eng. Perform. 31(7), 5983–5999 (2022)

Acknowledgements

The authors are very grateful for the encouragement and financial support of Fooladin Zob Amol company (FZA. Co). Meanwhile, this study was financially supported by the programs of Amirkabir University of Technology (through Grant program No. AUT/185739/01).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ghanbari, H., Ketabchi, M. & Damavandi, E. GG20-GCI Brake Drum: The Effect of Mn/S on Machinability and Tensile Behavior. Inter Metalcast (2024). https://doi.org/10.1007/s40962-024-01355-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40962-024-01355-z