Abstract

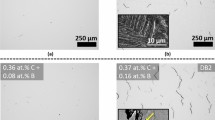

Bimetal materials are composed of dissimilar metals, which are increasingly used to fabricate components that withstand harsh thermal and mechanical environments. In this work, aluminum-brass bimetallic hollow cylinders were produced using the vertical centrifugal casting process, and their interface was studied. Aluminum melt, with two different liquid-to-solid volume ratios of 1.5 and 2.5, was cast into brass hollow cylinders preheated to 100–400°C and rotated at 800, 1600, and 2000 rotation-per-minute. The sector-shaped samples were then studied using X-ray diffraction analysis, optical microscopy, scanning electron microscopy, and energy-dispersive X-ray spectroscopy. It was found that the interface consisted of three discernible layers. These included the chill zone (Al2Cu5Zn4 + Al3Cu3Zn) near the brass side, platelet precipitate zone (Al2Cu precipitates scattered in α-Al solid solution matrix), and finally anomalous (or divorced) eutectic grains (α-Al/Al3Cu) near the aluminum side. Mechanical tests were carried out, in particular Brinell, Vickers and compression tests. The findings revealed that the adhesion of the interface was reduced by increasing the thickness of the interface. Fractography of fractured surfaces illustrated the presence of flat faces (Al2Cu precipitates) locked together and deep depressions associated with cup-shaped dimples (α-Al/Al3Cu eutectic).

Similar content being viewed by others

Data Availability

The authors declare that there are no restrictions on the availability of data and material.

References

M. Akbari, R.A. Behnagh, Dissimilar friction-stir lap joining of 5083 aluminum alloy to CuZn34 brass. Metall. Mater. Trans. B 43, 1177–1186 (2012). https://doi.org/10.1007/s11663-012-9682-y

M.A. Ali, M. Jahanzaib, A. Wasim et al., Evaluating the effects of as-casted and aged overcasting of Al-Al joints. Int. J. Adv. Manuf. Technol. 96, 1377–1392 (2018). https://doi.org/10.1007/s00170-018-1682-x

G. Li, W. Jiang, F. Guan et al., Microstructure, mechanical properties and corrosion resistance of A356 aluminum/AZ91D magnesium bimetal prepared by a compound casting combined with a novel Ni-Cu composite interlayer. J. Mater. Process. Technol. 288, 116874 (2021). https://doi.org/10.1016/j.jmatprotec.2020.116874

G. Zare, M. Divandari, H. Arabi, Investigation on interface of Al/Cu couples in compound casting. Mater. Sci. Technol. 29, 190–196 (2013). https://doi.org/10.1179/1743284712Y.0000000096

H.R. Zareie Rajani, A. Esmaeili, M. Mohammadi et al., The role of metal-matrix composite development during friction stir welding of aluminum to brass in weld characteristics. J. Mater. Eng. Perform. 21(11), 2429–2437 (2012). https://doi.org/10.1007/s11665-012-0178-3

S. Palraj, G. Subramanian, S. Palanichamy, Galvanic interactions of aluminium 3004 and brass in tropical marine atmosphere. J. Marine Sci. Appl. 13, 455–461 (2014). https://doi.org/10.1007/s11804-014-1274-6

J. Xu, X. Gao, Z. Jiang et al., Microstructure and hot deformation behaviour of high-carbon steel/low-carbon steel bimetal prepared by centrifugal composite casting. Int. J. Adv. Manuf. Technol. 86, 817–827 (2016). https://doi.org/10.1007/s00170-015-8232-6

A. Esmaeili, M.K. Besharati Givi, H.R. Zareie Rajani, A metallurgical and mechanical study on dissimilar Friction stir welding of aluminum 1050 to brass (CuZn30). Mater. Sci. Eng. A 528, 7093–7102 (2011). https://doi.org/10.1016/j.msea.2011.06.004

A.A. Ershov, T.A. Sycheva, P.F. Zasoukha, Reactional diffusion in three-layer aluminum-brass bimetal. Metal Sci. Heat Treat. (1997). https://doi.org/10.1007/BF00703007

Y. Fouad, Characterization of High strenght stainless Steel/Al/Brass composite tri-layered clad. Trans. Indian Inst. Met. (2014). https://doi.org/10.1007/s12666-014-0419-2

R.S. Timsit, Intermetallics growth at Alα-brass interfaces. Acta Metall. 33, 97–104 (1985). https://doi.org/10.1016/0001-6160(85)90223-8

R.S.Timsit, Electrical instabilities in stationary contacts: Al/Al and Al/Brass junctions. In: Electrical Contacts; Proceedings of the Thirty Fourth Meeting of the IEEE Holm Conference, (1988). https://doi.org/10.1109/HOLM.1988.16111

R.S. Timisit, Interdiffusion at Bimetallic Electrical Interfaces. IEEE Trans. Compon. Hybrids Manuf. Technol. (1986). https://doi.org/10.1109/TCHMT.1986.1136613

R.S. Timisit, Electrical instabilities in stationary contacts: Al-Plated-brass junctions. IEEE Trans. Compon. Hybrids Manuf. Technol. (1988). https://doi.org/10.1109/33.2961

A. Esmaeili, H.R. Zareie Rajani, M. Sharbati et al., The role of rotation speed on intermetallic compounds formation and mechanical behavior of friction stir welded brass/aluminum 1050 couple. Intermetallics 19, 1711–1719 (2011). https://doi.org/10.1016/j.intermet.2011.07.006

M. Shojaeefard, M. Akbari, M. Tahani et al., Sensitivity analysis of the artificial neural network outputs in friction stir lap joining of aluminum to brass. Adv. Mater. Sci. Eng. (2013). https://doi.org/10.1155/2013/574914

G.D. Janaki Ram, C. Robinson, Y. Yang et al., Use of ultrasonic consolidation for fabrication of multi-material structures. Rapid Prototyp. J. (2007). https://doi.org/10.1108/13552540710776179

X. Qi, G. Song, Interfacial structure of the joints between magnesium alloy and mild steel with nickel as interlayer by hybrid laser-TIG welding. Mater. Des. 31, 605–609 (2010). https://doi.org/10.1016/j.matdes.2009.06.043

L. Peng, L. Yajiang, W. Juan et al., Vacuum brazing technology and microstructure near the interface of Al/18-8 stainless steel. Mater. Res. Bull. 38, 1493–1499 (2003). https://doi.org/10.1016/S0025-5408(03)00176-4

J.G.Frydendahl, Multilayered Composites of AA3103 and Cu produced by acaumulative roll bonding (ARB). (2012)

M. Akbarifar, M. Divandari, On the interfacial characteristics of compound cast Al/brass bimetals. Inter Metalcast 11, 506–512 (2017). https://doi.org/10.1007/s40962-016-0101-z

Z. Zhang, W. Jiang, G. Li et al., Improved interface bonding of Al/Mg bimetal fabricated by compound casting with Nd addition. Mater. Sci. Eng. A 826, 141998 (2021). https://doi.org/10.1016/j.msea.2021.141998

M. Akbarifar, M. Divandari, Study of Al/cast iron interface and graphite behavior. J. Min. Metall. Sect. B 53, 53–59 (2017). https://doi.org/10.2298/JMMB160108027A

M. Sarvari, S. Ghaemi Khiavi, M. Divandari et al., Dissimilar joining of Al/Mg light metals by centrifugal compound casting process. Inter Metalcast (2022). https://doi.org/10.1007/s40962-022-00832-7

E. Hajjari, M. Divandari, S.H. Razavi et al., Intermetallic compounds and antiphase domains in Al/Mg compound casting. Intermetallics 23, 182–186 (2012). https://doi.org/10.1016/j.intermet.2011.12.001

E. Hajjari, M. Divandari, S. Razavi et al., Dissimilar joining of Al/Mg light metals by compound casting process. J. Mater. Sci. 46, 6491–6499 (2011). https://doi.org/10.1007/s10853-011-5595-4

G.X. Wang, E.F. Matthys, Experimental determination of the interfacial heat transfer during cooling and solidification of molten metal droplets impacting on a metallic substrate: effect of roghness and superheat. Int. J. Heat Mass Transf. 45, 4967–4981 (2002). https://doi.org/10.1016/S0017-9310(02)00199-0

E. Hajjari, M. Divandari, S.H. Razavi et al., Estimation of the transient interfacial heat flux between substrate/melt at the initiation of magnesium solidification on aluminum substrates using the lumped capcitance method. Appl. Surf. Sci. 257, 5077–5082 (2011). https://doi.org/10.1016/j.apsusc.2011.01.024

L.A. Jacobson, J. McKittric, Rapid solidification processing. Mater. Sci. Eng. R11, 355–408 (1994). https://doi.org/10.1016/0927-796X(94)90022-1

S. Emami, M. Divandari, H. Arabi et al., Effect of melt-to-solid insert volume ratio on Mg/Al dissimilar metals bonding. J. Mater. Eng. Perform. 22, 123–130 (2013). https://doi.org/10.1007/s11665-012-0243-y

E. Hajjari, M. Divandari, S. Razavi et al., Microstructure characteristics and mechanical properties of Al 413/Mg joint in compound casting process. Metall. Mater. Trans. A 43, 4667–4677 (2012). https://doi.org/10.1007/s11661-012-1296-0

X. Daming, J. Limin, F. Hengzhi, Effects of centrifugal and coriolis forces on the mold-filling behavior of titanium melts in vertically rotating molds. Res. Develop. (2008). https://doi.org/10.1016/j.actamat.2011.06.036

M. Gholami, M. Divandari, Interfacial phases and defects characteristics of Al/Cu-Zn bimetal produced via centrifugal casting process. Iran. J. Mater. Sci. Eng. 15, 52–61 (2018)

N. Zhang, C. Lei, T. Liu et al., Parameter optimization of Al-5Mg-3Zn-1Cu basin-shaped centrifugal casting: simulation and experimental verification. Int. J. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00822-9

J. Pan, M. Yoshida, G. Sasaki et al., Metal pipe joining with aluminum alloy by ultrasonic insert casting. Mater. Manuf. Proces. 15, 867–881 (2000). https://doi.org/10.1080/10426910008913027

V. Raghavan, Al-Cu-Zn (aluminum-copper-zinc). J. Phase Equilib. Diffus. 28, 183–188 (2007). https://doi.org/10.1007/s11669-007-9025-x

S.I. Fujikawa, Interdiffusion between aluminium and α-brass. Diffus. Mater. 95–98, 611–616 (1993). https://doi.org/10.4028/www.scientific.net/DDF.95-98.611

M. Gholami, M. Divandari, Effect of rotational speeds and heat content on the production of Al-Brass bimetal composite. J. Sci. Technol. Compos. 4, 219–228 (2017)

A. Biswas, D.J. Siegel, C. Wolverton et al., Precipitates in Al–Cu alloys revisited: atom-probe tomographic experiments and first-principles calculations of compositional evolution and interfacial segregation. Acta Mater. 59, 6187–6204 (2011). https://doi.org/10.1016/j.actamat.2011.06.036

B.A. Shoilock, C.R.M. Grovenor, K.M. Knowlcs, Compositional studies of Ω and Ө’ precipitates in an Al-Cu-Mg-Ag alloy. Scr. Metall. 24, 1239–1244 (1990). https://doi.org/10.1016/0956-716X(90)90335-E

E.I. Marukovich, A.M. Branovitsky, Y.S. Na et al., Study on the possibility of continuous-casting of bimetallic components in condition of direct connection of metals in a liquid state. Mater. Des. 27, 1016–1026 (2006). https://doi.org/10.1016/j.matdes.2005.02.007

H. Springer, A. Szczepaniak, D. Raabe, On the role of zinc on the formation and growth of intermetallic phases during interdiffusion between steel and aluminium alloys. Acta Mater. 96, 203–211 (2015). https://doi.org/10.1016/j.actamat.2015.06.028

B. Wei, D.M. Herlach, Rapid solidification of undercooled eutectic and monotectic alloys. Mater. Sci. Eng. A 173, 357–361 (1993). https://doi.org/10.1016/0921-5093(93)90244-9

X.R. Liu, C.D. Cao, B. Weisheng, Microstructure evolution and solidification kinetics of undercooled Co–Ge eutectic alloys. Scripta Mater. 46, 13–18 (2002). https://doi.org/10.1016/S1359-6462(01)01188-5

J.C. Viala, M. Peronnet, F. Barbeau et al., Interface chemistry in aluminium alloy castings reinforced with iron base inserts. Compos. Part A 33, 1417–1420 (2002)

E. Aguado, A. Baquedano, U. Uribe, et al. Comparative study of different interfaces of steel inserts in aluminium castings. In Materials Science Forum; Trans Tech Publ, (2013), pp 711-715. https://doi.org/10.4028/www.scientific.net/MSF.765.711

B. Xiong, C. Cai, B. Lu, Effect of volume ratio of liquid to solid on the interfacial microstructure and mechanical properties of high chromium cast iron and medium carbon steel bimetal. J. Alloy. Compd. 509, 6700–6704 (2011). https://doi.org/10.1016/j.jallcom.2011.03.142

M.H. Ghoncheh, S.G. Shabestari, M.H. Abbasi, Effect of cooling rate on the microstructure and solidification characteristics of Al2024 alloy using computer-aided thermal analysis technique. J. Therm. Anal. Calorim. (2014). https://doi.org/10.1007/s10973-014-3867-3

B. Xiong, C. Cai, H. Wan et al., Fabrication of high chromium cast iron and medium carbon steel bimetal by liquid–solid casting in electromagnetic induction field. Mater. Des. 32, 2978–2982 (2011). https://doi.org/10.1016/j.matdes.2011.01.006

S. Sarkar, A.K. Lohar, S.C. Panigrahi, Vertical centrifugal casting of aluminum matrix particle reinforced composites. J. Reinf. Plast. Compos. 28, 1013–1020 (2009). https://doi.org/10.1177/0731684407087757

M. Abbasi, A. Karimi Taheri, M.T. Salehi, Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process. J. Alloy. Compd. 319, 233–241 (2001). https://doi.org/10.1016/S0925-8388(01)00872-6

W.H.S. Lawson, H.W. Kerr, Mechanical behavior of rapidly solidified AI-AI2Cu and AI-AlaNi COMPOSITES. Metall. Trans. 2, 2853–2859 (1971). https://doi.org/10.1007/BF02813263

M. Gholami, M. Divandari, M.T. Salehi, Experimental study of effective parameters on production and mechanical properties of Al-brass bimetal composite. Modares Mech. Eng. 16, 170–178 (2016)

C.D. Beachem, The effects of crack tip plastic flow directions upon microscopic dimple shapes. Metall. Trans. A 6, 377–383 (1975). https://doi.org/10.1007/BF02667293

A. Gilbert, G.T. Hahn, C.N. Reid et al., Twin-induced grain boundary cracking in bcc metals. Acta Metall. 12, 754 (1964)

J.X. Zhou, X. Shen, Y.J. Yin et al., Gas-liquid two phase flow modelling of incompressible fluid and experimental validation studies in vertical centrifugal casting. Mater. Sci. Eng. (2015). https://doi.org/10.1088/1757-899X/84/1/012042

J. Zhang, J.X. Zhou, M. Zhang et al., Numerical simulation of filling process in vertical centrifugal casting based on projection-level set method. Adv. Mater. Res. 314–316, 364–368 (2011). https://doi.org/10.4028/www.scientific.net/AMR.314-316.364

E. Trejo, Centrifugal casting of an aluminium alloy (University of Birmingham, 2011)

L.L. Regel, W.R. Wilcox, Centrifugal materials processing. Int. Center Gravity Mater. Sci. Appl. (1997). https://doi.org/10.1007/978-1-4615-5941-2_1

W. Shi-ping, L. Chang-yun, G.U. Jing-jie et al., Numerical simulation and experimental investigation of two filling methods in vertical centrifugal casting. Trans. Nonferrous Met. Soc. China 16, 1035–1040 (2006). https://doi.org/10.1016/S1003-6326(06)60373-7

Q. Dong, Z. Yin, H. Li et al., Simulation study on filling and solidification of horizontal centrifugal casting babbitt lining of bimetallic bearing. Int. J. Metalcast. 15, 119–129 (2021). https://doi.org/10.1007/s40962-020-00429-y

Acknowledgments

We would like to express our gratitude to the members of Dr. M. Divandari's Lab. (Porous and Lattice Materials Laboratory of Iran University of Science and Technology).

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study's conception and design. Material preparation, data collection, and analysis were performed by [MG], [AD], and [MA]. The first draft of the manuscript was written by [MG] and review and editing were performed by [SGK]. Also, this research was under the supervision of [MD]. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Governing equations

Forces analysis

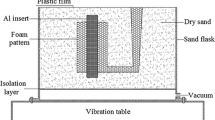

Mold rotation around its centerline not only causes a centrifuge field but also intensifies the gravitational force, which is exposed on both filling and solidifying liquid metal. By supposing the liquid metal to behave like an incompressible Newtonian fluid, the governing mass and momentum equations can be derived using the Navier-Stokes equations:

where F, ρ, P, µ, U <u, v, w>, and t represent, respectively, acceleration, fluid density, pressure, viscosity, velocity vector in Cartesian coordinates, and time. The acceleration components are affected by the centrifuge and Coriolis forces (Fig.

21). They are applied in three different directions \({a}_{x}\), \({a}_{y}\), and \({a}_{z}\):

where ω, ur, vr, and g, respectively, relate to angular velocity, velocities relative to X and Y directions, and gravity acceleration.56,57 Moreover, centripetal acceleration is also involved in this process. The acceleration responsible for uniform circular motion is called centripetal acceleration, and its value can be calculated by:

In which r is the mold radius and s represents a tangential velocity of a particle.58

Heat transfer

The thermal energy transfer equation in the VCC process can be derived as follows:

where T and fs represent temperature and solidified phase fraction, respectively; α also indicates thermal diffusivity and equals to:

In which λ, ρL, h, and cp are thermal conductivity, fluid density, latent heat, and specific heat, respectively.32 Actually, heat transfer increment at the centrifuge field alleviates the temperature gradient and accelerates the solidification rate so that directional solidification occurs.59

Solidification

Mold rotation improves alloy texture and reduces defects by pressurizing the melt.60 Generally, rapid heat extraction at the centrifuge field promotes directional solidification.59 The continuity and Navier-Stokes equations in a control volume of a fluid with vx, vy, and vz velocity components are as follows:

Equation (10) can be rewritten for cylindrical coordinates:

where ρ, p, \(\eta {\nabla }^{2}v\), and ρg are, respectively, stood for density, pressure, viscous force, and gravitational force.60,61

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gholami, M., Ghaemi Khiavi, S., Dehhaghi, A. et al. Microstructure and Mechanical Properties of the Interface of Aluminum-Brass Bimetals Produced via Vertical Centrifugal Casting (VCC). Inter Metalcast 18, 1204–1216 (2024). https://doi.org/10.1007/s40962-023-01096-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01096-5