Abstract

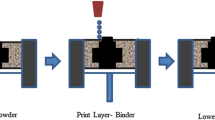

Process innovation through smart factory strategies is urgently needed in the flow of digital transformation, not just automation. As customer needs become diverse and industrial structures become more complex, production volume per item is rapidly decreasing. According to these market changes, interest in 3D printing is increasing. In this paper, novel methodologies for merging sand 3D printing technology into metal casting processes for foundry innovation were proposed. To see how effective the new approach is, we actually applied it to the mass production process of a medium-speed engine piston. The results show the effectiveness of the proposed approach that can increase productivity, improve quality, and reduce production costs.

Similar content being viewed by others

References

Wohlers Report 2023: 3D printing and additive manufacturing global state of the industry. wohlers associates, 2023.

World’s first plant to print jet engine nozzles in mass production, GE Reports, 15 July 2014. https://www.ge.com/news/reports/worlds-first-plant-to-print-jet-engine-nozzles-in

Additive manufacturing campus: components straight from the printer, BMW Group, 25 June 2020. https://www.bmwgroup.com/en/news/general/2020/additive-manufacturing.html

Additive manufacturing of manifolds based on 3D-printed sand cores, Bosch Rexroth (2019). https://dc-corp.resource.bosch.com/media/general_use/products/industrial_hydraulics_1/manifolds_and_plates/Factsheet_Hyd_Bloecke_final_EN.pdf

K.H. Han, Innovation of the casting process with sand 3D printing technology. J. Korea Foundry Soc. 41(1), 111–115 (2021)

E.S. Almaghariz, B.P. Conner, L. Lenner et al., Quantifying the role of part design complexity in using 3D sand printing for molds and cores. Inter Metalcast 10, 240–252 (2016). https://doi.org/10.1007/s40962-016-0027-5

S.R. Sama, T. Badamo, P. Lynch, G. Manogharan, Novel sprue designs in metal casting via 3D sand-printing. Addit. Manuf. 25, 563–578 (2019). https://doi.org/10.1016/j.addma.2018.12.009

A. Mostafaei, A.M. Elliott, J.E. Barnes et al., Binder jet 3D printing – Process parameters, materials, properties, modeling, and challenges. Prog Mater Sci (2021). https://doi.org/10.1016/j.pmatsci.2020.100707

S.R. Sama, T. Badamo, G. Manogharan, Case studies on integrating 3D sand-printing technology into the production portfolio of a sand-casting foundry. Inter Metalcast 14, 12–24 (2020). https://doi.org/10.1007/s40962-019-00340-1

J. Wang, S.R. Sama, G. Manogharan, Re-thinking design methodology for castings: 3D sand-printing and topology optimization. Inter Metalcast 13, 2–17 (2019). https://doi.org/10.1007/s40962-018-0229-0

H.B. Henderson, E.T. Stromme, M.S. Kesler et al., Additively manufactured single-use molds and reusable patterns for large automotive and hydroelectric components. Inter Metalcast 14, 356–364 (2020). https://doi.org/10.1007/s40962-019-00379-0

J. Walker, E. Harris, C. Lynagh et al., 3D printed smart molds for sand casting. Inter Metalcast 12, 785–796 (2018). https://doi.org/10.1007/s40962-018-0211-x

J.M. Walker, A. Prokop, C. Lynagh et al., Real-time process monitoring of core shifts during metal casting with wireless sensing and 3D sand printing. Addit. Manuf. 27, 54–60 (2019). https://doi.org/10.1016/j.addma.2019.02.018

T.E. Prucha, Metalmorphasis: change and transition. Inter Metalcast 15, 1110–1117 (2021). https://doi.org/10.1007/s40962-021-00625-4

Y. Son, The DfAM process design for metal 3D printing with PBF method. J. of the KSME 60(2), 34–37 (2020)

K.H. Han, Industry-specific Innovation with 3D printing: expansion of application fields to mass production and various industries. CAD Gr. 07, 23–27 (2020)

K. Kim, Engine parts manufacturer meets Sand 3D Printing… Samyoung Machinery goes beyond the limits of innovation. Industry News, 21 July 2020. http://www.industrynews.co.kr/news/articleView.html?idxno=38988

K.H. Han, J.W. Baek, S.Y. Park, T.W. Lim, J.M. Park, A case study on productivity innovation through convergence of sand 3d printing technology. J. Korean Soc. Precis. Eng. 38(9), 651–657 (2021). https://doi.org/10.7736/JKSPE.021.073

Acknowledgements

This paper is an invited submission to IJMC selected from presentations at the 74th World Foundry Congress, held October 16 to 20, 2022, in Busan, Korea, and has been expanded from the original presentation. This study was conducted as part of the project (No. 10076342) that received funding from the Advanced Technology Center Industrial Technology Innovation Program by the Ministry of Trade, Industry and Energy, Korea and the project (S3262661) that received funding from the SME Technology Innovation & Development Program (Hidden Champion 100) by the Ministry of SMEs and Startups, Korea.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper is an invited submission to IJMC selected from presentations at the 74th World Foundry Congress, held October 16 to 20, 2022, in Busan, Korea, and has been expanded from the original presentation.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, KH., Baek, JW., Lim, T.W. et al. Digital Transformation of Metal Casting Process Using Sand 3D Printing Technology with a Novel Methodology of Casting Design Inside a Core. Inter Metalcast 17, 2674–2679 (2023). https://doi.org/10.1007/s40962-023-01088-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01088-5