Abstract

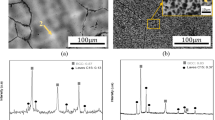

While the findings show the benefits of Be to reduce the deleterious effects of Fe-phases, this work does not promote its use. As noted, care must be taken due to the toxic nature of Be to ensure proper ventilation and environmental controls as well as personnel protection are in place. The present work was carried out on a series of heat-treatable aluminum-based aeronautical alloys containing various amounts of magnesium (Mg), iron (Fe), strontium (Sr) and beryllium (Be). The results show that Be (~300–400 ppm) causes partial modification of the eutectic silicon (Si) particles similar to that reported for Mg addition. Addition of 0.8 wt% Mg reduced the eutectic temperature by ~ 10 °C. During solidification of alloys containing high levels of Fe and Mg, without Sr, a peak corresponding to the formation of a Be–Fe phase (Al8Fe2BeSi) was detected at 611 °C, which is close to the formation temperature of α-Al. The Al–Be–Fe phase precipitates in a script-like morphology. Beryllium addition is beneficial in the case of high Fe contents as it lowers the harmful effects of Fe-phases in Al–Si alloys. In the case of high Fe contents, it seems that the addition of 500 ppm of Be is not sufficient for all interactions with other alloying elements. During the melting process, the formation of Be–Sr phase (probably SrBe3O4 compound) decreases the free Be content and hence the alloy mechanical properties. The role of Be in preventing the oxidation of Mg and in changing the chemistry and morphology of the Fe-intermetallics is observed through improved mechanical properties of Be-containing alloys. The partial modification effect of both Mg and Be appears to improve the alloy tensile properties.

Similar content being viewed by others

References

E.L. Rooy, ASM Handbook, Castings, vol. 15, 9th edn. (ASM International, Materials Park, 1992), pp. 743–769

T. Tunçay, S. Bayoğlu, The effect of iron content on microstructure and mechanical properties of A356 cast alloy. Metall. Mater. Trans. B 48, 794–804 (2017). https://doi.org/10.1007/s11663-016-0909-1

D. Bolibruchová, L. Richtárech, Effect of adding iron to the AlSi7Mg0.3 (EN AC 42 100, A356) alloy. Manuf. Technol. 13, 276–28 (2013)

M.T. Di Giovanni et al., Room temperature mechanical properties of A356 alloy with Ni additions from 0.5 wt to 2 wt %. Metals 8, 224 (2018). https://doi.org/10.3390/met8040224

O. Elsebaie, A.M. Samuel, F.H. Samuel, Effects of Sr-modification, iron-based intermetallics and aging treatment on the impact toughness of 356 Al–Si–Mg alloy. J. Mater. Sci. 46, 3027–3045 (2011)

Z. Ma, A.M. Samuel, F.H. Samuel, H.W. Doty, S. Valtierra, Paper 03–101 Effect of Fe content and cooling rate on the impact toughness of cast 319 and 356 aluminum alloys. AFS Trans. 111, 255–266 (2003)

F. Breton, New high strength 3xx series alloy case study: automotive wheel weight reduction, Paper 19–039. AFS Trans. 127, 183–188 (2019)

J. Shouxun, Y. Wenchao, G. Feng, W. Douglas, F. Zhongyun, Effect of iron on the microstructure and mechanical property of Al–Mg–Si–Mn and Al–Mg–Si die cast alloys. Mater. Sci. Eng. A 564, 130–139 (2013)

J.C. Hebeisen, B.M. Cox, B. Rampulla, HIP of aluminum castings. Adv. Mater. Process. 162(4), 38−40 (2004).

D. Weiss, K. Weiss, Improving mechanical properties in aluminum through enhanced filtering techniques. AFS Trans. 119, 117–121 (2011)

Q. Wang, C. Caceres, J. Griffiths, Damage by eutectic particle cracking in aluminum casting alloys A356/357. Metall. Mater. Trans. 34A, 2901–2912 (2003)

Aluminum Beryllium Master Alloys, http://www.freedomalloyssusa.com.

E.A. Elsharkawi, M.H. Abdelaziz, H.W. Doty et al., Effect of β-Al5FeSi and π-Al8Mg3FeSi6Phases on the impact toughness and fractography of Al–Si–Mg-based alloys. Inter Metalcast 12, 148–163 (2018). https://doi.org/10.1007/s40962-017-0153-8

J. Major, M. Hartlieb, Advances in aluminum foundry alloys for permanent and semi-permanent mold casting. Inter Metalcast 3, 43–53 (2009). https://doi.org/10.1007/BF03355452

A. Guo, X. Qiu, Z. Ke, et al., Effect of the injection velocity and the electromagnetic stirring on the mechanical properties of a Rheo-Diecast 357 Al alloy. Inter Metalcast (2021). https://doi.org/10.1007/s40962-021-00621-8

R. Fuoco, M. Moreira, Fatigue cracks in aluminum cylinder heads for diesel engines. Inter. Metalcast 4, 19–32 (2010). https://doi.org/10.1007/BF03355500

W.A. Bailey, Beryllium effect on strength and mechanical properties of 356 variant–T 6 Aluminum alloys. AFS Trans. 72, 443–454 (1964)

E.A. Elsharkawi, A.M. Samuel, F.H. Samuel, E. Simielli, G.K. Sigworth, Influence of solutionizing time, modification, and cooling rate on the decomposition of Mg-containing iron intermetallic phase in 357 alloys. AFS Trans. 120, 55–65 (2012)

L. Purdon, J.F. Major, T5 aging response of A356/357 hypoeutectic Al–Si foundry alloys under conditions of varying quench rate from the mould. AFS Trans. 121, 461–471 (2004)

F. Breton, A new alloy for automotive wheel weight reduction. Metal Cast. Des. Purch. 2019, 35–38 (2019)

K.J. Oswalt, A. Maloit, A study of the relationship of notch yield ratio and fracture toughness of structural aircraft quality D357 aluminum casting alloy. AFS Trans. 98, 865–877 (1990)

D. Weiss, Reduced silicon alloys for enhanced casting performance. AFS Trans. 127, 189–193 (2019)

S.S. Sreeja Kumari, R.M. Pillai, T.P.D. Rajan, B.C. Pai, Effect of individual and combined additions of Be, Mn, Ca and Sr on the solidification behavior, structure and mechanical properties of Al–7Si–0.3Mg–0.8Fe alloy. Mater. Sci. Eng. A 460–461, 561–573 (2007)

S. Shivkumar, S. Ricci Jr., B. Steenhoff, D. Apelian, G. Sigworth, An experimental study to optimize the heat treatment of A356 alloy. AFS Trans. 97, 791–810 (1989)

J.A. Taylor, D.H. StJohn, L.H. Zheng, G.A. Edwards, J. Barresi, M.J. Couper, Solution Treatment Effects in Al–Si–Mg Casting Alloys: Part 1–intermetallic phases. Alumin. Trans. 45, 95–110 (2001)

P.A. Burr, S.C. Middleburgh, R.W. Grimes, Crystal structure, thermodynamics, magnetics and disorder properties of Be–Fe–Al intermetallics. J. Alloys Compd. 639, 111–122 (2014). https://doi.org/10.1016/j.jallcom.2015.03.101

G.V. Raynor, G.R. Faulkner, J.D. Noden, A.R. Harding, Ternary alloys formed by aluminium, transitional metals and divalent metals. Acta Metall. 1, 629–648 (1953)

P.J. Black, The structure of T(AlFeBe). Acta Crystallogr. 8, 39–42 (1955)

M. Drouzy, S. Jacob, M. Richard, Interpretation of tensile results by means of quality index and probable yield strength. AFS Int. Cast Metals J. 5, 43–50 (1980)

S. Jacob, Quality index in predicting of properties of aluminum castings—a review. AFS Trans. 108, 811–818 (2000)

S.L. Bäckerud, G. Chai, J. Tamminen, Solidification Characteristics of Aluminum Alloys, Vol. 2 Foundry Alloys (AFS/Skanaluminium, Oslo, 1990)

S. Murali, K.S. Raman, K.S.S. Murthy, The formation of β-phase and Be–Fe phases in Al–7Si–0.3Mg alloy containing Be. Mater. Sci. Eng. A 190, 165–172 (1995)

E.A. Elsharkawi, Effect of Metallurgical Parameters on the Decomposition of the π-AlFeMgSi Phase in Al–Si–Mg Alloys and its Influence on the Mechanical Properties, Ph.D. Thesis, Université du Québec à Chicoutimi, Chicoutimi, Quebec, Canada (2011).

F.H. Samuel, P. Ouellet, A.M. Samuel, H.W. Doty, Effect of Mg and Sr additions on the formation of intermetallics in Al-6 Wt Pet Si-3.5 Wt Pet Cu-(0.45) to (0.8) Wt Pet Fe 319-type alloys. Metall. Mater. Trans. A. 29A, 2871–2884 (1998)

D. Apelian, S.K. Chaudhury, Heat Treatment of Aluminum Cast Components: Recent Developments and Future Challenges (WFO Technical Forum, St. Louis, 2005)

L.A. Narayanan, F.H. Samuel, J.E. Gruzleski, Dissolution of iron intermetallics in Al–Si alloys through nonequilibrium heat treatment. Metall. Mater. Trans. A. 26A, 2161–2174 (1995)

M. Tiryakioğlu, J.T. Staley, J. Campbell, Evaluating structural integrity of cast Al–7%Si–Mg alloys via work hardening characteristics: II. A new quality index. Mater. Sci. Eng. A 368, 231–238 (2004)

C.Y. Yang, S.L. Lee, C.K. Lee, J.C. Lin, Effect of Be and Fe on the mechanical and corrosion behaviour of A357 alloys. Mater. Chem. Phys. 93, 412–419 (2005)

D. Apelian, S. Shivkumar, G. Sigworth, Fundamental aspects of heat treatment of cast Al–Si–Mg alloys. AFS Trans. 97, 727–742 (1989)

J.A. Taylor, D.H. StJohn Barresi, M.J. Couper, Influence of Mg content on the microstructure and solid solution chemistry of Al–7Si–Mg casting alloys during solution treatment. Mater. Sci. Forum 331–337, 277–282 (2000)

Y. Wang, Y. Xiong, Effects of beryllium in Al–Si–Mg-Ti alloy. Mater. Sci. Eng. A 280(1), 124–127 (2000)

S. Murali, A. Trivedi, K.S. Shamanna, K.S.S. Murthy, Effect of iron and combined iron and beryllium addition on the fracture toughness and microstructures of squeeze-cast Al–7Si–0.3Mg alloy. J. Mater. Eng. Perform. 5(4), 462–468 (1996)

Z. Lin, Z. Wang, H. Yang, C. Chen, M. Lee, Mechanism for linear and nonlinear optical effects in SrBe3O4 crystal. J. Chem. Phys. 117(6), 2809 (2002)

H. Möller, G. Govender, W.E. Stumpf, R.D. Knutsen, Influence of temper condition on microstructure and mechanical properties of semisolid metal processed Al–Si–Mg Alloy A356. Int. J. Cast Met. Res. 22(6), 417–421 (2009)

M. Abdulwahab, I.A. Madugu, S.A. Yaro, S.B. Hassan, A.P.I. Popoola, Effects of multiple-step thermal aging treatment on the hardness characteristics of A356.0-type Al–Si–Mg alloy. Mater. Des. 32, 1160–1165 (2011)

N.D. Alexopoulos, M. Tiryakioglu, Relationship between fracture toughness and tensile properties of A357 cast aluminum alloy. Metall. Mater. Trans. A 40A, 702–716 (2009)

A. Morri, Empirical models of mechanical behaviour of Al–Si–Mg cast alloys for high performance engine applications. Metall. Sci. Technol. 28(2), 2–8 (2010)

E. Alibeiki, J. Rajabi, J. Rajabi, Prediction of mechanical properties of the heat treatment by artificial neural networks. J. Asian Sci. Res. 2(11), 742–746 (2012)

H.R. Ammar, A.M. Samuel, F.H. Samuel, E. Simielli, G.K. Sigworth, J.C. Lin, Influence of aging parameters on the tensile properties and quality index of Al–9 Pct Si–1.8 Pct Cu–0.5 Pct Mg 354-type casting alloys. Metall. Mater. Trans. A 43(1), 61–73 (2012). https://doi.org/10.1007/s11661-011-0808-7

P.W. Voorhees, G.B. McFadden, R.F. Boisvert, Numerical Simulation of Morphological Development during Ostwald Ripening. Acta Metall. 36(1), 207–222 (1988)

A.K. Gupta, D.J. Lloyd, S.A. Court, Precipitation hardening in Al–Mg–Si alloys with and without excess Si. Mater. Sci. Eng. A 316, 11–17 (2001)

J.R. Davis, Aluminum and Aluminum Alloys (ASM International, Geauga County, 2006). ISBN: 978-0-87170-496-2

A. Gaber, M.A. Gaffar, M.S. Mostafa, E.F.A. Zeid, Precipitation kinetics of Al–1.12 Mg2Si–0.35 Si and Al–1.07 Mg2Si–0.33 Cu alloys. J. Alloys Compd. 429, 167–175 (2007)

M. Vončin’, J. Medved, S. Kores, et al., Precipitation microstructure in Al–Si–Mg–Mn alloy with Zr additions. Mater. Charact. 155, 109820 (2019)

W.D. Callister, D.G. Rethwisch, Fundamentals of Materials Science and Engineering: An Integrated Approach, vol. 2012 (Wiley, New York, 2012)

G. Asghar, L. Peng, P. Fu, L. Yuan, Y. Liu, Role of Mg2Si precipitates size in determining the ductility of A357 cast alloy. Materials & Design 186, 108280 (2020)

Y. Ohmori, L.C. Doan, K. Nakai, Ageing processes in Al–Mg–Si alloys during continuous heating. Mater. Trans. 43(2), 246–255 (2002)

Acknowledgements

The authors would like to thank Amal Samuel for enhancing the quality of the used artwork.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Elsharkawi, E.A., Ibrahim, M.F., Samuel, A.M. et al. Understanding the Effect of Be Addition on the Microstructure and Tensile Properties of Al–Si–Mg Cast Alloys. Inter Metalcast 16, 1777–1795 (2022). https://doi.org/10.1007/s40962-021-00715-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00715-3