Abstract

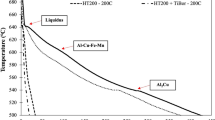

The development of new alloys characterized by a high strength-to-weight ratio and low production costs is one of the major objectives of the modern automotive industry with a view to lowering CO2 emissions and obtaining automotive castings that are both lightweight and capable of maintaining their performance under elevated temperature service conditions. The Al-2wt%Cu alloy is one such alloy; it contains 2wt% Cu, 0.05–1wt% Si, 0.4wt% Mg, 0.42wt% Fe, 0.7wt% Mn, and 0.02 wt%Ti (developed by General Motorrs-USA-coded GM220). The low Cu and Si content of the alloy, associated with an acceptable level of tensile strength, make this alloy suitable as a replacement for a number of other alloys such as the 319-type alloys used in engine blocks and cylinder heads. As a new alloy under development, the Al-2wt%Cu alloy has necessitated an in-depth investigation of its castability. Generally, the Al-2wt%Cu-based alloys exhibited higher resistance to hot tearing than 206-based alloys. It was found that an elevated mold temperature is beneficial in reducing the hot tearing susceptibility of the Al-2wt%Cu and 206 alloys in that the hot tearing susceptibility value decreased from 21 to 3, as the mold temperature was increased from 250 to 450 °C. The refinement of the grain structure obtained with Zr-Ti or Ti additions decreased the hot tearing severity as a result of an increase in the number of intergranular liquid films per unit volume and a delay in reaching the coherency point. Increasing the Si content reduced the hot tearing susceptibility of the Al-2wt%Cu alloy considerably; this reduction is attributed to an increase in the volume fraction of eutectic in the structure, and a decrease in the freezing range of the alloy. The addition of Sr caused a deterioration in the hot tearing resistance of the base alloy as a result of the formation of Sr-oxides and an extension of the freezing range of the alloy. It was also observed that α-Fe particles may obstruct the propagation of hot tearing cracks. The 1wt%Si-containing Al-2wt%Cu alloy was judged to be the best composition in view of its low hot tearing susceptibility.

Similar content being viewed by others

References

J. Campbell, The New Metallurgy of Cast Metals: Castings (Butterworth-Heinemann, Oxford, 2003), pp. 232–258

L. Liu, A.M. Samuel, F.H. Samuel, H.W. Doty, S. Valtierra, Influence of oxides on porosity formation in Sr-treated Al-Si casting alloys. J. Mater. Sci. 38, 1255–1267 (2003)

A.M. Samuel, H.W. Doty, S. Valtierra, F.H. Samuel, Influence of oxides on porosity formation in Sr-treated alloys. Int. J. Metalcast. 11, 729–742 (2017). https://doi.org/10.1007/s40962-016-0118-3

F.H. Samuel, P. Ouellet, A.A. Simard, Measurements of oxide films in Al-(6–17) wt%Si foundry alloys using the qualiflash filtration technique. Int. J. Cast Met. Res. 12, 49–65 (1999)

W.S. Pellini, Strain theory of hot tearing. Foundry 80, 125–199 (1952)

W.S. Pellini, H.F. Bishop, C.G. Ackerlind, Metallurgy and mechanics of hot tearing. Trans. Am. Foundrym. Soc. 60, 818–833 (1952)

J.A. Spittle, A.A. Cushway, Influences of superheat and grain structure on hot tearing susceptibilities of Al-Cu Alloy castings. Met. Technol. 10, 6–13 (1983)

R. Taghiabadi, A. Fayegh, A. Pakbin, M. Nazari, M.H. Ghoncheh, Quality index and hot tearing susceptibility of Al−7Si−0.35Mg−xCu alloys. Trans. Nonferrous Met. Soc. China 28, 1275–1286 (2018)

S. Li, K. Sadayappan, D. Apelian, Characterisation of hot tearing in Al cast alloys: methodology and procedures. Int. J. Cast Met. Res. 24, 88–95 (2011)

C. Davidson, D. Viano, L. Lu, D. StJohn, Observation of crack initiation during hot tearing. Int. J. Cast Met. Res. 19, 59–65 (2006)

J.B. Mitchell, S.L. Cockcroft, D. Viano, C. Davidson, D. StJohn, Hot tearing in cast Al alloys: mechanisms and process controls. Metall. Mater. Trans. A 38A, 2503–2512 (2007)

S. Li, D. Apelian, Hot tearing of aluminum alloys, A critical literature review. Int. J. Metalcasting 5, 23–40 (2011)

D.G. Eskin, L. Katgerman, Mechanical properties in the semi-solid state and hot tearing of aluminum alloys. Prog. Mater. Sci. 49, 629–711 (2004)

W.H. Kool, L. Katgerman, Evaluation of mechanical and non-mechanical hot tearing criteria for DC casting of an aluminum alloy. Light Met. 4, 753–758 (2003)

I.I. Novikov, “Goryachelomkost, Tsvetnykh Metallov Splavovi (Hot Shortness of Non-Ferrous Metals and Alloys),”p. 299 (1966).

C.H. Dickhaus, L. Ohm, S. Engler, Mechanical properties of solidifying shell of aluminum alloys. AFS Trans. 101, 677 (1994)

D.J. Lahaie, M. Bouchard, Physical modeling of the deformation mechanisms of semisolid bodies and a mechanical criterion for hot tearing. Metall. Mater. Trans. B 32, 697 (2001)

J. Langlais, J.E. Gruzleski, A novel approach to assessing the hot tearing susceptibility of aluminum alloy. Mater. Sci. Forum 331–337, 167–172 (2000)

J.A. Williams, A.R.E. Singer, Deformation, strength, and fracture above the solidus temperature. J. Inst. Met. 96, 5–12 (1968)

G.K. Sigworth, Hot tearing of metals. AFS Trans. 104, 1053–1062 (1996)

W.H. Kool, L. Katgerman, Hot tearing criteria evaluation for direct-chill casting of an Al-4.5 Pct Cu Alloy. Metall. Mater. Trans. A 36, 1537–1546 (2005)

L.Y. Zhao, Baoyin, N. Wang, V. Sahajwalla, R.D. Pehlke, The rheological properties and hot tearing behavior of an Al-Cu Alloy, Int. J. Cast Met. Res. 13(3), 167–174

B. Magnin, L. Maenner, L. Katgerman, S. Engler, Ductility and theology of an Al-4.5%Cu alloy from room temperature to coherency temperature. Mater Sci. Forum 1209, 217–222 (1996)

M. Uludağ, R. Çetin, D. Dispinar, Freezing range, melt quality, and hot tearing in Al-Si Alloys. Metall. Mater. Trans. A 49, 1948–1961 (2018)

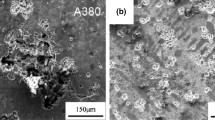

M. Uludağ, R. Çetin, D. Dispinar, M. Tiryakioğlu, The effects of degassing, grain refinement and Sr-addition on melt quality-hot tear sensitivity relationships in cast A380 aluminum alloy. Eng. Fail. Anal. 90, 90–102 (2018)

L. Lu, A.K. Dahle, C. Davidson, D. StJohn, Hot Tearing of Al-Si Alloys, Light Metals 2007, Morten Sorlie (Ed.), The Minerals, Metals & Materials Society, U.S.A., pp. 721–726 (2007)

A. S. Sabau, S. Mirmiran, C.Glaspie, S Li3 D. Apelian, A. Shyam, J. Allen Haynes, A F. odriguez, Hot-tearing of multicomponent Al-Cu alloys based on casting load measurements in a constrained permanent mold, The Minerals, Metals & Materials Society, TMS 2017 146th Annual Meeting & Exhibition Supplemental Proceedings, The Minerals, Metals & Materials Series, pp. 465–473. https://doi.org/10.1007/978-3-319-51493-2_44.

H. Akhyar, V. Malau, P.T. Iswanto, Hot tearing susceptibility of aluminum alloys using CRCM-Horizontal mold. Results Phys. 7, 1030–1039 (2017)

J. Liu, S. Kou, Susceptibility of ternary aluminum alloys to cracking during Solidification. Acta Mater. 125, 513–523 (2017)

D.G. Eskin, L. Katgerman, Mechanical properties in the semi-solid state and hot tearing of aluminum alloys. Prog. Mater. Sci. 49, 629–711 (2004)

J. Campbell, Entrainment Defects, Materials Science and Technology, Vol. 122, pp. 127–145

D. Jing-Zhi, H. Yu-Feng, C. Jun, Effect of Sc and Zr on microstructures and mechanical properties of As-Cast Al-Mg-Si-Mn Alloys. Trans. Nonferrous Met. Soc. China 19, 540–544 (2009)

S.M. Miresnaeil, J. Campbell, S.G. Shabestari, S.M.A. Boutorabi, Precipitation of Sr-Rich intermetallic particles and their influence on pore formation in Sr-modified A356 alloy. Metall. Mater. Trans. A 36A, 2341–2349 (2005)

R. Raiszadeh, W.D. Griffiths, A method to study the history of a double oxide film defect in liquid aluminum alloys. Metall. Mater. Trans. B 37B, 865–871 (2006)

D.G. Eskin, L. Katgerman, A quest for a new hot tearing criterion. Metall. Mater. Trans. A 38, 1511–1519 (2007)

D.G. Eskin, Suyitno, L. Katgerman, in Aluminum Cast, House Technology 2005, Proc. 9th Australasian Conf., J. Taylor, I. Bainbridge, and J. Granfield (Eds.), CSIRO Publishing, Collingwood, 2005, pp. 77–84

T.W. Clyne, G.J. Davies, “Comparison between Experimental Data and Theoretical Predictions Relating to Dependence of Solidification Cracking on Composition,” Solidification and Casting of Metals, Proc. Int. Conf., University of Sheffield, 1977, pp. 275–278

G.K. Sigworth, Grain refining of aluminum casting alloys. AFS Trans. 109, 1–12 (2001)

H. Liao, G. Sun, Mutual poisoning effect between Sr and B in Al-Si casting alloys. Scripta Mater. 48, 1035–1039 (2003)

L. Lu, A.K. Dahle, Effects of combined additions of Sr and AlTiB grain refiners in hypoeutectic Al-Si foundry alloys. Mater. Sci. Eng. A 435–436, 288–296 (2006)

J. Hutt, M. Easton, L. Hogan, D.H. StJohn, The Effect of Nucleant Particles and Alloy Chemistry on the Grain Structure of Aluminium Castings, Solidification Processing (Sheffield, England, 1997), pp. 268–272

C.H. Cáceres, I.L. Svensson, J.A. Taylor, Strength-ductility behaviour of Al-Si-Cu-Mg casting alloys in T6 temper. Int. J. Cast Met. Res. 15, 531–543 (2003)

L. Katgerman, A mathematical model for hot cracking of aluminum alloys during D.C. casting. JOM 34(2), 46–49 (1982)

F.H. Samuel, P. Ouellet, A.M. Samuel, H.W. Doty, Effect of Mg and Sr additions on the formation of intermetallics in Al-6 Wt Pct Si-3.5 Wt Pct Cu-(0.45) to (0.8) Wt Pct Fe 319-type alloys. Metall. Mater. Trans. A 29, 2871–2884 (1998)

S.A. Metz, M.C. Flemings, A fundamental study of hot tearing. AFS Trans. 78, 453–460 (1970)

S. Lin, C. Aliravci, M.O. Pekguleryuz, Hot tear susceptibility of aluminum wrought alloys and the effect of grain refining. Metall. Mater. Trans. A 38A, 1056–1068 (2007)

L. Lu, A.K. Dahle, D. StJohn, Hot Tearing of Al-Si Alloys, Light Metals: Proceedings of the Technical Sessions Presented by TMS Aluminum Committee at 136th Annual Meeting, The Minerals, Metals and Materials Society, Warrendale, PA 2007, pp. 721–726

J. Vero, The hot shortness of aluminum alloys. Metal Ind. 48, 431–442 (1936)

A. Norton, Hot shortness testing machine for aluminum alloys. ASME Trans. 8, 124 (1914)

W. Pellini, Strain theory of hot tearing. Foundry 80, 124–199 (1952)

L. Katgerman, D. Eskin, In search of prediction of hot cracking in aluminium alloys, in Hot cracking phenomena in welds II. ed. by H.H. Thomas Bollinghaus, C.E. Cross, J.C. Lippold (Springer, Berlin, 2008), pp. 3–18

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nabawy, A.M., Samuel, A.M., Doty, H.W. et al. A Review on the Criteria of Hot Tearing Susceptibility of Aluminum Cast Alloys. Inter Metalcast 15, 1362–1374 (2021). https://doi.org/10.1007/s40962-020-00559-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00559-3