Abstract

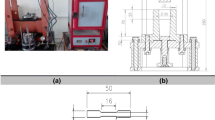

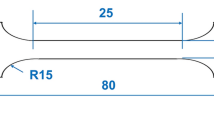

In this paper, the effects of squeeze casting parameters on the wear behavior of A390 aluminum alloy were investigated. For this purpose, the experiment was designed according to L9 Taguchi array that the squeeze pressure (60, 90 and 120 MPa), the superheats of liquid metal (50, 100 and 150 °C) and the die preheating temperature (200, 250 and 300 °C) were selected as the independent variables at three levels. On the contrary, the microstructure characteristics, the weight loss of specimen after wear test and friction coefficient were examined as dependent variables. The microstructural characterizations were also performed using optical microscopy equipped with image analyzer and SEM equipped with EDS. The squeeze casting was performed with a 20-ton hydraulic press in a cylindrical shape. According to the results, the increase in squeezing pressure from 60 to 120 MPa within the tested range leads to a decrease in primary silicon area by 48% and a decrease in silicon eutectic by 44.4%; however, applied pressure did not have any significant effects on morphology of phases. The wear tests were carried out using a computer-controlled pin on disk wear test machine in ambient temperature.

Similar content being viewed by others

References

A.B. El Shalakany, B.M. Kamel, A. Khattab, T.A. Osman, B. Azzam, M. Zaki, Improved mechanical and tribological properties of A356 reinforced by MWCNTs. Fullerenes. Nanotub. Carbon Nanostruct. 26(4), 185–194 (2018)

M. Rosso, I. Peter, C. Bivol, R. Molina, G. Tonno, Development of industrial components by advanced squeeze casting. Int. J. Mater. Form. 3(1), 787–790 (2010)

A. Hekmat-Ardakan, F. Ajersch, Thermodynamic evaluation of hypereutectic Al–Si (A390) alloy with addition of Mg. Acta Mater. 58(9), 3422–3428 (2010)

D.K. Dwivedi, Adhesive wear behaviour of cast aluminium–silicon alloys: overview. Mater. Des. 31(5), 2517–2531 (2010)

S.K. Dey, T.A. Perry, A.T. Alpas, Micromechanisms of low load wear in an Al–18.5% Si alloy. Wear 267, 515–524 (2009)

J. Zhang, A.T. Alpas, Transition between mild and severe wear in aluminium alloys. Acta Mater. 45(2), 513–528 (1997)

F. Alshmri, H.V. Atkinson, S.V. Hainsworth, C. Haidon, S.D.A. Lawes, Dry sliding wear of aluminium-high silicon hypereutectic alloys. Wear 313(1–2), 106–116 (2014)

B. Li, Z.F. Zhang, Z.G. Wang, J. Xu, Q. Zhu, Effect of heat treatment on microstructure and mechanical properties of A390 alloy. Adv. Mater. Res. 654, 1049–1053 (2013)

A.B. Elshalakany, T.A. Osman, A. Khattab, B. Azzam, M. Zaki, Microstructure and mechanical properties of Mwcnts reinforced A356 aluminum alloys cast nanocomposites fabricated by using a combination of rheocasting and squeeze casting techniques. Fullerenes, Nanotubes, Carbon Nanostruct. 26(4), 185–194 (2018)

C.D. Lee, Effects of microporosity on tensile properties of A356 aluminum alloy. Mater. Sci. Eng. 464, 249–254 (2007)

H. Ye, An overview of the development of Al-Si-alloy based material for engine applications. J. Mater. Eng. Perform. 12, 288–297 (2003)

H. Khodaverdizadeh, B. Niroumand, Effects of applied pressure on microstructure and mechanical properties of squeeze cast ductile iron. Mater. Design 32, 4747–4755 (2011)

M.R. Ghomashchi, A. Vikhrov, Squeeze casting: an overview. J. Mater. Process. Technol. 101, 1–9 (2000)

K. Lee, Y.N. Kwon, S. Lee, Effects of eutectic silicon particles on tensile properties and fracture toughness of A356 aluminum alloys fabricated by low-pressure-casting, casting-forging, and squeeze-casting processes. J Alloys Compd 461, 532–541 (2008)

A. Maleki, A. Shafyei, B. Niroumand, Effects of squeeze casting parameters on the microstructure of Lm13 alloy. J. Mater. Process. Technol. 209, 3790–3797 (2009)

M.T. Abou El-Khair, Microstructure characterization and tensile properties of squeeze-cast alsimg alloys. Mater. Lett. 59, 894–900 (2005)

S.A. Hassasi, M. Abbasi, S.J. Hosseinipour, Parametric investigation of squeeze casting process on the microstructure characteristics and mechanical properties of A390 aluminum alloy. Int. J. Met. 14(1), 69–83 (2020)

ASTM G99-04 (2011) Standard test method for wear testing with a pin-on-disk apparatus, 05: 1–5

B. Gajdzik, Crystallization and structure of cast A390.0 alloy with melt overheating temperature. Metalurgija 51, 321–324 (2012)

R. Li, L. Liu, L. Zhang, J. Sun, Y. Shi, B. Yu, Effect of squeeze casting on microstructure and mechanical properties of hypereutectic Al–X Si alloys. J. Mater. Sci. Technol. 33(4), 404–410 (2017)

Q. Zhang, M. Masoumi, H. Hu, Influence of applied pressure on tensile behaviour and microstructure of squeeze cast Mg alloy Am 50 with Ca addition. J. Mater. Eng. Perform. 21(1), 38–46 (2012)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hassasi, S.A., Abbasi, M. & Hosseinipour, S.J. Effect of Squeeze Casting Parameters on the Wear Properties of A390 Aluminum Alloy. Inter Metalcast 15, 852–863 (2021). https://doi.org/10.1007/s40962-020-00507-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00507-1