Abstract

Some results of materials characterization activities, dedicated to classical and notch mechanics fatigue and elastoplastic properties, have already been published for some Ferritic–Pearlitic Ductile Iron, including the patented heat treated Isothermed (IDI) and Austempered Ductile Iron (ADI) grades. Others have not yet been published. The possible use of all of these results in new standards is discussed in this paper. It is proposed that new standards should provide a criterion that is able to measure the process quality that represents more accurately the actual market needs and manufacturing capabilities. Classification of grades, considered by existing standards, is based on minimum properties for strength and ductility parameters that are separately evaluated. A different approach that is based on a quality index, which considers strength and ductility all in one, is proposed. However, this new proposed approach may not be sufficient to provide a satisfactory classification for the ADIs. This is because their fracture mechanical behavior and machinability can be correlated with their austenite stability. It could also be insufficient for the classification of the recent High Silicon Solid Solution Strengthened Ductile Irons that exhibit a decreasing ultimate tensile strength/proof stress ratio with increasing Si. For construction steels, fracture mechanics properties are sometimes believed to be related to the Charpy impact energy. This paper introduces an innovative practical and inexpensive data analysis, performed on the tensile test curve, which appears to be a potential estimator of fracture mechanical properties, at least for ADIs, where said properties could be correlated with the austenite stability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ductile iron, also referred to as nodular iron or spheroidal graphite iron, was patented in 1948. In this material, the graphite occurs as spheroids rather than flakes as in gray irons, providing unique combinations of mechanical properties. The high C and Si content provide the casting process advantages. The different grades are produced by controlling the matrix structure around the graphite either as cast or by subsequent heat treatment. Only minor compositional differences exist among the regular grades, and these adjustments are made to promote the desired matrix microstructures.1

Since early 1970s, Fiat standard 52215 provides indications for Ferritic–Pearlitic Ductile Iron grades having significantly improved minimum tensile properties, compared with grades indicated in ISO and other continental or national standards (hereafter indicated as “conventional standard”). The Fiat standard does not indicate special processes, but better processes (displacement toward top—right in a elongation at fracture A5 versus ultimate tensile strength R m diagram) and a narrower hardness range control.2

More recently, another improved approach has been proposed by an important European foundry Company (+GF + Silicon Boron Durability: SiBoDur).3

In the following discussions, the Fiat 52215 and +GF + SiBoDur materials are referred as “Non-Conventional Ferritic–Pearlitic” Ductile Irons (NCFPDIs).

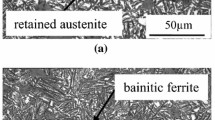

In 2006, Zanardi Fonderie submitted a patent application (now granted patent in several countries) for a material called “Isothermed Ductile Iron (IDI) with Perferritic matrix.” Isothermed and perferritic are neologisms; the first refers to the heat treatment while the latter to the matrix structure.4 An un-alloyed ferritic ductile iron casting is austenitized in the intercritical range, developing a convenient fraction of proeutectoidic ferrite. As a result of quenching in a salt bath (above the Ms), the austenite (without alloying) transforms into pearlite. The resultant structure, showing interconnected phases (see Figure 1), is called “perferrite,” different from the as cast bull-eye structure, where ferrite is isolated and surrounded by pearlite. This unique microstructure is the reason why it is possible to achieve the strength of fully pearlitic grades, even in the presence of a significant ferrite fraction.5

Under uniaxial tensile test conditions, both NCFPDIs and IDIs exhibit considerable ductility, which is mainly due to the presence of large ferrite fraction, that supports the use of von Mises yield criterion.6

Recently, new classes of high-performing ductile iron have become commercially available. In the European Standard EN 1563:2012, new grades of Si-alloyed ductile cast irons were introduced with increased strength and improved machinability. These grades are conventionally referred to as “Solid Solution Strengthened” Ferritic Ductile Irons (SSSFDIs).

The austempering process is a high performance, isothermal heat treating process that imparts superior properties to ferrous materials. The application of the austempering process to ductile irons produced a class of materials called austempered ductile iron (ADI) having a strength-to-weight ratio that exceeds that of aluminum.7 Unfortunately, the selection of ADIs as design materials has suffered, due to the lack of shared information on the technology to produce it and limited references in engineering textbooks and databases.

The structural design of castings is mostly based on design allowances, reported in specifications and standards that are experimentally determined primarily from a tensile test. However, other informative properties, such as fatigue strength, are considered.

Conventional tensile test results are representative of the material properties when performed on separately cast samples that are assumed to be free of flaws. In castings, the presence of flaws mainly influences the local fatigue strength. On the contrary, the ductility of the casting as a whole, i.e., the capability to deform plastically, is usually influenced to a minor extent by small size defects. Consequently, quasi-static tensile tests that are performed on samples extracted from casting regions, do not necessarily return material property values that are representative of the actual material design properties.

All material properties subsequently mentioned are obtained from separately cast test pieces—25 mm diameter Lynchburg bar and/or vertical rectangular specimen with cast-on feeder, Y 25 mm.

The present work aims to provide a framework for the future “all structural ductile irons” (XDIs) material standards, able to normatively classify: quality level (plastic properties), uniformity (hardness range), in addition to the grade (minimum strength). This aim is not new as this concept was already proposed by the author et al. to international standardization committees in the past.8 In fact, the first announcement of this idea originates with Siefer and Ortis in 1970, followed by Crew in 1974 and by Venugopalan and Alagarsamy in 1990, as reported in Ref. 9.

In actual international material standards, the designation table communicates to designers a brittle behavior for grades having minimum ultimate tensile strength (UTS, R m) equal or greater than 600 MPa. The designation values are so low because they consider a wide range of processes and a wide range of hardnesses.

The Ferritic Pearlitic Ductile Irons State of the Art

The Material Quality Index MQI

A plot of the elongation at fracture (A 5) versus ultimate tensile strength (R m) for the minimum properties of conventional and non-conventional grades is shown in Figure 2. The black dotted trend line:

best fitting the minimum properties of non-conventional ferritic (SSSFDI) and ferritic–pearlitic (NCFPDI and IDI) ductile iron grades is included in Figure 2. Also included for comparison purposes is the ADI grade ISO 17804/JS/800–10.

It is evident that a necessary condition to fulfill the minimum properties of a non-conventional grade is that the tensile test will show “Material Quality Index”

However, the condition will not be sufficient if it is necessary to fulfill both minimum properties at both limits of a given hardness (R m) range.

For instance, to fulfill both minimum properties of non-conventional standards in a hardness range of 30 HBW, it approximately requires an MQI ≥ 460.

The Competition in the R p0.2 Range 440–510 MPa

Figure 3 shows the relationship of R m (UTS) versus R p0.2 (yield strength). In the range of yield strength 440–510 MPa, the three different modes SSSFDI, NCFPDI and IDI offer complementary opportunities to designers.

It is worth noting how the dR m/dR p0.2 slope for SSSFDI is significantly lower compared with NCFPDI, IDI and ADI grades (Figure 3). Consequently, SSSFDI high yield grades are affected by a lower (R m − R p0.2) range.

The Si content (4.3 %), necessary for minimum R p0.2 = 470 MPa of EN-GJS-600-10 in EN 1563, is at the upper tolerated level.

It is well known that increasing the silicon content shrinks the process window, as indicated by the Henderson diagram.10 Difficulties in avoiding porosity increase with increasing Si content with the likelihood of chunky graphite forming in wall thicknesses above 60 mm.

As a result, designers should collaborate very closely with foundry engineers before the design final release when specifying SSSFDI. Foundry engineers should, likewise, be very careful during commercialization activities as foundry plant managers will have to keep the process under very accurate control to cast this material.

Nevertheless, considering the above mentioned limitations, the SSSFDI grade EN-GJS-600-10 is expected to be of interest in a wide range of uniform wall thicknesses.

The NCFPDI approach is significantly less critical than SSSFDI at 4.3 % Si. NCFPDI has been common practiced in a number of quality DI foundries since the early 1970s, following Fiat 52215 requirements.2 More recently, the +GF + SiBoDur high strength grades offer important opportunities in the automotive lightweight design initiatives (+GF + calls this approach as “bionic” design).3

The main requirement for a NCFPDI quality foundry process is the ability to control the hardness range in a narrow interval. However, if the casting wall thicknesses are not uniform, it could be difficult to guarantee the benchmark properties in any section when adopting NCFPDIs. This could happen because of the slow cooling rate in sand molds, together with the addition of pearlite promoters, both factors enhancing the hardness differences between different sections of the casting. Hence, these NCFPDI processes should be preferred only for uniform and relatively thin-walled castings.

IDI4 has no limitations with the Si content, which can be selected to avoid the formation of porosity and chunky graphite in different sized sections of the casting, and/or for required Charpy impact values at room or low temperatures. In other words, the as-cast foundry practice is the one generally adopted for conventional fully ferritic grades.

If the casting wall thicknesses are not uniform, it will be easier (comparing with NCFPDI grades) to guarantee the benchmark properties in most sections for IDIs. This happens because no pearlite promoting additions are made and because of the higher (compared with sand molds) cooling rate into the salt bath, which ultimately limits the hardness differences between the different section sizes of the casting. For this reason, IDI could be preferred when section sizes are not uniform and/or are too heavy to get the required non-conventional properties with NCFPDI high strength grades.

Being fully ferritic in the as-cast condition prior to heat treatment, IDI allows the application of the most economic foundry practice in term of feeding system and pre-machining. These advantages are balanced by the heat treatment additional cost.

Numerical Description of the Plastic Flow Curve

When comparing XDIs with steels, little consideration is generally given to the fact that the plastic deformation pattern of XDIs and steels is different.11 Using the Voce approach for different grades of XDIs and for different grades of commercial Q&T steels, coauthor3 developed indicators that are able to discriminate the strain hardening shape of ADIs from those of ferritic–pearlitic DIs and/or steels.12 When applied to one tested ADI, these indicators correlated well with the austempering time (the austenite stabilization progress) more consistently than with the elongation at fracture.13

The different behavior of ADIs obtained by robust processes (stable austenite), compared with non-conventional ferritic SSSFDIs and/or ferritic–pearlitic NCFPDIs and IDIs, is another reason for other superior properties of this material family: ductility, Charpy impact at room and very low temperatures and fracture mechanical properties, together with a good machinability.

It is reasonable to assume that the tensile test curve shape could potentially be a “story telling” about the microstructure and the material process. Microstructure description and its contractual definition are far too simple as communicated in material standards. Typically, the production process is not completely disclosed to the end user for understandable competitive concerns.

If the tensile test curve would be able to tell the story of the process, a great improvement could be envisaged in the field of contractual agreement and on the confidence level offered to designers. The use of this innovative approach as well as further research activities in this direction should be encouraged, with particular regard to ADIs applications.

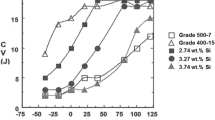

Material Response to Temperature and Strain Rate

Coauthors4 performed uniaxial tensile characterization for the grade ADI UTS min 1050 MPa over the temperature range comprising −60 to +70 °C, and for a strain rate ranging from 0.001 and 1000 s−1, and compared to ADI UTS min 1200 MPa, High Silicon ADI and 42CrMo4 Q&T steel.14 Some results for ADI 1050 are shown in Figure 4. The work will be completed with the curve “strain at failure” versus “triaxiality factor” when special applications will ask for this kind of information.

Charpy Impact Value and Fracture Mechanical Properties

Some designers are concerned with the substitution of steel castings, forgings and weldments with ductile iron castings (XDIs). This could be because, in the lack of fracture mechanics data, some empirical correlations known for families of steels are assumed to also hold true for ductile irons. How this criterion should not be applicable to XDIs is easily verified in ISO 1083, EN 1563, ISO 17804 and also supported by.11 , 15 , 16

A first approach to material selection could assume that the fracture mechanics behavior of XDIs at room temperature is comparable to that of some commercial steels of similar strength. Advising to be careful in evaluating a data collection from multiple testing sources, consider the comparison of a test done with Zanardi samples on an ADI17 with typical properties of forged steel for high-speed trains wheels (Figure 5). Similar evidence was revealed in 1999 in a public report of the Deutsche Bahn Technical Center18 “(In ADI wheels) cracks are propagating at a lesser extent than in the comparable steel wheel samples. Cracks are regularly intercepted by the deformed graphite nodules.” Also in 2005,19 “With respect to the maintenance methods used at present by the German railway company, Deutsche Bahn AG, ADI wheels are usable without objections.”

Figure 5 shows also the properties measured on this last ADI material (ADI19).

For all three materials, the stable crack propagation rate coefficients, C and m, and the threshold stress intensity factor of non-propagating cracks, ΔK th, are taken from the correspondent reports. The slope connecting ΔK th with the stable crack propagation range was estimated by graphical interpretation on the experimental graphs for the two ADIs. It should be noted that a complete graph for steel with an R = 0.1 load ratio was not available in the literature so a slope was estimated graphically from data for an R = 0.3 load ratio.

The slope at the static instability range has been calculated connecting the point showing the beginning of the deviation from linearity (critical rate) with the fracture toughness indicated for each material in the correspondent report associated with a conventional crack propagation rate of 10−5 m/cycle (fracture toughness values are not referred to the same measurement procedure). Table 1 lists the numerical data plotted in Figure 5.

In some cases, the adoption of proper grades of ADI, instead of steels, could give an advantage with regard to the transition temperature as is indicated in Ref. 16.

Once again, a reminder that it is necessary to be careful in simply comparing data from different laboratories. The reader’s attention is directed to the graph in Figure 6 where data coming from references20 and21 have been included.

Referring to Figure 6, one might conclude:

-

1.

For all lines from 5 to 600 [nm/cycle]: Designers willing to consider substituting one grade of steel with ductile iron could have the opportunity to find a grade of ductile iron having a similar or better crack propagation rate;

-

2.

Lines 70 versus 200: Demonstrate that the modern manufacturing processes for Ferritic–Pearlitic Ductile Irons are significantly better than old ones;

-

3.

Line 70: Pearlitic, Ferritic–Pearlitic, Ferritic grades (dots from top left to bottom right) obtained by the same principal process do not show significant differences in the crack propagation rate;

-

4.

Line 20 versus 50: The same grade of ADI can show different crack propagation rates, depending on the quality of the manufacturing process (The authors propose this occurs because of a dependence on the austenite stability);

-

5.

Line 50 versus 70: Austempered Ductile Irons crack propagation rates are not significantly different from those of conventional Ferritic–Pearlitic grades.

Even in the absence of a wide and consistent experimental support, the authors consider the sentences from 1 to 4 as reasonable and sentence 5 as incorrect. These statements are made because the results for the tested materials do not report processing details which results in a generalization of the results. Unfortunately, this kind of approach is sometimes found in the literature. A consequence of this has been the unintended creation of obstacles to the growth of ADI materials in some countries.

What appears to be evident to the authors is the urgent need to have, in the standards, normative procedures for evaluating the material quality, enabling the informative prediction for some critical design parameters (e.g., for ADI: fracture mechanical properties, machinability, in some cases constitutive plastic flow at low temperatures and high strain rate).

For designers, tensile properties, Brinell hardness and their correlation with the infinite life fatigue strength on un-notched specimens are not sufficient to warrant a conversion from steel to XDIs in critical applications.

Proposal for an Improved Approach to the XDIs Material Standards

New XDIs material standards should be divided into two separate sections: normative and informative.

Normative Section

Normative section, the base for contractual agreements and process and/or product control, should be based on the following principal dimensions:

-

1.

QUALITY INDEX

-

2.

PLASTIC FLOW SHAPE/FRACTURE AND NOTCH MECHANICS

-

3.

GRADE: minimum R m and/or HB

-

4.

UNIFORMITY: range (HBmax − HBmin)

Quality Index

With reference to Figure 7, a quality index

is proposed for SSSFDIs, NCFPDIs and IDIs grades.

In a previous works,8 this expression was found to be the best fit for the experimental data from a uniform process. Being the dominating variable, the material hardness was influenced by the pearlite content.

For ADI grades, the proposed quality index is now defined as

The two expressions lead to approximately the same value for MQI when R m = 750–900 MPa (region D in Figure 7). In this way, a direct quality comparison between IDI and ADI in the region D, where both exist, can be made.

MQI-FP = 360 is the level described by the existing non-conventional material standards minimum properties (dotted line), while 460 is the level necessary to allow a ΔHBW = 30, representing the minimum non-conventional requirements.

MQI-ADI = 600 (dotted line) is the level corresponding to the minimum properties of the existing grade ISO 17804/JS/800-10 and approximately to the grades ISO 17804/JS/900-8 and ISO 17804/JS/1050-6.

It is assumed that the same MQI can be extended to the higher strength ADIs. The level 660 is necessary to allow a ΔHB = 30, respecting the minimum non-conventional requirements.

For SSSFDIs, NCFPDIs and IDIs, the minimum proposed levels of MQI (ensuring a minimum A5 = 5 %) could be regarded as necessary condition for the adoption of the Von Mises yielding criterion even for the highest grades. In this way, the range of UTS R m = 600–900 MPa will be available to design for substitution of steels.

In the case of ADI, when achieving MQI-ADI = 600/660, a 5 % minimum elongation is ensured only for ADIs having UTS R m ≈ 1200 MPa. It could be of interest to evaluate if the von Mises yielding criterion could apply to the higher strength ADIs only upon availability of processes based on better MQI-ADI index.

To ensure a minimum MQI value, the material testing standards should also require that room temperature quasi-static tensile tests be performed on separately cast test samples and/or be cut from defect free areas (at the manufacturer’s discretion) within the casting.

Plastic Flow Shape/Fracture and Notch Mechanics

For a given UTS (R m) and elongation at fracture (A5), the shape of the plastic flow curve can be very different, when comparing ductile irons vs steel and between ductile irons having a different matrix (e.g., ferritic–pearlitic and ausferritic). It was suggested11 that this different shape could be responsible for different Charpy impact values.

The new standards should consider some evaluation of the plastic flow shape, assuming a correlation exists with fracture and/or notch mechanical properties. The most simple shape factor to be considered is the R m versus R p0.2 relationship.

Material standards should require a minimum value for R m versus R p0.2 for all grades. Measurements discriminating the plastic flow curve shape could be required, following the Voce approach and, as described above, if in the future this suggested practice will be considered. Charpy impact energy on un-notched test probes could be maintained for grades behaving on the upper shelf at the test temperature.

Alternatively, a direct measure of fracture or notched mechanical properties could be considered on test probes taken from the casting at a location left to the designer’s discretion. The following types of testing could be suggested:

-

a)

un-notched finite life number of cycles at a given load;

-

b)

un-notched infinite life fatigue limit measured using only one test probe (e.g., Locati method);

-

c)

fracture toughness estimated by a tensile test on a round sharply notched test probe.

Testing following a) and/or b) measures the material properties and the effects of the presence of a defect, if any, inside the test probe. This approach could be of interest for the designer asking the foundry for a given performance at a critical location in the casting, without regarding if unsatisfactory results are coming from poor material or from a defect. This approach could, also, be accepted by foundries because what is measured is what is needed, fatigue strength, and not a non-correlated variable, as is elongation at fracture in the conventional tensile test.

Testing following a) is currently in use (on sound test probes) for the construction of the Wöhler SN curve, for the determination of the smooth fatigue strength.

Testing following b) has been used at Zanardi Fonderie for determining the fatigue strength of ADI on un-machined surfaces.5 Defects on un-machined surfaces are not sharp enough to behave like cracks. For this, the Wöhler SN curve slope is sufficient enough to enable the use of Locati method.

Testing following c) should measure only the material properties and not the effect of a defect, assumed to be less critical compared with a sharp notch. A testing procedure is under development at Padova University, Department. of Mechanical Engineering.22 , 23

The use of fatigue testing using sharply notched test probes should not be recommended as a current test in a material standard. In fact, with this kind of test probes, the Wöhler SN curve shows a low slope, limiting the applicability of the Locati method.

Sharply notched test probes are of current use for the determination of the Threshold Value of the Stress Intensity Factor ΔKth [MPa m0.5]; however, a number of test probes are required, using classical methods (e.g., staircase), limiting the applicability to research and general characterization activities.

Grade

On the same tensile test probe, the Brinell hardness (HBW) should be measured and correlated with the measured R m and R p0.2. Using standard relationships,

value for the minimum hardness to be measured at the selected location on the casting should be established, as required from the “Grade.”

Uniformity

The maximum hardness, to be measured at the selected location on the casting, should be defined following the required “Uniformity”:

Informative Section

Informative section or the base for design should describe the design properties expected when the normative requirements are fulfilled.

This part of the standard should indicate the expected design properties including:

-

1.

infinite life fatigue properties in un-notched, sharply notched and un-machined conditions at room temperature;

-

2.

stabilized cyclic curve and strain controlled low cycle fatigue properties at room temperature;

-

3.

wear resistance properties at room temperature;

-

4.

machining properties;

-

5.

tensile plastic flow constitutive curve for different strain rates and temperatures;

-

6.

contact fatigue and tooth root bending fatigue properties for gear applications at room temperature;

-

7.

Paris law parameters at room temperature;

-

8.

fracture toughness values at room and low temperatures;

-

9.

stress strain curves in bending, torsion, compression

-

10.

other properties (e.g., weldability,…).

Conclusions

A new normative approach for nodular and/or spheroidal graphite and/or ductile iron—including non-conventional ferritic–pearlitic (in as cast or heat treated state), High Silicon as cast Ferritic “Solid Solution Strengthened” as well as Ausferritic Austempered grades—is herein described.

In “Normative” section, material classification should be mainly based upon measurements coming from the uniaxial tensile test on test probes taken from Lynchburg 25 mm in diameter (L25) and/or 25 mm in thickness (Y25) test samples, and considering not only the conventional values R m, R p0.2, A5, HBW, but also a combination of these and, possibly in the future, a measurement of the strain hardening profile of the tensile test curve.

A separate “informative” part of the standard should indicate the expected design properties, corresponding to the values measured following the normative requirements, not only in the wall thickness corresponding to the L25 or Y25 test samples but also on greater wall thicknesses, typically corresponding to the standard test samples Y50, Y75, Y100 (dimensions in mm).

A wider development of ductile iron castings applications, in substitution of steel components, requires an improved confidence by designers on the material fracture mechanical properties.

Future research work should be dedicated to verify how a fracture toughness test, executed by mean of a tensile test on a sharply notched round test probe, could be representative of the entire fracture mechanical behavior, including the threshold ΔK th and the Paris’ law da/dN = C (ΔK)m.

Hopefully, a correlation could be verified between the results of said fracture toughness test and measurements on the plastic flow curve shape. If a strong correlation will be found to occur, a simple conventional tensile test, with novel data analysis, would be found sufficient to assure the confidence on the material fracture mechanical properties.

Charpy impact energy on un-notched test probes could be considered an ancillary test for those grades behaving on the upper shelf at the test temperature and also for the estimation of the transition temperature.

A number of the required information is already available on Zanardi Fonderie materials, tested at the foundry laboratory and/or at University or external laboratories.

The available data have two main limitations:

-

they have not been planned and analyzed under a consistent and robust statistical framework;

-

with a few exceptions, they are referred to separately cast test bars Lynchburg diameter 25 mm and/or Y25 mm.

A complete critical revision of the work, which has already been done, formalization of the testing procedures, re-testing inside a consistent and robust statistical framework with extension to Y50, Y75, Y100 mm, should be strongly encouraged.

The a.m. activities could be regarded as a pre-work item in view of new material standards.

The release of a parallel comparative handbook that is dedicated to casting design with ductile iron materials and component design using steel castings, forgings, fabrications, should also be considered.

New standards could design “Informative section” providing description of testing and data analysis procedures together with an open framework of tables, where a number of cells could be filled up by cooperating organizations, following priorities indicated by the market.

References

F. Iacoviello, V. Di Cocco. Ductile irons: ferritic—pearlitic. in Encyclopedia of Iron, Steel, and Their Alloys (Taylor and Francis, New York), pp 1126–1131

Fiat Auto Normazione: Ghisa a grafite sferoidale—Norma materiali 52215

S. Hess: Lightweight by bionic design approach—Georg Fischer Automotive 09.10.2014

Zanardi Fonderie SpA: Method for manufacturing spheroidal cast iron mechanical components—Patent granted Europe, USA, China, Hong Kong

S. Masaggia, The development of ADI and IDI in Italy. Procedia Engineering 2(2010), 1459–1476 (2010)

N. Bonora, A. Ruggiero, Micromechanical modeling of composites with mechanical interface–Part II: damage mechanics assessment. Compos. Sci. Technol. 66(2), 323–332 (2006)

J.R. Keough, K.L. Hayrynen, G.L. Pioszak. Designing with Austempered Ductile Iron (ADI). AFS Proc. 1–15 (2010)

F. Zanardi, ISO/TC 25/SC 2/WG 1 NYYY 2001-12-10, R. Gast, Procedure for the Adoption of a Material Quality Index (John Deere, USA; Zanardi Fonderie, Italy)

Ductile Iron Data for Design Engineers/Section III Engineering Data/Part 1 Tensile Properties/Relationships between Tensile Properties www.ductile.org

American Foundrymen Society: Ductile Iron Handbook ISBN 0-87433-124-2: 1992

F. Zanardi: Ductile iron, isothermed ductile iron, and austempered ductile iron material structural design, 2013 Keith Millis Symposium on Ductile Cast Iron

G. Angella, F. Zanardi, R. Donnini, On the significance to use dislocation-density-related constitutive equations to correlate strain hardening with microstructure of metallic alloys: the case of conventional and austempered ductile irons. J. Alloys Compd. 669, 262 e 271 (2016)

R. Donnini, F. Zanardi, M. Maldini, G. Angella, Studio dell’avanzamento del processo di austempering attraverso l’analisi meccanica e microstrutturale dell’ausferrite, in Congresso AIM 2016

A. Ruggiero, G. Iannitti, ADI 1050 costitutive model compared with ADI 1200, SiSSADI and 42CrMo4 Q&T steel. Unpublished

Transactions of the American Foundrymen’s Society 106: Martinez, Boeri et al. (1998)—Impact and Fracture Properties of ADI, compared with SAE 4140 Steel

Applied Process—Letting Mr. Charpy die: evaluating the usefulness of Charpy impact testing on Ductile Iron—Meghan Oaks

E. Gasparini, G. Meneghetti, Una banca dati sul comportamento a fatica delle ghise sferoidali austemperate, XXX Convegno Nazionale AIAS—Alghero (SS), 12–15 settembre 2001 (E. Gasparini, Caratterizzazione meccanica delle ghise sferoidali austemperate, Tesi di Laurea, Dipartimento di Ingegneria Meccanica, Università di Padova, A. A. 1999–2000

On the Suitability of ADI as an Alternative Material for (Railcar) Wheels—Dr. Katrin Mädler, Deutsche Bahn Technical Center

M. Kuna, M. Springman, M. Mädler, P. Hübner, G. Pusch, Fracture mechanics based design of a railway wheel made of austempered ductile iron”. Eng. Fracture Mech. 72, 241–253 (2005)

F. Iacoviello, O. Di Bartolomeo, M. Cavallini, Resistenza alla propagazione delle cricche di fatica nelle ghise sferoidali austemperate, Conference paper 2004, www.researchgate.net/publication/255785371

H.Z. Boyerd, Atlas of Fatigue Curves. (ASM International, New York, 1989)

E. Cordioli, G. Meneghetti, S. Masaggia, E. Veneri, Studio Teorico e Sperimentale Per Ricavare la Tenacità a Frattura di Una Ghisa Sferoidale Austemperata, Master Thesis, Dipartimento di Ingegneria Industriale, Università di Padova, A. A. 2011–2012

R. Crudo, G. Meneghetti, Stima Sperimentale Della Tenacità a Frattura di Ghise Sferoidali Austemperate ADI 1000, ADI 1200 e Acciaio 39NiCrMo3, Master Thesis, Dipartimento di Ingegneria Industriale, Università di Padova, A. A. 2014-2015

Acknowledgments

The corresponding author is grateful to the Department. of Mechanical Engineering, University of Padova, particularly to prof. Giovanni Meneghetti who in the last 15 years strongly contributed in the field of fatigue design in the presence of defects. Thank you to Dr. Kathy Hayrynen, PhD (Applied Process) for her kind help in reviewing the text.

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article is available at http://dx.doi.org/10.1007/s40962-017-0145-8.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Zanardi, F., Bonollo, F., Angella, G. et al. A Contribution to New Material Standards for Ductile Irons and Austempered Ductile Irons. Inter Metalcast 11, 136–147 (2017). https://doi.org/10.1007/s40962-016-0095-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-016-0095-6