Abstract

Dam stability is one of the most important issues in hydraulic engineering. Microfractures and damage commonly occur during impoundment, which might lead to serious dam problems. In this study, based on the engineering background of the Sanhekou hydropower station, microseismic monitoring and numerical simulation were employed to systematically investigate the microfracture and damage characteristics of the dam body. First, the microseismic monitoring system was established to capture the microfractures inside the dam. The results indicated that the rise in water level elevation has a significant effect on the microfracture and damage characteristics of the dam body, especially during the early stage of impoundment. This can be reflected by the variation in the derived source parameters, i.e., the b value, daily energy release, daily apparent stress and daily apparent volume. In addition, the failure mode of the microfractures could be determined by using the ES/EP value of microseismic events and the moment tensor inversion method. The cracking orientation of the failure surfaces could also be determined by the moment tensor inversion method. Subsequently, numerical simulation was conducted where the initial damage of the dam was considered by integrating the microseismic monitoring data. The simulation results suggested that dam deformation under impoundment considering microseismic feedback agrees well with the real field measured results. The stress level of the dam toe was larger than that of the dam heel, and both the dam toe and dam heel were under compression before impoundment. However, with increasing water level elevation, the stress status of the dam heel area changes from compression to tension. The findings in this study will provide a better understanding of the damage and failure mechanism of dams during impoundment, which might be helpful for the design and support of dams in hydropower stations.

Article Highlights

-

Microseismic monitoring was conducted to capture the microfractures inside the dam during impoundment.

-

Damage evolution of the dam during impoundment was investigated.

-

Cracking mechanism of the dam were analysed using moment tensor inversion method.

-

Numerical simulation was carried out by considering the initial damage within the dam body.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The stability of a dam body during construction and operation periods is one of the most important issues in hydraulic engineering. In the life cycle of a dam, there is a high incidence period of dam accidents during the initial impoundment stage because in this period, the dam body and foundation are prone to local deformation, damage and cracking, which might cause serious economic and social consequences. For example, the Malpasset arch dam in France suddenly broke due to water storage seepage of the left bank (Jaeger 1963). Numerous internal cracks developed during the first impoundment of France's Tolla dam, which brought substantial difficulties to subsequent normal operations (Corns et al. 1988). Therefore, to ensure dam stability during the impounding period, it is of great engineering significance to investigate the deformation and stress distribution of the dam during the impounding process and reveal the underlying mechanism of the microdamage in the dam body.

The fractures of a dam during the impounding process are commonly located inside the dam body. Therefore, it is difficult for the traditional on-site method to effectively determine the accuracy of fracture information, e.g., fracture location, energy release and crack length. The microseismic monitoring technique has advantages in obtaining multiple source information of the internal fractures of rocks and other brittle materials. This technique has been widely used in the fields of rock engineering to characterize slopes (Spillmann et al. 2007; Occhiena et al. 2014; Liu et al. 2018), underground tunnels (Huang et al. 2022; Li et al. 2022a, b), mines (Shi et al. 2022; Li et al. 2022a, b; Dong et al. 2020) and hydraulic fields (Liu et al. 2017; Zhuang et al. 2019). Xiao et al. (2022) established a microseismic monitoring system at the Shuangjiangkou hydropower station, and the temporal and spatial characteristics of the microfractures of the underground powerhouse were analysed in detail. A constitutive relation of the surrounding rocks was developed based on the influencing radius of the microseismic events. He et al. (2016) systematically analysed the characteristics of microseismic events before and after the impoundment of the Guanyinyan hydropower station and further evaluated the potential risk of the dam. Ma et al. (2017) analysed the stability of the rock slopes of the Dagangshan hydropower station using the microseismic monitoring technique. A hybrid microseismic energy density and microseismic magnitude-frequency method was developed to determine slope stability. However, it should be noted that although microseismic monitoring has been widely used in the field of rock engineering, there are relatively few studies on the stability of the dam body using this technology, especially the damage and failure evolution of the dam body during the impoundment stage.

The numerical simulation method is another effective method to determine dam stability during the impounding process owing to its convenience in obtaining the deformation and stress characteristics of any location in the dam body. In addition, with rapid improvements in computing methods and hardware, it is possible to conduct large-scale analyses of actual rock engineering problems. Wang et al. (2020) utilized the modified nonlinear finite element program to study the abutment movements of the Jinping arch dam based on the theory of the effective stress principle. Kim et al. (2014) investigated the deformation characteristics of the Dagu dam in South Korea before and after impoundment based on the two-dimensional finite element method. The simulation results demonstrated that the downstream stilling basin has little effect on dam deformation, and with increasing water level elevation upstream, both the deformation along the downstream direction and vertical direction increase. Mahinroosta et al. (2015) proposed a new collapse prediction framework and integrated it into a numerical model to investigate the collapse settlement of a 178 m high rockfill dam during the impounding process. The effect of the first filling rate on dam deformation was simulated.

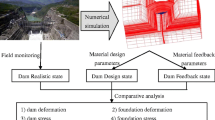

Although numerous efforts have been made to analyse dam stability using the numerical simulation method, it should be noted that the simulation parameters in previous studies, especially with regard to the mechanical properties of the materials, are commonly determined by early field test results, which fail to consider the local damage of the rocks and concrete during the construction and impoundment of the dam body. Notably, the deviation of the simulation parameters may cause inaccurate simulation results. Some scholars have tried to modify the material parameters before conducting simulations. Xu et al. (2014) conducted a feedback analysis of the stability of a dam based on the finite element method, and the initial damage of the dam body was taken into consideration according to the microseismic data. Zhao et al. (2017, 2019) combined field monitoring data with numerical simulation results to determine the stability of an underground tunnel. The initial damage degree of the rocks was calculated based on the source parameters derived from field monitoring and the releasable energy derived from numerical simulation. Although preliminary numerical investigations considering the initial damage have been carried out to analyse rock engineering problems, there is basically no relevant work in analysing the mechanical responses of dams during the impounding process.

In this study, to investigate the microfracture characteristics and damage evolution of the dam during the impounding process at the Sanhekou hydropower station, microseismic monitoring and numerical simulation methods were employed. First, a microseismic monitoring system was established to capture the microfracture characteristics inside the dam body. Microseismic events and source parameter characteristics were systematically analysed to determine the microfracture and damage behaviours of the dam body. Subsequently, the initial damage derived by the microseismic events was further integrated into the numerical model. Both the displacement and stress evolution inside the dam body during the impounding process were numerically investigated. The findings in this study can provide a more accurate understanding of the microfracture and damage evolution of dams during the impounding process.

2 Overview of the Sanhekou hydropower station

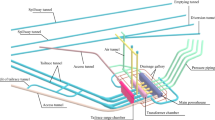

As an important part of the Hanjiang-to-Weihe River Valley Water Diversion Project, the Sanhekou hydropower station, located in Shaanxi Province, China, has a full reservoir capacity, a regulating reservoir capacity and an installed hydropower capacity of 7.1 × 108 m3, 6.62 × 108 m3 and 60 MW, respectively, as shown in Fig. 1. The rolled concrete dam of the Sanhekou hydropower station is designed in the shape of a double-curvature arch, with a maximum height and crest width of 145 m and 9 m, respectively. Figure 2 illustrates the schematic diagram of the Sanhekou Dam from the front view. The bottom and top elevations of the dam are 501 m and 646 m, respectively. The dam can be divided into 10 sections, and the maximum width of the crown cantilever is approximately 40 m. Notably, there are three traffic galleries, i.e., the 515 m traffic gallery, 565 m traffic gallery and 610 m traffic gallery, located in the dam body, with elevations of 515 m, 565 m and 610 m, respectively.

3 Analysis of microseismic activities

3.1 Setup of the microseismic monitoring system

A microseismic monitoring system from ESG corporation was established at the Sanhekou hydropower station to monitor the microfracture characteristics in the dam body. The microseismic monitoring system mainly consists of acceleration sensors, a Paladin digital signal acquisition system, a Hyperion digital signal processing system, a data communication modem, cables and optical fibers. Figure 3 illustrates the layout of acceleration sensors in the Sanhekou Dam from both three-dimensional and plane views. Six acceleration sensors with a high sensitivity value of 30 V/g and response frequency ranging from 0.05 to 5 kHz were embedded in a 515 m traffic gallery and the access gallery at a certain distance. Notably, those sensors have the ability to capture the microfracture signals within a radius of 100 m. Figure 4 shows the network topology diagram of the microseismic monitoring system. The microfracture signals captured by acceleration sensors are first transmitted to the Hyperion digital signal processing system through the cables and optical fibers for storage. On-site technicians have the authority to access and process these data at any time for the early warning analysis.

To ensure the accuracy of the positioning results, the field knock test was carried out to determine an optimal p-wave velocity. As the P-wave velocity in concrete materials is roughly within the range of 3500–5000 m/s, the different values of the P-wave velocity with an increment of 100 m/s were analysed. Figure 5 depicts the variation in the positioning error with increasing defined P-wave velocity. The optimal P-wave velocity should be 4100 m/s for the microseismic monitoring system of Sanhekou Hydropower station, and the corresponding positioning error is approximately 7.59 m.

3.2 Temporal, spatial and intensity characteristics of microseismic events

Figure 6 illustrates the spatial distribution of all microseismic events of the Sanhekou Dam from January 13, 2021, to August 10, 2021, where the water level elevation in this period increased from 551.2 to 596.3 m. Note that each sphere in Fig. 6 demonstrates a microseismic event, and the colour of spheres refers to the moment magnitude of the events. The microseismic events were distributed in a large area of the dam at an elevation from 506 to 630 m but were mainly concentrated at the bottom and middle areas of the dam, i.e., at an elevation ranging from 506 to 550 m.

Figure 7 depicts the time series of daily microseismic event counts, accumulative release energy and water level elevation from January 13, 2021, to August 10, 2021. The dam body was in a calm stage from January to March. In this stage, both the daily microseismic event counts and accumulative release energy were under a very low level. The obvious increase in the daily microseismic event count first appeared from April 7, 2021, to April 15, 2021. A total of 110 microseismic events were captured, with a dramatic increase in the accumulative energy release (approximately 8 times growth from 0.8 × 104 to 6.4 × 104 J). Notably, the water level elevation exhibited a nearly linear increase throughout March and April. However, during this timeframe, the cumulative energy release curve experienced a rapid surge, particularly upon surpassing the 565 m water storage level. This indicates that when the water level exceeds 565 m, many micro-cracks have developed inside the dam body, and these cracks may further develop into macro-cracks. After April 20, 2021, the dam was under continuous impounding and the water level elevation rose from 570 to 592 m. There were two sudden increases in the daily microseismic events count. However, the accumulative energy release did not show an obvious growth trend, demonstrating that microfractures that occurred during this period did not affect the stability of the dam body.

3.3 Seismic source mechanism analysis

3.3.1 The b value and daily energy release

The b value is a parameter describing the distribution of seismic events with different magnitudes, which was proposed by Gutenberg and Richter (1944) and can be expressed as:

where M0 is the magnitude of the seismic events, N(M0) is the frequency of the seismic events with magnitudes exceeding M0 and parameter a represents the seismic activity level.

As both the seismic event count and the accumulated energy release increased significantly from April 7, 2021 to April 9, 2021, the variations in the b value and daily energy release from March 23, 2021 to April 20, 2021, were analysed in detail in this section, as shown in Fig. 8. Notably, there is a close relationship between the rock fracture characteristics and the variation in the b value (Ma et al. 2022). With decreasing b values, the proportion of microseismic events with large magnitudes increases, indicating that the rock masses might be in an unstable state. Figure 8 shows that although both the b value and daily energy release fluctuated from March 20 to April 1, they basically remained at a stable level. However, after April 1, the daily energy release showed an obvious upwards trend. At the same time, the b value roughly decreases before gradually increasing. Notably, the daily energy release and b value reached the maximum and minimum values on April 7, indicating that there was a large degree of fractures inside the dam. This is also very consistent with the actual field observations; that is, on April 7, a circular crack with a width of 12 mm appeared in the access gallery, as shown in Fig. 9.

3.3.2 Daily apparent stress and daily apparent volume

The apparent stress can represent the stress level of the dam body to a certain extent. With increasing apparent stress, the possibility of microfractures in the rock masses increases. In addition, the rapid increase in apparent volume is also an important indicator that can reflect the microfractures of the rock masses. In this section, the variations in the daily apparent stress and daily apparent volume of all microseismic events from March 23, 2021 to April 20, 2021 were analysed in detail.

Figure 10 illustrates the daily apparent stress and daily apparent volume versus time. During the period from March 23 to April 20, the daily apparent stress showed four obvious variation stages, exhibiting the characteristics of rapidly increasing before decreasing. In the first stage, i.e., from March 23 to March 29, the apparent stress first increases to approximately 0.027 MPa before falling to a very low level of 0.005221 MPa. In addition, the daily apparent volume also showed a slightly increasing trend. In the second stage, i.e., from March 29 to April 5, the daily apparent stress increases again to approximately 0.154 MPa before dropping to 0.00608 MPa. A similar phenomenon was also captured for the condition of the daily apparent volume. In the third stage, i.e., from April 5 to April 11, significant increases in the daily apparent stress and daily apparent volume were found. Both the daily apparent stress and apparent volume increased to maximum values of 135 MPa and 2.42 × 104 m3, respectively, on April 7, which is also the time when the circular crack of the access gallery occurred. In the fourth stage, i.e., from April 11 to April 21, the magnitude of the daily apparent stress during this period is approximately 0.28 MPa, which is much less than that in the third stage. Interestingly, although both increases in the daily apparent stress and daily apparent volume were found in those four stages, the time for the increase in daily apparent volume lagged behind that for the increase in daily apparent stress, particularly in the fourth stage.

3.3.3 P wave and S wave energy

In seismology, the ratio of the S wave energy to P wave energy, i.e., Es/Ep, is an important indicator that can reflect the failure mechanism of rocks. Previous investigations have suggested that rock fracture is caused by tensile failure if Es/Ep is less than 3, the failure mode is mixed fracture if Es/Ep ranges from 3 and 10, and the fracture of rocks is dominated by shear failure if Es/Ep is larger than 10 (Boatwright and Fletcher 1984; Hudyma and Potvin 2010). However, the above classification might not be suitable for concrete materials, especially the concrete of the Sanhekou Dam. In this section, the classification of Es/Ep in determining the microfracture modes in the Sanhekou Dam is first proposed. Then, the failure mechanics of the Sanhekou Dam are analysed.

Our previous studies have demonstrated that the circular cracks on the top of the gallery in the Sanhekou Dam are caused by tensile failure (Zhuang et al. 2019). Hence, a total of 30 seismic events near the circular cracks on the top of galleries in the Sanhekou Dam were screened out, and the Es/Ep values of those seismic events were analysed. To better understand the distribution characteristics of Es/Ep of those seismic events, ten segments of Es/Ep from 0 to 10 were produced. Figure 11 illustrates the proportion of microseismic events in different segments, where segment 1 refers to Es/Ep values ranging from 0 to 1, and segment 2 refers to Es/Ep values ranging from 1 to 2. All microseismic events were located from segment 1 to segment 9, demonstrating that the Es/Ep values of all microseismic events are less than 9. Hence, for the determination of the failure mode inside the dam body of the Sanhekou hydropower station, microfractures with Es/Ep values less than 9 are caused by tensile failure. Correspondingly, microfractures with Es/Ep values larger than 9 are caused by shear or mixed failure.

Table 1 summarizes the distribution of the Es/Ep values of all microseismic events from January 13, 2021, to August 10, 2021. It can be seen that 34.4% of all microseismic events have an Es/Ep value less than 9, indicating that 34.4% of the microfractures inside the dam body were caused by tensile failure.

3.4 Moment tensor inversion of the source parameters

The analysis of Es/Ep could effectively obtain the failure mechanism of the microfractures inside the dam body, i.e., the tensile failure mode, the shear failure mode and the mixed failure mode. However, such an indicator fails to obtain detailed information on the failure surfaces, e.g., the radius of the failure surfaces and the orientation of the failure surfaces. The moment tensor inversion method can not only obtain the failure mode of the microfractures but also identify the cracking orientation of the failure surfaces.

3.4.1 Brief introduction of the moment tensor inversion method

The moment tensor inversion method was first developed by Gilbert (1970) and has been widely used to better understand the focal mechanism. Microseismic moment tensors are generally second-order symmetric moment tensors that satisfy the conservation theorem of angular momentum. The microseismic moment tensor matrix can be expressed as follows:

If a microseismic event is captured by the microseismic monitoring system, then the displacement recorded by each sensor can be calculated:

where U and G refer to the maximum displacement in the far-field and Green’s function, which are the n × 1 matrix and n × 6 matrix, respectively. Notably, there are 6 independent components within the total 9 components of the microseismic moment tensor matrix. Therefore, for a microseismic monitoring system with more than 6 microseismic sensors, matrix M can be easily solved.

Once the moment tensor matrix is determined, it can be disassembled to calculate the proportion of each failure component, i.e., the determination of the failure modes. The decomposition method proposed by Knopoff and Randall (1970) is widely used. In this method, the moment tensor is decomposed into an isotropic part (ISO), a pure double couple part (DC) and a compensated linear vector dipole part (CLVD). Assuming that m1, m2 and m3 are the three eigenvalues of the matrix, the specific decomposition form of the moment tensor can be expressed as follows:

where EISO, ECLVD, and EDC can be expressed as:

Notably, EISO and ECLVD are dominated by tensile failure, and EDC is dominated by the shear failure component. It is assumed that parameters PDC, PISO, and PCLVD are the proportions of those three parts in the moment tensor matrix. According to the theory proposed by Ohtsu (1995), the fracture is caused by tensile failure if PDC ≤ 40%, the fracture is caused by shear failure if PDC ≥ 60%, and the fracture is the mixed failure mode if PDC ranges from 40 to 60%.

Notably, Eq. (4) can also be expressed by the normal direction and motion direction of the failure surface (Aki and Richards 2020):

where u and S refer to the displacement of the failure surface along the motion direction and the surface area of the failure surface. λ and μ are Lame constants. \(\overrightarrow{{\varvec{n}}}\) and \(\overrightarrow{{\varvec{v}}}\) represent the normal vector and motion vector of the failure surface, respectively. Since the moment tensor matrix is symmetric, the relationship between the eigenvector and \(\overrightarrow{{\varvec{n}}}\) and \(\overrightarrow{{\varvec{v}}}\) can be calculated:

where \(\overrightarrow {{{\mathbf{e}}_{1} }} {,}\;\overrightarrow {{{\mathbf{e}}_{2} }} \;{\text{and}}\;\overrightarrow {{{\mathbf{e}}_{3} }}\) refer to the eigenvectors corresponding to the maximum, middle and minimum eigenvalues, respectively. Assuming that β is the angle between \(\vec{\user2{n}}\) and \(\vec{\user2{v}}\), \({\vec{\mathbf{n}}} \cdot {\vec{\mathbf{\nu }}}\) can be determined according to Eq. (8):

Hence, the normal vector of the failure surface can be calculated:

3.4.2 Results of moment tensor inversion

Based on the abovementioned moment tensor inversion method, the failure mechanism of the circular cracks of the access gallery was analysed in this section. A total of 30 microseismic events within 30 m of the access gallery were selected for the moment tensor inversion analysis, and the corresponding results are summarized in Table 2. It could be found that 57% of the concrete failures of the access gallery were induced by shear fracture, which is slightly higher than that induced by tensile fracture. Figure 12 shows the comparison of the fracture modes in the Sanhekou Dam determined by the Es/Ep indicator and the MT inversion method. The results derived by those two methods are quite similar, which further verifies the correctness of those two methods in determining the failure mechanism of rock and concrete fractures.

Figure 13 illustrates the failure surface information of the circular cracks of the access gallery in the Sanhekou Dam from the X–Y plane, Z–Y plane and three-dimensional view. Note that each circle refers to a microseismic event and that the radius of the circle corresponds to the influencing radius of that microfracture. To distinguish the failure modes of the microseismic events, the shear failures are marked with red circles, while the tensile failures are marked with yellow circles in Fig. 13. The formation of the circle cracks in the access gallery is the result of the combined action of the tensile and shear failures. In particular, the cracking of the top gallery is caused not only by tensile failure but also by shear failure. Moreover, the orientation of the failure surfaces along the access gallery varies from 73° to 96°, as shown in Fig. 13b.

4 Numerical modelling of the damage evolution of the dam considering the microseismic characteristics

4.1 Brief introduction of the numerical method considering damage

Field monitoring results indicated that the dam was damaged to a certain extent in the process of reservoir impoundment. Therefore, it is no longer suitable to adopt the initial mechanical parameters of the dam body obtained in the design stage for numerical modelling. To accurately simulate the mechanical responses of the dam, the numerical dam model should be carefully preprocessed by considering the existing damage information. In this section, based on the finite element method, numerical simulation was carried out to analyse the stress characteristics and damage evolution of the dam. It should be noted that the microseismic source parameters derived by the microseismic monitoring technique were carefully addressed to determine the damage degrees of the dam at the different locations. These parameters will be further imported to the numerical model as the initial value. Similar methods have been proposed by many scholars, e.g., Xu et al. (2014) and Zhao et al. (2017, 2019), with regard to the stability analysis of slopes and underground openings. Therefore, only a brief description of the numerical method was introduced, and the novelty of the method utilized in this study was highlighted.

According to the first law of thermodynamics, the total input energy per rock mass unit (U) under external loading can be expressed as:

where Ue refers to the releasable elastic strain energy of the rock mass unit, which is recoverable. Ud is the dissipation energy of the rock mass unit, and this value will be equal to zero if the rock mass is under elastic deformation. U and Ue can be calculated in terms of the principal stresses and strains in different directions based on the theory of elastic mechanics (Solecki and Conant 2003):

In the process of rock failure, part of the elastic energy stored in the rock mass will release and propagate from the source to the surrounding rock mass in the form of elastic waves, which can be captured by the microseismic monitoring system. Based on the theory of seismology, the values of the seismic source parameters, e.g., location, magnitude, source radius (R0) and seismic energy (\(\Delta \overline{U}\)), can be determined using microseismic monitoring data (Boatwright and Fletcher 1984). Notably, the seismic efficiency (η) is defined as the ratio of \(\Delta \overline{U}\) to \(\Delta U\), i.e., \(\eta = {{\Delta \overline{U} } \mathord{\left/ {\vphantom {{\Delta \overline{U} } {\Delta U}}} \right. \kern-0pt} {\Delta U}}\), which can be determined by the field impact test (Liu et al. 2017; Xu et al. 2014).

Rock mass damage is an essential characteristic of energy input and release under external loading (Gong et al. 2021). Therefore, the damage variable D can be defined as the ratio of the release energy to the total input energy as follows:

The abovementioned damage variable D will be further imposed into the numerical model, and the equivalent damage mechanics method is utilized. Previous studies have demonstrated that the damage to a rock mass is accompanied by the deterioration of the elastic modulus (Tang 1997). Hence, the initial damage of the dam body could be considered by deteriorating the corresponding elemental elastic modulus as follows:

where parameters E0 and E refer to the initial elastic modulus and the damaged modulus, respectively.

Notably, the damage degree of the rock mass at different distances to the seismic source is not identical. Therefore, in this study, the damage degree for the different elements (\(D{\prime}\)) is assumed to be:

where parameter d refers to the distance from the elemental centre to the seismic source.

4.2 Numerical model setup

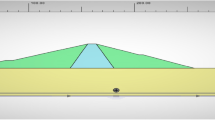

In this section, a numerical model of the Sanhekou hydropower station, including the dam body and the slopes on both sides, was established to analyse the stress variation and damage evolution characteristics of the dam under different water level elevations (Fig. 14). According to the real geological and engineering background of the Sanhekou hydropower station and to eliminate the boundary effect on the simulation results, the length, width and height of the numerical model are 700 m, 425 m and 305 m, respectively, although the maximum height and length of the dam body are only 145 m and 472 m. As the water level elevation downstream of the dam is quite low, only the water pressure upstream of the dam was analysed. The self-weight of the dam body was taken into consideration, and the bottom boundary of the dam was set as the fixed boundary. The numerical model was divided into 791,850 elements (302,400 elements for the dam body), and a hexahedral element with eight nodes was utilized. The properties of the dam body and slopes are shown in Table 3, which were determined during an on-site engineering geological survey and laboratory experiment. The Mohr–Coulomb criterion and maximum tensile stress criterion were utilized in this study to determine the shear and tensile failures of the dam and slopes under different water level elevations. According to the actual water level elevation at different times, four typical simulation cases were determined, i.e., dead water level (558 m), two intermediate water levels (590 m and 620 m) and normal water level (643 m). It should be noted that according to the field impact test, parameter η of the Sanhekou Dam is equal to 0.00396352.

4.3 Simulation results

4.3.1 Damage distribution inside the Sanhekou Dam considering the microseismic event data

During the period from January 13, 2021, to August 10, 2021, a total of 1516 microseismic events were recorded, indicating that initial damage had occurred. Therefore, before systematically analysing the mechanical responses of the Sanhekou Dam under different water level elevations, the initial damage should first be considered in the numerical model. Table 4 summarizes part of the source parameters obtained from the microseismic monitoring system, and those messages will be analysed in the numerical simulation based on the method introduced in Sect. 4.1. Figure 15 shows the derived initial damage characteristics of the Sanhekou Dam. The initial damage characteristics are mainly concentrated at the bottom of the dam body, with the maximum and minimum values of damage degree approximately equal to 0.85 and 0.05, respectively.

4.3.2 Numerical verification

In this section, to verify the correctness of the numerical simulation, the displacement results derived by numerical simulation and field monitoring at different locations of the Sanhekou Dam were compared. The displacement monitoring devices were installed on the top of the dam, which are − 142 m, 0 m and 145 m away from the top centre, and have been marked as Location A, Location B and Location C, respectively, in Fig. 14. Therefore, the radial and tangential displacements at those three locations under a water level elevation of 620 m derived by numerical simulation and field monitoring were compared and summarized in Table 5. The comparison results demonstrated that the displacement results derived by numerical simulation are basically consistent with those derived by field monitoring, and the data remain on the order of magnitude, which verifies the accuracy of the numerical simulation.

4.3.3 Stress status of the Sanhekou Dam under different water level elevations

Figures 16 and 17 depict the minimum and maximum principal stress contours of the dam body under different water level elevations. Note that a positive value demonstrates that the dam is under tension. For the condition of a water level elevation equal to 558 m, the minimum and maximum principal stresses in the area of the dam toe are approximately − 4.0 MPa and − 1.0 MPa, while the minimum and maximum principal stresses in the area of the dam heel are approximately − 5.0 MPa and − 1.8 MPa, respectively. For the condition of a water level elevation equal to 590 m, the minimum and maximum principal stresses in the area of the dam toe are approximately − 5.5 MPa and − 1.2 MPa, while the minimum and maximum principal stresses in the area of the dam heel are approximately − 2.0 MPa and − 1.4 MPa, respectively. For the condition of water level elevation equal to 620 m, the minimum and maximum principal stresses in the area of the dam toe are approximately − 6.0 MPa and − 1.5 MPa, while the minimum and maximum principal stresses in the area of the dam heel are approximately − 1.5 MPa and 0.6 MPa, respectively. For the condition of water level elevation equal to 643 m, the minimum and maximum principal stresses in the area of the dam toe are approximately − 7.0 MPa and − 2.0 MPa, while the minimum and maximum principal stresses in the area of the dam heel are approximately − 2.0 MPa and 1.5 MPa, respectively.

Figure 18 depicts the variation in the minimum and maximum principal stresses at the centre of the dam toe area and dam heel area under different water level elevations. Both the dam toe and dam heel were under compression when the water level elevation was equal to 558 m and 590 m, respectively. However, with increasing water level elevation, the stress status of the dam heel area changed from compression to tension. In addition, it is interesting to note that the stress level of the dam toe is larger than that of the dam heel when the water level elevation is relatively low (the water level elevation equals 558 m and 590 m). This is because the gravity centre of the double curvature arch dam is close to the upstream side of the dam body. However, with increasing water level elevation, the effect of the water level elevation plays a dominant role in determining the stress status of the dam body; both the minimum and maximum stresses of the dam heel area increase, while both the minimum and maximum stresses of the dam toe decrease. The above phenomena can also be obtained from the microseismic results. Figure 18 shows the contours of the concentrated area of microseismic deformation of the dam body when the water level elevation is 558 m and 620 m, respectively. With increasing water level elevation, the area of microseismic deformation concentration shifted from the dam heel area to the dam toe area. This is very consistent with the transfer characteristics of stress derived by the numerical simulation, which further proves the correctness of the numerical method in this study.

5 Conclusions

The main conclusions are summarized as follows:

-

(1)

The rise of the water level elevation has a significant effect on the microfracture and damage characteristics of the dam body, especially in the early stage of the impoundment. A large number of considerable fractures occurred inside the dam body when the water level elevation exceeded 565 m. The seismic source parameters, including the b value, daily apparent stress, and daily apparent volume, showed a significant change trend in this period, reflecting the damage and stress evolution inside the dam body.

-

(2)

Both the Es/Ep value and the moment tensor inversion method could effectively reflect the failure information of the failure surfaces. In addition, the moment tensor inversion method has the advantages of obtaining the cracking orientation of the failure surfaces. The cracking in the access gallery on April 7 is the result of the combined action of shear and tensile failure. The orientation of the failure surfaces along the access gallery varies from 73° to 96°

-

(3)

The deformation of the dam under impoundment considering the microseismic feedback agrees well with the real field measured results. The stress level of the dam toe was larger than that of the dam heel, and both the dam toe and dam heel were under compression before impoundment. However, with increasing water level elevation, the stress status of the dam heel area changes from compression to tension.

Availability of data and materials

Not applicable.

References

Aki K, Richards PG (2002) Quantitative seismology, 2nd edn. University Science Books, Sausalito

Boatwright J, Fletcher JB (1984) The partition of radiated energy between P and S waves. Bull Seismol Soc Am 74:361–376

Corns CF, Lombardi G, Jansen RB (1988) Concrete dam performance and remedial measures. Springer

Dong L, Tang Z, Li X et al (2020) Discrimination of mining microseismic events and blasts using convolutional neural networks and original waveform. J Cent South Univ 27(10):3078–3089

Gilbert F (1970) Research note excitation of the normal modes of the earth by earthquake sources. Geophys J 22(2):223–226

Gong F, Wang Y, Wang Z, Pan J, Luo S (2021) A new criterion of coal burst proneness based on the residual elastic energy index. Int J Min Sci Technol 31(4):553–563

Gutenberg B, Richter CF (1944) Frequency of earthquakes in California. Bull Seism Soc Am 34(4):185–188

He G, Li B, Wang X, et al (2016) Integrated analysis of the formation mechanism of cracks in a concrete dam using microseismic monitoring and numerical simulation. J Sens

Huang X, Xu N, Wu W et al (2022) Instability of an intersecting fault-dyke system during deep rock excavation. Int J Rock Mech Min Sci 153:105087

Hudyma M, Potvin YH (2010) An engineering approach to seismic risk management in hardrock mines. Rock Mech Rock Eng 43(6):891–906

Jaeger C (1963) The malpassetreport. Water Power 15(2):55–61

Kim Y, Seo M, Lee C et al (2014) Deformation characteristics during construction and after impoundment of the CFRD-type Daegok Dam, Korea. Eng Geol 178:1–14

Knopoff L, Randall MJ (1970) The compensated linear-vector dipole: a possible mechanism for deep earthquakes. J Geophys Res 75(26):4957–4963

Li Y, Deng H, Wen L et al (2022a) Method for identifying and forecasting mining-induced earthquakes based on spatiotemporal characteristics of microseismic activities in Fankou lead/zinc mine. Minerals 12(3):318

Li B, Ding Q, Xu N et al (2022b) Characteristics of microseismic b-value associated with rock mass large deformation in underground powerhouse caverns at different stress levels. J Cent South Univ 29(2):693–711

Liu X, Tang C, Li L et al (2017) Microseismic monitoring and 3D finite element analysis of the right bank slope, Dagangshan hydropower station, during reservoir impounding. Rock Mech Rock Eng 50:1901–1917

Liu X, Tang CA, Li L et al (2018) Microseismic monitoring and stability analysis of the right bank slope at Dagangshan hydropower station after the initial impoundment. Int J Rock Mech Min Sci 108:128–141

Ma K, Tang CA, Liang ZZ et al (2017) Stability analysis and reinforcement evaluation of high-steep rock slope by microseismic monitoring. Eng Geol 2017(218):22–38

Ma K, Wang H, Liao ZY, Peng YL, Wang KK (2022) Precursor of microseismic energy and stress evolution induced by rockburst in coal mining: a case study from Xiashijie, Shannxi, China. Geomech Geophys Geo-Energ Geo-Resour 8:134. https://doi.org/10.1007/s40948-022-00435-w

Mahinroosta R, Alizadeh A, Gatmiri B (2015) Simulation of collapse settlement of first filling in a high rockfill dam. Eng Geol 187:32–44

Occhiena C, Pirulli M, Scavia C (2014) A microseismic-based procedure for the detection of rock slope instabilities. Int J Rock Mech Min Sci 69:67–79

Ohtsu M (1995) Acoustic emission theory for moment tensor analysis. Res Nondestruct Eval 6(3):169–184

Shi F, Zhang D, Wang P, et al (2022) Investigation on rock mass stability monitoring system and activity characteristic in deep mining. In: MATEC web of conferences, vol 356, p 1009

Solecki R, Conant RJ (2003) Advanced mechanics of materials. Oxford University Press, London

Spillmann T, Maurer H, Green AG et al (2007) Microseismic investigation of an unstable mountain slope in the Swiss Alps. J Geophys Res 112(B7):B07301

Tang CA (1997) Numerical simulation of progressive rock failure and associated seismicity. Int J Rock Mech Min Sci 34:249–261

Wang S, Liu Y, Yang Q et al (2020) Analysis of the abutment movements of high arch dams due to reservoir impoundment. Rock Mech Rock Eng 53(5):2313–2326

Xiao P, Mao H, Qian B et al (2022) Stability analysis of surrounding rock mass in underground powerhouse considering damage effect of microfractures. J Rock Mech Geotech Eng 14:1115–1130

Xu NW, Dai F, Liang ZZ et al (2014) The dynamic evaluation of rock slope stability considering the effects of microseismic damage. Rock Mech Rock Eng 47(2):621–642

Zhao Y, Yang T, Zhang P et al (2017) The analysis of rock damage process based on the microseismic monitoring and numerical simulations. Tunn Undergr Space Technol 69:1–17

Zhao Y, Yang T, Yu Q et al (2019) Dynamic reduction of rock mass mechanical parameters based on numerical simulation and microseismic data–a case study. Tunn Undergr Space Technol 83:437–451

Zhuang D, Ma K, Tang C et al (2019) Study on crack formation and propagation in the galleries of the Dagangshan high arch dam in Southwest China based on microseismic monitoring and numerical simulation. Int J Rock Mech Min Sci 115:157–172

Funding

This research was supported by the National Natural Science Foundation of China (Grant Nos. 51974055, 51904189, 42122052), the Joint Fund of Natural Science Basic Research Program of Shanxi Province (Grant No. 2021JLM-11), the Fund of China Petroleum Technology and Innovation (Grant No. 2020D-5007-0302) and the supported by Yunnan Fundamental Research Projects (Grant No. 202001AT070150).

Author information

Authors and Affiliations

Contributions

Ke Ma: conceptualization, methodology, supervision; Yu Li: data processing, writing—original draft preparation; Zhiyi Liao: methodology, software, writing—reviewing and editing; Zuorong Wang: validation; Zhengchun Jiang: figure processing; Rulin Wang: data processing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics approval and consent to participate

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ma, K., Li, Y., Liao, Z. et al. Investigation of the microfracture and damage characteristics of dam during impoundment at Sanhekou hydropower station. Geomech. Geophys. Geo-energ. Geo-resour. 10, 101 (2024). https://doi.org/10.1007/s40948-024-00818-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-024-00818-1