Abstract

The study of progressive failure of reservoir rocks is very important for the stability analysis of ultra-deep boreholes. The progressive failure can be characterized by the crack initiation stress (CI), crack damage stress (CD) and peak stress (Peak), which is controlled by the evolution of cracks in rock and is significantly affected by confining pressure. To explore the effect of high confining pressure and initial crack on the progressive failure, the initial crack density of 121 sedimentary rock samples was characterized by acoustic waves, and the progressive failure under different confining pressures was analyzed. Experiments show that the ratios of CI to Peak (CI/Peak) and CD to Peak (CD/Peak) increase significantly with confining pressure, which is agreement with the existing conclusion from low confining pressure (0–52 MPa), but those decrease for high confining pressure (68–85 MPa) above critical point of sandstone. The CI/Peak and CD/Peak decrease with increase of initial crack density, which is sensitive to confining pressure but independent of rock type and grain size. The CD of sandstone is pertinent to the friction coefficient of cracks. These results laid a foundation for analyzing the evolution mechanism of wellbore damage and predicting the timing of wellbore instability in ultra-deep wells.

Article highlights

-

Experiments show that CD/Peak and CI/Peak do not monotonically increase with confining pressure, which is unverified in previous publications.

-

Initial crack density, characterized by acoustic waves, affects CI/Peak and CD/Peak dependently on confining pressure.

-

The influence of the confining pressure and initial crack density on damage stress is pertinent to crack frictions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

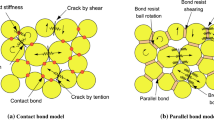

Rocks in nature generally contain initial micro-defects such as cracks and pores. The failure of brittle rocks under compression loading is progressive, including the crack initiation, growth, and coalescence (Brace et al. 1966; Chen et al. 2021; Zhang et al. 2020a, 2019, 2020b). The study of progressive failure is very important for the stability analysis of residual coal pillar, goaf, gas storage and borehole wall (Ma et al. 2020, 2023). Rock type, mineral particle size, crack and pore distribution influence rock failure (Byun et al. 2015; Patel and Martin 2020; Yin et al. 2019; Zhang et al. 2011; Zhao et al. 2020). Nicksiar and Martin (2014) found that the content of hard minerals and the size of mineral particles affect the crack initiation stress (CI), through statistics of the uniaxial compressions of different rock types including igneous, sedimentary, and metamorphic. Still, rock types and mineral composition do not affect the ratio of CI to Peak (CI/Peak). In addition, experiments show that the ratio of CD to Peak (CD/Peak), as an intrinsic property of the low-porosity rock, can be used to describe the failure process in rock engineering (Xue et al. 2013). These conclusions are all from the experiments under uniaxial compression or low confining pressure. There are few reports on CI/Peak and CD/Peak for high confining pressure. Theoretical analysis (Liu et al. 2017), numerical simulation (Nicksiar and Martin 2014) and laboratory experiments (Hoek and Martin 2014) were carried out to study the factors influencing the crack initiation (CI) and damage stresses (CD). But these results are mainly about the qualitative analysis of rock types, mineral particle size and shape. There are a few experimental studies about influence of initial cracks on the failure process. Patel and Martin (2020) investigated the role of initial crack volume on the failure of granite using bonded particle model. They found that cracks among the mineral grains and associated void space played a major role in CI for uniaxial compression. Yin et al. (2019) studied the relationship between initial cracks and failure process of schist quantitatively for uniaxial compression using the scanning electron microscope. Our experiments report the impact of initial cracks on failure process under high confining pressure based on acoustic waves.

The wave velocities are related to the microstructural characteristics and stress state of rocks (Fortin et al. 2007; Shapiro 2003; Wang 2001). Specifically, in the failure process under compression, the growth of cracks and the collapse of pore structures are the primary mechanisms for reducing the elastic wave velocity for crystalline and porous rocks (Scott Jr et al. 1993). The effective medium theory is useful for linking elastic modulus to composition matrix, fluid, cracks, and pores of rocks. Microstructural can be back analyzed based on the relationship between elastic wave velocity and elastic modulus. Le Ravalec and Guéguen (1996) calculated the equivalent elastic properties of an isotropic material using an extended differential self-consistent model which considers the effects of circular pores and cracks. The effective elastic properties of materials containing cracks of various shapes can be calculated based on the noninteraction approximation model, which assumes crack and pore distributions are random (Sayers and Kachanov 1995; Walsh 1965). In addition, Sayers and Kachanov (1995) proved that the noninteraction approximation model is the most appropriate for both isotropic and aligned cracks and remains accurate for high crack density when assuming locations of crack centers are homogenous.

This paper reports experiments of 121 sedimentary rocks from deep reservoirs. We carry out elastic wave velocity (\({V}_{p}, {V}_{s}\)) tests before triaxial compression with confining pressure of 12–85 MPa. The density of initial cracks is calculated using elastic wave velocities. The effect of confining pressure and initial crack density on CI and CD in failure process is investigated with these experiments, providing a reference for analyzing the surrounding rock stability of underground space, deep drilling, and others.

2 Samples isotropy from wave velocities

The initial crack density is of key importance in rock failure but is difficult to measure. Thus, this has given rise to characterize crack density with wave velocities under the isotropic assumption. We will discuss the sample isotropy in this section as a prerequisite for back-analyzing crack density in Sect. 5.1.

Experimental samples are from the Junggar Basin (southern and northwest margins) in Xinjiang. These samples are from sandstone, mudstone, and conglomerate reservoirs in the oil field. Cored samples (25 × 50mm) are dried in a vacuum oven at 60 °C for 48 h. There are 121 samples cored along the wellbore (V) and the wellbore radius (H) in Fig. 1a.

P- and S-wave velocities (\({V}_{p}, {V}_{s}\)) are measured at room temperature without confining pressure. Anisotropic parameters of P- and S-waves are calculated using elastic wave velocities, as Eq. (1) (Thomsen 1986),

where \({\gamma }_{s}\) and \({\gamma }_{p}\) are anisotropic parameters of S-and P-wave velocities. \({V}_{sH}\) and \({V}_{pH}\) are S-and P-wave velocities of samples cored along the wellbore radius. \({V}_{sV}\) and \({V}_{pV}\) are S-and P-wave velocities of samples cored along the wellbore.

We use the mean values of S- and P-wave velocities of samples cored along the wellbore (\({{V}_{sV}}^{m}, {{V}_{pV}}^{m}\)) and wellbore radius (\({{V}_{sH}}^{m}, {{V}_{pH}}^{m}\)) to calculate the anisotropy of samples (Table 1). Anisotropic parameters shows that the mudstone b is more anisotropic than other samples in Table 1. The P-wave anisotropy parameters are 0.033–0.053 and 0.132–0.047 for sandstone, 0.088–0.089 and 0.052–0.068 for conglomerate, and 0.042 and 0.029 for mudstone a. These anisotropic parameters are obviously lower than 0.16–0.66 and 0.17–0.72 of anisotropic sandstone and mudstone in Sun (2019). We can conclude that samples show less anisotropy and can be assumed as isotropic except mudstone b. Meanwhile, Table 2 shows petrophysical properties of samples.

3 The progressive failure for different rock types

The progressive failure, characterized by CI/Peak and CD/Peak, is inherent property of rock resulting from statistics of uniaxial experiments (Zafar et al. 2022; Shirole et al. 2020), which is unverified for rocks under high confining pressure. In this section, a big data from experiments of different rock types is used to fit CI/Peak and CD/Peak for high confining pressure, investigating difference in progressive failure between uniaxial and triaxial tests.

3.1 The determination of CI and CD

In this paper, we use the MTS816 to carry out triaxial compression experiments with confining pressures which are 12–85 MPa. The loading rate is 0.04% axial strain, and stress–strain curves are obtained. Martin (1993) divided the progressive failure process of brittle rock into five stages, (1) initial crack closure, (2) linear elastic deformation, the start point of this stage is defined as the crack closure stress (CC), (3) crack initiation and stable growth begin at the crack initiation stress (CI), (4) crack unstable growth and coalescence occurs between the crack damage stress (CD) and the peak stress (Peak), (5) failure and post-peak behavior. The characteristic stresses are captured in stress–strain curves as shown in Fig. 1b. The CD corresponds to the turning point of the volumetric strain, the CI is determined using the LSR method (Nicksiar and Martin 2013a; Wen et al. 2018) (Fig. 1c), and the CC is determined with the ASR (Rong et al. 2018; Zhang and Tang 2020) method (Fig. 1d).

3.2 The CI/Peak and CD/Peak ratios

Under triaxial compression conditions, the CI/Peak and CD/Peak for 121 sedimentary rock samples are drawn in Fig. 2. The CI and CD have a linear relationship with the Peak according to the linear least squares fitting. The results illustrate that CI/Peak under confining pressures of 12–24 MPa, 40–52 MPa and 66–85 MPa are 0.579, 0.637, and 0.623 (As shown in Fig. 2a). Figure 2b shows that CD/Peak are 0.913, 0.929 and 0.938 for 12–24 MPa, 40–52 MPa and 66–85 MPa confining pressures from our experiments. The CI/Peak and CD/Peak obviously change for different confining pressures, and we will discuss this phenomenon in detail in Sect. 4.

a Relationship between the initiation stress and the peak stress of sedimentary rocks under different confining pressures, b Relationship between the damage stress and the peak stress of sedimentary rocks under different confining pressures (the solid line is the regression line; the dotted line is the 95% confidence interval; black marker is sandstone; red marker is mudstone; blue marker is conglomerate)

Results in publications (Nicksiar and Martin 2013a; Xue et al. 2013) show that the CI/Peak and CD/Peak are independent of rock types under uniaxial and triaxial compression for low confining pressure. To further ascertain whether different rock types have similar CI/Peak and CD/Peak for high confining pressure, the fitting results of sandstone, mudstone, and conglomerate are shown in Fig. 2. The R2 of the regression lines of all data sets are above 0.97, indicating that the data of sandstone, mudstone and conglomerate are all in good agreement with fitted lines. Therefore, the CI/Peak and CD/Peak of sedimentary rock are also independent of rock types for high confining pressure.

Table 2 shows that average grain size of mudstone is the smallest, followed by sandstone and conglomerate. In Fig. 2, data points with different grain sizes are distributed in a relatively narrow range around the fitting lines. This proves that grain size has a negligible effect on the CI/Peak and CD/Peak for triaxial compression, which agrees with result from Nicksiar and Martin (2013a) and Xue et al. (2013). They found that grain size is not a significant factor in controlling the CI/Peak and CD/Peak based on uniaxial compression tests. Therefore, the CI/Peak and CD/Peak can be used to evaluate the progressive failure of rock neglecting the rock types and grain sizes.

Grain size has less effect on the CI/Peak and CD/Peak, but will influence the absolute values of CI, CD and Peak. Figure 3 presents higher CI, CD and Peak of conglomerate than mudstone and sandstone as increase of grain size. The increasement of CI, CD are nearly equal to that of Peak varying from mudstone, sandstone and conglomerate. CI/Peak and CD/Peak are almost unchanged on account of the same increasement of CI, CD and Peak.

4 Effect of confining pressure on CI/Peak and CD/Peak

The effect of confining pressure on progressive failure from previous publications (Nicksiar and Martin 2013b; Xue et al. 2013; Li et al. 2020; Huang et al. 2021; Wen et al. 2018) are inconsistent resulting from absence of experiments of high confining pressure. We investigate the evolution of CI/Peak and CD/Peak for different confining pressures from 0 to 85 MPa in this part.

Wen et al. (2018) concluded that CI/Peak linearly increases with confining pressure. However, Nicksiar and Martin (2013b) believed that the confining pressure has no significant inhibition on the initiation of new cracks and has little influence on CI/Peak. As mentioned above, the confining pressure in this paper ranges from 12 to 85 MPa while it is mainly 0 – 20 MPa used by Nicksiar and Martin (2013b). Triaxial experiments from our work further support that high confining pressure strongly affects CI/Peak. Figure 4a shows that CI/Peak increase from 0.42–0.57 to 0.63–0.67 with confining pressures from 0–24 to 40–85 MPa for sedimentary rocks.

a Effects of confining pressure on CI/Peak and CD/Peak for sedimentary rocks including sandstone, mudstone and conglomerate. b Effects of confining pressure on CI/Peak and CD/Peak for sandstone (The data in the red circle is lower than the mean value at 68–85 MPa; The data in the blue circle is higher than the mean value at 40–52 MPa). c Effects of confining pressure on CI, CD and Peak for sandstone

The moderate increasement of confining pressures significantly enhanced the CD/Peak for sedimentary rocks. CD/Peak is 0.91 for 12–24 MPa in Fig. 4a, which is obviously higher than 0.73–0.78 for 0 MPa obtained by Xue et al. (2013). Yang (2016) concluded similar results that the ratio of CD/Peak increases from 0.71 to 0.95 with 0 MPa to 35 MPa. For high confining pressure, there is slightly increase from 0.91 to 0.93 when confining pressure increase from 12–24 MPa to 68–85 MPa.

More specifically, the CD/Peak and CI/Peak of sandstone are illustrated in Fig. 4b. Figure 4b presents that CD/Peak and CI/Peak do not monotonically increase with confining pressure, which decrease by 10.4% and 4.2% when confining pressure increases from 40–52 MPa to 68–85 MPa. For 68–85 MPa, most data points are near the lower bound of the confidence interval, while most data points are near the upper bound for 40–52 MPa. These results indicate that the downward trend is more significant than average for most samples. This downward trend is significant for sandstone, but for mudstone and conglomerate, more experiments need to be conducted in the future.

Figure 4c shows that CI, CD and Peak increase differently with the increase of confining pressure for sandstone. CI and CD increases by 59% and 39% respectively, both above the 34% of Peak when confining pressure increases from 12–24 MPa to 40–52 MPa. The high increasement of CI and CD results in growth of CI/Peak and CD/Peak. The CI/Peak and CD/Peak shows downward trend for 68–85 MPa, due to the lower rise of CI and CD than Peak. Figure 4c presents that CI is almost unchanged (0.5%) but Peak increases by 11%. The results suggest that there is a critical point for confining pressure to inhibit microcrack cracking, and 40–52 MPa could be the threshold value of sandstone.

5 Relationship between initial crack density and stress ratios

The crack distribution controls progressive failure process, which is sensitive to confining pressure. However, the evaluation of crack density has remained challenge. In this part, acoustic waves are adopted to back-analyze initial crack density of sandstone based on the equivalent medium model, and thus the effect of initial crack density on CI/Peak and CD/Peak is discussed.

5.1 Initial crack densities of the samples

The elastic properties of isotropic rocks depend partly on pore (spherical) and crack (coin-shaped) distribution. The initial cracks distributed in rock account for about 1% of porosity, but they were the dominant factor affecting elastic properties (Nicolas et al. 2017b). In addition, the extension and sliding of cracks between or within mineral grains were the primary microscopic mechanism of a progressive failure process (Patel and Martin 2020). Byun et al. (2015) proved that the coin-shaped crack assumption was suitable for dry rocks. The elastic wave velocities are measured in the dry condition in this paper, so that initial crack properties are back-analyzed for coin-shaped cracks in this paper.

Equations (2)–(5) present the relationship between elastic modulus and the crack density \(\omega\). (Mallet et al. 2013) based on isotropic assumption of samples.

where \({E}_{0}\), \({G}_{0}\) are young`s modulus and shear modulus of rock matrix, \({E}^{*}\), \({G}^{*}\) the effective young`s modulus and the effective shear modulus, \({v}_{0}\) the effective Poisson’s ratio, \(h\) the geometric parameters of a coin-shaped crack in Eq. (3), \(\delta\) a dimensionless parameter characterizing the stress state inside rock in Eq. (4), \(\omega\) the scalar crack density of the rock in Eq. (5).

In Eq. (4), \({K}_{f}\) is the bulk modulus of the fluid inside the rock, \({K}_{f}\) is 1 for dry case in this paper, \(\xi =c/a\) the average width to length ratio of the cracks, and \(c\) and \(a\) the half-width and half-length of the cracks. We use Budiansky and O’Connell’s (1976) (Nicolas et al. 2017a) definition of crack density \(\omega\) in Eq. (5).

where \(V\) is the volume of REV element, \(N\) the number of cracks in REV, \({a}_{i}\) the half-length of the \(i\) th crack.

The effective elastic modulus also can be calculated using elastic wave velocities as Eqs. (6) and (7).

\({E}^{*}=\frac{9{K}^{*}{G}^{*}}{3{K}^{*}+{G}^{*}}\), where \({E}^{*}\) is the effective young`s modulus, \({K}^{*}\) the effective bulk modulus, \({G}^{*}\) the effective shear modulus, \(\rho\) the density of rock.

Substituting Eqs. (6) and (7) into Eq. (2), the relationship between the initial crack properties and the elastic wave velocities can be established. The parameters of initial cracks are back-analyzed using the P-wave velocities obtained in Sect. 2. Mallet et al. (2013) and Ghabezloo (2015) used wave velocities to back-analyze the crack density of glass, and the number of back-analyzed cracks was consistent with the measurements. It is worth noting that the crack density (\(\omega\)) in the above model is dimensionless in a statistical sense.

The young`s modulus of matrix \({E}_{0}\) is about 75 GPa (Fortin et al. 2007; Qin et al. 2022), the effective poison ratio \({v}_{0}\) is about 0.2 for sandstone (Mavko et al. 2020; Paterson and Wong 2005). In this paper, initial crack density \(\omega\) of sandstone (Appendix A) is back-analyzed using the least-squares method.

5.2 Effects of initial crack density on stress ratios

In Fig. 5, CI/Peak and CD/Peak of sandstone show a decreasing trend with the increase of the initial crack density for 12–24 MPa and 68–85 MPa, and they decrease more significantly for 12–24 MPa. However, it appears that CI/Peak and CD/Peak are relatively insensitive to the initial crack density for 40–52 MPa. These results confirm the effect of initial crack density on stress ratios is affected by confining pressure.

The effect of the initial crack density is weakened when the confining pressure increases from 12–24 to 40–52 MPa. The effect is enhanced when confining pressure increases from 40–52 to 68–85 MPa, see Fig. 5. For 12–24 to 40 – 52 MPa, the confining pressure significantly increase the CI/Peak and CD/Peak so that eliminate weakened effect from initial crack density. The initial crack density becomes dominate factor and reduces the CI/Peak and CD/Peak when the influence of confining pressure is weakened above critical point. Figure 4c shows that critical confining pressure is 40–52 MPa for sandstone.

Patel and Martin (2020) used PFC simulation to study the effect of initial cracks on rock mechanical properties of granite. A microfracture was created in the model by reducing the tensile strength of all elements in a flat-jointed contact to zero. They found that the model with higher initial crack density can accommodate more lateral extension among the grains and delay the crack initiation. Hence CI/Peak shows an increasing trend (from 0.29 to 0.41) with increasing initial crack density without confining pressure. However, our triaxial experiments statistically suggest a reversed trend that CI/Peak decreases with initial crack density for 12–24 MPa. The confining pressure inhibits lateral extension and accelerate crack initiation, making the significantly difference in influence of initial crack density between uniaxial and triaxial compression tests. We can infer that confining pressure is the main factor rather than the initial crack density for low confining pressure from the huge difference, although it is between granite simulations and sandstone experiments. It is an interesting topic proving this inference by experiments for future study.

6 The dependence of CD stress on crack properties

The initiation and propagation of stress-induced cracks can be analyzed using linear elastic fracture mechanics, involving micromechanical parameters such as the porosity, friction coefficient of initial crack, crack density, crack dimension and fracture toughness (Ashby and Sammis 1990; Baud et al. 2014; Ding et al. 2017; Li et al. 2018; Nicolas et al. 2017a; Wong et al. 1996; Zhang and Ma. 2021; Zhang and Ma. 2021; Zhang et al. 2024). The sliding of initial cracks among grains is the primary mechanism of crack initiation and extension under high confining pressure in experiments (Liu et al. 2017; Huang et al. 2021). And the crack density and friction-slip properties of cracks have a marked impact on the CI and CD. We will use the wing crack model (Ashby and Sammis 1990), which can describe the properties and interaction of cracks, to study the dependence of CD on initial cracks.

Firstly, we adopt the three-dimensional damage mechanic model (Ashby and Sammis 1990) to describe the cracking process with the axial load \({\sigma }_{1}\) for different confining pressure \({\sigma }_{3}\) as Eq. (8).

where \({S}_{1}\) and \({S}_{3}\) are defined as \({S}_{1}={\sigma }_{1}\sqrt{\pi a}/{K}_{{\text{IC}}}\) and \({S}_{3}={\sigma }_{3}\sqrt{\pi a}/{K}_{{\text{IC}}}\).

In Eq. (8), the constants are defined as \(A=\sqrt[3]{D/{D}_{0}}-1\), \(B=1+2{{A}^{2}D}_{0}^{2/3}/\left(1-{D}^{2/3}\right)\), \({C}_{1}={A}_{3}/{A}_{1}\), \({C}_{2}={\pi }^{2}{\alpha }^{3/2}/{A}_{1}\), \({C}_{3}=2{\alpha }^{2}{\pi }^{2}/{A}_{1}\).

where \({A}_{1}=\pi \sqrt{\beta /3}\left({\left(1+{\mu }^{2}\right)}^{1/2}-\mu \right)\), \({A}_{3}={A}_{1}\left({\left(1+{\mu }^{2}\right)}^{1/2}+\mu \right)\left({\left(1+{\mu }^{2}\right)}^{1/2}-\mu \right)\).

Specific parameters of sandstone are determined from publication of Ashby and Sammis (Ashby and Sammis 1990), the dimensionless coefficients \(\alpha\) and \(\beta\) are 0.7 and 0.45, the half-length of the initial crack \(a\) is 0. 25 mm based on grain size in Table 2, the friction coefficient of the initial crack \(\mu\) is 0.6. The fracture toughness \({K}_{{\text{IC}}}\) of sandstone samples are obtained with semi-disk test, which are \(0.76{\text{MPa}}\sqrt{{\text{m}}}\).

The initial damage factor \({D}_{0}\) and the damage factor \(D\) during loading are defined as,

The \(\omega\) is defined in Eq. (5), then the initial damage factor \({D}_{0}\) can be obtained.

Furthermore, the critical wing crack length for the damage stress threshold is Eq. (11) (Li et al. 2018).

Substituting Eq. (11) into Eq. (8), we can obtain the relationship between crack damage stress (CD is the value of axial stress \({\upsigma }_{1}\) corresponding to the strat of crack unstable growth) and crack density (\(\omega\)). The crack damage stress of sandstone calculated with the above model are shown in Fig. 6 for different confining pressure (20, 45 and 80 MPa). We find that model results agree well with experiments when initial crack densities are less than 1. Meanwhile, CD decreases rapidly with the initial crack density.

However, model results for high initial crack density (\(\omega >1\)) are significantly lower than the experimental data. As shown in Fig. 6, model results with an increasing friction coefficient of initial crack (from 0.6 to 0.75) are consistent with experiments for samples with high initial crack density. This fact shows that damage stress increases with friction coefficient of cracks when crack density is high. Samples treated above 1000 °C show the same trend. They have higher crack density and concurrently increased friction coefficient of cracks, due to mineral melting and pores filling examined by XRD and SEM (Yi et al. 2021). Zhang et al. (2020c) found that the friction coefficient is the dominant factor affecting the failure process of water-saturated sandstone after introducing SC−CO2. We can conclude that the crack damage stress is also sensitive to friction coefficient when the crack density is high.

7 Conclusions

In this paper, the effect of initial crack density and high confining pressure on progressive failure are investigated based on triaxial compressions of 121 sedimentary rocks. Several conclusions can be drawn as follows:

The confining pressure significantly affects CI/Peak which increases from 0.42–0.57 to 0.63–0.67 with confining pressures from 0–20 to 12–85 MPa. CD/Peak increases from 0.73–0.78 to 0.91–0.95 with confining pressures from 0 to 85 MPa, concluding from experiments of sedimentary rocks.

Specifically, results from sandstone presents that CD/Peak and CI/Peak do not monotonically increase with confining pressure, which decrease by 10.4% and 4.2% when confining pressure increases from 40–52 to 68–85 MPa. There is a critical point for confining pressure to inhibit microcrack cracking, and 40–52 MPa could be the threshold value of sandstone.

The effect of initial crack is sensitive to confining pressure. That is weakened when the confining pressure increases from 12–24 to 40–52 MPa but enhanced when the confining pressure increases from 40–52 to 68–85 MPa. The initial crack density becomes dominate factor and reduces the CI/Peak and CD/Peak when the influence of confining pressure is weakened above critical point.

Results from damage mechanic model agree well with experiments when initial crack density is low, and CD decreases rapidly with the initial crack density. CD is also sensitive to friction coefficient of crack when crack density is high. The enhancement of friction coefficient to CD is obvious.

Data availability

All the data, models or code generated or used in the present study are available from the corresponding author by request.

Abbreviations

- \({\text{CI}}\) :

-

Crack initiation stress

- \({\text{CD}}\) :

-

Crack damage stress

- \({\text{Peak}}\) :

-

Peak stress

- CI/Peak:

-

The ratio of CI to Peak

- CD/Peak:

-

The ratio of CD to Peak

- \({\gamma }_{s}\), \({\gamma }_{p}\) :

-

Anisotropic parameters of S-and P-wave velocities

- \({V}_{sH}\), \({V}_{pH}\) :

-

S-and P-wave velocities of samples along the wellbore radius

- \({V}_{sV}\), \({V}_{pV}\) :

-

S-and P-wave velocities of samples along the wellbore

- \({{V}_{sV}}^{m}\), \({{V}_{pV}}^{m}\), \({{V}_{sH}}^{m}\), \({{V}_{pH}}^{m}\) :

-

Mean values of S- and P-wave velocities of samples

- \(LSR\) :

-

Lateral strain response (Nicksiar and Martin 2013a)

- \(ASR\) :

-

Axial strain response (Zhang and Tang 2020)

- \({E}^{*}\) :

-

Effective young’s modulus

- \({G}^{*}\) :

-

Effective shear modulus

- \({E}_{0}\) :

-

Bulk modulus of rock matrix

- \({G}_{0}\) :

-

Shear modulus of rock matrix

- \({v}_{0}\) :

-

Effective Poisson’s ratio

- \(h\) :

-

Geometric parameters of coin-shaped crack

- \(\delta\) :

-

Dimensionless parameter of the equivalent medium model

- \({K}_{f}\) :

-

Bulk modulus of fluid inside rock pores

- \(c\) :

-

Half-width of crack

- \(a\), \({a}_{i}\) :

-

Half-length of crack

- \(\xi\) :

-

Average ratio of width to length

- \(V\) :

-

Volume of the representative elementary volume (REV)

- \(\omega\) :

-

Scalar microcrack density

- \(N\) :

-

Number of cracks in a REV

- \(\rho\) :

-

Rock density

- \({K}^{*}\) :

-

Effective bulk modulus

- \(\alpha\), \(\beta\) :

-

Dimensionless coefficients in damage model

- \({\sigma }_{1}\), \({\sigma }_{3}\) :

-

Axial and confining stresses

- \({K}_{{\text{IC}}}\) :

-

Model I fracture toughness

- \(\mu\) :

-

Friction coefficient of the initial crack

- \({l}_{{\text{lim}}}\) :

-

Critical wing crack length for the damage stress

- \({D}_{0}\), \(D\) :

-

Initial crack density and crack density during loading

References

Ashby M, Sammis C (1990) The damage mechanics of brittle solids in compression. Pure Appl Geophys 133:489–521

Baud P, Wong T-F, Zhu W (2014) Effects of porosity and crack density on the compressive strength of rocks. Int J Rock Mech Min Sci 67:202–211. https://doi.org/10.1016/j.ijrmms.2013.08.031

Brace W, Paulding B Jr, Scholz C (1966) Dilatancy in the fracture of crystalline rocks. J Geophys Res 71:3939–3953. https://doi.org/10.1029/JZ071i016p03939

Budiansky B, O’connell RJ (1976) Elastic moduli of a cracked solid. Int J Solids Struct 12:81–97. https://doi.org/10.1016/0020-7683(76)90044-5

Byun J-H, Lee J-S, Park K, Yoon H-K (2015) Prediction of crack density in porous-cracked rocks from elastic wave velocities. J Appl Geophys 115:110–119. https://doi.org/10.1016/j.jappgeo.2015.02.020

Chen L, Zhang G, Zou Z, Guo Y, Zheng X (2021) The effect of fracture growth rate on fracture process zone development in quasi-brittle rock. Eng Fract Mech. https://doi.org/10.1016/j.engfracmech.2021.108086

Ding X, Zhang G, Zhao B, Wang Y (2017) Unexpected viscoelastic deformation of tight sandstone: insights and predictions from the fractional Maxwell model. Sci Rep 7:1–11. https://doi.org/10.1038/s41598-017-11618-x

Fortin J, Guéguen Y, Schubnel A (2007) Effects of pore collapse and grain crushing on ultrasonic velocities and Vp/Vs. J Geophys Res Solid Earth. https://doi.org/10.1029/2005JB004005

Ghabezloo S (2015) A micromechanical model for the effective compressibility of sandstones. Eur J Mech A-Solids 51:140–153. https://doi.org/10.1016/j.euromechsol.2014.12.007

Hoek E, Martin C (2014) Fracture initiation and propagation in intact rock–a review. J Rock Mech Geotech Eng 6:287–300. https://doi.org/10.1016/j.jrmge.2014.06.001

Huang Z, Gu Q, Wu Y, Wu Y, Li S, Zhao K, Zhang R (2021) Effects of confining pressure on acoustic emission and failure characteristics of sandstone. Int J Min Sci Technol 31:963–974. https://doi.org/10.1016/j.ijmst.2021.08.003

Le Ravalec M, Guéguen Y (1996) High-and low-frequency elastic moduli for a saturated porous/cracked rock-differential self-consistent and poroelastic theories. Geophysics 61:1080–1094. https://doi.org/10.1190/1.1444029

Li X, Qi C, Shao Z, Ma C (2018) Evaluation of strength and failure of brittle rock containing initial cracks under lithospheric conditions. Acta Geophys 66:141–152. https://doi.org/10.1007/s11600-018-0123-4

Li XF, Li HB, Liu LW, Liu YQ, Ju MH, Zhao J (2020) Investigating the crack initiation and propagation mechanism in brittle rocks using grain-based finite-discrete element method. Int J Rock Mech Min Sci. https://doi.org/10.1016/j.ijrmms.2020.104219

Liu Q, Wei L, Liu X, Liu J, Pan Y (2017) A revised empirical method for predicting crack initiation based on Griffith strength criterion. Chin J Rock Mech 36:1561–1569. https://doi.org/10.13722/j.cnki.jrme.2016.0398. (In Chinese)

Ma Q, Tan Y, Liu X, Gu Q, Li X (2020) Effect of coal thicknesses on energy evolution characteristics of roof rock-coal-floor rock sandwich composite structure and its damage constitutive model. Compos B 198:108086. https://doi.org/10.1016/j.compositesb.2020.108086

Ma Q, Liu X, Tan Y et al (2023) Numerical study of mechanical properties and microcrack evolution of double-layer composite rock specimens with fissures under uniaxial compression. Eng Fract Mech. https://doi.org/10.1016/j.engfracmech.2023.109403

Mallet C, Fortin J, Guéguen Y, Bouyer F (2013) Effective elastic properties of cracked solids: an experimental investigation. Int J Fract. https://doi.org/10.1007/s10704-013-9855-y

Mavko G, Mukerji T, Dvorkin J (2020) The rock physics handbook. Cambridge University Press

Nicksiar M, Martin C (2013a) Crack initiation stress in low porosity crystalline and sedimentary rocks. Eng Geol 154:64–76. https://doi.org/10.1016/j.enggeo.2012.12.007

Nicksiar M, Martin CD (2013b) Crack initiation stress in low porosity crystalline and sedimentary rocks. Eng Geol 154:64–76. https://doi.org/10.1016/j.enggeo.2012.12.007

Nicksiar M, Martin C (2014) Factors affecting crack initiation in low porosity crystalline rocks. Rock Mech Rock Eng 47:1165–1181. https://doi.org/10.1007/s00603-013-0451-2

Nicolas A, Fortin J, Guéguen Y (2017a) Micromechanical constitutive model for low-temperature constant strain rate deformation of limestones in the brittle and semi-brittle regime. Geophys J Int 211:300–321. https://doi.org/10.1093/gji/ggx299

Nicolas A et al (2017b) Brittle and semibrittle creep of Tavel limestone deformed at room temperature. J Geophys Res: Solid Earth 122:4436–4459. https://doi.org/10.1002/2016JB013557

Patel S, Martin CD (2020) Impact of the initial crack volume on the intact behavior of a bonded particle model. Comput Geotech. https://doi.org/10.1016/j.compgeo.2020.103764

Paterson MS, Wong T (2005) Experimental rock deformation: the brittle field, vol 348. Springer

Qin X, Han DH, Zhao L (2022) Measurement of grain bulk modulus on sandstone samples from the Norwegian continental shelf. J Geophys Res: Solid Earth 127:e2022JB024550. https://doi.org/10.1029/2022JB024550

Rong G, Peng J, Cai M, Yao M, Zhou C, Sha S (2018) Experimental investigation of thermal cycling effect on physical and mechanical properties of bedrocks in geothermal fields. Appl Therm Eng 141:174–185. https://doi.org/10.1016/j.applthermaleng.2018.05.126

Sayers CM, Kachanov M (1995) Microcrack-induced elastic wave anisotropy of brittle rocks. J Geophys Res: Solid Earth 100:4149–4156. https://doi.org/10.1029/94JB03134

Scott Jr T, Ma Q, Roegiers J (1993) Acoustic velocity changes during shear enhanced compaction of sandstone. In: International journal of rock mechanics and mining sciences & geomechanics abstracts. vol 7. Elsevier, pp 763–769 https://doi.org/10.1016/0148-9062(93)90020-E

Shapiro SA (2003) Elastic piezosensitivity of porous and fractured rocks. Geophysics 68:482–486. https://doi.org/10.1190/1.1567215

Shirole D, Hedayat A, Ghazanfari E, Walton G (2020) Evaluation of an ultrasonic method for damage characterization of brittle rocks. Rock Mech Rock Eng 53:2077–2094. https://doi.org/10.1007/s00603-020-02045-y

Sun Y (2019) Experimental and model studies on anisotropy of shales China University of Petroleum (Beijing)

Thomsen LJG (1986) Weak elastic anisotropy. Geophysics 51:1954–1966

Walsh J (1965) The effect of cracks on the compressibility of rock. J Geophys Res 70:381–389. https://doi.org/10.1029/JZ070i002p00381

Wang Z (2001) Fundamentals of seismic rock physics. Geophysics 66:398–412

Wang J, Ge H, Liu J, Shen Y, Zhang Z, Luo S, Liu D (2022) Effects of gravel size and content on the mechanical properties of conglomerate. Rock Mech Rock Eng 55:2493–2502. https://doi.org/10.1007/s00603-021-02760-0

Wen T, Tang H, Ma J, Wang Y (2018) Evaluation of methods for determining crack initiation stress under compression. Eng Geol 235:81–97. https://doi.org/10.1016/j.enggeo.2018.01.018

Wong RH, Chau KT, Wang P (1996) Microcracking and grain size effect in Yuen Long marbles. Int J Rock Mech Min Sci Geomech Abstr 5:479–485. https://doi.org/10.1016/0148-9062(96)00007-1

Xue L, Qin S, Sun Q, Wang Y, Lee LM, Li W (2013) A Study on crack damage stress thresholds of different rock types based on uniaxial compression tests. Rock Mech Rock Eng 47:1183–1195. https://doi.org/10.1007/s00603-013-0479-3

Yang S-Q (2016) Experimental study on deformation, peak strength and crack damage behavior of hollow sandstone under conventional triaxial compression. Eng Geol 213:11–24. https://doi.org/10.1016/j.enggeo.2016.08.012

Yi Z, Gao L, Xiyong W, Ze C, Ze L, Rui W (2021) Microfabric characteristics of tight sandstone of Xujiahe Formation in western Sichuan after high temperature and its effect on mechanical properties. Chin J Rock Mech Eng 40(11):2249–2259. https://doi.org/10.13722/j.cnki.jrme.2021.0135. (In Chinese)

Yin X, Yan E, Huang S, Feng B, Wang L (2019) Influence of microscopic characteristics on the anisotropy of crack initiation stress and crack propagation of schist. Chin J Rock Mech Eng 38(7):1373–1384. https://doi.org/10.13722/j.cnki.jrme.2018.1401. (In Chinese)

Zafar S, Hedayat A, Moradian O (2022) Evolution of tensile and shear cracking in crystalline rocks under compression. Theoret Appl Fract Mech 118:103254. https://doi.org/10.1016/j.tafmec.2022.103254

Zhang S, Ma X (2021) Global frictional equilibrium via stochastic local coulomb frictional slips. J Geophys Res Solid Earth. https://doi.org/10.1029/2020jb021404

Zhang Z, Tang C (2020) A novel method for determining the crack closure stress of brittle rocks subjected to compression. Rock Mech Rock Eng 53:4279–4287. https://doi.org/10.1007/s00603-020-02156-6

Zhang X, Wang S, Han G, Zhang B (2011) Crack propagation study of rock based on uniaxial compressive test—a case study of schistose rock. Chin J Rock Mech Eng 30(09):1772–1781 (In Chinese)

Zhang S, Wu S, Chu C, Guo P, Zhang G (2019) Acoustic emission associated with self-sustaining failure in low-porosity sandstone under uniaxial compression. Rock Mech Rock Eng 52:2067–2085. https://doi.org/10.1007/s00603-018-1686-8

Zhang S, Wu S, Zhang G (2020a) Strength and deformability of a low-porosity sandstone under true triaxial compression conditions. Int J Rock Mech Min Sci 127:104204. https://doi.org/10.1016/j.ijrmms.2019.104204

Zhang G, Zhou D, Wang P, Zhang K, Tang M (2020b) Influence of supercritical CO2-water on the micromechanical properties of sandstone. Int J Greenhouse Gas Control 97:103040. https://doi.org/10.1016/j.ijggc.2020.103040

Zhang M, Zhang G, Chen L, Sun W (2024) The discrete fracture process zone of shale on micrometer scale. Int J Rock Mech Min Sci 175:105679. https://doi.org/10.1016/j.ijrmms.2024.105679

Zhao Y, Gao Y, Wu S (2020) Influence of different concealment conditions of parallel double flaws on mechanical properties and failure characteristics of brittle rock under uniaxial compression. Theor Appl Fract Mech 109:102751. https://doi.org/10.1016/j.tafmec.2020.102751

Funding

The authors wish to acknowledge the support of the National Science Foundation of China (No. 51925405 and No. 51774299) and the Strategic Cooperation Projects of CNPC with CUPB (No. ZLZX2020-02).

Author information

Authors and Affiliations

Contributions

All the authors contribute to this research, and M.Z.: Investigation, Methodology, Formal analysis, Visualization, Writing—original draft; G.Z.: Validation, Formal analysis, Resources, Supervision, Writing—review and editing; W.S.: Writing—review and editing; L.C., X.Z. and C.X.: Data analysis.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest that may affect the research reported in this paper. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethics approval

The authors declare that this paper does not involve ethical issues.

Consent to publish

The work described was original research that has not been published previously and the manuscript is approved by all the authors for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, M., Zhang, G., Sun, W. et al. Effect of crack density on crack initiation and damage for high confining pressure using wave velocities. Geomech. Geophys. Geo-energ. Geo-resour. 10, 92 (2024). https://doi.org/10.1007/s40948-024-00802-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-024-00802-9