Abstract

With the large scale mining of coal and the increase of abandoned goafs under weakly cemented aquifer strata in Western China, it is urgent to study the time dependent mechanical properties of water sensitive aquifer strata. In this paper, creep behavior of dry and saturated medium-grain sandstone, which represent two limit states affected by water, were studied and compared. The results showed that water greatly weakens the compressive strength of medium-grained sandstone, but the difference in axial strain between dry and saturated rock samples decreases with the increase of confining pressure. The creep compression volume of rocks decreases with the increase of deviatoric stress, and only under low confining pressure does the creep volume of rocks exhibit expansion. There is an order of magnitude difference in creep strain between medium grained sandstone and other common rocks. The instantaneous elastic modulus has a negative exponential relationship with deviating stress. The creep rate has a positive exponential relationship with deviating stress. Based on Burges model with exponential damage variables, the law of the influence of confining pressure on creep model parameters has been discussed. The linear relationship between elastic modulus of medium-grained sandstone and parameters of Burgers model with damage was found. The research results are conducive to the convenient prediction of creep behavior of medium grained sandstone engineering and the long-term stability control of the surrounding rock.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

There are many shallow coal seams with simple geological structure in Western China. Coal in eastern China has been mined for a long time, and shallow coal resources have been depleted. The coal mining activity and the number of abandoned mines in Western China are increasing (Ning et al. 2017; Wang et al. 2023). However, due to the late diagenetic period of medium-grain sandstone in the western coal measures, the particle cementation of the rock is poor and the rock strength is low. The characteristics of rock damage and fracture in coal seam mining are different from those in the eastern hard strata (Zhang et al. 2015; Tan et al. 2017; Jiao et al 2021). The ecological environment of mining areas in Western China is fragile, and the underground contains precious water resources. The rough mining of coal seams causes water loss and even water inrush accidents in the goaf area (Wang et al. 2012). Therefore, it is necessary to clarify the mechanical properties, especially the creep mechanical properties of medium-grained sandstone for the stability of water-resisting layer in Western China.

For the conventional mechanical properties of soft rock, great progress has been made by many researches over the years (Cao et al. 2016; Zhou et al. 2016; Lollino and Andriani 2017; Ning et al. 2017; Wang et al. 2017; Mansouriand and Ajalloeian 2018; Bian et al. 2019; Hou et al. 2019; Yang et al. 2019; Fu et al. 2022; Chen et al. 2023). However, an important feature of soft rock is that the deformation is obvious under external force, and it is time-dependent. For example, when the Tanern highway tunnel passed through chlorite and other soft rock areas, the deformation of the surrounding rock was severe and the maximum speed reached 20 cm/d, which seriously threatened the stability of the tunnel. After modification of design scheme and secondary support, the deformation of surrounding rock tended to be stable, and the convergence time of tunnel wall deformation exceeded 300 days (Xu et al. 2011). Given that the underground environment is rich in water systems, the mechanical properties of soft rock have to consider the influence of water. Especially under the continuous action of external forces, the deformation and mechanical response of water-bearing rocks will be more different, which directly affects the stability and control measures of underground engineering.

Up to now, a lot of researches on the influence of water on creep properties of rocks have been done and some valuable results have been achieved (Waza et al. 1980; Lockner 1993; Sun 1999; Masuda 2001; Yang et al. 2007; Okubo et al. 2010; Nara et al. 2013; Tang et al. 2018; Yu et al. 2019; Li et al. 2023). For example, Lockner (1993) carried out creep tests on granite and sandstone under uniaxial stress. The results showed that creep deformation increased with the water content, and the steady creep rate of rock under dry and saturated conditions was two orders of magnitude different. Okubo et al. (2010) carried out creep tests on saturated Tage tuff for 2.5 years and 12 years. Creep strain and strain rate can be expressed as power functions of time. Sun (1999) found that the long-term compressive strength of viscous red sandstone after saturation was only 46.3% of the corresponding strength in dry state. Yang et al. (2007) found that water content and deviatoric stress are the most important factors affecting rock creep behavior based on triaxial creep tests of shale with different water content. In a word, the effect of water on rock creep is mainly manifested in the following aspects: with the increase of water content, the mechanical properties of rock are gradually weakened, the creep deformation and creep rate increase, and the duration of steady creep prolongs. However, it is impossible to find a unified law of the influence of water on rock creep properties because of the different mineral composition and internal structure of different rocks. The creep characteristics of weakly cemented medium grained sandstone with water content need to be studied, which will provide a basis for understanding the creep behavior of weakly cemented water-resisting layer and providing control strategies.

The acquisition of rock mechanical properties can provide a prerequisite for selecting a constitutive relationship that accurately describes its mechanical behavior. Researchers have established constitutive models to describe the creep mechanical behavior of corresponding rocks from various perspectives such as energy, strain, defect area, and mechanical parameter degradation (Ru et al. 2023). One of the widely used types of constitutive models is established from the perspective of energy dissipation of damage, and it basically meets the needs of rock engineering (Yang et al. 2015). However, the key to the application of constitutive models lies in determining the correct model parameters. In the past, it is a common practice to obtain the relationship between creep and time by laboratory test, and the creep model parameters by fitting experimental data with constitutive relation can then be obtained. This method is of high accuracy, but time-consuming and laborious. Hamzaa and Stace (2018) have shown that the creep and conventional mechanical behavior of the same type of rock are interrelated. They discovered a linear relationship between the conventional mechanical parameters and creep mechanical parameters of intact muddy siltstone. Based on this, it is meaningful to explore the relationship between creep model parameters of medium grained sandstone with good homogeneity and conventional mechanical parameters, and attempt to find a parameter expression method for creep models represented by conventional mechanical parameters.

In this paper, the weakly cemented medium-grain sandstone which is widely abundant in Western China is taken as the research object. The conventional mechanical properties and creep mechanical properties of dry and saturated rocks under different confining pressures are experimentally studied to obtain its unique rheological properties and the effect of water on the rheological properties. The relationship between deformation parameters and parameters of creep model is established to enrich the rapid determination method of creep model parameters.

2 Experimental method

2.1 Sample preparation

Medium-grain sandstone samples used in the test were taken from Ordos Mining Area, China. Medium-grain sandstone was formed in the Jurassic period. By identifying the physical composition of medium grained sandstone, it was found that the mineralogical compositions mainly include quartz (27.75%), illite (16.18%), chlorite (8.09%) and albite (47.98%), as shown in Fig. 1. Illite and chlorite are clay minerals, accounting for about 24% the total mineral composition of medium-grained sandstone.

Dry and saturated specimens for conventional triaxial compression and rheological tests were prepared in accordance with the procedures outlined by ISRM (1981). The ratio of height to diameter of medium-grain sandstone specimens used in the test is 2:1. The diameter is about 50 mm and the height is about 100 mm, and the error of the surface roughness less than 0.02 mm (Fig. 1). The processed standard sample is placed in a well ventilated laboratory and weighed once an hour until its quality remains unchanged, indicating that it has dried (Zhou et al. 2016). The dry standard sample is placed in clean water and weighed every half an hour for the first 10 h, and every hour after 10 h until its mass remains unchanged, indicating saturation (Zhou et al. 2016; Tang et al. 2018). The saturation ratio of medium-grained sandstone measured by experiment is 8.55–9.24%.

2.2 Axial load classification

The key to the creep test of multi-axial loading is to determine the magnitude of each step load. Therefore, before the creep test, we should carry out the conventional triaxial compression test of dry and saturated medium grained sandstone. The confining pressure (σ3) is designed as 1.5 MPa, 3.0 MPa, 4.5 MPa and 6.0 MPa. The displacement loading method is adopted for axial compression. Firstly, the confining pressure is applied at a loading rate of 0.1 MPa/s to a predetermined value and servo remains unchanged. Then, the axial pressure is applied at a loading rate of 0.06 mm/min, which is equal to the confining pressure. Finally, the axial pressure is applied at the same loading rate until the specimen fails. The experimental data is synchronously recorded during the experiment, and the experimental results are analyzed after the experiment. The experimental results show that rock strength increases with confining pressures, and the strength of dry rock under the same confining pressure is obviously greater than that of saturated rock, as shown in Fig. 2. The compressive strength of dry sample is 26.5 MPa, 30.7 MPa, 34.3 MPa and 38.1 MPa respectively, and the compressive strength of saturated sample is 18.6 MPa, 23.8 MPa, 26.8 MPa and 29.3 MPa with σ3 of 1.5 MPa, 3.0 MPa, 4.5 MPa and 6.0 MPa.

The axial load of the test starts from about 50–60% of the compressive strength. The difference between two adjacent loads is 2.0 MPa. The load difference between two adjacent confining pressures at the beginning of creep is 2.5 MPa. The specific implementation scheme is shown in Table 1.

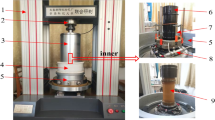

2.3 Creep test equipment and procedures

Triaxial creep test was carried out on RLJW-2000 servo-controlled testing machine (Gu et al. 2019; Tan et al. 2019). The creep characteristics of rock specimens under constant temperature (25 ± 1.5 °C) were tested by multi-axial loading on a single specimen with equal confining pressure. At the beginning of the test, the confining pressure is loaded to the set value at the rate of 0.05 MPa /s, then the axial deviating stress is loaded to the first level at the rate of 0.06 mm /min. The axial pressure is maintained for 6 h before loading to the second level, and so on until the specimen is destroyed. It should be emphasized that a loading rate of 0.06 mm/min is also used when loading between adjacent creep levels.

3 Results and discussion

3.1 Time-dependent strain of medium-grain sandstone

3.1.1 Behavior of axial strain with time

The creep deformation of saturated and dry medium-grain sandstone with time is shown in Fig. 3. The instantaneous strain of the specimen is obvious at each stage of deviatoric stress. The first-stage instantaneous deformation of saturated rock under different confining pressure differs slightly and remains at about 0.35%, while the first-stage instantaneous deformation of dry rock decreases with the increase of confining pressure, which shows that confining pressure restrict the instantaneous deformation of dry rock more obviously. After the first stage of loading, with the increase of loading level, the instantaneous deformation increases gradually, and the gap between saturated and dry rock axial deformation increases, as marked in Fig. 3. This also confirms that confining pressure has more significant constraint effect on the instantaneous compression deformation of dry rock samples.

When the deviatoric stress is not large enough, such as confining pressure 3.0 MPa and deviatoric stress less than 14 MPa, the rock samples only show instantaneous deformation and decay creep. The rock deformation reaches a stable state in a short time after instantaneous loading. When the deviatoric stress increases to a certain extent, the rock deformation shows obvious time correlation. The rock deformation takes longer to reach a stable state. With the level of axial deviator stress increases, the steady-state creep deformation rate accelerates until accelerated creep occurs.

The increase of confining pressure improves the maximum deformation and bearing capacity of medium-grain sandstone. When saturated rock is failure, the loading level is low and the axial strain is large, which indicates that the deformation capacity of medium-grain sandstone under the influence of water is increases and the bearing capacity decreases.

3.1.2 Behavior of lateral strain with time

The trend of lateral strain is similar to that of axial strain, as shown in Fig. 3. But the dynamic principle of lateral deformation and axial deformation is different (Zhang et al. 2016). In the early stage of multi-axial loadings, the lateral compactness of primary cracks and voids in specimens is generally less than the axial strain. Then it is compacted to the minimum with the increase of deviatoric stress. Time dependence means the degree to which deformation is influenced by time factors. The stronger the time dependence, the greater the influence of time on deformation. The restructuring of particles in rock enhances the lateral deformation capacity, and the time dependence of lateral strain is greater than that of axial strain. For medium-grain sandstone in coal measures, the instantaneous lateral strain under deviatoric stress is less than the instantaneous axial strain, and the lateral deformation of rock increases faster than the axial deformation after load stabilization. Under the same confining pressure, the difference of lateral strain between saturated and dry rock samples is very small. The maximum lateral deformation ability of both samples is similar, and their maximum lateral strain decreases with the increasing of confining pressure.

3.1.3 Behavior of volumetric strain with time

Volume deformation of rock generally includes two stages: volume compaction and creep dilatation (Zhang et al. 2016; Belmokhtar et al. 2017). The volume compaction of medium-grain sandstone is usually reflected in the first or two loading stages, and the subsequent loading stages are characterized by dilatancy behavior. The strain rate in compaction stage is smaller than that in dilatancy stage, and the dilatancy strain increases sharply when rock is near failure.

The maximum volumetric compressive strain of dry rock samples increases with the confining pressure, and the maximum dilatancy strain decreases with the increasing of confining pressure. For saturated rock samples, the difference of volumetric compressive strain under different confining pressure is very small, which remains about 0.2%, while the volume dilatancy under low confining pressure is the most obvious. In addition, the maximum volumetric compression strain of saturated rock is larger than that of dry rock, and the maximum volumetric dilatation strain is smaller than that of dry rock. These differences gradually decrease with the increase of confining pressure.

3.2 Instantaneous elastic modulus

In multi-axial creep loading, both instantaneous loading and constant axial stress can cause macroscopic changes in mechanical properties, which can be reflected by the instantaneous elastic modulus between two adjacent loading levels (Zhao et al. 2017). The stress–strain curve between adjacent creep levels is approximately a straight line, and its slope can be regarded as the instantaneous elastic modulus. Based on this, the elastic modulus of rock samples during each instantaneous loading was calculated, as shown in Fig. 4. The elastic modulus of saturated and dry medium-grain sandstone decreases exponentially with the increasing of deviatoric stress. Considering that the attenuation of elastic modulus can reflect the damage situation of rocks (Ma et al. 2023), it is speculated that the rock damage increases with the increase of deviatoric stress. Further fitting was performed on the relationship between instantaneous elastic modulus and deviator stress under different confining pressures, as shown in Fig. 4. It indicates that the damage of medium-grain sandstone increases exponentially with the increasing of deviatoric stress.

3.3 Strain rate analysis

The creep rate represents the stable creep deformation per unit time. Its value is equal to the slope of the creep curve during the stable creep stage. The creep rate of dry and saturated medium grained sandstone under different confining pressures and deviatoric stresses is shown in Fig. 5. The creep rate of dry and saturated rock samples under the same confining pressure increases with the increase of deviatoric stress, and the increase amplitude becomes more and more obvious. Taking the confining pressure of 4.5 MPa as an example, the creep rate of dry rock samples is 1.38 × 10–3/h under deviatoric stress of 21.5 MPa, and 1.70 × 10–3/h under deviatoric stress of 23.5 MPa, indicating an increase of 23.2%. When the deviator stress increa ses to 25.5 MPa, the creep rate is 2.40 × 10–3/h, indicating a 41.2% increase. The creep rate of saturated rock samples is 1.08 × 10–3/h under deviatoric stress of 16.5 MPa, and 1.50 × 10–3/h under deviatoric stress of 18.5 MPa, indicating an increase of 38.9%. When the deviator stress increa ses to 20.5 MPa, the creep rate is 2.66 × 10–3/h, indicating a 77.3% increase. It can be seen that the effect of the same deviatoric stress difference on the creep rate of saturated sandstone is more significant.

The creep rate of saturated rock sample is higher than that of dry rock sample under the same confining pressure. The creep rate of saturated rock sample decreases more greatly with the increase of confining pressure, but it is still higher than that of dry rock samples. Compared with other types of rocks, the creep rate of medium grained sandstone is 1–3 orders of magnitude higher. For example, the creep rate of red soft rock under confining pressure of 5.0 M Pa is about 3 × 10–6/h (Deng et al. 2016), the creep rate of claystone under confining pressure of 6.0 MPa is about 7 × 10–5/h (Liu et al. 2018), and the creep rate of shale rocks under confining pressure of 4.5 MPa is about 8.0 × 10–6/h (Brijes and Priyesh 2015). This indicates that medium grained sandstone is prone to accumulate creep deformation and instability failure in a short period of time. Therefore, for the unloading surrounding rock of medium grained sandstone underground engineering, timely support control should be carried out.

The creep rate of dry and saturated medium grained sandstone under different confining pressures decreases overall with the increase of confining pressure. The creep rate of dry rock samples with confining pressure of 1.5 MPa and deviating stress of 18.5 MPa is 2.05 × 10–3/h. The creep rate of dry rock samples is 1.80 × 10–3/h when the confining pressure is increased to 6.0 MPa and the deviatoric stress is 26.0 MPa. The creep rate of saturated rock samples with confining pressure of 1.5 MPa and deviating stress of 13.5 MPa is 4.25 × 10–3/h. The creep rate of saturated rock samples is 1.64 × 10–3/h when the confining pressure is increased to 6.0 MPa and the deviatoric stress is 21.0 MPa. The application of confining pressure has a significant limiting effect on the axial creep rate of medium grained sandstone. In practical engineering, support reinforcement can increase the binding force, and the deformation rate of medium grained sandstone can be effectively suppressed. This is different from some soft rock underground projects, where the large deformation of the rock mass will continue even with increased support constraints (He and Wang 2022).

Ma and Daemen (2006) pointed out that the steady state creep rate of tuff lava has a power function relationship with deviatoric stress, and the higher the stress, the more obvious the exponential relationship is. In this paper, the exponential function relationship (y = AeBx) between steady creep rate and deviatoric stress of medium grain sandstone in is shown in Fig. 6. A and B are both experimental parameters, which are greater than 0. The fitted exponential relation is consistent with the conclusion that the elastic modulus decreases exponentially with deviatoric stress. That is, the higher the deviatoric stress, the faster the damage of rock and the faster the creep rate.

3.4 Creep model analysis

The creep experimental data can be analyzed and displayed through constitutive models. The parameters in these models can correspond to the inherent creep characteristics of rock materials. So it is important to quantitatively obtain the creep characteristics of materials for engineering stability prediction and engineering design.

For medium-grained sandstone, the rock presents deceleration creep and steady creep under deviating stress, i.e. linear creep. This creep behavior can be well described by Burgers model. However, according to the above experimental results, the damage of medium-grain sandstone accumulates exponentially under multi-axial creep loading, and the isochronal stress–strain relationship changes nonlinearly. Therefore, we should use the damage Burgers model to describe the creep behavior of medium-grain sandstone, and its expression is as follows (Zhu et al. 2010):

where ε is the strain, σ is the stress, t is time, E0 M, η0 M, E0 K, η0 K are viscoelasticity coefficient of damage Burgers model, εc is viscous strain.

It can be seen from Formula (1) that there is a non-linear term (1/e−mεc) in the Burgers model with damage, which is consistent with the conclusion that the damage increases exponentially with the deviatoric stress. m is a coefficient related to rock properties. The greater the m value, the more serious the material damage is under the same viscous strain. Based on the research results of Zhu et al. (2010), the satisfactory fitting result can be obtained by fitting the curve with m = 40.

Based on the creep test results, the Levenberg–Marquardt algorithm is introduced into the least squares method for solving nonlinear problems to identify the parameters in the creep model. The fitting of parameters is achieved by compiling formula (1) using Matlab software and introducing the least squares method with Levenberg–Marquardt algorithm. Due to the incomplete accelerated creep process of some specimens in Fig. 5, the experimental data at the loading level prior to specimen failure were uniformly fitted. The identified parameters of Burgers model with damage are shown in Table 2. The model was found to be suitable to describe the experimental data with good accuracy (R2 = 0.91 − 0.99).

The results in Table 2 show that the saturated rocks with smaller stiffness also have smaller creep parameters than the dry rocks, which results in larger creep deformation. The creep parameters of medium-grain sandstone increase with the confining pressure, and the relationship between rock stiffness and confining pressure is also positive. Therefore, we can infer that the creep model parameters of medium-grained sandstone correspond to its elastic modulus. This inference will make it possible for us to obtain the parameters of creep model based on the instantaneous deformation parameters of rocks.

Maxwell parameter E0 M reflects the instantaneous deformation of rock specimen under axial loading. The E0 M values of the creep curves of saturated medium grained sandstone at the penultimate loading level under confining pressures of 1.5 MPa, 3.0 MPa, 4.5 MPa, and 6.0 MPa are 6.12, 6.78, 9.27, and 10.86, respectively. The E0 M values of the creep curves of dry medium grained sandstone are 9.31, 10.08, 12.48, and 14.17, respectively. Since the second to last loading level is the level before accelerated creep failure, this indicates that the instantaneous deformation of medium grained sandstone before accelerated creep increases with the increase of confining pressure. The premise of this conclusion is that medium grained sandstone with high confining pressure also bears greater axial loads. Therefore, in practical underground engineering, the medium sand rock mass with support constraints can withstand greater vertical loads and instantaneous deformation.

As for the variation of E0 M with deviatoric stress, taking 4.5 MPa confining pressure as an example, the relationship of E0 M with deviatoric stress as shown in Fig. 7 shows that the instantaneous deformation of medium-grain sandstone increases with the increase of deviatoric stress, which reflects the non-linear characteristics of rock creep, and also confirms the phenomena illustrated by the isochronal stress–strain curve. In addition, the first creep (deformation recoverable) and the second creep (deformation non recoverable) properties of rocks can be reflected by Kelvin parameters η0 K and Maxwell parameter η0 M, respectively. The η0 M is small and η0 K is large for saturated rock samples under the same confining pressure. It indicates that the recoverable ability of medium grained sandstone deformation after water absorption is enhanced. This may be because the porosity of medium grained sandstone is high (Gu et al. 2023). After water absorption, mineral particles with high clay content absorb water and soften, while water also fills the gaps between mineral particles, enhancing their deformation recovery ability. Injecting some special liquid materials into the rock mass may become a way to improve the mechanical properties of medium grained sandstone.

3.5 Relationship between instantaneous and creep parameters

From the above analysis, it can be seen that there is a corresponding relationship between conventional deformation characteristics and creep deformation characteristics (Hamzaa and Stace 2018). Therefore, the creep model parameters can be normalized by dividing them by a certain conventional mechanical parameter. Considering that elastic modulus is the fundamental parameter reflecting the deformation properties of rock masses and one of the most easily obtained mechanical parameters in conventional experiments, elastic modulus is chosen as the basis for normalization of creep model parameters in an attempt to explore the possibility of using elastic modulus as a function to represent creep model parameters.

The creep model parameters are divided by the elastic modulus (E) under the same confining pressure are shown in Fig. 8. The results show that the regularity of creep properties of saturated and dry medium-grain sandstones after normalization is more obvious. The ratio of creep model parameters to E decreases with the increase of confining pressure, and the magnitude of the decrease seems relatively close. This indicates a direct correlation between the conventional mechanical properties and creep properties of medium grained sandstone.

Therefore, parameters of Burgers model with damage and elastic modulus (E) are plotted in Fig. 9. It is found that the relationship between them can be described by a linear function, and the accuracy of the description is more than 0.89. That is to say, the creep parameters of saturated and dry medium-grain sandstones can be calculated according to the formula parameter = a + bE when the elastic modulus (E) of rocks is known. The values of a and b are given in Table 3.

The discovery of the relationship between the parameters of the damage Burgers model and the elastic modulus provides a new approach for quickly obtaining creep model parameters. Only for the medium grained sandstone in this study, there is a good linear correlation between its elastic modulus and creep model parameters. The effectiveness of creep model parameters based on elastic modulus representation in predicting the creep behavior of medium grained sandstone still needs further verification. It should be emphasized that medium grained sandstone has good homogeneity and a strong linear correlation between its elastic modulus and creep model parameters. However, due to the fact that most coal measures rocks belong to sedimentary rocks, their homogeneity is generally lower than that of medium grained sandstone in coal measures. Whether there is a simple corresponding relationship between their elastic modulus and creep model parameters still needs to be explored.

4 Conclusions

The main purpose of this study is to investigate and compare the triaxial creep behavior of saturated and dry medium-grain sandstone, which can provide guidance for the control of medium grained sandstone rock layers and roadway surrounding rocks under the influence of water. The relationship between conventional mechanical properties and creep model parameters of medium-grain sandstone is further discussed.

-

1.

The first-loading instantaneous deformation of saturated rock under different confining pressures is similar, but that of dry rock decreases with the increase of confining pressure, which indicates that increasing constraints is effective in controlling deformation of dry medium grained sandstone. Thereafter, the instantaneous and creep deformation of the specimens increase with the increase of deviatoric stress, and the decay creep gradually develops into stable creep and then accelerated creep. There is an order of magnitude difference in creep strain between medium grained sandstone and other common rocks.

-

2.

The lateral strain after load stabilization increase faster than that of axial strain. The rock volume is gradually compressed in the first or two stages of axial loading and then expanded in other loading stages. The difference in the maximum volumetric compressive strain of saturated samples under different confining pressures is small. The strength of medium grained sandstone after water absorption significantly decreases, but the volume compression changes little.

-

3.

The creep deformation of medium-grain sandstone has non-linear characteristics, that is, the creep of medium grained sandstone under multi-axial loading will transition from viscoelastic deformation to viscoplastic deformation. This is reflected in the negative exponential relationship of elastic modulus and deviatoric stress, and the positive exponential relationship of creep rate and deviatoric stress. The creep rate of saturated sandstone is generally faster than that of dry rock. The medium grained sandstone surrounding rock affected by water should be supported in a timely manner.

-

4.

Based on damage Burgers model, the fitting of creep test data under different confining pressures is successfully realized. Compared with dry rock, saturated rock with smaller stiffness has smaller creep parameters. The linear relationship with high correlation between elastic modulus and parameters of damage Burgers model is found. This relationship is beneficial for convenient prediction of rock creep behavior based on conventional mechanical parameters in the future.

Data availability

The data used to support the findings of this research are included within the paper.

References

Belmokhtar M, Delage P, Ghabezloo S, Conil N (2017) Thermal volume changes and creep in the Callovo-Oxfordian claystone. Rock Mech Rock Eng 50(9):2297–2309

Bian K, Liu J, Zhang W, Zheng XQ, Ni SH, Liu ZP (2019) Mechanical behavior and damage constitutive model of rock subjected to water-weakening effect and uniaxial loading. Rock Mech Rock Eng 52(1):97–106

Brijes M, Priyesh V (2015) Uniaxial and triaxial single and multistage creep tests on coal-measure shale rocks. Int J Coal Geol 137:55–65

Cao P, Wen YD, Wang YX, Yuan HP, Yuan BX (2016) Study on nonlinear damage creep constitutive model for high-stress soft rock. Environ Earth Sci 75(10):900

Chen G, Li Y, Li T, Zhang G (2023) Experimental study on the mechanical properties of intermittent jointed sandstone considering water-rock interaction and confining pressure effect. Bull Eng Geol Environ 82:113. https://doi.org/10.1007/s10064-023-03156-w

Deng HG, Zhou ML, Li JL, Sun XS, Huang YL (2016) Creep degradation mechanism by water-rock interaction in the red-layer soft rock. Arab J Geosci 9:601

Fu JW, Labuz JF, Cheng HX, Hou RB, Zhu WS (2022) Simulating progressive failure in fractured saturated rock under seepage condition using a novel coupled model and the application. Geomech Geophys Geo-Energ Geo-Resour 8:42

Gu QH, Ma Q, Tan YL, Jia ZC, Zhao ZH, Huang DM (2019) Acoustic emission characteristics and damage model of cement mortar under uniaxial compression. Constr Build Mater 213:377–385

Gu QH, Zhao GM, Meng XR, Sun J, Cheng X, Xu WS, Zhang RF (2023) Creep behavior and its prediction of saturated weakly cemented medium-grain sandstone under multi-axial loadings. Geofluids 2023:3747027

Hamzaa O, Stace R (2018) Creep properties of intact and fractured muddy siltstone. Int J Rock Mech Min Sci 106:109–116

He MC, Wang Q (2022) Excavation compensation method and key technology for surrounding rock control. Eng Geol 307:106784

Hou RB, Zhang K, Tao J, Xue XR, Chen YL (2019) A nonlinear creep damage coupled model for rock considering the effect of initial damage. Rock Mech Rock Eng 52(5):1275–1285

ISRM (1981) Rock characterization, testing and monitoring. In: Brown ET (ed) ISRM (International Society for Rock Mechanics) suggested methods. Pergamon, Oxford

Jiao YY, Wu KB, Zou JP, Zheng F, Zhang XF, Wang C, Li X, Zhang C (2021) On the strong earthquakes induced by deep coal mining under thick strata-a case study. Geomech Geophys Geo-Energ Geo-Resour 7:97

Li JD, Gao Y, Yang TH, Zhang PH, Deng WX, Liu FY (2023) Effect of water on the rock strength and creep behavior of green mudstone. Geomech Geophys Geo-Energ Geo-Resour 9:101

Liu ZB, Shao JF, Xie SY, Conil N, Zha WH (2018) Effects of relative humidity and mineral compositions on creep deformation and failure of a claystone under compression. Int J Rock Mech Min Sci 103:68–76

Lockner D (1993) Room temperature creep in saturated granite. J Geophys Res-Sol Ea 98(B1):475–487

Lollino P, Andriani GF (2017) Role of brittle behaviour of soft calcarenites under low confinement: laboratory observations and numerical investigation. Rock Mech Rock Eng 50(7):1863–1882

Ma L, Daemen JJK (2006) An experimental study on creep of welded tuff. Int J Rock Mech Min Sci 43(2):282–291

Ma Q, Liu XL, Tan YL, Derek E, Shang JL, Song DQ, Liu XS, Yan FY (2023) Numerical study of mechanical properties and microcrack evolution of double-layer composite rock specimens with fissures under uniaxial compression. Eng Fract Mech 289(2):109403

Mansouri H, Ajalloeian R (2018) Mechanical behavior of salt rock under uniaxial compression and creep tests. Int J Rock Mech Min Sci 110:19–27

Masuda K (2001) Effects of water on rock strength in a brittle regime. J Struct Geol 23(11):1653–1657

Nara Y, Yamanaka H, Oe Y, Kaneko K (2013) Influence of temperature and water on subcritical crack growth parameters and long-term strength for igneous rocks. Geophys J Int 193:47–60

Ning JG, Wang J, Tan YL, Zhang LS, Bu TT (2017) In situ investigations into mining-induced overburden failures in close multiple-seam longwall mining: a case study. Geomech Eng 12(4):657–673

Okubo S, Fukui K, Hashiba K (2010) Long-term creep of water-saturated tuff under uniaxial compression. Int J Rock Mech Min Sci 47:839–844

Ru WK, Hu SC, Zhou AH, Luo PK, Gong H, Zhang CX, Zhou XD (2023) Study on creep characteristics and nonlinear fractional-order damage constitutive model of weakly cemented soft rock. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-023-03493-y

Sun J (1999) Rheology of rock and soil materials and its application in engineering. Chinese Architecture and Building Press, Beijing

Tan YL, Gu QH, Ning JG, Liu XS, Jia ZC, Huang DM (2019) Uniaxial compression behavior of cement mortar and its damage-constitutive model based on energy theory. Materials 12(8):1309

Tan YL, Liu XS, Ning JG, Lv YW (2017) In situ investigations on failure evolution of overlying strata induced by mining multiple coal seams. Geotech Test J 40(2):244–257

Tang SB, Yu CY, Heap MJ, Chen PZ, Ren YG (2018) The influence of water saturation on the short-and long-term mechanical behavior of red sandstone. Rock Mech Rock Eng 51(9):2669–2687

Wang FT, Wei XQ, Shao DL, Zhang C (2023) The progressive failure mechanism for coal pillars under the coupling of mining stress and water immersion in underground reservoirs. Bull Eng Geol Environ 82:103. https://doi.org/10.1007/s10064-023-03151-1

Wang Y, Yang WF, Li M, Liu X (2012) Risk assessment of floor water inrush in coal mines based on secondary fuzzy comprehensive evaluation. Int J Rock Mech Min Sci 52:50–55

Wang Q, Pan R, Jiang B, Li SC, He MC, Sun HB, Luan YC (2017) Study on failure mechanism of roadway with soft rock in deep coal mine and confined concrete support system. Eng Fail Anal 81:155–177

Waza T, Kurita K, Mizutani H (1980) The effect of water on the subcritical crack growth in silicate rocks. Tectonophysics 67:25–34

Xu WY, Nie WP, Zhou XQ, Shi C, Wang W, Feng SR (2011) Long-term stability analysis of large-scale underground plant of Xiangjiaba hydro-power station. J Cent South Univ T 18(2):511–520

Yang CH, Wang YY, Li JG, Gao F (2007) Testing study about the effect of different water content on rock creep law. J China Coal Soc 7:695–670

Yang SQ, Xu P, Ranjith PG (2015) Damage model of coal under creep and triaxial compression. Int J Rock Mech Min Sci 80:337–345

Yang W, Zhang Q, Ranjith PG, Yu R, Luo G, Huang C, Wang G (2019) A damage mechanical model applied to analysis of mechanical properties of jointed rock masses. Tunn Undergr Sp Tech 84:113–128

Yu CY, Tang SB, Tang CA, Duan D, Zhang YJ, Liang ZZ, Ma K, Ma TH (2019) The effect of water on the creep behavior of red sandstone. Eng Geol 253:64–74

Zhang JH, Wang LG, Li QH, Zhu SS (2015) Plastic zone analysis and support optimization of shallow roadway with weakly cemented soft strata. Int J Min Sci Tech 25(3):395–400

Zhang Y, Shao JF, Xu WY, Jia Y (2016) Time-dependent behavior of cataclastic rocks in a multi-loading triaxial creep test. Rock Mech Rock Eng 49(9):3793–3803

Zhang ZT, Gao WH (2020) Effect of different test methods on the disintegration behaviour of soft rock and the evolution model of disintegration breakage under cyclic wetting and drying. Eng Geol 279:105888

Zhao YL, Zhang LY, Wang WJ, Wan W, Li SQ, Ma WH, Wang YX (2017) Creep behavior of intact and cracked limestone under multi-level loading and unloading cycles. Rock Mech Rock Eng 50(6):1409–1424

Zhou Z, Cai X, Cao W, Li X, Xiong C (2016) Influence of water content on mechanical properties of rock in both saturation and drying processes. Rock Mech Rock Eng 49(8):3009–3025

Zhu JB, Wang B, Wu AQ (2010) Study of unloading triaxial rheological tests and its nonlinear damage constitutive model of jinping hydropower station green sandstone. Chin J Rock Mech Eng 29(3):528–534

Funding

This research was funded by Anhui Provincial Natural Science Foundation (No. 2208085QE143), National Natural Science Foundation of China (No. 51974009, 52074168), Anhui Province Science and Technology Major Project (No. 202203a07020011), Anhui Province “Provincial Special Expenditure Plan” Leading Talent Project (No. T000508), Collaborative Innovation Project of Anhui Province Universities (GXXT-2021-075), State and Local Joint Engineering Laboratory for Gas Drainage & Ground Control of Deep Mines (Henan Polytechnic University (No. SJF2208), Anhui Engineering Research Center of Exploitation and Utilization of Closed/Abandoned Mine Resources (No. EUCMR202203), and Scientific Research Foundation for High-level Talents of Anhui University of Science and Technology (No. 2021yjrc20).

Author information

Authors and Affiliations

Contributions

Conceptualization, Gu QH and Tan YL; methodology, Gu QH and Zhao GM; experiment, Gu QH; formal analysis, Mneg XR and Cheng X; writing—original draft preparation, Gu QH; writing—review and editing, Gu QH and Cheng X. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Consent to publish

The Author confirms that the work described has not been published before (except in the form of an abstract or as part of apublished lecture. review, or thesis), and its publication has been approved by all co-authors.

Competing interests

The author(s) declared no potential conflict of interest with respect to the research, authorship, and/ or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gu, Q., Tan, Y., Zhao, G. et al. Creep behavior of dry and saturated medium-grain sandstone and its relationship with conventional mechanical properties. Geomech. Geophys. Geo-energ. Geo-resour. 10, 52 (2024). https://doi.org/10.1007/s40948-024-00771-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-024-00771-z