Abstract

Gravity heat pipe system has previously been proven as an environmental and efficient technology in exploiting hot dry rock. However, it is unclear what geothermal reservoir siting is more favorable for the system’s heat extraction performance. Herein, we analyzed the influences of geothermal field siting (rock property and reservoir environment) on heat extraction performance of gravity heat pipe systems through a 3D thermal–hydraulic coupled model. It is found that rock properties have huge influences on heat compensation, heat extraction ratio and heat compensation ratio. Low rock density, low rock specific heat capacity and high thermal conductivity could increase heat compensation, heat extraction ratio and heat compensation ratio. It is also found that geothermal reservoir environment affects the heat extraction rate seriously. High initial temperatures and low temperature gradients increase heat extraction rates. Geothermal reservoir pressure affects the heat extraction performance slightly, and low initial pressures increase heat extraction rate. The study results would provide suggestions on deep geothermal exploitation locations.

Article highlights

-

1.

A 3D thermal-hydraulic coupled model is established.

-

2.

The effects of different geothermal reservoir siting are analyzed.

-

3.

Rock properties have huge influences on heat compensation.

-

4.

Geothermal reservoir environment affects heat extraction rate greatly.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Geothermal energy is a clean energy, which has a big number of advantages (cleanness, stability, and large-scale reserves). Deep geothermal has huge application potential, and it has been followed with interest. Hot dry rock (HDR) is a main form of deep geothermal energy, which can be utilized to generate electricity. At the depth of 3–10 km underground, HDR sources are very abundant in China (about \(2.52\times 10^{25}\) J) (Tester et al. 2007; Wang et al. 2013). The utilization of HDR has a good application prospect. Deep geothermal utilization technology has made great progress, and various mining technologies have emerged. In the 1970 s, the concept of enhanced geothermal systems (EGS) was proposed (Lu 2018), and the system test was carried out in the Fenton Hill project. At present, EGS is the primary deep geothermal exploitation technology, which extracts deep geothermal energy by injecting cold fluid into fractured reservoirs (Liu et al. 2021a). EGS has developed many novel exploitation forms. In order to get more heated fluid from fractured reservoirs, the form of multiple production wells in fractured reservoirs was adopted in the Soultz project (Genter et al. 2010; Egert et al. 2020). Li et al. (2019) studied the heat extraction performance of double horizontal wells by studying multi-staged fracturing. In order to utilize fractured reservoirs efficiently and increase production performance, a novel multilateral-well EGS was proposed (Song et al. 2018), and the EGS form has many injection and production wells around the main wellbore. Compared with traditional EGS, multilateral-well EGS has higher output power, accumulative heat energy and heat extraction ratio. In addition, many researchers also analyzed the effects of working fluid (Shi et al. 2018) and fracture network distribution (Shi et al. 2019a, b) on multilateral-well EGS. Zhang et al. (2019) proposed a tree-shaped well EGS, and the EGS with a tree-shaped well can decrease flow impedance and increase heat extraction performance. However, EGS has been facing fluid loss problems. A large amount of fluid loss is often the primary failure reason in practical engineering. Facing fluid loss problems, many scholars proposed subsurface heat exchangers to avoid fluid loss. A downhole coaxial heat exchanger technology was proposed in 2013 (Yekoladio et al. 2013). Working fluid is extracted from the inner tube and injected into the annulus, and this can increase circulating power output. In order to decrease wellbore resistance, Dehkordi et al. (2015) shorten the spacing between down-hole pipes and borehole walls, and results show the compact wellbore design can increase heat extraction efficiency. Finsterle et al. (2013) combined the micro-hole array method and HDR utilization. The application of micro-hole arrays can provide reasonable flow paths in fractured reservoirs, and this can avoid heat breakthrough and increase recovery factor. Wolff (yyyy) proposed an underground multi-horizontal-wells system, and the heat extraction performance was quantitatively analyzed. In addition, Jiang et al. (2016) also found that the underground multi-horizontal-well system has good application prospects. After oil drilling projects ended, many oilfields with abundant geothermal energy were abandoned. Many kinds of technologies are proposed to extract geothermal energy in abandoned oilfield wells (Zhang et al. 2014; Weijermars et al. 2018; Shu et al. 2019; Caulk and Tomac 2017). In 2020, a novel deep geothermal exploitation technology achieved a successful field test. The good thermal conductivity of gravity heat pipe is utilized to exploit deep geothermal energy (Huang et al. 2018; Huang and Cao 2021), and the deep geothermal exploitation technology has good utilization prospects.

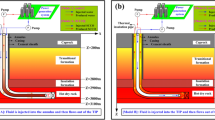

Gravity heat pipe utilizes phase change of working fluid to quickly transfer heat, which has the characteristics of high heat transfer performance and excellent isothermal performance (Zhang et al. 2021; Tian et al. 2017; Eidan et al. 2021; Chen et al. 2021). It is one of the most effective heat transfer devices at present. An ultra-long gravity heat pipe that utilizes HDR was proposed (Jiang et al. 2017; Daily 2020). Figure 1 shows the schematic diagram of gravity heat pipe system. The working principle of geothermal energy extraction using a gravity heat pipe is as follows: The working fluid is introduced into the gravity heat pipe and its interior is evacuated to a negative pressure state using a vacuum pump. Initially, the liquid is located at the bottom of heat pipe. The evaporator section is heated by the high-temperature rocks in the deep underground, reaching the evaporation temperature of the liquid. The liquid absorbs heat and vaporizes, becoming steam. Under a small pressure difference, the steam flows through the adiabatic section towards the condenser section on the surface. In the condenser section, heat is released and the steam condenses back into a liquid. Subsequently, under the influence of gravity, the liquid flows back to the evaporator section, and this cycle continues, extracting the dry-hot rock thermal energy from the deep underground to the surface. During December 2019–April 2020, Daily (2020), cctv.com (2020), Huang et al. (2022a, 2022b) conducted a field test that utilized a 3000 m heat pipe to exploit HDR in Tangshan, Hebei province. The heat pipe used in this experiment was developed in-house and employed deionized water as the working fluid. It generated steam with a maximum temperature of approximately 90 \(^{\circ }\)C, while the average temperature of the underground formation surrounding the subsurface heat pipe was 95.6 \(^{\circ }\)C. Throughout the 30-day continuous heat mining process, the heat extraction rate maintained an average value of 190 kW, showing no discernible downward trend. Selection of working fluid and effect of key parameters of super-long gravity heat pipe are also studied. The field test has confirmed the technical feasibility of utilizing a super-long gravity heat pipe for extracting HDR geothermal energy. Unlike enhanced geothermal systems, gravity heat pipe systems can save pump work. Because working fluid circulates in heat pipe, working fluid does not directly contact rock, it also effectively avoids working fluid loss (Panel 2006), pipeline scaling (Borgia et al. 2012) and subsequent environmental pollution problems (Kim et al. 2018; Templeton et al. 2020; Kraft and Deichmann 2014). Gravity heat pipe system is a promising geothermal exploitation technology.

In order to strengthen heat transfer between evaporation section and fractured reservoir, in gravity heat pipe system, CO\(_{2}\) is utilized to fill fractured reservoir (Pruess 2006; Randolph and Saar 2011). Compared with conventional fluid mediums, CO\(_{2}\) has better buoyancy and settling force under the same temperature difference (Span and Wagner 1996). Meanwhile, CO\(_{2}\) has low viscosity, which can obtain a greater seepage velocity under the same pressure difference. Therefore, the use of CO\(_{2}\) can strengthen natural convection. In addition, gravity heat pipe system also has a CO\(_{2}\) sequestration function. As a heat exchange working substance, CO\(_{2}\) property has vital influences on heat exchange performance. In deep geothermal environment, CO\(_{2}\) is in supercritical state (Pruess 2008; Heidaryan et al. 2011; Jarrahian and Heidaryan 2012; Heidaryan and Jarrahian 2013). Meanwhile, geothermal reservoir environments (temperature, temperature gradient, pressure and pressure gradient) have great influences on CO\(_{2}\) properties. Therefore, it is necessary to analyze the effects of reservoir environment on heat extraction performance of gravity heat pipe system.

In this study, we established a 3D thermal–hydraulic (TH) model to compare the influences of reservoir conditions on gravity heat pipe systems. Four characteristic parameters (heat extraction rate, heat extraction ratio, cumulative heat compensation and heat compensation ratio) are proposed to investigate the heat extraction performance under various geothermal conditions. Pressure field, temperature field and velocity field are also considered. Firstly, fractured reservoir properties (permeability, heat conductivity, density and heat capacity) is investigated. Then, the effects of initial temperature,temperature gradient, initial pressure and pressure gradient on gravity heat pipe system are studied. This would provide meaningful suggestions for the location selection of gravity heat pipe system.

2 Mathematical model

In this section, we make some reasonable assumptions about the calculation model. Then, based on different reservoir area characteristics, corresponding control equations in different areas are also established. Finally, the feasibility of TH coupling model is verified.

2.1 Model assumptions

In practical deep geothermal environment, HDR has very low permeability, and HDR can be seen as impermeable in this study. Fractured reservoir includes fracture network. Fractured reservoir has higher permeability than HDR. In order to simulate the heat exchange process in geothermal reservoir efficiently, we also made some basic assumptions, as follows: (1) HDR and fractured reservoir are set as isotropic equivalent continuous porous media. (2) The heat exchange process between fluid and rock obeys Fourier’s law, and it can be expressed by the local heat balance. (3) The fluid flow process in geothermal reservoir obeys Darcy’s law. (4) CO\(_{2}\) is in a supercritical state in a deep geothermal environment (Cao et al. 2016), and its physical properties are very sensitive to the geothermal environment. Span and Wagner (S–W EOS) (Span and Wagner 1996) proposed the equation of state for CO\(_{2}\). It has a high calculation accuracy, and its applicable range is also wide (216.95 K < T < 1100 K, 0.52 MPa < p < 800 MPa). The density of CO\(_{2}\) can be expressed by compressibility factor [46]. However, the calculation process is very complex, and it is very difficult to calculate in geothermal simulation. In this study, the pressure range is between 15 and 40 MPa, and the temperature range is between 273 and 533 K. [47] proposed a state equation about supercritical carbon dioxide drilling fluid, which has similar accuracy to the S–W EOS in deep geothermal environments. The application range of state equation is closer to the deep geothermal environment, and it is often used in deep geothermal exploitation simulation (Guo et al. 2019; Qu et al. 2017; Liu et al. 2021b). It can be described as follows:

2.2 Governing equations

Fluid flow in geothermal reservoir can be written by the mass conservation equation:

where \(\rho _{f}\) is the fluid density, \(\epsilon _{p}\) is the porosity. u denotes Darcy velocity (m/s), and it can be expressed as:

where k is the permeability of geothermal reservoir(m\(^{2}\)). \(\mu _{f}\) denotes the fluid dynamic viscosity (Pa s), and \(gz\rho _{f}\) is the gravity item, in which g, z and \(\rho _{f}\) are the gravitational acceleration (m/s\(^{2}\)), the vertical direction and the fluid density (kg/m\(^{3}\)), respectively.

In this study, because fluid has a very low flow velocity in fractured reservoirs, rock and working fluid have almost the same temperature. Local heat balance can be used to express the heat exchange between fluid and rock. Energy equation is established to describe the heat exchange process in geothermal reservoirs. The energy equation includes fluid and solid phases, which is expressed as follows:

where T (K) is geothermal reservoir temperature, \(\left( \rho C_{p} \right) _{eff}\) is the effective specific heat capacity, which can be expressed as \( \left( \rho C_{p} \right) _{eff}=\varphi \rho _{f}C_{f}+\left( 1-\varphi \right) \rho _{s}C_{s}\). \(C_{s}\) and \(C_{f}\) denote the solid and fluid heat capacities (J/(kg k)), respectively. \(\rho _{s}\) indicates the solid density (kg/m\(^{3}\)). \(q_{T}\) is expressed as follow:

where \(\lambda _{eff}\) is the effective thermal conductivity, which is written as \(\lambda _{eff}=\varphi \times \lambda _{f}+\left( 1- \varphi \right) \times \lambda _{s}\). where \(\lambda _{s}\) and \(\lambda _{f}\) are the solid and fluid thermal conductivities (W/ (m K)), respectively.

2.3 Validation of numerical model

In this section, we verified the applicability of the TH model. The calculation area is a 1000 m\(\times \)1000 m\(\times \)200 m cuboid, and it represents a fractured reservoir (Fig. 2a). There are two fractures in the fractured reservoir. The distance between injection and production wells is 350 m. In addition, the length of injection and production wells is 50 m. The practical fractured reservoir environment is similar with the calculation area in this study. The top surface temperature and temperature gradient of the fractured reservoir are 473 K and 50 K/km, respectively. The initial pressure is set at 30 MPa, and the production well pressure remains at 20 MPa. In addition, the injection rate is 10 kg/s, and the injection temperature is 293 K. Table 1 shows the properties of fracture and HDR. As shown in Fig. 2, we can see that the production results of the present model are very similar with the results (Guo et al. 2019). In the heat extraction process during 30 years, the absolute errors are no higher than 1.5 K. This means that the present model can simulate flow heat transfer in porous media. Therefore, the proposed model can be used to analyze heat extraction progress in a gravity heat pipe system.

3 Calculation model

In this section, we established a suitable geothermal reservoir to study heat extraction performance. In addition, four characteristic parameters (heat extraction rate, heat extraction ratio, cumulative heat compensation and heat compensation ratio) are used to study heat extraction comprehensively.

3.1 Initial and boundary conditions

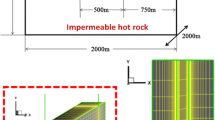

In this section, the calculation area (including fractured reservoir and HDR) is a 500 m\(\times \)500 m\(\times \)500 m cube. The center area represents a fractured reservoir (200 m\(\times \)200 m\(\times \)300 m cube), and the fractured reservoir is at the depth (D) of 3700–4000 m (Fig. 3). The upper and lower surface distance between fractured reservoir and calculation area is 100 m, and the distance of surrounding boundaries is 150 m. The reservoir environment is described as follows: the initial bottom temperature and pressure are 500 K and 35 MPa, respectively. Reservoir temperature and reservoir pressure increase linearly in the depth direction, and the temperature gradient and pressure gradient are 0.05 K/m and 9500 Pa/m, respectively. In the calculation area, external surfaces are seen as adiabatic conditions. The interfaces between surrounding HDR and fractured reservoir are inter-boundary, which means heat flux and temperature are continuous. Besides, the external faces are impermeable boundaries. Based on rock properties of the Qiabuqia geothermal field in the Gonghe Basin, China (Lei et al. 2020; Chen et al. 2019), Table 2 shows the properties of HDR and fractured reservoir.

In this study, the gravity heat pipe is seen as an ideal gravity heat pipe. That indicates the adiabatic section and evaporation section have excellent thermal insulation and excellent temperature uniformity, respectively. In the calculation model, adiabatic section is set as adiabatic boundary. The evaporation section is set as isothermal boundary, and the isothermal temperature is 460 K. The adiabatic section and evaporation section are located in HDR and fractured reservoir, and the lengths are 100 m and 300 m, respectively. Ultra-long gravity heat pipe should consider flow resistance loss and carrying limit (Jiang et al. 2017; Faghri 1995), and the radius of gravity heat pipe is set to 0.1 m in this study.

3.2 Characteristic parameter definition

Four parameters are defined to study the effects of geothermal field conditions on heat extraction performance, namely heat extraction rate, heat extraction ratio, cumulative heat compensation and heat compensation ratio (Liu et al. 2021b).

The heat extraction rate (\(Q_{g}\)) is calculated by four characteristic paraments. A denotes the evaporation section area (m\(^{2}\)). h (W/m\(^{2}\) K)) indicates the heat transfer coefficient between geothermal reservoir and gravity heat pipe. T (K) denotes fractured reservoir temperature, and \(T_{g}\) (K) indicates the temperature of evaporation section. \(Q_{g}\) can be expressed as follows:

Heat extraction ratio (\(\eta \)) is the ratio of fractured reservoir heat loss to the heat release when fractured reservoir temperature drops to evaporation section temperature. It is expressed as follow.

where \(V_{f}\) (\(m^{3}\)) defines fractured reservoir volume. \(T_{i}\) is initial reservoir temperature. T(t) represent the reservoir temperature at time t. \(T_{g}\) (K) represents evaporation section temperature. \(C_{p,f}\) (J/(kg K)) is fractured reservoir heat capacity. \(\rho _{f}\) (kg/m\(^{3}\)) denotes fractured reservoir density.

Surrounding HDR heat loss represents the cumulative heat compensation (\(\beta \)), which can be expressed by

where \(V_{h}\) (\(m^{3}\)) is surrounding HDR volume. \(C_{p,h}\) (J/(kg K)) is HDR heat capacity. \(\rho _{h}\) (kg/m\(^{3}\)) denotes HDR density.

The heat compensation ratio (\(\alpha \)) denotes that the surrounding HDR heat loss divided by the entire reservoir heat loss (fractured reservoir and HDR). It can be written as follow.

4 Results and discussion

This chapter includes two sections. In the first section, the effects of rock properties on heat extraction performance and reservoir field change are investigated. In the second section, we analyzed the influences of four fractured reservoir environments (initial temperature, temperature gradient, initial pressure and pressure gradient) on heat extraction performance.

4.1 Effects of fractured reservoir properties

In this section, the effects of rock properties on heat extraction performance are investigated. The common rock properties are considered, which include permeability, thermal conductivity, density and specific heat capacity. Four parameters, namely heat extraction rate, heat extraction ratio, accumulative heat compensation and heat compensation ratio, are used to evaluate heat extraction performance. In addition, pressure field and velocity field are also considered.

4.1.1 Effects of fractured reservoir permeability

Fluid velocity distributions under different reservoir permeabilities are compared. As shown in Fig. 4, we can see that fluid velocity around gravity heat pipe is larger than that of other areas. This is because the temperature difference between gravity heat pipe and fractured reservoir is high, which drives fluid flow in fractured reservoir. In addition, fluid velocity in fractured reservoir increases with the increase of fractured reservoir permeability. High permeability drops the flow resistance, which increases fluid velocity. Fluid velocity increases when fractured reservoir permeability becomes higher. Figure 5 shows the reservoir pressure changes under different permeabilities. It can be seen that the change difference is very small under different permeabilities. This is because fluid can extract more heat energy when reservoir permeability is high. High reservoir permeability means that more fluid is stored in fractured reservoir. During the heat-absorbing process, the temperature changes are similar under different permeabilities. Therefore, the pressure changes under different permeabilities have a small difference.

In the heat extraction process of gravity heat pipe system, CO\(_{2}\) will form natural convection to enhance heat exchange. Darcy resistance has huge effects on carbon dioxide flow, and natural convection is closely related to the fractured reservoir permeability. Therefore, it is necessary to study the effects of fractured reservoir permeability on heat extraction performance. the heat extraction performance differences under different fractured reservoir permeabilities is compared. The reservoir permeability is set to \(1\times 10^{-15}\) m\(^{2}\), \(3\times 10^{-15}\) m\(^{2}\), \(6\times 10^{-15}\) m\(^{2}\), \(1\times 10^{-14}\) m\(^{2}\) and \(2\times 10^{-14}\) m\(^{2}\), respectively. Figure 6a shows the heat extraction rate trend under different fractured reservoir permeabilities. Obviously, when fractured reservoir permeability decreases from \(2\times 10^{-14}\) to \(1\times 10^{-15}\) m\(^{2}\), the heat extraction rate gradually decreases. We also see that the heat extraction rate difference becomes smaller when fractured reservoir permeability is very low. This is because when fractured reservoir permeability gradually decreases, the heat exchange form of natural convection will decrease. Heat extraction is more dependent on heat conduction, which weakens the heat exchange efficiency. Heat extraction ratio has a small difference under different permeabilities. This is because fractured reservoir temperature difference under different permeabilities is small. Although gravity heat pipe has greater heat extraction efficiency in high fractured reservoir permeability, this has small effects on fractured reservoir temperature change. This is because fractured reservoir with high permeability gets more heat from the surrounding HDR.

The effects of rock permeability on heat compensation are studied. As shown in Fig. 6b, we can see that the gravity heat pipe can get more heat compensation in high-permeability fractured reservoir. High fractured reservoir permeability can strengthen natural convection between the working fluid and HDR, and HDR will lose more energy. Gravity heat pipe system can get more heat compensation under high permeability fractured reservoirs, and there will also be a larger heat compensation ratio. The heat compensation and heat compensation ratio have similar trends.

4.1.2 Effects of rock thermal conductivity

In the heat extraction process of gravity heat pipe system, heat conduction also plays an important role in heat exchange process. Therefore, it is very necessary to study the influences of rock thermal conductivity on heat extraction performance. Rock thermal conductivity is set to 1.8 W/(m K), 2.1 W/(m K), 2.4 W/(m K), 2.7 W/(m K) and 3 W/(m K), respectively. Figure 7a shows the changes of heat extraction rate and heat extraction ratio under different rock thermal conductivities. We can see that the heat extraction rate is positively correlated with rock thermal conductivity in the first 37 years. Then, the heat extraction rate decreases with the increase of rock thermal conductivity after 37 years. This is because rock can transfer more heat when rock thermal conductivity is higher. This means large rock thermal conductivity can strengthen heat exchange between gravity heat pipe and fractured reservoir in the initial stage. As the gravity heat pipe system runs, large rock thermal conductivity makes rock temperature around gravity heat pipe drop faster. This can decrease the temperature difference between gravity heat pipe and fractured reservoir, which weakens natural convection heat exchange. In addition, rock thermal conductivity has huge effects on heat extraction ratio. We can see that heat extraction ratio increases with the increase of rock thermal conductivity. CO\(_{2}\) is easy to extract heat when rock thermal conductivity is higher, which can drop fractured reservoir temperature. This can make greater use of the fractured reservoir heat, resulting in a higher heat extraction ratio.

The effects of rock thermal conductivity on heat compensation are studied. As shown in Fig. 7b, we can see that rock thermal conductivity has huge effects on cumulative heat compensation and heat compensation ratio. The cumulative heat compensation and heat compensation ratio increase with the increase of rock thermal conductivity. This is because high rock thermal conductivity can conduct more heat. When the temperature of fractured reservoir drops, fractured reservoir can get more heat from HDR. Therefore, cumulative heat compensation and heat compensation ratio are higher. As shown in Fig. 8, heat conductivity has a great influence on reservoir pressure distribution. Reservoir pressure increases with the increase of heat conductivity. This is because heat pipe can gain more heat from surrounding HDR in high heat conductivity reservoir, which increases the temperature of fractured reservoir. High temperatures can increase fluid viscosity and flow impedance, which increases reservoir pressure.

4.1.3 Effects of rock density

In this section, the influences of rock density on heat extraction performance are studied. Rock density is set to 2450 kg/m\(^{3}\), 2550 kg/m\(^{3}\), 2650 kg/m\(^{3}\), 2750 kg/m\(^{3}\) and 2850 kg/m\(^{3}\), respectively. Figure 9a shows that rock density has small effects on heat extraction rate. When rock density is higher, the heat extraction rate is higher. At the same reservoir temperature, rock with a lower density can store less heat. When gravity heat pipe extracts heat from fractured reservoir, the temperature of fractured reservoir drops faster. This can reduce the temperature difference between the gravity heat pipe and fractured reservoir, which can weaken heat transfer. Therefore, the heat extraction rate increases with the increase of rock density. Figure 9a also shows the influences of rock density on heat extraction ratio. Heat extraction ratio decreases as the rock density increases. This is because fractured reservoir contains less heat when rock density is low. The heat absorbed by gravity heat pipe will account for a larger proportion of fractured reservoir energy.

The heat compensation changes under different rock densities are analyzed. As shown in Fig. 9b, we can see that rock density has huge effects on cumulative heat compensation and heat compensation ratio. Cumulative heat compensation and heat compensation ratio increase as rock density decreases. This is because gravity heat pipe is easy to drop the temperature of fractured reservoir with low rock density. Low fractured reservoir temperatures can increase the temperature difference between fractured reservoir and HDR. Therefore, gravity heat pipe system has higher heat compensation when rock density is low. However, the change difference is small under different rock densities. As shown in Fig. 10, reservoir pressure increases with the decrease of rock density. High reservoir density means more heat is stored in reservoir, and reservoir has good homeothermy. With time, working fluid in fractured reservoir with high density can more heat compensation, and this will decrease flow impedance and reservoir pressure.

4.1.4 Effects of rock specific heat capacity

In this section, the influences of rock specific heat capacity on heat extraction performance are analyzed. Rock specific heat capacity is set to 800 J/(kg K), 900 J/(kg K), 1000 J/(kg K), 1100 J/(kg K) and 1200 J/(kg K), respectively. Figure 11a shows the change trends of heat extraction and heat extraction ratio under different rock specific heat capacities. We can see that rock specific heat capacity has small effects on heat extraction rate. Gravity heat pipe system slightly increases heat extraction rate in larger rock specific heat capacity. This is because when the specific heat capacity is larger, the temperature drop is small under the same heat loss. Therefore, fractured reservoir with a high specific heat capacity has a high fractured reservoir temperature, which has a huge temperature difference between gravity heat pipe and fractured reservoir. The heat exchange between gravity heat pipe and fractured reservoir is very strong. In addition, we also see that specific heat capacity has greater impacts on heat extraction ratio. Gravity heat pipe system increases the heat extraction ratio when the specific heat capacity is small. This is because when specific heat capacity is small, the energy stored in reservoir is less. Therefore, when gravity heat system extracts the same amount of heat, the extraction heat accounts for a larger proportion of fractured reservoir energy. Therefore, the heat extraction ratio is larger when rock specific heat capacity is smaller.

The heat compensation change trends under different rock specific heat capacity are studied. As shown in Fig. 11b, we can see that gravity heat pipe system with small specific heat capacity can obtain more heat compensation. This is because gravity heat pipe makes the temperature of a fractured reservoir drop faster when it extracts the same heat from fractured reservoir with small rock specific heat capacity. This can result in a larger temperature difference between fractured reservoir and HDR, which can conduct more energy to fractured reservoir. Therefore, this results in larger heat compensation and heat compensation ratio. As shown in Fig. 12, reservoir pressure increases with the decrease of reservoir heat capacity. This is because working fluid in fractured reservoir can gain more heat from surrounding HDR, and this increases flow viscosity and flow impedance.

4.2 Effects of fractured reservoir environment

Geothermal fields in different regions have different geological environments, and suitable geological environments hold the key to practical geothermal engineering success. In this section, we analyzed the influences of four fractured reservoir environments (initial temperature, temperature gradient, initial pressure and pressure gradient) on heat extraction performance. Furthermore, the temperature field is analyzed under different temperature gradients.

4.2.1 Effects of fractured reservoir initial temperature

In this section, we compared the effects of reservoir temperature on heat extraction performance under the same temperature gradient. The reservoir bottom temperature is defined as 480 K, 490 K, 500 K, 510 K and 520 K, respectively. In order to ensure that the temperature difference between gravity heat pipe and fractured reservoir remains unchanged, the evaporation section temperature is set to 440 K, 450 K, 460 K, 470 K and 480 K, respectively. Figure 13a shows that heat extraction changes under different reservoir temperatures. We can see when the temperature difference between gravity heat pipe and fractured reservoir remains the same. Gravity heat pipe system can achieve better heat extraction performance when reservoir temperature is higher. With the rising of fractured reservoir temperature, the density difference of carbon dioxide at the same temperature difference is greater. Therefore, this can form a stronger buoyancy to enhance the natural convection. During the reservoir temperature range (480–520 K), gravity heat pipe system can perform better in high reservoir temperatures. In addition, reservoir temperature has small effects on heat extraction ratio. Although gravity heat system has a higher heat extraction rate in high reservoir temperatures, its maximum heat extraction is much higher.

The effects of reservoir temperature on heat compensation are studied. As shown in Fig. 13b, reservoir temperature has a small effect on heat compensation. Although reservoir temperature is different, the temperature difference between fractured reservoir and HDR is almost the same. Thermal exchange of HDR into fractured reservoir has a small difference. The heat compensation ratio slightly increases with the decrease of reservoir temperature. This is because heat compensation is almost the same under different reservoir temperatures. The heat extraction rate is low when reservoir temperature is low, and heat compensation has a bigger proportion in entire reservoir energy loss.

4.2.2 Effects of fractured reservoir temperature gradient

In this section, we studied the influences of temperature gradients on heat extraction performance. The bottom temperature of reservoir remains unchanged. The reservoir temperature gradient is set to 0.03 K/m, 0.04 K/m, 0.05 K/m, 0.06 K/m and 0.07 K/m, respectively. In order to ensure the temperature difference between gravity heat pipe and reservoir central temperature is the same, the evaporation temperature of gravity heat pipe is set to 465 K, 462.5 K, 460 K, 457.5 K and 455 K, respectively. As shown in Fig. 14, when reservoir bottom temperature remains unchanged, the average temperature becomes higher with the decrease of temperature gradient. Temperature field is more even in lower temperature gradients. Furthermore, four isotherms are displayed in temperature field. It can be seen that low-temperature isotherms (465K and 475K) are closed to gravity heat pipe when temperature gradient is low. This means that gravity heat pipe has greater temperature difference with enclosing HDR.

The heat extraction performance changes under different temperature gradients are studied. As shown in Fig. 15a, we can see that temperature gradient has huge effects on heat extraction rate. Gravity heat pipe system increases the heat extraction rate in smaller temperature gradient. When fractured reservoir has a higher temperature gradient, fluid velocity around heat pipe has a sharp decrease from the bottom to the top of heat pipe. Low fluid velocity has negative effects on natural convection, which can weaken the heat exchange between heat pipe and fractured reservoir. Small temperature gradient means that gravity heat pipe and fractured reservoir has great temperature difference. Gravity heat pipe can get more heat from geothermal reservoir. In addition, the temperature gradient has a small effect on heat extraction ratio. Although gravity heat pipe system can extract more heat in fractured reservoir with small temperature gradient. Small temperature gradient means fractured reservoir average temperature is high, and fractured reservoir can store more heat energy. Therefore, the difference of temperature gradient on heat extraction ratio is small. Figure 15b shows the changes of heat compensation and heat compensation ratio. We can see that the difference under different temperature gradients is very small. This is because changes of reservoir gradient have little effect on the temperature difference between fractured reservoir and HDR.

4.2.3 Effects of fractured reservoir initial pressure

In this section, the effects of reservoir initial pressure on heat extraction performance are compared. The initial pressure is defined as 31 MPa, 33 MPa, 35 MPa, 37 MPa and 39 MPa, respectively. Figure 16a shows the trend of heat extraction rate and heat extraction ratio under different initial pressures. The initial pressure has a small effect on the heat extraction rate. We can see that heat extraction rate slightly decreases with the increase of initial pressures. This is because the viscosity of CO\(_{2}\) is very high when reservoir pressure is higher. This can reduce carbon dioxide velocity and weaken heat exchange between gravity heat pipe and fracture. In addition, heat extraction ratio is almost the same under different initial pressures. This is because the heat extraction difference is small. Figure 16b shows heat compensation and heat compensation ratio under different reservoir pressures. We can see that heat compensation and heat compensation ratio almost remain unchanged under different reservoir pressures. This is because small heat extraction difference leads to the small temperature difference between fractured reservoir and HDR. Therefore, HDR does not supplement more heat energy to the fractured reservoir.

4.2.4 Effects of fractured reservoir pressure gradient

In this section, the effects of pressure gradients on heat extraction performance are compared. The bottom pressure of fractured reservoir remains 35 MPa. The pressure gradient is defined as 7500 Pa/m, 8500 Pa/m, 9500 Pa/m, 10500 Pa/m and 11500 Pa/m, respectively. Figure 17a shows the trends of heat extraction rate and heat extraction ratio under different pressure gradients. We can see that pressure gradient has small effects on heat extraction rate and heat extraction ratio. The heat extraction rate has a slight increase with the increase of pressure gradient. This is because that carbon dioxide property shows the opposite effects on heat exchange between gravity heat pipe and fractured reservoir. When CO\(_{2}\) is in deep geothermal environment, the viscosity becomes high with the increase of reservoir pressure. When the pressure gradient is larger, the pressure at the top of fractured reservoir will be lower, and carbon dioxide has a lower viscosity. This can slightly strengthen natural convection. In addition, carbon dioxide has a greater density in higher reservoir pressure. This can form a density difference resulting in greater flow velocity, which enhances heat extraction performance. Due to the small difference of heat extraction rate, the heat extraction ratio also has a small difference under different pressure gradients. Figure 17b shows cumulative heat compensation and heat compensation ratio under different pressure gradients. We can see that pressure gradient has small effects on cumulative heat compensation and heat compensation ratio. Because temperature difference between fractured reservoir and HDR almost remains the same.

5 Conclusions

This study optimizes the deep geothermal exploitation siting of gravity heat pipe geothermal systems by establishing a three-dimensional TH coupling model. The effects of geothermal reservoir rock properties and reservoir environment on heat extraction rate, heat extraction ratio, heat compensation and heat compensation ratio are studied. In addition, the pressure field, temperature field and velocity field are also analyzed. The key findings are as follows:

Gravity heat pipe system has higher heat extraction ratio and heat compensation when reservoir permeability is higher. Geothermal reservoir material properties have a small influence on heat extraction rate, but properties have greater influences on heat extraction ratio, heat compensation and heat compensation ratio. Rock thermal conductivity mainly affects heat transfer speed in fractured reservoirs. High thermal conductivity can lead to higher heat compensation, heat extraction ratio and geothermal reservoir pressure. Density and specific heat capacity of rock affect heat extraction performance by affecting the energy contained in geothermal reservoirs. Geothermal reservoirs with high density and specific heat capacity can contain more energy, and heat pipe cannot effectively absorb reservoir energy, resulting in lower heat extraction ratio and heat compensation, heat compensation ratio and reservoir pressure.

Geothermal reservoir environment has great influences on heat extraction rate, but has small influences on heat extraction ratio, heat compensation ratio and heat compensation. Geothermal reservoir environment mainly affects heat extraction rate by affecting the physical properties of CO\(_{2}\). Reservoir temperature and temperature gradient have great influences on heat extraction rate. High reservoir temperatures and low temperature gradients will lead to high heat extraction rate. In addition, reservoir pressure and pressure gradient have small effects on heat extraction rate. The heat extraction rate decreases with the increase in initial reservoir pressure.

References

Borgia A, Pruess K, Kneafsey TJ, Oldenburg CM, Pan L (2012) Numerical simulation of salt precipitation in the fractures of a CO\(_{2}\)-enhanced geothermal system. Geothermics 44:13–22

Cao W, Huang W, Jiang F (2016) Numerical study on variable thermophysical properties of heat transfer fluid affecting EGS heat extraction. Int J Heat Mass Transf 92:1205–1217

Caulk RA, Tomac I (2017) Reuse of abandoned oil and gas wells for geothermal energy production. Renew Energy 112:388–397

cctv.com (2020) Breakthrough in the technology of dry hot rock geothermal resources exploitation. Tangshan, Hebei province, has no pumping to extract dry hot rock geothermal energy for heating. Website. https://tv.cctv.com/2020/04/30/VIDEduoTaXBlBFqWEIbJtYS7200430.shtml

Chen T, Liu G, Liao S (2019) Impacts of boundary conditions on reservoir numerical simulation and performance prediction of enhanced geothermal systems. Energy 181:202–213

Chen J, Cen J, Huang W, Jiang F (2021) Multiphase flow and heat transfer characteristics of an extra-long gravity-assisted heat pipe: an experimental study. Int J Heat Mass Transf 164:120564

Daily G (2020) “extra-long gravity heat pipe heat extraction test” made a major breakthrough in key technologies. Website. http://www.cnr.cn/hebei/jrhb/20200429/t20200429_525073469.shtml

Dehkordi SE, Schincariol RA, Reitsma S (2015) Thermal performance of a tight borehole heat exchanger. Renew Energy 83:698–704

Egert R, Korzani MG, Held S, Kohl T (2020) Implications on large-scale flow of the fractured EGS reservoir Soultz inferred from hydraulic data and tracer experiments. Geothermics 84:101749

Eidan AA, Alshukri MJ, Al-fahham M, AlSahlani A, Abdulridha DM (2021) Optimizing the performance of the air conditioning system using an innovative heat pipe heat exchanger. Case Stud Therm Eng 26:101075

Faghri A (1995) Heat pipe science and technology. Global Digital Press, Columbia

Finsterle S, Zhang Y, Pan L, Dobson P, Oglesby K (2013) Microhole arrays for improved heat mining from enhanced geothermal systems. Geothermics 47:104–115

Genter A, Evans K, Cuenot N, Fritsch D, Sanjuan B (2010) Contribution of the exploration of deep crystalline fractured reservoir of Soultz to the knowledge of enhanced geothermal systems (EGS). CR Geosci 342(7–8):502–516

Guo T, Gong F, Wang X, Lin Q, Qu Z, Zhang W (2019) Performance of enhanced geothermal system (EGS) in fractured geothermal reservoirs with CO2 as working fluid. Appl Therm Eng 152:215–230

Heidaryan E, Jarrahian A (2013) Modified Redlich–Kwong equation of state for supercritical carbon dioxide. J Supercrit Fluids 81:92–98

Heidaryan E, Hatami T, Rahimi M, Moghadasi J (2011) Viscosity of pure carbon dioxide at supercritical region: measurement and correlation approach. J Supercrit Fluids 56(2):144–151

Huang W, Cao W (2021) Numerical study and economic analysis of gravity heat pipe hot dry rock geothermal system. CIESC J 72:1302–1313 [in Chinese]

Huang W, Cao W, Jiang F (2018) A novel single-well geothermal system for hot dry rock geothermal energy exploitation. Energy 162:630–644

Huang W, Chen J, Cen J, Cao W, Li Z, Li F, Jiang F (2022a) Heat extraction from hot dry rock by super-long gravity heat pipe: Effect of key parameters. Energy 248:123527

Huang W, Cen J, Chen J, Cao W, Li Z, Li F, Jiang F (2022b) Heat extraction from hot dry rock by super-long gravity heat pipe: a field test. Energy 247:123492

Jarrahian A, Heidaryan E (2012) A novel correlation approach to estimate thermal conductivity of pure carbon dioxide in the supercritical region. J Supercrit Fluids 64:39–45

Jiang P, Li X, Xu R, Zhang F (2016) Heat extraction of novel underground well pattern systems for geothermal energy exploitation. Renew Energy 90:83–94

Jiang F, Huang W, Cao W (2017) Mining hot dry rock geothermal energy by heat pipe: conceptual design and technical feasibility study. Adv New Renew Energy 5(6):426–434

Kim K-H, Ree J-H, Kim Y, Kim S, Kang SY, Seo W (2018) Assessing whether the 2017 mw 5.4 Pohang earthquake in South Korea was an induced event. Science 360(6392):1007–1009

Kraft T, Deichmann N (2014) High-precision relocation and focal mechanism of the injection-induced seismicity at the Basel EGS. Geothermics 52:59–73

Lei Z, Zhang Y, Zhang S, Fu L, Hu Z, Yu Z, Li L, Zhou J (2020) Electricity generation from a three-horizontal-well enhanced geothermal system in the Qiabuqia geothermal field, China: slickwater fracturing treatments for different reservoir scenarios. Renew Energy 145:65–83

Li S, Feng X-T, Zhang D, Tang H (2019) Coupled thermo-hydro-mechanical analysis of stimulation and production for fractured geothermal reservoirs. Appl Energy 247:40–59

Liu G, Zhou C, Rao Z, Liao S (2021a) Impacts of fracture network geometries on numerical simulation and performance prediction of enhanced geothermal systems. Renew Energy 171:492–504

Liu G, Zhou C, Liao S (2021b) Comparative study on heat extraction performance between gravity heat pipe system and enhanced geothermal system. Geothermics 96:102218

Lu S-M (2018) A global review of enhanced geothermal system (EGS). Renew Sustain Energy Rev 81:2902–2921

M-LI Panel (2006) The future of geothermal energy: impact of enhanced geothermal systems (EGS) on the United States in the 21st century. Geothermics 17(5–6):881–882

Pruess K (2006) Enhanced geothermal systems (EGS) using CO\(_{2}\) as working fluid-a novel approach for generating renewable energy with simultaneous sequestration of carbon. Geothermics 35(4):351–367

Pruess K (2008) On production behavior of enhanced geothermal systems with CO\(_{2}\) as working fluid. Energy Convers Manag 49(6):1446–1454

Qu Z-Q, Zhang W, Guo T-K (2017) Influence of different fracture morphology on heat mining performance of enhanced geothermal systems based on COMSOL. Int J Hydrogen Energy 42(29):18263–18278

Randolph JB, Saar MO (2011) Coupling carbon dioxide sequestration with geothermal energy capture in naturally permeable, porous geologic formations: implications for CO\(_{2}\) sequestration. Energy Procedia 4:2206–2213

Rostamian H, Lotfollahi MN (2016) Modified Redlich–Kwong and Peng–Robinson equations of state for solubility calculation of solid compounds in supercritical carbon dioxide. Indian J Sci Technol 9:16

Shi Y, Song X, Shen Z, Wang G, Li X, Zheng R, Geng L, Li J, Zhang S (2018) Numerical investigation on heat extraction performance of a CO\(_{2}\) enhanced geothermal system with multilateral wells. Energy 163:38–51

Shi Y, Song X, Li J, Wang G, YuLong F, Geng L (2019a) Analysis for effects of complex fracture network geometries on heat extraction efficiency of a multilateral-well enhanced geothermal system. Appl Therm Eng 159:113828

Shi Y, Song X, Wang G, Li J, Geng L, Li X (2019b) Numerical study on heat extraction performance of a multilateral-well enhanced geothermal system considering complex hydraulic and natural fractures. Renew Energy 141:950–963

Shu B, Zhu R, Tan J, Zhang S, Liang M (2019) Evolution of permeability in a single granite fracture at high temperature. Fuel 242:12–22

Song X, Shi Y, Li G, Yang R, Wang G, Zheng R, Li J, Lyu Z (2018) Numerical simulation of heat extraction performance in enhanced geothermal system with multilateral wells. Appl Energy 218:325–337

Span R, Wagner W (1996) A new equation of state for carbon dioxide covering the fluid region from the triple-point temperature to 1100 K at pressures up to 800 MPa. J Phys Chem Ref Data 25(6):1509–1596

Templeton DC, Wang J, Goebel MK, Harris DB, Cladouhos TT (2020) Induced seismicity during the 2012 Newberry EGS stimulation: assessment of two advanced earthquake detection techniques at an EGS site. Geothermics 83:101720

Tester JW, Anderson BJ, Batchelor A, Blackwell D, DiPippo R, Drake E, Garnish J, Livesay B, Moore M, Nichols K et al (2007) The future of geothermal energy-impact of enhanced geothermal systems (EGS) on the United States in the 21st century; Massachusetts Institute of Technology (MIT): Cambridge, MA, USA, 2006. In: Proceedings of thirty-second workshop on geothermal reservoir engineering, Stanford University, Stanford, California, January 22–24

Tian E, He Y-L, Tao W-Q (2017) Research on a new type waste heat recovery gravity heat pipe exchanger. Appl Energy 188:586–594

Wang G, Li K, Wen D, Lin W, Lin L, Liu Z, Zhang W, Ma F, Wang W (2013) Assessment of geothermal resources in China. In: Thirty-eighth workshop on geothermal reservoir engineering

Weijermars R, Burnett D, Claridge D, Noynaert S, Pate M, Westphal D, Yu W, Zuo L (2018) Redeveloping depleted hydrocarbon wells in an enhanced geothermal system (EGS) for a university campus: progress report of a real-asset-based feasibility study. Energy Strateg Rev 21:191–203

Wolff SSH. Geothermal electricity generation project—underground closed geothermal heat exchanger. In: Symposium: geothermal electricity e an investment in the future

Yekoladio PJ, Bello-Ochende T, Meyer JP (2013) Design and optimization of a downhole coaxial heat exchanger for an enhanced geothermal system (EGS). Renew Energy 55:128–137

Zaiming W (2008) Feature research of supercritical carbon dioxide drilling fluid. China University of Petroleum (East China), Qingdao

Zhang Y-J, Li Z-W, Guo L-L, Gao P, Jin X-P, Xu T-F (2014) Electricity generation from enhanced geothermal systems by oilfield produced water circulating through reservoir stimulated by staged fracturing technology for horizontal wells: a case study in Xujiaweizi area in Daqing oilfield, China. Energy 78:788–805

Zhang J, Xie J, Liu X (2019) Numerical evaluation of heat extraction for EGS with tree-shaped wells. Int J Heat Mass Transf 134:296–310

Zhang T, Cai J, Wang L, Meng Q (2021) Comparative and sensitive analysis on the filling, operating and performance patterns between the solar gravity heat pipe and the traditional gravity heat pipe. Energy 238:121950

Acknowledgements

This work was supported by the National Natural Science Foundation of China [Grant Numbers 52076218]; the Fundamental Research Funds for the Central Universities of Central South University [2023ZZTS0007]; the Postgraduate Scientific Research Innovation Project of Hunan Province [CX20230097].

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhou, C., Wang, Y., Liu, G. et al. Optimal HDR exploitation siting of gravity heat pipe geothermal systems via reservoir simulation. Geomech. Geophys. Geo-energ. Geo-resour. 10, 51 (2024). https://doi.org/10.1007/s40948-024-00764-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-024-00764-y