Abstract

Pore pressure is a crucial factor affecting reservoir stimulation, especially in unconventional reservoirs, because it can control crack initiation and propagation. However, studies on the effect of initial pore pressure on hydraulic fracturing in low-permeability reservoirs are lacking, and fracturing mechanism remains unclear. Therefore, we conducted hydraulic fracturing tests under initial pore pressure, and proposed an improved fracturing initiation criterion to elucidate the fracturing mechanism of tight sandstone. The results demonstrated that the breakdown pressure increased with the initial pore pressure by 8 to 24%, and its evolution was identified approximately by the improved initiation criterion, which resulted in the complicated, invisible and intense features of the macroscopic fracture morphology and microscopic crack. The finding was mainly due to the viscous stress induced by fracturing disturbance under initial pore pressure and represented the dual interaction between rock structure and work fluid viscosity. As a result, the change in microporous diameter in micropores and a high pressure to failure can be obtained. Accordingly, the initial pore pressure in tight sandstone may not only induce n effective stress on the skeleton but also be responsible for the double effect on the fracturing mechanism with high pressure and intense failure features, which should be given attention in unconventional reservoir stimulation.

Highlights

-

An improved initiation criterion was proposed considering the initial pore pressure effect.

-

Breakdown pressure of tight sandstone fracturing increased with initial pore pressure.

-

Viscous stress was responsible for the fracturing mechanism with high pressure and aggravated failure feature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Hydraulic fracturing has been a key technique for deep and unconventional reservoirs stimulation to exploit resource and increase permeability in petroleum engineering since 1948 (Veatch et al. 1989), and it has been widely used in reservoir stimulation with remarkable results (Rahman and Rahman 2010; Zhang et al. 2022a; Lyu et al. 2020). Accordingly, high or ultra-high pore pressures are prevalent in the hydrocarbon reservoir, especially unconventional reservoir; thus, the in situ stress in reservoir not a hydrostatic component (Zhang and Wieseneck 2011; Zhang 2011, 2013, Zhang and Yin 2017). Additionally, the diffusion of fluid or a large amount of residual fluid will cause an abnormal initial pore pressure (Scanlon et al. 2014, Hou et al. 2017a, b), which may lead to changes in the reservoir mechanical response and affect the direction of fracturing propagation and wellbore stability (Zhang and Wieseneck 2011; Li et al. 2016). Hence, investigating the influence of initial pore pressure is crucial for understanding the fracturing mechanism of unconventional hydrocarbon reservoirs.

A number of micropores and cracks can be found in rocks, and the connectivity between them affects the rock mechanical response (Yang et al. 2014); subsequently, the hydromechanical coupled phenomenon will be triggered when the fracturing fluid is injected. On the basis of the permeability property of rocks, injection pressure disperses in micropores and cracks along the radial direction during failure process. Accordingly, many researchers investigated the effect of fluid–solid coupling in the fracturing response. For example, Lockner and Byerlee (2016) and (Masuda et al. 1990) studied the influence of injection rate on fracturing mechanism, and found that tension cracks were prone to be induced at high injection rate while shear cracks at low injection rate. A point-stressed model between fracturing pressure and injection rate was proposed, considering the distribution of pore pressure around the borehole (Ito and Hayashi 1991) and thus defining the upper and lower limits of breakdown pressure and extending them to the breakdown pressure evolution under tectonic stress (Ito 2008). Further, based on the pressurization rate of injection fluid, Detournay and Cheng (1992) introduced a length scale to probe the model, when the circumferential stress intensity factor (KI) around the borehole exceeds the lengths scale stress intensity factor, failure occurs immediately. However, these studies mainly focused on the pore pressure field induced by the fracturing process, which may be different from the mechanism of the initial pore pressure.

The gas permeability of rock is considerably higher than that of water (typically 3–5 orders of magnitude higher); i.e. supercritical CO2 or liquid N2 can penetrate into micro-nano pores and form a relatively uniform pore pressure field (Hou et al. 2017a, b). Therefore, the fracturing perturbation over a uniform pore pressure field is dependent not only on the evolution of injection pressure, but also on the structural characteristics of rocks, such as bedding or natural fractures (Zhang et al. 2017). Moreover, studies focused more on pore water pressure in laboratory and field (Zhao and Huang 2021; Zhao et al. 2022). Simultaneously, the diffusion distance of high viscosity fluids in porous media is finite (Rudakov and Sobolev 2019; Zhao et al. 2020), prolonging the formation of a uniform pore pressure field, whereas the time scale of fracturing process is very short (Kumar et al. 2017), which means that the fracturing response varies with the pore pressure fluid properties. Furthermore, water-based fracturing fluid remain the primary choice for large-scale reservoir stimulation due to mature fracturing technology (He et al. 2020). Hence, the study of the water-based fluid fracturing mechanism under initial pore pressure of low permeability reservoirs is in line with the field demand.

On the basis of reservoir conditions, Li et al. (2015a, b), Ma et al. (2015a, b) studied the effect of pore pressure distribution on fracture propagation in brittle rocks using a numerical method, and they concluded that local microcrack activation controls fracture propagation direction and breakdown pressure. Bruno and Nakagawa (1991) observed that both the pore pressure at the crack tip and the local pore pressure gradient influence failure behavior, causing crack propagation along the direction of maximum pore pressure. Moreover, based on the theory of maximum strain energy release and experimental results, Rahul et al. (2019) statistically analyzed 421 fracturing data in 13 wells and combined with cohesive zone model, and discovered that the effective stress in the reservoir is a crucial effect on fracture network, and the higher the effective stress, the wider, shorter, and the more radial fractures are. These researches mainly focused on the local non-uniform distribution of pore pressure (Gao et al. 2019; Birikh and Rudakov 1982; Ren et al. 2022; Anthony and Emmanuel 2022). However, Li et al. (2015a, b) compared the fracturing response of different pore pressure fields in numerical simulation and observed that the mechanical strength ascended with pore pressure field, which is inconsistent with the effective stress theory. Huang et al. (2015) defined the splitting factor to explain the enhancement effect of pore pressure field formation based on the closed and connected pore pressure field on the initial pore pressure field. Further, experiment-based studies that illustrate the effect of the initial pore pressure on the fracturing mechanical response, especially for low permeability reservoirs are limited, and such type of research should be carried out to fill the gap in literatures.

This work aims to elaborate how pore pressure field affects the mechanical response of tight sandstone under fracturing perturbation. Distilled water was used as a working fluid to investigate the fracturing response of tight sandstone under different pore pressure fields in laboratory, and an improved initiation criterion was proposed to capture the evolution of breakdown pressure and elucidate the fracturing mechanism by combining with macro-microscale cracks features. In addition to specific procedures are, Sect. 2 introduces the basic properties of tight sandstone (Ma et al. 2021), experimental apparatus and method, and the pore pressure field distribution. Section 3 describes the experimental results on the evolution of breakdown pressure and corresponding to the macro-microscale crack morphology. Finally, Sect. 4 proposes an improved fracturing initiation criterion to elaborate the main effect factors of the initial pore pressure on low permeability reservoirs and reveal their fracturing mechanism. The research results can be used to further understand the fracturing mechanism of unconventional reservoir simulation and optimize the fracturing technology.

2 Experimental schemes

2.1 Experimental apparatus and material

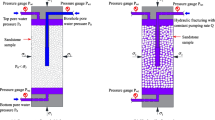

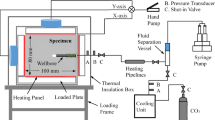

The experimental apparatus included a multifield coupling triaxial machine system (Wu et al. 2021) composed of a loading system, a controlling system and a data acquisition system. The loading system contains an axial stress with 1500 kN axial loading force, a confining pressure of 100 MPa and pore pressure system of 100 MPa, and each subsystem is controlled by controlling system in parallel, which can be adjusted in time depending on experimental requirements. Further, the data acquisition system can collect the data of the loading subsystem and the control state in real time in the course of the experiment, at a time interval of 0.25 s. The details was provided in Fig. 1. Additionally, the circumferential strain adopted a UEI strain acquisition instrument (Lianhua Electronics Company, USA, with four-channel vibration acquisition, and interval of 0.25 s) that can collect the strain variation in the course of tests. At the axial middle position of the specimen, strain gauges are posted along the radial direction (The strain gauge from Japan, type AF, and size 120 ohms, size 4 × 2 mm). The strain gauges of circumferential strain are pasted using waterproof glue (Ergo 5400 glue, Switzerland), thus water will not affect the strain acquisition until sample breakage.

In this paper, tight sandstone cores are obtained from Keshen area in Kuqa Depression, Tarim Basin, NW China (Ma et al. 2021), and were processed into samples with dimensions of height 50 mm and diameter 25 mm. The velocity, porosity, density and the permeability are 4012.13 m/s, 1.45%, 2.75 g/cm and 1.45 × 10− 2 mD (gas permeability), respectively, which belongs to low permeability category (Feng et al. 2019; Sander et al. 2017). Moreover, the mineral composition of tight sandstone comprised brittle mineral 60.28% (dolomite 18.82% and quartz 41.46%) and clay 12.56%, albite 27.75%, which has a high brittleness index (Meng et al. 2021). The basic mechanical properties include uniaxial compression strength (UCS) and uniaxial tension strength (UTS) are 145.26 MPa and 12.73 MPa, respectively. The details can be found in Sect. 2 in the study of Ma et al. (2021). Besides, the velocity and density of tight sandstone samples are selected to reduce the discreteness between experimental samples. The microstructures of tight sandstone was detected using scanning election microscopy (SEM) and found it have compact microstructure (seeing Fig. 2). The physical and mechanical properties of tight sandstone and the effect of initial pore pressure on fracturing mechanism will be further analyzed in Sect. 3.1.

To mimic the fracturing tests in laboratory, a low-speed driller was used to drill a 31 mm depth and 3 mm diameter borehole in the center of tight sandstone samples, and a 25 mm height and 2.5 mm diameter fracturing channel steel pipe, and epoxy resin glue (shear strength and tensile strength are more than 28 and 40 MPa, respectively) was used to bond the steel pipe and borehole inner boundary, in 24 h dry environment. The work fluid (deionized water) is injected into the central borehole in constant pressure mode, diffused around the borehole used to generate an initial pore pressure, and then reinjected in constant current mode to stimulate fracturing tests.

2.2 Experimental initial pore pressure derivation

First, the diffusion effect in porous materials is accompanied by the process of injection work fluid. Zeng et al. (2018) used a logarithmic functions to explore the pore pressure disturbance generated by the diffusion effect in the course of fracturing

where \(\beta\) is the compressibility of fracturing fluid, \({p}_{\text{i}}\) is the initial pore pressure, t is the period of fluid injection, \(q\) is the injection rate of fracturing fluid, \(k\) is the rock permeability \(\kappa =k/\mu n\beta\), \(n\) is the rock porosity, \(\mu\) is the viscosity of fracturing fluid, and \(h\) is the borehole depth. \(Ei\left(x\right)\) is the exponential integral function defined by:

Hence, the pore pressure \(p\left(r,t\right)\) generated by the diffusion effect is mainly associated with the injection pressure \({p}_{w}\). Figure 3 shows that the pore pressure \(p\left(r,t\right)\) evolving with time in the course of fracturing based on Eq. 1. The radial pore pressure is small and its disturbance around the borehole is finite. Therefore, the effect of pore pressure disturbance in the course of hydraulic fracturing is insufficient, and the formation of a comparative pore pressure field is difficult to achieve. Conversely, the method of constant injection pressure in the borehole for a certain interval and then diffusion to generate pore pressure field is effective.

Second, the diffusion effect of work fluid in the course of fracturing yields the following assumptions: rocks are permeable, the capillary effect can be negligible, and pore pressure around the borehole is caused by fracturing fluid diffusion and follows 1D Darcy seepage law (Larson 1963; Shi et al. 2021).

Equation 3 is based on the radial coordinate system. The initial and boundary conditions are follows:

where \(b\) is the borehole radius, \({p}_{w}\) is the injection pressure on the wall during the constant injection period, coupled with fluid incompressibility and radial symmetry, and the radical pore pressure field by Darcy’s law:

According to the law of conservation of mass, the radial flow flux (Fig. 4) around borehole boundary can be calculated as follows:

where \(Q\) is the flow flux, and the micropores after permeation are fully saturated in this work. After determining the flux Q and reversing Eq. 3, the pore pressure distribution across the radial direction can be determined (Fig. 5). The pore pressure first rapidly drops and then moderately descends with radial distance. Simultaneously, the variation is coordinated, and the faster decline with radial distance, the higher constant injection pressure. After the predetermined diffusion time elapses (approximately 12 h), the work fluid is reinjected into the central hole in 1 ml/min mode to mimic the fracturing tests in laboratory. Further, fracturing disturbance may induce the abnormal fracturing phenomenon, which should be elucidated using the improved initiation criterion.

2.3 Experimental method

The high pore pressure field prevailing in tight sandstone reservoirs of Kuqa foreland basin, Tarim Basin (Jiang and Sun 2019), is the basis for the laboratory study. Accordingly, to reproduce tight sandstone reservoirs in-situ conditions (the horizontal stress of at least 40 MPa), the confining pressures of tests are 20 and 40 MPa, and the axial stress is set to be 5 MPa higher than the confining pressure. Given that the radial flow of low permeability rock lasts for several hours compared with few days allowed for axial flow tests (Feng et al. 2020). Hence, the radial flow not only eases the generation pore pressure in laboratory, but also attenuates the effect of creep and water–rock interactions (Schimmel et al. 2022). In addition, the initial pore pressure generated by diffusion effect of constant injection pressure includes four injection pressure levels (i.e. 10, 20, 30 and 40 MPa) in this work. Accordingly, immediately after the predetermined diffusion interval elapses, the fracturing fluid is reinjected in the central borehole in constant current mode (1 mL/min) to mimic the fracturing tests. The following is schematic the experimental procedures.

-

1.

First, the samples were fixed into the chamber (Fig. 1) with a heat shrinkable sleeve and fixing rings in both ends. Additionally, the confining pressure and axial stress are increased to a predetermined value, and then stability is maintained for 0.5 h.

-

2.

Then, fracturing fluid was injected into the central borehole in constant pressure mode (12 h) to produce a pore pressure field around the borehole. Given the low porosity of tight sandstone, the pores are completely saturated after infiltration.

-

3.

Next, fracturing tests were conducted in constant flow mode (1 mL/min). A sudden increase in the confining pressure was accompanied by failure process, which can be used as a basis for judgment (He et al. 2017).

-

4.

Finally, the fracturing pressure, confining pressure and axial stress were unloaded successively after failure, and the variation in pressure and circumferential strain data during tests were recorded.

Figure 6 shows the experimental schematic of this work. Different pore pressure properties may change the evolution of injection pressure and fracturing mechanism. We have conducted fracturing tests of clear water and liquid CO2, and compared the fracturing patterns under different in-situ stress, with the details provided in the study of Ma et al. (2021). The results further consolidate the optimization of the fracturing technology in field. Simultaneously, we discovered the effect of initial pore pressure distribution on fracturing mechanism, which led to the experimental study. The permeation time (12 h) is responsible for the initial pore pressure distribution, which also provides favorable evidence for the initiation criterion and fracture morphology analysis in the Sect. 3.1.

3 Experimental results

3.1 Evolution of injection pressure and breakdown pressure

For unconventional low permeability reservoirs, the rock structure is compact and the flow between pores after saturation is difficult to achieve, especially for viscous fluids (Shukla et al. 2004). Thus, the abnormal pore pressure occurs under long-term geological evolution and further affects the recovery of hydrocarbon resource (Ma and Zoback 2017). Thereby, studying the effect of initial pore pressure on the tight rock fracturing test in laboratory can provide the preliminaries for elaborating the fracturing mechanism.

Figures 7 and 8 show the injection pressure and circumferential strain-time curves for tight sandstone at different constant injection pressures, which corresponds to 20 and 40 MPa confining pressure, respectively. Confining pressure can significantly increase the breakdown pressure, and the initial pore pressure filed also presents an increasing tendency. Furthermore, the response of circumferential strain in fracturing tests varies synchronously with the injection pressure-time curve, and a significant V-shape is observed in front and after failure (Ma et al. 2015a, b). The response of circumferential strain is roughly consistent with the initial pore pressure, and the higher the initial pore pressure, the larger the variation amplitude. The confining pressure also plays a definite effect in amplitude change. Table 1 shows an overview of the experimental data in this work. The initial pore pressure causes the failure of tight sandstone in high pressure, which induces the response of circumferential strain aggravation. We compared the breakdown pressure of tight sandstone fracturing tests between both conditions (about 56 and 76 MPa at 20 and 40 MPa confining pressures, respectively; Ma et al. 2021). The breakdown pressure increases by 8 to 24% under the initial pore pressure, which is consistent with the research results of Huang et al. (2018). Additionally, the confining pressure further strengthens the incremental results to become more pronounced at initial pore pressure. Therefore, the effect of the initial pore pressure filed should be considered in initiation criterion for low permeability reservoir fracturing.

3.2 Macro-micro fracture plane

The fracture plane not only elaborates the process of crack propagation in fracturing, but also reflects multiscale fracturing mechanism characteristic (Ma et al. 2021; Zhou et al. 2019). Thus, the fracture plane can be an auxiliary with discriminating the effect of initial pore pressure on tight sandstone fracturing mechanism. Further, the stress state of the experimental setup in this work is an axial loading higher than the confining pressure. According to the conventional breakdown model (Sampath et al. 2018), the cracks mainly along the axial direction.

Figure 9 shows the representative macro-microscale fracture plane under 20 and 40 MPa confining pressures. More complex and invisible cracks appear when the confining pressure is 40 MPa, especially at high initial pore pressure (Fig. 9d). The main cracks are inclined and do not coincide with the axial stress direction. Additionally, the degree of wedging between cracks is imperfect as fractured samples, with localized areas of scattered fragments. However, the cracks are coincidental overall. Further, the crack morphology evolves to become invisible in the axial plane. Occasionally, cracks also perpendicular to the axial direction with a descending initial pore pressure. Simultaneously, the macro fracture morphology at 20 MPa confining pressure shows similarity to that at 40 MPa confining pressure (Fig. 9b). And the fractured plane becomes intricate and untraceable under initial pore pressure. Correspondingly, these phenomena may be due to the downhole cores with increased number of fissures caused by stress relaxation and long-term detention despite the improvement of the selected specimens. This phenomenon is the precise cause of the initial pore pressure encountering fracturing disturbance, which may be prone to preferred damage zone initiation and propagation. As a result, complicated macroscale fracture morphology, such as inclined or perpendicular cracks, are observed, and they further induce the fracturing with high breakdown pressure. Gao et al. (2019) suggested that the non-uniform distribution of the pore pressure field attracted the cracks propagation, leading to more complicated macroscopic morphology. For tight sandstone, the fracturing disturbance at initial pore pressure may further exacerbate the effect of non-uniform distribution in the preferred direction, which is a complicated plane.

In a microscopic observation, SEM is one of most effective methods to observe the microscopic feature (He et al. 2020). To investigate the effect of initial pore pressure on tight sandstone fracturing microscopic crack distribution, we cut a small piece along the fractured sample to carry out SEM observation (Fig. 9). The microcracks in fractured specimens are mainly along the boundary of particle mineral separation (Fig. 9a). However, the microcracks behavior under initial pore pressure with fracturing disturbance is more intense. The microcrack deflection occurs because of microscale particles stripping (Fig. 9b), and arrest of cracking is observed (Fig. 9c). The cracks penetrated straight through the particles and appeared multiple invisible (Fig. 9d). Hence, the effect of initial pore pressure on the microscopic response of tight sandstone is more significant (He et al. 2020). Thus, the fracturing perturbation under initial pore pressure may induce micro damage in the preferred mode.

4 Analysis of fracturing initiation criterion and discussion

4.1 Improved initiation criterion with initial pore pressure

The breakdown pressure increasing the tight sandstone fracturing with initial pore pressure is a remarkable phenomenon, which should be explained in theory to further reveal its mechanism. Numerous initiation criteria are used to elaborate the fracturing behavior based on experimental and engineering conditions (Sampath et al. 2018); these criteria include the conventional breakdown model (Hubbert and Willis 1957), poro-elastic breakdown method (Wanniarachchi et al. 2015), point stress model (Ito 2008), stress intensity factor-based methods (Zhou et al. 2019; Hardy 1973; Rummel 1987; Ren et al. 2022; Anthony and Emmanuel 2022; Zhang et al. 2022a, b, c). The stress intensity factor-based model adopts mode I crack (KI) to approach the fracture toughness of rock (KIC), and thus stress state and tension strength are crucial parameters to obtain the breakdown pressure (Sampath et al. 2018). For low permeability reservoirs, it is a geological phenomenon that the pore pressure field leads to abnormal in-situ stress gradient (Zhang 2013), which is an indispensable factor affecting hydraulic fracturing initiation and propagation. Thus, an improved initiation model considering initial pore pressure is proposed on the basis of the stress intensity factor method.

Stress intensity factor method mainly adopts tensile mode in initiation criterion (Hou et al. 2017a, b; Bruno and Nakagawa 1991; Larson 1963; Zhou et al. 2019, Anthony and Emmanuel 2022), which integrates the effects of the in-situ stress field, injection pressure in borehole, and pore pressure field.

where KI is the total stress intensity factor, K1(\({\sigma }_{h}\)) is the stress intensity factor generated by the confining pressure, K2(pw) is the stress intensity factor generated by injection pressure in the borehole, K3(p) is the stress intensity factor generated by pore pressure field. The previous stress intensity factor can be solved by introducing the microcrack length (a) in the analytical method (Rummel 1987), which can be expressed as follows:

Newman (1971) studied the stress factor of a two-dimensional crack under different stress state and proposed three stress intensity factor component induced by different stress components:

where r is the initial crack length, and F0 is geometry factor of stress field, which is related to r/a in the paper. F1 is the geometry factor of the injection pressure, which is related with the initial crack length r and borehole radius a. The initiation and propagation of microcracks during the injection pressure penetrate into the micro-cracks and generates pore pressure (Hou et al. 2017a, b; Zhou et al. 2019, Anthony and Emmanuel 2022). Thus, crack initiation occurs when the stress intensity factor approaches to the fracture toughness as follows:

where KIC is fracture toughness of rock, which can be concluded by rock properties (Ranjith et al. 2019), and Pb is the breakdown pressure of fracturing. Further, according to analytical solution in Eq. 7 and coupled with Eq. 12, the breakdown pressure (Pb) can be determined following the study of Zhang and Yin (2017).

However, the initial pore pressure in low permeability properties can prevent the high viscosity fluid permeating into the micropores or cracks, which in turn affects the fracturing response and failure process (Rahul et al. 2017). Thus, the effect of initial pore pressure should be considered in the fracturing initiation criterion in tight sandstone fracturing tests, and the permeation resistance from the initial pore pressure can be quantitatively characterized by viscous stress \({\sigma }_{\nu }\) (Wu et al. 2012; Forquin and Erzar 2010; Wang et al. 2016)

where \(R\) is the radius of microcracks, which is assumed to be elliptical and \(h\) is the elliptical height. The quotient of \(dh/dt\) is proportional to the change in porosity\(\Delta {\Phi }\), as follows:

A The state constitutive evolution of skeleton stress based on porosity variable can be expressed as follows Olivier (2004):

where \({k}^{e}\) is the effective bulk modulus of the skeleton and \(\Delta p\) is the pore pressure variable, which mainly considers the coordination effect on micropore size. Thus, viscous stress plays a negative role in hindering fluid flow between micro pores and are similar to the confining pressure effects. Integrating Eq. 16 into Eq. 14, an improved the initiation criterion with the initial pore pressure is proposed.

Figure 10 displays the comparison of breakdown pressure between experimental data and theoretical results. For tight sandstone, the initial pore pressure plays a role not only in reducing the effective stress in fracturing but also in the induced disturbance, as viscous stress, strengthening the confining pressure effects. Notably, some discrepancies between the theoretically predicted results and experimental data, although the trends are consistent (Fig. 10). The theoretically predicted results are significantly higher than experimental data, with relative errors ranging from 6.23 to 19.36%. Possibly, the pore pressure field p(r) is a linear approximation in Eq. 17 and is larger than the experimental parameter. Additionally, the improved initiation criterion does not consider the effect of the connectively pore pressure on effective stress, which may also cause discrepancy. Ultimately, the initial pore pressure enhances the breakdown pressure in the fracturing response of tight sandstone with low permeability characteristic, and the improved initiation criterion can broadly capture this phenomenon.

To more explicitly elucidate the effect of initial pore pressure on the improved initiation criterion, we quantitatively characterize and substitute the proposed viscous stress \({\sigma }_{\nu }\) (variation of \({\sigma }_{\nu }\) = 2.5–10 MPa, interval of 2.5 MPa) into Eq. 17, coupled with the basic properties of tight sandstone (Ma et al. 2021), to obtain the evolution of the breakdown pressure with crack length, as shown in Fig. 11. The results show that the breakdown pressure decreases rapidly with the increase in crack length and remains stable when the crack length approaches 0.003 mm. Simultaneously, when the viscous stress \({\sigma }_{\nu }\) is increased from 2.5 to 10 MPa, the difference in the breakdown pressure is more than 5 MPa, implying that changing only the initial pore pressure still increases the breakdown pressure, which further corroborates the experimental results in this work and shows the effective of the improved initiation criterion.

4.2 The influence of work fluid property

Breakdown pressure, an important parameter associated with fracturing, is mainly controlled by reservoir stress state. Additionally, work fluid type, injection rate of work fluid, and sample dimensions can cause changes in breakdown pressure in fracturing tests (Ito and Hayashi 1991; Ma et al. 2021). The results in this study indicate that initial pore pressure also induce changes in breakdown pressure. The stress relaxation of reservoir rock is occasionally responsible for the abnormal high breakdown pressure in fracturing (Ma and Zoback 2017). However, according to forgoing experimental results, micro-macroscale features differ from natural fractures or microcracks activated by pore pressure of low viscosity fracturing fluid diffusion (Ji et al. 2020) and permeation in high porosity rocks (Toan et al. 2018). The evolution of breakdown pressure under the initial pore pressure in laboratory is attributed to the induced viscous stress in micropores and cracks in theoretical analysis, which hinders the work fluid penetration for viscosity fluid (Nowman 1971; Ishida et al. 2016). For low permeability rocks, the time scale of the fracturing stage (Fig. 6C) is notably shorter than that of the initial pore pressure stage (Fig. 6B), which causes difficulty in the fracturing fluid, especially high-viscosity fluids, to re-infiltrate into the micropores and cracks in fracturing (Fig. 3). This situation incidentally induces fracturing disturbance. Thus, similar to the confining pressure effect, this condition allows for fracturing disturbance to be released in a concentered manner, which in turn aggravates the macro-microscale failure mode. Thus, the work fluid property is a crucial parameter that affects the fracturing response (Fig. 12), that is, the evolution of viscous stress \({\sigma }_{\nu }\) with work fluid viscosity and stress state under initial pore pressure. The viscous stress \({\sigma }_{\nu }\) ascends nonlinearly with the increment in fracturing fluid viscosity, with a surge at 300–400 mPa s fluid viscosity, and the low viscosity fluid caused difficulty in the formation of an effective viscous stress due to the high flow ability capability. Hou et al. (2017a, b) investigated the fracturing response under pore pressure distribution with liquid nitrogen and observed that the breakdown pressure is negatively correlated with pore pressure field. Additionally, the effect of stress state is subdued and the increase is negligible with confining pressure. Accordingly, the work fluid viscosity is crucial in enabling the initial pore pressure to induce viscous stress a \({\sigma }_{\nu }\) that can sufficiently to affect the fracturing response.

Some authors have investigated the influence of pore pressure gradients, such as pore fluid cavitation near crack regions, that may cause a negative effect on the breakdown pressure (Zhao and Huang 2021; Forquin and Erzar 2010; Wang et al. 2016), the phase transition may play a crucial effect on the change of breakdown pressure. Additionally, Meng et al. (2021) found that the decrease of penetration is responsible for the increase in breakdown pressure but not for oil. Evidently, fluid viscosity may have an appropriate interval, and this finding is attributed to the increase in fluid viscosity. Further, the experimental results of fluid used in this work, which was responsible for the fracturing mechanism, can be well encapsulated in theoretical analysis.

4.3 The influence of rock structure

The microscopic composition of rock structure controls the permeation path and pore pressure distribution characteristics and affects further the initiation and propagation in fracturing (Hou et al. 2017a, b). The response mechanism of rocks with different microscopic structure under fracturing disturbance is worth exploring, especially in regard to initial pore pressure. Pore pressure may activate rocks with high-porosity or structurally weak plane, in the preferred direction rather than protect them (Yu et al. 2021; Ji et al. 2020) investigated the influence of uniform pore pressure on the fracture activation, and observed that the pore pressure field may induce stress yield in accordance with the Mohr-Coulomb criterion and lead to integral instability. Thus, when a high-porosity or structurally weak plane is subjected to the pore pressure field, it may only exert an effective stress and cause difficulty in the formation of sufficient viscous stress to affect the variation in microporous diameter (\(dh/dt\)). However, Ma et al. (2021) thought that the micro-pores or fissures of tight sandstone need a high pore pressure to be activated (Fig. 13), with \({K}_{I}=F/\sqrt{\pi l}\), microcrack initiation will occur in presence of other additional forces (Ma et al. 2021; Ishida et al. 2016), and the compact of tight sandstone maintains the pore pressure in micropores and cracks from fracturing disturbance (Fig. 2). Therefore, the fracturing mechanism of tight sandstone with initial pore pressure may be associated with compact structure characteristics. Ultimately, the effect of the initial pore pressure on fracturing mechanism of tight sandstone can be summarized as follows.

-

1.

Viscous stress response stage. The fracturing disturbance induced by the increase of injection pressure, which occurs because of the initial pore pressure in the micropores and fissures, can impede viscous fluid diffusion. This response in turn will change the microporous diameter (\(dh/dt\)), leading to generation of viscous stress (Fig. 14C). The viscous stress is closely associated with initial pore pressure, but the fracturing disturbance is insufficient to penetrate. Additionally, incremental approaches are needed for initiation (Fig. 10), with a high breakdown pressure under initial pore pressure.

-

2.

Initiation and propagation stage. The fracturing disturbance effect is enhanced when the injection pressure is continuously increased, corresponding to the variation of microporous diameter (\(dh/dt\)), which may reach a certain limitation and will be partially activated. However, even though tight sandstone has compact structure, the long-term period weathering and stress release may contain numerous fissures in individual samples. These fissures provide a preferred direction to be activated and form a complex fracture morphology (Fig. 11). Yan et al. (2021) hypothesized that the relaxation of injection pressure can further promote the width of fracture network. Thus, the injection pressure is not effectively released at the high pore pressure field, which in turn causes a small fracture width (Fig. 9).

Figure 14 elucidates the tight sandstone fracturing mechanism under initial pore pressure. The fracturing disturbance induces viscous stress due to the initial pore pressure in micropores and cracks, which contributes to high breakdown pressure in fracturing. The microscopic mechanism evolution varies with viscous stress until the change in microporous diameter value is sufficient to activate the fissures. Then, the initial pore pressure is responsible for fracturing mechanism evolution with more complicated planes (Fig. 9). Thus, the interaction between rock and work fluid is crucial in the stability of local structures with pore pressure disturbance. Toan et al. (2018) found that the difference in saturation water between the porous domains and fracture may induce nonuniform pressure distribution in porous, not on the fracture. Accordingly, the work fluid viscosity and rock structure characteristics are responsible for the underlying mechanism of the effectiveness of the initial pore pressure. Consequently, the influence of initial pore pressure on geological reservoirs may be not only bear effective stress on the skeleton, but also exert a double effect with high breakdown pressure and complicated plane. This finding needs to be further discussed in combination with engineering information.

According to the forgoing analysis, the breakdown pressure and the fracture plane show challenges to reservoir stimulation under initial pore pressure. Therefore, studies should clarify whether an abnormal pore pressure phenomenon exists in reservoirs before exploitation. However, the pore pressure field mainly exists in reservoirs with large lithologic changes (Zhang and Wieseneck 2011), and it can lead to the minimum horizontal principle stress change and control fracturing response. Even though the cores experience in-situ stress field release and long-term sealed storage, which may affect the experiment results with relative errors, they can effectively show that the initial pore pressure affects the fracture response. Comprehensive geological information should be considered before application of fracturing to match the optimization method. The fracturing mechanism response of tight sandstone under initial pore pressure causes complicated and invisible fracture morphologies, which are definitely closely associated with the original defects in reservoirs.

5 Conclusion

In this work, the effect of initial pore pressure on the hydraulic fracturing of tight sandstone is investigated in laboratory. An improved initiation criterion based on the stress intensity factor method, which considers the initial pore pressure effect is proposed to further elucidate the fracturing mechanism. The results shows that the effect of initial pore pressure on fracturing of tight sandstone is an enhancement and not further deterioration. The main conclusions are as follows.

-

1.

The breakdown pressure of tight sandstone fracturing ascends with the initial pore pressure, with an increase of 8–24%. The evolution tendency is approximately identified by an improved initiation criterion. And the fracturing disturbance under initial pore pressure can promote macroscopic and microscopic fracture features in complicated, invisible and intense, respectively.

-

2.

The viscous stress induced by fracturing disturbance is the dual interaction between rock structure and work fluid viscosity. The compact of tight sandstone can protects the pore pressure in micropores and cracks from fracturing disturbance with a high pressure, and such condition is attributed to the viscous stress. Simultaneously, work fluid viscosity is a crucial parameter, which is responsible for the change in microporous diameter in the course of fracturing, aggravating macro-microscale failure feature in this work.

-

3.

For tight sandstone, the initial pore pressure may not only exert an effective stress on the skeleton but also have another double effect, which results in a fracturing mechanism with high breakdown pressure and complicated feature. This finding should be carefully considered for reservoir stimulation.

References

Anthony P, Emmanuel D (2022) The arrest and recession dynamics of a deflating hydraulic fracture in a permeable elastic medium in a state of plane strain. Int J Solids Struct 254–255:111906

Birikh RV, Rudakov RN (1982) Slow motion of a permeable sphere in a viscous fluid. Fluid Dyn 17(5):792–793

Bruno MS, Nakagawa FM (1991) Pore pressure influence on tensile fracture propagation in sedimentary rock. Int J Rock Mech Min Sci 28(4):261–273

Detournay E, Cheng A (1992) Influence of pressurization rate on the magnitude of the breakdown pressure. Int J Rock Mech Min Sci Geomech Abstr 32(2):325–333

Feng R, Chen S, Bryant S, Liu J (2019) Stress-dependent permeability measurement techniques for unconventional gas reservoirs: review, evaluation, and application. Fuel 256:115987

Feng R, Liu J, He Y, Chen S (2020) Fast permeability measurements of tight and sorptive gas reservoirs using a radial-flow transient technique. J Nat Gas Sci Eng 84:103673

Forquin P, Erzar B (2010) Dynamic fragmentation process in concrete under impact and spalling tests. Int J Fract 163(1):193–215

Gao Q, Han S, Cheng Y, Yan C, Sun Y, Han Z (2019) Effects of non-uniform pore pressure field on hydraulic fracture propagation behaviors. Eng Fract Mech 221:106682

Hardy MP (1973) Fracture mechanics applied to rock. PhD thesis. University of Minnesota, Minneapolis

He J, Lin C, Li X, Zhang Y, Chen Y (2017) Initiation, propagation, closure and morphology of hydraulic fractures in sandstone cores. Fuel 208:65–70

He J, Li X, Yin C, Zhang Y, Lin C (2020) Propagation and characterization of the micro cracks induced by hydraulic fracturing in shale. Energy 195:116449

Hou P, Gao F, Gao Y, Yang Y, Cai C (2017a) Effect of pore pressure distribution on fracture behavior of sandstone in nitrogen fracturing. Energy Explor Exploit 35(5):609–626

Hou P, Gao F, Ju Y, Gao Y, Liu J (2017b) Effect of water and nitrogen fracturing fluids on initiation and extension of fracture in hydraulic fracturing of porous rock. J Nat Gas Sci Eng 45:38–52

Huang B, Zhao X, Xue W, Sun T (2018) Experimental investigation on the impact of initial pore pressure on breakdown pressure of borehole radial fracture for unsaturated mortar hydraulic fracturing under true triaxial stress. J Porous Media 21(11):1041–1057

Huang C, Liu C, Gao Y, Lu B (2015) Failure mechanism of concrete under pore water pressure. J SiChuan Univ (Eng Sci Edn) 47(S2):76–80

Hubbert MK, Willis DG (1957) Mechanics of hydraulic fracturing. Trans Am Inst Mining Metal Eng 210(6):153–163

Ishida T, Chen YQ, Bennour Z, Yamashita H, Inui S, Nagaya YY, Naoi M, Chen Q, Nakayam Y, Nagano Y (2016) Features of CO2 fracturing deduced from acoustic emission and microscopy in laboratory experiments. J Geophys Res Solid Earth 121:8080–8098

Ito T, Hayashi K (1991) Physical background to the breakdown pressure in hydraulic fracturing tectonic stress measurements. Int J Rock Mech Min Sci Geomech Abstr 28(4):285–293

Ito T (2008) Effect of pore pressure gradient on fracture initiation in fluid saturated porous media. Rock Eng Fract Mech 75:1753–1762

Jiang T, Sun X (2019) Development of Keshen ultra-deep and ultra-high pressure gas reservoirs in the Kuqa foreland basin, Tarim Basin: understanding and technical countermeasures. Nat Gas Ind B 6:16–24

Ji Q, Jiang H, Yu X, Yagoub AElGA, Zhou C, Chen L (2020) Efficient and environmentally-friendly dehydration of fructose and treatments of bagasse under the supercritical CO2 system. Renewable Energy 162:1–12

Kumar S, Zielonka M, Searles K, Dasari G (2017) Modeling of hydraulic fracturing in ultra-low permeability formations: the role of pore fluid cavitation. Eng Fract Mech 184:227–240

Larson VC (1963) Understanding the Muskat method of analyzing pressure build-up curves. J Can Pet Technol 2:136–141

Li L, Xia Y, Tang C (2015a) Investigation on the effect of pore pressure gradient on fracture propagation in rock materials. Mater Res Innov 19(S1):237–240

Li X, Feng Z, Han G, Derek E, Saffer D (2015b) Hydraulic fracturing in shale with H2O, CO2 and N2. In: Forty-ninth US rock mechanics/geomechanics symposium, American Rock Mechanics Association, San Francisco, USA

Li X, Lei X, Li Q (2016) Injection-induced fracturing process in a tight sandstone under different saturation conditions. Environ Earth Sci 75:1466

Lockner DA, Byerlee JD (2016) Hydrofracture in Weber Sandstone at high confining pressure and differential stress. J Phys Res 82(14):2018–2026

Lyu S, Wang S, Chen X, Wang S, Wang T, Shi X, Dong Q, Li J (2020) Natural fractures in soft coal seams and their effect on hydraulic fracture propagation: a field study. J Pet Sci Eng 192:107255

Ma D, Cheng C, Ding C, Song J, Hu D, Zhou H (2021) Comparisons of fracturing mechanism of tight sandstone using liquid CO2 and water. J Nat Gas Sci Eng 94:1875–5100

Ma S, Guo JC, Li LC, Tham LG, Xia Y, Tang C (2015a) Influence of pore pressure on tensile fracture growth in rocks: a new explanation based on numerical testing. Front Earth Sci 9(3):412–426

Ma X, Zoback MD (2017) Lithology-controlled stress variations and pad-scale faults: a case study of hydraulic fracturing in the Woodford Shale, Oklahoma. Geophysics 82(6):35–44

Ma Y, Liu Z, Zhou g, Wang J W (2015b) Study of tri-stage fracturing characteristic of borehole based on strain of hole-wall in hydraulic fracturing process. Rock Soil Mech 36(8):2151–2168

Masuda K, Nishizawa O, Kusunose K, Satoh T, Takahashi M, Kranz RL (1990) Positive feedback fracture process induced by nonuniform high-pressure water flow in dilatant granite. J Geophys Res 95(B13):21583

Meng F, Wong LNY, Zhou H (2021) Rock brittleness indices and their applications to different fields of rock engineering: a review. J Rock Mech Geotech Eng 13:221–247

Newman JRJC (1971) An Improved Method of Collection for the stress analysis of cracked plates with various shaped boundaries. NASA TN D-6376

Olivier C (2004)Poromechanics. France

Rahman MM, Rahman MK (2010) A review of hydraulic fracture models and development of an improved pseudo-3D model for stimulating tight oil gas sand. Energy Sources Part A Recover Util Environ Eff 32(1):1416–1436

Rahul P, Hans DP, Josef S (2017) Pore pressure effects on fracture net pressure and hydraulic fracture containment: insights from an empirical and simulation approach. J Pet Sci Eng 157:724–736

Ranjith PG, Zhang CP, Zhang ZY (2019) Experimental study of fracturing behaviour in ultralow permeability formations: a comparison between CO2 and water fracturing. Eng Fract Mech 217:106541

Ren L, Yu Z, Zhao J, Lin Ra, Wu J, Wu J, Song Y (2022) Hydraulic fractures simulation in non-uniform stress field of horizontal shale gas well. J Pet Sci Eng 216:110843

Rudakov D, Sobolev V (2019) A mathematical model of gas flow during coal outburst initiation. Int J Min Sci Technol 29:791–796

Rummel F (1987) In: Atkinson BK (ed) Fracture mechanics approach to hydraulic fracturing stress measurements. Fracture Mechanics of Rock. Academic Press, London, pp 217–239

Sampath KHSM, Perera MSA, Ranjith PG (2018) Theoretical overview of hydraulic fracturing break-down pressure. J Nat Gas Sci Eng 58:251–265

Sander R, Pan Z, Luke DC (2017) Laboratory measurement of low permeability unconventional gas reservoir rocks: a review of experimental methods. J Nat Gas Sci Eng 37:248–279

Scanlon BR, Reedy RC, Nicot JP (2014) Comparison of water use for hydraulic fracturing for unconventional oil and gas versus conventional oil. Environ Sci Technol 48:12386–12393

Schimmel MTW, Hangx SJT, Spiers CJ (2022) Effect of pore fluid chemistry on uniaxial compaction creep of Bentheim sandstone and implications for reservoir injection operations. Geomech Energy Environ 29:100272

Shi R, Liu J, Wang X, Wei M, Derek E (2021) A critical analysis of shale laboratory permeability evolution data. Energy 236:121405

Shukla S, Zhu D, Hill D (2004) The effect of phase saturation conditions on wormhole propagation in carbonate acidizing. SPE J 11(3):273–281

Toan DC, Hussain F, Schrefler BA (2018) Porous media fracturing dynamics: stepwise crack advancement and fluid pressure oscillations. J Mech Phys Solids 111:113–133

Veatch RW, Moschovidis ZA (1989) An overview of hydraulic fracturing, in recent advances in hydraulic fracturing. Soc Pet Eng Richardson 12:1–38

Wang Q, Liu Y, Peng G (2016) Effect of water pressure on mechanical behavior of concrete sunder dynamic compression state. Constr Build Mater 125:501–509

Wanniarachchi WAM, Ranjith PG, Perera MSA, Lashin A, Al Arifi N, Li JC (2015) Current opinions on foam-based hydro-fracturing in deep geological reservoirs. Geomech Geophys Geo-Energy Geo-Resour 1(3–4):121–134

Wu S, Chen X, Zhou J (2012) Influence of strain rate and water content on mechanical behavior of dam concrete. Constr Build Mater 36:448–457

Wu Y, Tao J, Wang J, Zhang Y, Peng S (2021) Experimental investigation of shale breakdown pressure under liquid nitrogen pre-conditioning before nitrogen fracturing. Int J Min Sci Technol 31(4):611–620

Yan H, Zhang J, Li B, Zhu C (2021) Crack propagation patterns and factors controlling complex crack network formation in coal bodies during tri-axial supercritical carbon dioxide fracturing. Fuel 286:119381

Yang TH, Tham LG, Tang CA, Liang ZZ, Tsui Y (2004) Influence of heterogeneity of mechanical properties on hydraulic fracturing in permeable rocks. Rock Mech Rock Eng 37(4):251–275

Yu B, W F, Tom D, Wei Y, Deng L (2021) Heterogeneous evolution of pore structure during loess collapse: insights from X-ray micro-computed tomography. CATENA 201:105206

Zeng F, Cheng X, Guo J, Chen Z, Xiang J (2018) Investigation of the initiation pressure and fracture geometry of fractured deviated wells. J Pet Sci Eng 165:412–427

Zhao Y, Yang T, Zhang P, Xu H, Wang S (2020) Inversion of seepage channels based on mining-induced microseismic data. Int J Rock Mech Min Sci 126:104180

Zhao X, Huang B (2021) Distribution relationship of pore pressure and matrix stress during hydraulic fracturing. ACS Omega 6(45):30569–30579

Zhao C, Zhang Z, Wang S, Lei Q (2022) Effects of fracture network distribution on excavation-induced coupled responses of pore pressure perturbation and rock mass deformation. Comput Geotech 145:104670

Zhang J, Wieseneck J (2011) Challenges and surprises of abnormal pore pressures in the shale gas formations. Paper SPE 145964 presented at SPE annual technical conference and, exhibition, Denver, Colorado, USA

Zhang J (2011) Pore pressure prediction from well logs: methods, modifications, and new approaches. Earth Sci Rev 108:50–63

Zhang J (2013) Effective stress, porosity, velocity and abnormal pore pressure prediction accounting for compaction disequilibrium and unloading. Mar Pet Geol 45:2–11

Zhang J, Yin S (2017) Fracture gradient prediction: an overview and an improved method. Pet Sci 4(4):11

Zhang X, Wang JG, Gao F, Ju Y (2017) Impact of water, nitrogen and CO2 fracturing fluids on fracturing initiation pressure and flow pattern in anisotropic shale reservoirs. J Nat Gas Sci Eng 45:291–306

Zhang F, Wang X, Bai J, Wu W, Wu B, Wang G (2022a) Fixed-length roof cutting with vertical hydraulic fracture based on the stress shadow effect: a case study. Int J Min Sci Technol 32(2):295–308

Zhang H, Shen Z, Xu L, Gan L, Liu D, Wu Q, Tan J, Sun Y, Ma Z (2022b) Experimental and theoretical investigation on hydraulic fracturing in cement mortar exposed to sulfate attack. Mater Des 223:111226

Zhang H, Shen Z, Xu L, Gan L, Ma Z, Wu Q, Liu D (2022c) Experimental investigation on hydraulic fracturing in cement mortar with tensile stress. Eng Fract Mech 259:108058

Zhou D, Zhang G, Prasad M, Pu W (2019) The effects of temperature on supercritical CO2 induced fracture: an experimental study. Fuel 247:126–134

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51674247).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ma, D., Wu, Y., Yin, J. et al. Effect of initial pore pressure on the hydraulic fracturing of tight sandstone: an experimental study. Geomech. Geophys. Geo-energ. Geo-resour. 9, 15 (2023). https://doi.org/10.1007/s40948-023-00547-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-023-00547-x