Abstract

Coal burst is one of the principal hazards in development panels of underground coal mines. This study develops a practical approach to quantitatively estimate coal burst proneness in development roadways. A rigorous numerical and statistical study is conducted to establish a novel burst proneness rating (BPR) system based on energy release characteristics. The rating system includes eight geological and geotechnical factors and covers a wide range of inputs. A dataset including 18 field cases (9 burst and 9 no-burst cases) was used to validate the proposed rating system and to determine a critical BPR value (i.e. the threshold value of burst cases). The probability \(\hat{p}_{burst}\) of coal bursts was then obtained based on BPR logistic regression. The computed rating values using the BPR system can distinguish burst and no-burst cases that are in line with the scope of the eight input parameters in this study. The model results also showed that the mining depth was the most significant contributor of the energy release, along with roof elastic modulus and coal mass conditions. These results suggested that an environment that consists of relatively weak and brittle coal under high vertical stresses and surrounded by a relatively soft strata could promote unstable failures such as coal bursts.

Highlights

-

This study develops a practical approach to quantitatively estimate coal burst proneness in development roadways.

-

The computed rating values using the rating system can distinguish burst and no-burst cases that are in line with the scope of the eight input parameters in this study.

-

The results suggested that an environment that consists of relatively weak and brittle coal under high vertical stresses and surrounded by a relatively soft strata could promote unstable failures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Internationally, rock and/or coal bursts have been recognised as one of the most catastrophic hazards experienced in underground mines and tunnels (Ortlepp and Stacey 1994; Kaiser et al. 1996; Cai 2013; Iannacchione and Tadolini 2016; Mark and Gauna 2016; Mark 2018; Li et al. 2019). In general terms, rockburst refers to an unstable rock failure involving large amounts of energy, released in a sudden and violent manner. During a rockburst, failed/broken material is rapidly ejected into mine openings. Commonly, coal burst term is used in underground coal industry and it specifically refers to a rockburst event where coal is the type of ejected material (Hebblewhite and Galvin 2017; Zhang et al. 2017).

Due to the complexity of rockbursts, there are over 70 criteria and indices available in the literature aiming to predict rockbursts in underground mines and tunnels (Zhou et al. 2012, 2018; Li et al. 2014; Zhang et al. 2017; Jia et al. 2021). Moreover, there are several qualitative and semi-quantitative classification systems used to assess the coal burst potential in coal mines, commonly based on local empirical knowledge and site-specific data. For example, in the United States, a coal burst assessment system with six indicators is used to assess the burst risk during roadway development and longwall retreat (Mark and Gauna 2016). The six indicators are: mining depth, pillar layout, multiple seam interaction, geology, mining layouts and practices and coal burst history. In Poland, coal burst proneness is assessed by a detailed rating system, which includes 16 geological and mining factors with rating points for each sub-factor (Vardar et al. 2018a). In China, a similar coal burst rating system was proposed empirically with seven geological factors and 12 mining factors, based on coal burst experience obtained from Chinese longwall conditions (Dou and He 2001). Vardar et al (2018a) developed a semi-quantitative coal burst classification system based on back-analysis of case studies from Australia, China and the United States. This classification system identified nine critical geological and geotechnical factors and can be utilised in both longwall retreat and development. However, the rating points or the threshold of assessment indicators in a multi-index system are empirically determined according to specific-site or national mining conditions (Vardar 2019; Wei 2020). Thus, the application of those systems may be limited in mine sites with different conditions. In addition, of the indicators, it is the indices related to stress and energy that are primarily used to predict and evaluate the severity of coal bursts (Zhou et al. 2018).

Although the occurrence of coal burst is a result of the complex impacts of many factors, a major component of coal burst mechanism is associated with energy storage and release. Cook (1963) was the first to point out the importance of the energy changes in underground mining and the link between the ‘excess’ energy and rockbursts in South African gold mines. Cook et al (1966) adopted the elastic theory to quantitatively describe the deformation around underground excavations, showing that a large amount of gravitational potential energy converts to other forms of energy and at least half of the energy change is released in one form or another. The released energy is either in the form of non-violent dissipation or in the form of violent events. Thus, rockburst occurs when the energy release rate is greater than the rate at which energy can be dissipated non-violently during excavations, which forms the initial concept of Energy Release Rate (ERR) criterion. This criterion was then widely applied in underground mines in South Africa and it was found that the ERR value has a strong correlation with rockburst occurrence (Cook et al. 1978; Maleki et al. 1987; Spottiswoode 1990; Heasley 1991; Jager and Ryder 1999). In the following years, researchers further studied the energy changes during mining and provided detailed calculations of the energy balance and its components (Salamon 1974, 1983, 1984; Walsh 1977; Budavari 1983; Blight 1984; Napier 1991; Hedley 1992; Brady and Brown 2013; Danko et al. 2020; Yang et al. 2020; Jiang et al. 2021). For example, Salamon (1984) followed Cook’s logic (Cook et al. 1966) and rigorously analysed the energy changes in the underground mining process. He stated that the excess energy can simply be described as the difference between the work done by the external forces and the total stored and dissipated energies, which is further discussed in Sect. 3.4. Furthermore, since ERR is limited for estimating the impacts of geological discontinuities, Ryder (1988) proposed the excess shear stress (ESS) criterion to specifically assess the possible seismic energy and seismic magnitude produced by fault-slip.

With improvements in computational power and advanced numerical modelling techniques in recent decades, a number of researchers studied unstable failures and rockbursts using the energy calculations and advanced explicit numerical method software packages. Wei et al (2021) developed a coal burst risk classification using energy-based numerical modelling approach to estimate the risk potential when longwall approached a major fault. Khademian and Ozbay (2018) computed the radiated seismic energy to assess the rock burst intensity using numerical method with energy balance concept. Hofmann utilised boundary element method to compute and calibrate the source parameters (e.g., seismic moment, potency and seismic energy) of rockbursts in hard rock mines (Hofmann and Scheepers 2011; Hoffmann et al. 2013). Manouchehrian and Cai (2018) estimated the velocity and kinetic energy of the ejected rocks in a deep tunnel using an explicit numerical package. These studies once again demonstrated the robustness of the energy approach in evaluation of mining-induced seismicity and associated burst occurrences.

Given the increasing incidence of coal bursts in Australian mines, it is necessary to conduct systematic research to combat the coal burst risks at underground coal mines. This study aims to develop a practically applicable assessment approach to quantitatively estimate coal burst proneness in development roadways. A rigorous numerical and statistical study is conducted to establish a novel burst proneness rating system based on energy release characteristics. The developed rating system includes eight geological and geotechnical factors and covers a wide range of inputs. The impacts of the selected factors on coal burst proneness are analysed. A dataset including 18 field cases (9 burst and 9 no-burst cases) is then used to validate the rating system and to determine the critical value (i.e., the threshold value of burst cases) in the system. Using the developed rating system, coal burst proneness of the ground conditions can be estimated for a given roadway and the results can be compared to other known burst and no-burst cases.

2 Parametric analysis design

2.1 Identification of the critical factors

In this study, it is postulated that a coal burst, presumably in the form of a strain burst in development, is more likely to occur if the following three conditions are present (Salamon and Wagner 1979; Salamon 1983):

-

1.

large amount of stored strain energy due to high stresses

-

2.

a soft loading system surrounding the burst material (i.e. coal)

-

3.

a (brittle) failure near excavation boundaries.

According to the three critical conditions above, eight geological and geotechnical factors were selected for a numerical parametric analysis and shown in Table 1. These factors mainly cover mining depth, near seam geology, coal properties and cleating. For the sake of brevity, the factor codes (e.g., F1) are used to refer to the individual factors in Table 1. It should be noted although known to be an important factor, presence of major geological structures is not in the scope of this study.

As shown in Fig. 1, F1 is attributed to storage of strain energy in rock and coal mass, as it determines the vertical stress magnitude. Factors F2, F3, F4 and F5 were attributed to the control of the loading system stiffness, which can increase coal burst potential when sufficiently low (i.e., soft). Lastly, factors F6, F7 and F8 were postulated to be the main controlling factors of the failure characteristics (brittleness) in the ribs, hence energy release. The determination of magnitudes of each factor is discussed in Sect. 3.

2.2 The parametric analysis design using the identified factors

The total number of numerical models required in a traditional full factorial parametric study increases exponentially as the number of factors and levels of the factors increases. This, in turn, results in inefficient and time-consuming practices. To overcome these difficulties and to reduce the number of experiments, the Design of Experiments (DoE) approach was implemented in this study (Fisher 1960). The DoE is a systematic technique for planning an experiment and conducting statistical analysis of the responses to draw valid conclusions while optimising the number of experiments required. Combined with the precision of the numerical models, this approach can provide balanced and reliable conditions at a minimum number of model runs.

The Taguchi method (Taguchi 1986), also referred as the robust design or orthogonal arrays, is a well-established fractional factorial DoE technique that is increasingly being applied to rock engineering as well as other engineering fields (Roy 2001, 2010; Aydin et al. 2013; Wasantha and Ranjith 2014; Bahaaddini et al. 2016; Kim et al. 2018; Palchik 2020). The Taguchi method can provide a dramatic reduction in the total time and costs for a given analysis while maintaining the output quality (Taguchi 1986; Taguchi and Konishi 1987; Wu and Wu 2000; Taguchi et al. 2005). According to the Taguchi principles, an orthogonal array (O.A.) has the following properties:

-

1.

In the experiment, all factor levels must be used for each factor.

-

2.

In the experimental design each level of a given factor should appear an equal number of times to balance the influence of the levels.

-

3.

The factor levels must be arranged in a way that all factors (columns) are mutually orthogonal.

An OA is often designated by La(bc) where a, b and c represent the maximum number of experiments to be conducted, factor levels (entry in the array) and factors (columns in the array), respectively.

The responses obtained from the experiments (i.e. models) need to be grouped to analyse the influence of the factors of varying levels. Thus, the average response at each level is calculated as follows:

where \(\overline{{A_{k} }}\) is the average response of factor A at level k; n is the total number of responses at level k of factor A, and \(R_{i}\) is the ith response at level k.

In this study a standard orthogonal array of L18(21 × 37) was adopted to design the parametric analysis. This OA contains eight factors where one of the factors has two levels and the other seven have three levels. This design requires a total number of 18 models to be constructed where the inputs are systematically altered. Table 2 shows the parametric analysis design where the inputs for the factors were modified for each numerical model according to Taguchi’s L18(21 × 37) orthogonal array.

3 Numerical modelling setup

3.1 Model configurations

The study focused on simulation of a roadway excavation scenario using the UDEC numerical modelling package (Itasca 2014b). As shown in Fig. 2, the numerical models were 65.5 m in width and 63 m in height where a rectangular roadway of 5.5 m width and 3 m height was located at the centre of the models. These roadway dimensions are commonly preferred in Australian underground coal mines (Galvin 2016). The bottom boundary of the model was fixed while the lateral boundaries were only allowed to move in the vertical direction. The roadway was assumed to be subjected to a constant vertical stress which was applied at the top model boundary. Figure 2 illustrates an example model geometry and boundary conditions. During the numerical analysis, the magnitude of the stress was modified according to different depth of cover (F1). i.e., 300 m, 500 m and 700 m. Hence, a vertical stress of 7.5 MPa, 12.5 MPa and 17.5 MPa respectively were applied to the relevant models. Considering the general in situ stress trends in Australian coal mines, the minimum horizontal stress was assumed to be equal to the vertical stress while the maximum horizontal stress to vertical stress ratio of two was assumed (Hillis et al. 1998; Mark and Gadde 2010; Farmer 2012; Galvin 2016). Additionally, the direction of maximum horizontal stress was assigned to be parallel to the roadway drivage direction (i.e., out-of-plane in models), as it is the commonly preferred practice in longwall panel designs in Australia to minimise roof deterioration (Mark and Gadde 2010; Farmer 2012; Galvin 2016). Finally, quadrilateral zones (i.e., mesh) with four nodes were used throughout the model as it is more suitable for the Mohr–Coulomb strain-softening (MCSS) constitutive model used in the study (Itasca 2014a). The average zone edge length was 0.25 m in the coal seam, 0.5 m in the immediate roof and the first 10 m of the floor away from the seam; and 2.5 m in the main roof and the rest of the floor unit.

3.2 Mechanical properties of rock units

Three hypothetical types of rock units were modelled based on their compressive strength and elastic modulus: ‘weak’ (Rock-1), ‘moderate’ (Rock-2) and ‘strong’ (Rock-3). Hence, a range of roof and floor rock conditions that are commonly used in numerical modelling of underground coal mining scenarios were considered (Esterhuizen and Karacan 2005; Zipf 2006a; Karacan 2009; Shen 2014; Lawson et al. 2017; Chen et al. 2018, 2021; Le et al. 2018; Ju et al. 2021). In all models, the main roof consisted of Rock-3. The floor unit (F5) was either Rock-2 or Rock-3, based on the given modelling scenarios. Similarly, the immediate roof properties (F4) varied between the three rock types during the numerical analysis. Additionally, the immediate roof thickness (F2) was also altered in this study. The three thickness values used for the immediate roof were 5 m, 10 m and 15 m.

The Mohr–Coulomb strain-softening (MCSS) constitutive model was used for all rocks. Once a compressive failure took place, the material cohesion was linearly reduced to its residual value over a plastic strain of 0.05 and kept constant beyond the ‘critical strain’ value. The material friction angle, on the other hand, was assumed to be constant in all models in this study. A tensile strength to uniaxial compressive strength (UCS) ratio of 0.1 was used for the rocks and the residual tensile strength dropped to zero after a 0.001 plastic strain in tension. Lastly, a UCS (in MPa) to elastic modulus (in GPa) ratio of three was used to model the rocks. The MCSS input properties of the three rock types are listed in Table 3.

Horizontal bedding planes were also included in both the roof and floor. The spacing of these discontinuities was 2.5 m in the main roof and floor whereas three different spacing values were considered in the immediate roof: 0.5 m, 1.5 m and 2.5 m. For practical reasons the bedding spacings in the immediate roof were expressed as the number of beddings within a 5 m section of the immediate roof (F3): 9 beddings per 5 m; 4 beddings per 5 m; and 1 bedding per 5 m. In this way, it was intended to use average values of bedding density for the mining conditions as the bedding spacing is difficult to measure in the field. The bedding planes, including the ones in the coal seam, were modelled using Coulomb-slip with a residual strength constitutive model. These discontinuities had a peak friction angle of 30°, a peak cohesion 0.5 MPa and zero tensile strength (Zipf 2006b; Esterhuizen et al. 2010). Once a shear failure occurs, the friction angle dropped to 20° while the cohesion was completely lost. The normal and shear stiffness of the discontinuities were assigned to be 50 GPa/m and 5 GPa/m, respectively.

The effects of the pillar contact (i.e. rock-coal interface) friction angle (F6) were also examined in this study. Similar to the bedding planes, these discontinuities were modelled using Coulomb-slip with a residual strength constitutive model. The only difference was the peak friction angle value varied between 20° and 30° to simulate ‘weaker’ (level 1) and ‘stronger’ (level 2) contact conditions.

It is imperative to give additional emphasis to the coal properties as they govern the rate and extent of deformation in the ribs. To calibrate coal properties, several pillar (3 m of pillar height) compression tests were simulated, then the calculated pillar strengths were compared to the UNSW pillar design formula (Salamon et al. 1996). The MCSS constitutive model was used for the coal where the input properties were determined based on a sufficient agreement between the empirical pillar strength values was obtained (Vardar 2019). The elastic modulus of the coal was assumed to be 2 GPa and Poisson’s ratio was 0.25 while the other input properties were determined throughout the pillar compression simulations. The calibrated coal properties are given in Table 4.

The calibration process also produced a coal mass compressive strength of approximately 6.65 MPa. This value was obtained using the following equation:

where c is cohesion while φ is friction angle.

In the study, a coal mass UCS of 6.65 MPa was taken as the intermediate factor level (level 2) for the coal mass strength (F7). The lower (level 1) and higher (level 3) coal mass strength inputs were varied ± 25% of this value: 5 MPa and 8.3 MPa, respectively, which was achieved by varying ± 25% of the cohesion only and kept the friction angle and tension the same.

In addition to the coal mass strength, the cleating density within the coal seam was also investigated. The horizontal bedding planes within the coal seam had a vertical spacing of 0.5 m. The sub-vertical cleats were modelled to have a dip angle of 90° with a random deviation up to 10°. To simulate the varying cleating conditions observed in coal seams, the average horizontal spacing of these discontinuities was assigned to be 0.3 m, 0.6 m and 0.9 m. Thus, the three levels of cleat spacing to bedding spacing ratios (F8) in the analysis were 0.6, 1.2 and 1.8, respectively.

Similar to all the other discontinuities in this study, the cleats were also modelled using a Coulomb-slip with residual strength constitutive model. Their peak and residual friction angles were 25° and 20°, respectively; while the cohesion or tensile strength values were taken as zero. Table 5 lists the properties used for the bedding planes (both in rock and coal) and the cleats (in coal) in this study.

3.3 Gradual excavation of the roadway

After the material and discontinuity properties were assigned and the boundary conditions and in situ stresses were applied, the model was solved to reach an initial static equilibrium. Next, the gradual roadway excavation was performed using a build-in FISH function (Itasca 2014b) that reduces the interior boundary forces in a total of 10 stages. Hence, a continuous mining scenario, which is more realistic for underground coal mining operations, was simulated.

3.4 Energy release in underground excavations

Salamon (1984) investigated the energy changes in underground excavations. The study proposed that, before and after an excavation, the total released energy, Wr, can be expressed in the following form (Salamon 1984):

where Um represents the strain energy stored within the mined-out portion of the rock mass whereas Wk is the total radiated seismic (i.e. kinetic) energy which would be dissipated through damping until the new equilibrium is attained (Salamon 1984; Hedley 1992).

In UDEC, the energy terms are calculated using the same general nomenclature provided by Salamon (1984). The two terms, Um and Wk, can be explicitly calculated for an excavation scenario in UDEC (Itasca 2014b). In numerical modelling, the strain energy in the mined-out material (Um) consists of the strain energy in the blocks (\(U_{mb}\)) and the contact joints (\(U_{cj}\)) bounding the excavated blocks, as given by Eq. 4 (Itasca 2014b).

where \(A\) is the area of the mined-out material (block); \(E\) is the Young’s modulus of the mined-out material; \(\nu\) is Poisson’s ratio; \(\sigma_{1}\), \(\sigma_{2}\), and \(\sigma_{3}\) are the principal stresses in the material; \(f_{n}\) and \(f_{s}\) are the normal and shear force along the contact joints; \(k_{n}\) and \(k_{s}\) are the normal and shear stiffness of the contact joints; nb is the number of blocks in the mined-out material; nz is the number of zones in the block; nc is the number of contacts.

The total radiated seismic (i.e. kinetic) energy, \(W_{k}\), equals the total damped energy (\(W_{d}\)) of the entire model system before and after a static excavation (i.e., from one equilibrium to another equilibrium), as given by Eq. 7 (Itasca 2014b).

where \(W_{dj}\) is the damped energy over a timestep at a grid point, \(j\); nt is the number of calculating timesteps performed in the modelling before and after the excavation; ngp is the number of grid points within the entire model system.

In practice, the seismic energy component (Wk) can be recorded by mine microseismic systems, and is the controlling factor for the damage caused by a rockburst (McGarr et al. 1979; Napier 1991; Hedley 1992; Spottiswoode 1993; Ortlepp and Stacey 1994). Furthermore, the seismic efficiency (commonly expressed as a percentage), which refers to the ratio of seismic or kinetic energy to the total released energy, can be expressed by Wk/Wr. The seismic efficiency can then be used to evaluate the burst proneness of different scenarios: the higher the seismic efficiency, the higher the rockburst potential (Hedley 1992).

Therefore, the total seismic energy (Wk) and the seismic efficiency (Wk/Wr) terms were closely associated with unstable failures in underground mines. The magnitude of seismic energy was argued to be proportional to the damage caused by rockbursts (i.e., consequence), whereas the seismic efficiency was considered to be an indicator of burst potential (i.e., likelihood). Thus, this study postulated that these two energy terms can be used to assess the coal burst risk in roadways.

4 Model results and discussion

4.1 Energy release mechanisms and multiple regression

Table 6 lists the calculated energy terms for each numerical model using Eq. 3, where the total released energy (Wr) is equal to the sum of the strain energy stored in the mined-out material (Um) and the total seismic energy (Wk).

4.1.1 Influence of the factors on energy release

Figures 3 and 4 illustrate the average total seismic energy and seismic efficiency responses for each factor level, respectively. These values were obtained based on Eq. 1. As expected, both Wk and Wk/Wr show a similar trend for all the considered factors.

It was observed that the two energy terms (Wk and Wk/Wr) increased as the mining depth, thickness of the immediate roof rock, contact friction angle and the cleat spacing to bedding spacing ratio increased. Mining depth (F1) showed a substantial impact on the energy terms as it controls the in situ vertical stress magnitude, which constitutes the available strain energy in the rock and coal mass. The influence of immediate roof thickness (F2) was less significant compared to mining depth. A noticeable increase in total seismic energy was recorded when the thickness increased from 5 to 10 m whereas this effect diminished as the thickness further increased to 15 m. The seismic efficiency, however, increased steadily as the immediate roof unit became thicker. The increase in the energy terms can be explained by the reduction in the stiffness of the immediate roof unit as its thickness got larger. In the aspect of the pillar contacts (F6), higher seismic energy and seismic efficiency magnitudes caused by higher peak friction angle inputs were attributed to the larger shear stress drops on the contacts (Gu and Ozbay 2014; Iannacchione and Tadolini 2016). Lastly, it was observed that both energy terms increased as the cleat spacing to bedding spacing ratio (F8) increased. A possible explanation for this is the stable dissipation of energy through frictional work of the discontinuities. Thus, it was argued that inadequate friction work done on the cleats was transformed to additional kinetic energy within the system. However, when the cleat spacing was decreased, the cleat density was increased, more energy could be dissipated in a stable manner, reducing the total seismic energy release magnitudes and brittleness (Tahmasebinia et al. 2018; Vardar et al. 2018b, 2019).

On the contrary, the findings indicated an inverse relationship between the two energy terms and the elastic modulus of the immediate roof and floor; the number of bedding planes in the immediate roof rock; coal mass strength and the cleat to bedding spacing ratio. The elastic modulus of the roof and floor units (F4 and F5) is one of the main contributors of surrounding strata stiffness (Salamon 1970; Galvin 2016; Vardar et al. 2017). The density of horizontal bedding planes (F3) can also reduce the stiffness of the loading system as they decrease the equivalent modulus of the rock mass at the immediate roof. These factors, in turn, promote the tendency of unstable failures by reducing the local mine stiffness (Salamon 1970). Furthermore, lower coal strength values (F7) lead to more instabilities in the ribs, hence more fracturing and an increased probability of initiating a coal burst when interacting with a soft loading system.

These findings on the roof and floor strata conditions suggest mechanical explanations for the development bursts described by Mark (2018) in the North Fork Valley, Colorado, United States. These events, which were some of the most powerful bursts experienced in the United States, were reported to occur in seams surrounded by thick and relatively weak rock units. Therefore, based on the outcomes of this study, it was argued that highly bedded and laminated and low-to-moderate strength near seam rock units can substantially increase the coal burst proneness as they reduce the loading system stiffness. Thus, total seismic energy and seismic efficiency values increase accordingly.

In addition to the mechanical reasoning above, the influences of the factors have been statistically evaluated. The t-ratio of each factor, representing the ratio of the parameter (i.e. factor) coefficient to the corresponding standard error, was calculated (Ghilani 2017) using the results of the regression analyses (as described in detail in Sect. 4.1.2). The results are illustrated in Fig. 5, including a 90% confidence interval, implying a t-ratio of 1.37 for 10 degrees of freedom. The statistical analysis also confirmed the observations obtained from Figs. 3 and 4. According to the results, the most significant contributing factor was the mining depth (F1) followed by the elastic modulus of the roof (F4) and coal properties (F7). Hence, it was demonstrated that an environment consisting of ‘weak’ and brittle coal under high vertical stresses and surrounded by a relatively soft strata can promote unstable failures, hence large magnitudes of seismic energy release.

4.1.2 Multiple regression

Based on the factors and results listed in Tables 2 and 6, multiple regression analyses were performed and the following formulae obtained to estimate the total seismic energy and seismic efficiency terms:

where F1, F2… F8 are the used inputs of the relevant factors within the scope given in Table 1. The unit of Wk is J (Joule) in Eq. 8. These two equations were then used to calculate the burst proneness rating (BPR) values of development roadways (Sects. 4.2 and 4.3).

The validity of the formulae was examined by comparing the predicted values (i.e., regression results) to the calculated ones (i.e., numerical results). Figures 6 and 7 illustrate the comparisons for Wk and Wk/Wr, respectively. The figures show the developed regression equations are able to provide adequate predictions for the energy terms.

Plots of the residuals (i.e., the difference between the predicted and the calculated values) against the predicted energy terms were also examined. As illustrated in Figs. 8 and 9, the residuals are randomly scattered, implying there is no systematic bias in the regression models.

4.2 The burst proneness rating system

Based on the numerical modelling analysis, this study aimed to develop a rating system to evaluate the coal burst proneness of a given roadway and/or sections of a roadway. To achieve this goal, first, the exponential function defined in Eq. 8 was linearised by taking the natural logarithm (i.e., ln) of the calculated Wk responses in Table 6. Thus, the relationship between ln(Wk) and Wk/Wr was represented by a linear equation, as illustrated in Fig. 10.

Relationship between ln(Wk) and Wk/Wr based on the modelling results in Table 6

Next, these two energy terms were combined to calculate the Burst Proneness Rating (BPR) using an ellipse equation as below, where c is a constant.

To determine the value of c, it was assumed that the case with highest Wk and Wk/Wr values, within the scope of the study (parameters in Table 1), had a BPR of 100. Then, incorporating these three values into Eq. 10, the value of c was calculated as 61,858. Hence, the generic BPR formula was established as follows:

The unit of Wk is J (Joule) in both Eq. 10 and Eq. 11. Therefore, the BPR of various cases in relation to the ‘worst-case’ of BPR = 100 can be calculated using Eq. 11. To better demonstrate the complete BPR calculation procedure, a hypothetical case is given as below:

Assume a roadway scenario where:

-

mining depth is 400 m

-

immediate roof thickness is 10 m

-

5 bedding planes are identified within the first 5 m into the immediate roof which has a 7 GPa field elastic modulus, while the floor field elastic modulus is considered to be 10 GPa

-

pillar contact has about 20° of friction angle

-

coal mass compressive strength is 6.2 MPa while the cleat spacing to bedding spacing ratio is 1.5.

Based on the regression equations, the above-mentioned conditions would produce about 0.33 MJ total seismic energy and a seismic efficiency of 14.76%. Once these two energy terms are obtained, the BPR value can be calculated using Eq. 11. For this given case, the BPR is equal to 38.84.

Using the same calculation procedure above, the following section back-analyses the BPR values of several burst and no-burst cases from Australia and the United States.

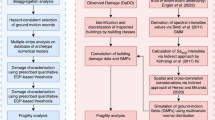

4.3 Implementation of the BPR system and logistic regression

To assess the performance of the proposed BPR system, 11 cases from Australia and 7 from the United States are considered. The U.S. cases used in the back analysis have been discussed mechanistically in Mark (2018). The geological and geotechnical conditions of the 18 cases are shown in Table 7. The dataset of the 18 cases has 9 burst and 9 no-burst cases, as illustrated in Fig. 11. The energy terms of Wk and Wk/Wr in Table 7 are calculated using Eq. 8 and Eq. 9, respectively. Then, the BPR values are determined using Eq. 11. Furthermore, a logistic regression was performed to determine a threshold BPR value above which an elevated coal burst proneness is expected. Figure 11 illustrates the calculated BPR values of the back-analysed cases, sorted lowest to highest, with a dashed line representing the obtained threshold BPR value of 46.875.

BPR values of the burst and no-burst cases, and the BPR threshold value (dashed) obtained by logistic regression. Note: ‘no-burst' means the mine in the case number had not experienced coal bursts. In contrast, ‘burst’ refers to that coal burst had occurred in the roadway of the mine with the case number

The BPR values of the eighteen cases appear relatively linear in Fig. 11, as the depth of cover inputs in the database range from 150 to 707 m in a reasonably uniform distribution. Also, mining depth is a dominant factor in energy release. Thus, the results are relatively consistent with the depth of cover values.

Although Fig. 11 shows a fair distinction between the burst and no-burst cases, the logistic regression analysis is still dependent on the number of cases. Therefore, misclassification can be expected such as Case 8 and Case 11. Coal burst Case 8 was caused by a seismic event magnitude of 2.9 (ML). It indicates that the incident was likely to be a fault-slip burst. However, this energy release mechanism is beyond the scope of this study; hence the inaccuracy is explainable. On the other hand, no-burst Case 11 belongs to a mine where seismic activity is frequently experienced, but no coal bursts have been reported.

The misclassifications may also be attributed to inconsistencies between the BPR values obtained from the modelling results and the BPR values from the regression formulae. The mean absolute error for the BPR values based on the previously modelled 18 cases was approximately 2.8. This implies that, in particular, cases close to the threshold value should be considered with caution. As new cases are incorporated into the system database, the threshold value itself will also be updated.

According to the logistic regression results based on the 18 cases, the estimated probability \(\hat{p}_{burst}\) of coal bursts can then be expressed (Eq. 12) based on the BPR values.

Nonetheless, the back-analysis results demonstrate that the proposed Burst Proneness Rating system is capable of distinguishing burst and no-burst cases with a certain level of accuracy. The system can therefore be used by geotechnical engineers to evaluate the coal burst proneness of development roadways and to obtain preliminary guidance.

5 Discussion and limitations

The aims of this study are to (i) establish an energy-based quantitative classification system, mainly considering strain burst potential in development roadways; (ii) present a robust and practical methodology that can be used to incorporate numerical modelling results and empirical data into geotechnical hazard risk assessment tools.

Despite the practical benefits of the BPR system, it must be emphasised that the results should not be interpreted as a definitive indicator of coal burst risk in a given roadway. As discussed in the introduction section, multiple factors play roles in the occurrence of bursts in underground mines. Thus, the coal burst risk can be significantly increased if additional factors or triggers are involved. Geological structures (e.g., fault, dyke and fold), multi-seam interactions and high in-seam gas pressures are some examples of these additional parameters. The impacts of excavation conditions (e.g., ground support, mining rate, seam thickness, pillar dimensions and roadway configuration) can also influence the magnitude and rate of the energy release. Thus, it is worth further investigation that can consider other influencing factors (i.e., other than the factors in Table 1) and expand the scope of application of the current BPR system.

It is also recommended that the assumptions made in the numerical modelling are considered carefully when the BPR system is used. For instance, the direction and magnitude of the major and minor horizontal stresses relative to the roadway can alter the rib deformation modes and immediate roof stability (Galvin 2016). Moreover, presence of single or multiple joint sets in the coal seams can induce local instabilities such as rib spalling or toppling. These types of events may alter the energy release mechanisms and influence the burst proneness. Future research may investigate such interactions. Additionally, as the numerical models required several assumptions to be made regarding the material and discontinuity properties, the implications of these assumptions may also be examined by future sensitivity studies.

Furthermore, as Eq. 8 dictates, the relationship between the eight considered factors and the seismic energy magnitude is an exponential one. Although the BPR formula (Eq. 11) does not explicitly show this relationship, the underlying energy release mechanisms are still accounted for in the BPR calculations. Therefore, it expected that the bursts in roadways with high BPR values (e.g. 90 or more) are expected to be significantly more severe, as the seismic energy magnitudes change in a non-linear fashion. Thus, along with the BPR values, the calculated energy terms should also be taken into account.

6 Conclusions

This study developed an innovative approach to quantitatively assess coal burst proneness using numerical and statistical analyses. Eight geological and geotechnical input parameters were considered in the burst proneness rating (BPR) system, where the critical BPR value (i.e. the threshold value of burst cases) was determined by a dataset including 18 field cases (9 burst and 9 no-burst cases). The probability \(\hat{p}_{burst}\) of coal bursts was then obtained based on BPR logistic regression results. The computed rating values using the BPR system can clearly distinguish burst and no-burst cases that are in line with the scope of the eight input parameters in this study.

The sensitive analysis of the eight parameters showed that the mining depth was the most significant contributor to the energy release, along with roof elastic modulus and coal mass conditions. These results indicated that an environment that consists of relatively weak and brittle coal under high vertical stresses and surrounded by a relatively soft strata could promote unstable failures such as coal bursts in development panels.

Overall, the proposed assessment approach has shown promising accuracy in identifying burst-prone conditions using quantitative inputs. Furthermore, the back-analysis results demonstrate that the BPR system can assist geotechnical engineers in evaluating the burst proneness in development roadways.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Aydin G, Karakurt I, Aydiner K (2013) Prediction of the cut depth of granitic rocks machined by abrasive waterjet (AWJ). Rock Mech Rock Eng 46(5):1223–1235

Bahaaddini M, Hagan P, Mitra R, Hebblewhite B (2016) Numerical study of the mechanical behavior of nonpersistent jointed rock masses. Int J Geomech 16(1):04015035

Blight GE (1984) Soil mechanics principles in underground mining. J Geotech Eng 110(5):567–581

Brady BH, Brown ET (2013) Rock mechanics: for underground mining. Springer, Berlin

Budavari S (1983) Response of the rock mass to excavations underground, Rock Mechanics in Mining Practice. The South African Institute of Mining and Metallurgy Monograph Series M, vol 5, pp 55–76

Cai M (2013) Principles of rock support in burst-prone ground. Tunn Undergr Sp Tech 36:46–56

Chen L, Shen B, Dlamini B (2018) Effect of faulting on coal burst–A numerical modelling study. Int J Min Sci Technol 28(5):739–743

Chen H, Di Q, Zhang W, Li Y, Niu J (2021) Effects of bedding orientation on the failure pattern and acoustic emission activity of shale under uniaxial compression. Geomech Geophys Geo-Energy Geo-Resour 7(1):1–17

Cook N (1963) The basic mechanics of rockbursts. J South Afr Inst Min Metall 64(3):71–81

Cook N, Hoek E, Pretorius J, Ortlepp W, Salamon M (1966) Rock mechanics applied to study of rockbursts. J South Afr Inst Min Metall 66(10):436–528

Cook N, Fenton C, Lancaster F, More-O'Ferall R, Nienaber W, van Schalkwijk A, Steijn R, Tyser J, Wagner H, Waterman D (1978) An industry guide to the amelioration of hazards of rockbursts and rockfalls. Chamber of Mines of South Africa

Danko G, Jobbik A, Baracza M, Varga G, Kovacs I, Wittig V (2020) Energy potential of a single-fracture, robust, engineered geothermal system. Geomech Geophys Geo-Energy Geo-Resour 6(1):1–14

Dou L, He X (2001) Prevention theory and technology of rockburst. China University of Mining and Technology Press, Xuzhou

Esterhuizen G, Karacan C (2005) Development of numerical models to investigatepermeability changes and gas emission around longwall mining panel. In: Proceedings Alaska Rocks 2005, The 40th U.S. Symposium on Rock Mechanics (USRMS). American Rock Mechanics Association

Esterhuizen, E, Mark, C, Murphy MM (2010) Numerical model calibration for simulating coal pillars, gob and overburden response. In: Proceedings of the 29th international conference on ground control in mining, Morgantown, pp 46–57

Farmer IW (2012) Coal mine structures. Springer, Berlin

Fisher RA (1960) The design of experiments, 7th ed

Galvin JM (2016) Ground engineering principles and practices for underground coal mining. Springer, Berlin

Ghilani CD (2017) Adjustment computations: spatial data analysis. Wiley, New York

Gu R, Ozbay U (2014) Distinct element analysis of unstable shear failure of rock discontinuities in underground mining conditions. Int J Rock Mech Min Sci 68:44–54

Heasley KA (1991) An examination of energy calculations applied to coal bump prediction. In: Proceedings 32nd U.S. Symposium on Rock Mechanics (USRMS). American Rock Mechanics Association

Hebblewhite B, Galvin J (2017) A review of the geomechanics aspects of a double fatality coal burst at Austar Colliery in NSW, Australia in April 2014. Int J Min Sci Technol 27(1):3–7

Hedley DG (1992) Rockburst handbook for Ontario hardrock mines (Canmet)

Hillis RR, Meyer JJ, Reynolds SD (1998) The Australian stress map. Explor Geophys 29(3–4):420–427

Hofmann G, Scheepers L (2011) Simulating fault slip areas of mining induced seismic tremors using static boundary element numerical modelling. Min Technol 120(1):53–64

Hoffmann G, Murphy S, Scheepers L, van Aswegen G (2013) Surface stress modelling of some shear slip seismic events that occurred in Anglogold Ashanti’s tabular mines. In: Proceedings 8th international symposium on rockbursts and seismicity in mines, pp 219–231

Iannacchione A, Tadolini SC (2016) Occurrence, prediction, and control of coal burst events in the U.S. Int J Min Sci Technol 26(1):39–46

Itasca (2014a) Universal Distinct Element Code (UDEC) Version 6.0. Itasca Consulting Group Inc, Mineapolis

Itasca (2014b) Universal Distinct Element Code v6.00 users' manual. Itasca, Minneapolis

Jager A, Ryder J (1999) A handbook on rock engineering practice for tabular hard rock mines. Safety in Mines Research Advisory Committee, Johannesburg: South Africa

Jia Y, Tang J, Lu Y, Lu Z (2021) The effect of fluid pressure on frictional stability transition from velocity strengthening to velocity weakening and critical slip distance evolution in shale reservoirs. Geomech Geophys Geo-Energy Geo-Resour 7(1):1–13

Jiang C, Li Z, Wang W, Wen Z, Duan M, Geng W (2021) Experimental investigation of the mechanical characteristics and energy dissipation of gas-containing coal under incremental tiered cyclic loading. Geomech Geophys Geo-Energy Geo-Resour 7(3):1–15

Ju M, Wang D, Shi J, Li J, Yao Q, Li X (2021) Physical and numerical investigations of bedding adhesion strength on stratified rock roof fracture with longwall coal mining. Geomech Geophys Geo-Energy Geo-Resour 7(1):1–31

Kaiser PK, Tannant DD, McCreath DR (1996) Canadian rockburst support handbook. Geomechanics Research Centre, Laurentian University, Sudbury

Karacan CÖ (2009) Elastic and shear moduli of coal measure rocks derived from basic well logs using fractal statistics and radial basis functions. Int J Rock Mech Min Sci 46(8):1281–1295

Khademian Z, Ozbay U (2018) Computational framework for simulating rock burst in shear and compression. Int J Rock Mech Min Sci 110:279–290

Kim B-H, Larson MK, Lawson HE (2018) Applying robust design to study the effects of stratigraphic characteristics on brittle failure and bump potential in a coal mine. Int J Min Sci Technol 28(1):137–144

Lawson HE, Tesarik D, Larson MK, Abraham H (2017) Effects of overburden characteristics on dynamic failure in underground coal mining. Int J Min Sci Technol 27(1):121–129

Le TD, Oh J, Hebblewhite B, Zhang C, Mitra R (2018) A discontinuum modelling approach for investigation of longwall top coal caving mechanisms. Int J Rock Mech Min Sci 106:84–95

Li CC, Stjern G, Myrvang A (2014) A review on the performance of conventional and energy-absorbing rockbolts. J Rock Mech Geotech Eng 6(4):315–327

Li CC, Mikula P, Simser B, Hebblewhite B, Joughin W, Feng X, Xu N (2019) Discussions on rockburst and dynamic ground support in deep mines. J Rock Mech Geotech Eng 11(5):1110–1118

Maleki H, Aggson J, Miller F, Agapito J (1987) Mine layout design for coal bump control. In: Proceedings 6th international conference on ground control in mining. West Virginia University, Morgantown, pp 32-46

Manouchehrian A, Cai M (2018) Numerical modeling of rockburst near fault zones in deep tunnels. Tunn Undergr Sp Tech 80:164–180

Mark C (2018) Coal bursts that occur during development: A rock mechanics enigma. Int J Min Sci Technol 28(1):35–42

Mark C, Gadde M (2010) Global trends in coal mine horizontal stress measurements. In: Coal operators' conference. University of Wollongong

Mark C, Gauna M (2016) Evaluating the risk of coal bursts in underground coal mines. Int J Min Sci Technol 26(1):47–52

McGarr A, Spottiswoode S, Gay N, Ortlepp W (1979) Observations relevant to seismic driving stress, stress drop, and efficiency. J Geophys Res Solid Earth 84(B5):2251–2261

Napier J (1991) Energy changes in a rockmass containing multiple discontinuities. J South Afr Inst Min Metall 91(5):145–157

Ortlepp W, Stacey T (1994) Rockburst mechanisms in tunnels and shafts. Tunn Undergr Sp Tech 9(1):59–65

Palchik V (2020) Analysis of main factors influencing the apertures of mining-induced horizontal fractures at longwall coal mining. Geomech Geophys Geo-Energy Geo-Resour 6(2):1–11

Roy RK (2001) Design of experiments using the Taguchi approach: 16 steps to product and process improvement. Wiley, New York

Roy RK (2010) A primer on the Taguchi method. Society of Manufacturing Engineers, Southfield

Ryder J (1988) Excess shear stress in the assessment of geologically hazardous situations. J South Afr Inst Min Metall 88(1):27–39

Salamon M (1970) Stability, instability and design of pillar workings. Int J Rock Mech Min Sci Geomech Abstr 7(6):613–631

Salamon MDG (1974) Rock mechanics of underground excavations. In Proceedings of the 3rd ISRM congress, Denver, CO, pp 951–1099. National Academy of Sciences

Salamon M (1983) Rockburst hazard and the fight for its alleviation in South African gold mines. In: Conference on rockbursts, prediction and control. Institute of Mining and Metallurgy London

Salamon M (1984) Energy considerations in rock mechanics: fundamental results. J South Afr Inst Min Metall 84(8):233–246

Salamon MDG, Wagner H (1979) Role of stabilizing pillars in the alleviation of rock burst hazard in deep mines. In: Proceedings 4th ISRM congress. International Society for Rock Mechanics and Rock Engineering

Salamon M, Galvin J, Hocking G, Anderson I (1996) Coal pillar strength from back-calculation. Part of a New South Wales Joint Coal Board Research Project-Strata Control for Coal Mine Design. University of New South Wales, School of Mines, Sydney

Shen B (2014) Coal mine roadway stability in soft rock: a case study. Rock Mech Rock Eng 47(6):2225–2238

Spottiswoode S (1990) Volume excess shear stress and cumulative seismic moments. In: Proceedings 2nd international symposium on rockbursts and seismicity in Mines, Minneapolis, p A397 (Pergamon)

Spottiswoode S (1993) Seismic attenuation in deep-level mines. Rockbursts and Seismicity in Mines, pp 409–414

Taguchi G (1986) Introduction to quality engineering: designing quality into products and processes

Taguchi G, Konishi S (1987) Taguchi methods: orthogonal arrays and linear graphs. Tools for quality engineering. American Supplier Institute, Dearborn

Taguchi G, Chowdhury S, Wu Y (2005) Taguchi’s quality engineering handbook. Wiley, New York

Tahmasebinia F, Zhang C, Canbulat I, Vardar O, Saydam S (2018) Computing the damage and fracture energy in a coal mass based on joint density. Int J Min Sci Technol 28(5):813–817

Vardar O (2019) Assessment of effects of geological and geotechnical factors on coal burst proneness. Ph.D. thesis, University of New South Wales, Sydney

Vardar O, Tahmasebinia F, Zhang C, Canbulat I, Saydam S (2017) A review of uncontrolled pillar failures. Procedia Eng 191:631–637

Vardar O, Zhang C, Canbulat I, Hebblewhite B (2018a) A semi-quantitative coal burst risk classification system. Int J Min Sci Technol 28(5):721–727

Vardar O, Zhang C, Tahmasebinia F, Canbulat I, Hebblewhite B (2018b) DEM analysis of the effect of discontinuities on coal mass brittleness. In: Rock dynamics and applications 3. CRC Press, Cambridge, pp 239–244

Vardar O, Zhang C, Canbulat I, Hebblewhite B (2019) Numerical modelling of strength and energy release characteristics of pillar-scale coal mass. J Rock Mech Geotech Eng 11:935–943

Walsh JB (1977) Energy changes due to mining. In: Proceedings Int J Rock Mech Min Sci Geomech Abstr. Elsevier, New York, pp 25–33

Wasantha P, Ranjith P (2014) The Taguchi approach to the evaluation of the influence of different testing conditions on the mechanical properties of rock. Environ Earth Sci 72(1):79–89

Wei C (2020) Assessment of fault-slip behaviour and the associated coal burst occurrence in longwall mining. Ph.D. Thesis, University of New South Wales, Sydney, Australia

Wei C, Zhang C, Canbulat I, Huang W (2021) Numerical investigation into impacts of major fault on coal burst in longwall mining–a case study. Int J Rock Mech Min Sci 147:104907

Wu Y, Wu A (2000) Taguchi methods for robust design. ASME Press, New York

Yang S-Q, Yang J, Xu P (2020) Analysis on pre-peak deformation and energy dissipation characteristics of sandstone under triaxial cyclic loading. Geomech Geophys Geo-Energy Geo-Resour 6(1):1–15

Zhang C, Canbulat I, Hebblewhite B, Ward CR (2017) Assessing coal burst phenomena in mining and insights into directions for future research. Int J Coal Geol 179:28–44

Zhou J, Li X, Shi X (2012) Long-term prediction model of rockburst in underground openings using heuristic algorithms and support vector machines. Saf Sci 50(4):629–644

Zhou J, Li X, Mitri HS (2018) Evaluation method of rockburst: state-of-the-art literature review. Tunn Undergr Sp Tech 81:632–659

Zipf K (2006a) Numerical modeling procedures for practical coal mine design. In: Proceedings Golden Rocks 2006a, The 41st U.S. Symposium on Rock Mechanics (USRMS). American Rock Mechanics Association

Zipf K (2006b) Numerical modelling procedures for practical coal mine design. In: Proceedings Golden Rocks 2006b, 41st U.S. Symposium on Rock Mechanics (USRMS), Golden, Colorado. American Rock Mechanics Association

Acknowledgements

The authors acknowledge Assistant Professor Ihsan Berk Tulu for providing mine conditions of the U.S. cases used for the back analysis in the manuscript.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions. This study is funded by the Australian Coal Association Research Program (ACARP) (No. C26066).

Author information

Authors and Affiliations

Contributions

OV wrote the main manuscript text and conducted the numerical modelling. CW reviewed the manuscript and drew some of the figures in the manuscript. CZ reviewed the manuscript and provided guidance on the numerical modelling. IC reviewed the manuscript and provided guidance on the research methodology. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent for publication

All of the authors agree to the submission and publication (if accepted) of this manuscript in the Geomechanics and Geophysics for Geo-Energy and Geo-Resources. Authors declare that the work in this study is original research that has not been published previously and is not under consideration for publication elsewhere, in whole or in part. All the authors approved the enclosed manuscript. We confirm that we understand Geomechanics and Geophysics for Geo-Energy and Geo-Resources is an open access journal that levies an article processing charge per articles accepted for publication. By submitting our article we agree to pay this charge in full if our article is accepted for publication.

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Vardar, O., Wei, C., Zhang, C. et al. An energy-based quantitative coal burst proneness rating system for development roadways. Geomech. Geophys. Geo-energ. Geo-resour. 9, 19 (2023). https://doi.org/10.1007/s40948-023-00531-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-023-00531-5