Abstract

Induced earthquakes and shallow groundwater contamination are two environmental concerns associated with the interaction between hydraulic fracturing (fracking) operations and geological faults. To reduce the risks of fault reactivation and faults acting as fluid conduits to groundwater resources, fluid injection needs to be carried out at sufficient distances away from faults. Westwood et al. (Geomechanics and geophysics for geo-energy and geo-resources, pp 1–13, 2017) suggest a maximum horizontal respect distance of 433 m to faults using numerical modelling, but its usefulness is limited by the model parameters. An alternative approach is to use microseismic data to infer the extent of fracture propagation and stress changes. Using published microseismic data from 109 fracking operations and analysis of variance, we find that the empirical risk of detecting microseismicity in shale beyond a horizontal distance of 433 m is 32% and beyond 895 m is 1%. The extent of fracture propagation and stress changes is likely a result of operational parameters, borehole orientation, local geological factors, and the regional stress state. We suggest a horizontal respect distance of 895 m between horizontal boreholes orientated perpendicular to the maximum horizontal stress direction and faults optimally orientated for failure under the regional stress state.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Induced earthquakes caused by hydraulic fracturing (fracking) have been documented in Canada, the United Kingdom (UK) and the United States of America (USA) (Wilson et al. 2017). The occurrence of felt fracking-induced earthquakes is rare but earthquakes up to magnitude 4.6 have been induced (BCOGC 2015) and the smallest reported felt fracking-induced earthquake had magnitude 1.5 (BGS 2017), making fracking-induced earthquakes a matter of public concern. In the paper “Horizontal respect distance for hydraulic fracturing in the vicinity of existing faults in deep geological reservoirs: a review and modelling study”, Westwood et al. (2017) use numerical modelling to investigate how far from faults fluid injection for fracking should be carried out to avoid felt, induced seismicity. They conclude that the maximum horizontal respect distance is 433 m. This horizontal respect distance may also be important for reducing the risk of shallow groundwater contamination; it has been proposed that faults may act as fluid conduits between shales and shallow groundwater resources (Kissinger et al. 2013; Birdsell et al. 2015).

We applaud Westwood et al. (2017) in providing the first analysis of this kind, however a number of factors were kept constant in the modelling scenarios and no uncertainty estimates or sensitivity analyses were carried out on: injection volume, injection rate, Young’s modulus, shear modulus, bulk modulus, Poisson’s ratio, pore pressure, coefficient of friction, friction angle, cohesion, fracture aperture, permeability, compressibility, fracture orientation, or depth. Furthermore, the modelling did not include poroelastic effects. Changes in the model parameters and the inclusion of poroelasticity may lead to different horizontal respect distances. We propose that there is an alternative approach. Microseismic data has been used to suggest a vertical respect distance of 600 m between fracked reservoirs and aquifers (Davies et al. 2012, 2013a), and this research now forms the basis of UK legislation (Infrastructure Act 2015). The purpose of this comment is to augment the study by Westwood et al. (2017) by using microseismic data to empirically determine a horizontal respect distance to faults.

2 Fracking related micro and macroseismicity

Microseismic events are weak earthquakes (the British Geological Survey classify microseismic events as those with magnitudes less than two) of natural or anthropogenic origin. Microseismic monitoring is routinely used during fracking fluid injection to track fracture propagation and infer the extent of stimulated fractures (Mayerhofer et al. 2010). Microseismicity associated with these processes is usually too small to be felt by humans at the surface. Monitoring may also detect seismicity related to the reactivation of pre-existing geological faults (e.g. Kratz et al. 2012). Fault reactivation can be identified by spatial trends in microseismic events or from the occurrence of larger macroseismic events (Davies et al. 2013b). Macroseismic events are more likely to be felt by humans at the surface. The reactivation of faults indicates that injected fluid has reached the fault plane or has perturbed the stress state of the fault without reaching it itself. Microseismic monitoring can thus provide a measure of fracture propagation length and the extent of stress changes beyond the induced fractures.

3 Method

Peer-reviewed literature and conference papers were searched for plan-view maps or cross sections of fracked boreholes with microseismic data. Maps and cross sections without borehole geometries or scale bars were excluded and scales were adjusted where necessary. The horizontal distances between the furthest detected microseismic events and the associated fluid injection stages were measured. When no stage intervals were shown or it was unclear which stage related to which cluster of microseismic events, the perpendicular distance between the furthest detected microseismic event and the borehole was measured. Where the distance between the furthest detected microseismic event and the borehole was ambiguous because microseismic data from adjacent boreholes overlapped, the distance between the outer borehole and the furthest outer microseismic event was measured. Microseismic event location errors were ignored because most sources did not provide error values. All distances were converted to SI units. The injection volumes, injection rates, and reservoir lithologies were noted where possible.

Analysis of variance (ANOVA) and multiple and partial regression were used to determine statistically significant factors and covariates. Lithology was taken as a factor with three levels (coal, sandstone, or shale) and the covariates were injection volume and injection rate. The Anderson–Darling test was used to assess the normality of the data prior to analysis and if necessary the data were transformed. The ANOVA was performed with and without the covariates, but inclusion of the covariates severely limited the size of the dataset. Therefore, multiple regression was used to understand the role of injection volume and rate, and partial regression analysis was used to estimate the relative importance of these covariates in explaining microseismic distance variation. All statistical significance was judged at the 95% probability of being greater than zero.

4 Results

One hundred and nine examples of fracking fluid injection with suitable microseismic maps or cross sections were found. Distances between injection stages or boreholes and the furthest detected microseismic events ranged from ~ 59–720 m (Table S1); up to ~ 287 m more than the maximum horizontal respect distance of Westwood et al. (2017). A cumulative distribution function of the dataset implies that the probability of observing a microseismic event at a distance > 433 m is ~ 12% and observing one at > 720 m is ~ 1% (Fig. 1). However, our sample size is an extremely small proportion of the total number of fracking operations carried out globally. Consequently, risk calculated using the cumulative distribution function is not representative of the total population of global fracking operations.

In general, fracking operations in coal had their furthest detected microseismic events nearer than those in sandstones and those in sandstones were nearer than in shales (Fig. 2). Normality tests on the distributions showed them to be log-normal and so all data were log-transformed prior to the ANOVA. The ANOVA showed that there was a statistically significant difference between coal, sandstone, and shale lithologies for the distance of the furthest detected microseismic event. The least squares mean (the marginal mean taking account of other levels in the factor) for shale was 363 m (338–389 m), where the range is the standard error in the least squares mean. The least squares means for coal and sandstone were 91 m (75–109 m) and 190 m (182–200 m), respectively. Given this ANOVA the probability of exceeding 433 m was 0.1% in coal, 2% in sandstone, and 32% in shale. There was a 1% chance of exceeding 228 m in coal, 494 m in sandstone, and 895 m in shale.

Of the 109 examples, 16 had both injection volume and rate data. A further nine examples had just injection rate data. A statistically significant empirical relationship (R2 = 0.74) exists between injection volume and distance to the furthest detected microseismic event (Fig. 3a). The relationship between injection rate and distance to the furthest detected microseismic event was much weaker (R2 = 0.30), but still statistically significant (Fig. 3b). The best-fit multiple regression model (Eq. 1) explained 91% of the variation:

where D is the distance of the furthest detected microseismic event (m), V is the injection volume (m3), and r is the injection rate (m3/min). Only those covariates found to be statistically significant were include in Eq. 1 and the values in brackets below Eq. 1 represent the standard errors in the coefficient. On application of partial regression analysis, the terms in volume (V and log V) in Eq. 1 were found to be more important than the term in rate (log r). When those cases with both volume and rate of injection data available were considered in the ANOVA, there was no significant difference between lithologies, with or without including covariates, indicating there is no evidence that fluid injection parameters explain the difference between lithologies.

5 Discussion

5.1 Limitations of microseismic data

All determined microseismic locations have an error associated with them, which may increase or decrease the inferred extent of fractures and stress changes. Additionally, detection will only be complete above a particular magnitude. This magnitude can be calculated from a Gutenberg-Richter plot and is dependent on the sensitivity, location, and type of monitoring equipment (Johnston and Shrallow 2011; Warpinski 2014). Biased detection can lead to misleading microseismic maps (Warpinski 2014) and, if the array is particularly poorly designed, the reactivation of faults could be missed and the inferred extent of stimulation could be entirely controlled by the detection limit. Even for well-designed arrays stress changes may occur beyond recorded microseismic clouds (Lacazette and Geiser 2013).

5.2 Orientation of horizontal boreholes, maximum horizontal stress, and faults

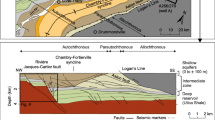

Fracking-induced fault reactivation is most likely to occur when faults are optimally orientated relative to the regional stress state. For example, the fracking-induced earthquakes at Preese Hall, UK, are hypothesised to have occurred from left-lateral shear along an optimally orientated fault striking at 47° to the maximum horizontal stress (SHmax) (Fig. 4) (Clarke et al. 2014). Horizontal fracking boreholes are normally drilled perpendicular to SHmax to maximise the extent of fracture propagation and stimulation, thereby maximising oil and gas recovery. The orientation of pre-existing natural fractures is also an important consideration in borehole placement (Gale et al. 2007). When boreholes are drilled non-perpendicular to SHmax and then fracked, the fracture extent from the borehole may be less than the actual fracture length, and thus smaller than a horizontal respect distance based on perpendicular fracture growth (Fig. 5). Because of these directional effects, the orientation of horizontal boreholes, maximum horizontal stress, and faults are important considerations for determining site specific horizontal respect distances.

Adapted from Clarke et al. (2014)

Map showing the epicentre of the fracking-induced earthquake of 2nd August 2011 (PH Event) in relation to the hypothesised fault which slipped and the orientations of the maximum (SHmax) and minimum (SHmin) horizontal stress directions.

Schematic diagram of the microseismic map shown by Kilpatrick et al. (2010). The solid line shows the approximate horizontal borehole orientation. The dashed lines show the approximate orientation and extent of propagated fractures inferred from microseismic data. The extent of fractures from the borehole and the length of the longest fracture are marked with labelled arrows

5.3 Horizontal respect distance

The microseismic data compiled in this study suggest that fracture propagation and stress changes can occur beyond the 433 m horizontal respect distance of Westwood et al. (2017). The empirical risk of microseismicity in shale beyond 433 and 895 m is 32 and 1%, respectively. We also note that fracking operations at the Poland Township, Ohio, USA, are hypothesised to have reactivated a fault/fracture zone up to 850 m away from the borehole (Skoumal et al. 2015). The extent of fracture propagation and stress changes is likely to be a combined result of operational parameters, borehole orientation, local geological factors, and the regional stress state. We recommend a horizontal respect distance of 895 m between horizontal boreholes orientated perpendicular to SHmax and faults optimally orientated for failure in their regional stress state (Fig. 6). More extensive studies done using much larger microseismic datasets with known operational parameters and regional stress settings may be able to provide more site specific horizontal respect distances to faults. However, until this analysis is carried out current best practice for fracking fluid injection may be to use the 895 m horizontal respect distance between injection stages and all faults.

Schematic diagram illustrating: the 1000 m below surface Infrastructure Act (2015), the 600 m vertical respect distance of Davies et al. (2012, 2013a), the 433 m horizontal respect distance of Westwood et al. (2017), and the 895 m horizontal respect distance of this study. The horizontal borehole is orientated perpendicular to the maximum horizontal stress and the fault is optimally orientated for failure

6 Conclusions

Westwood et al. (2017) used numerical modelling to provide a maximum horizontal respect distance of 433 m between fracking fluid injection and faults. However, numerical modelling is limited by the selected model parameters. An alternative approach is to use microseismic data and measure the horizontal distances between fluid injection points and the furthest detected microseismic events. Using a sample set of 109 fracking examples, we find that the empirical risk of detecting microseismicity in shale beyond a horizontal distance of 433 m is 32% and beyond 895 m is 1%. Fracking operations in shales generally had their furthest detected microseismic events at greater distances than those in coals and sandstones. Injection volume and rate both showed statistically significant relationships with the distance to the furthest detected microseismic event. However, there was no evidence that fluid injection parameters explained the microseismic distance differences between lithologies. The extent of fracture propagation and stress changes is likely a result of operational parameters, borehole orientation, local geological factors, and the regional stress state. We suggest a horizontal respect distance of 895 m between horizontal boreholes orientated perpendicular to the maximum horizontal stress direction and faults optimally orientated for failure in their regional stress state. Until further analysis is done using more extensive datasets with known operational parameters and regional stress settings, applying a horizontal respect distance of 895 m between fracking fluid injection points and all faults may be a cautionary approach.

References

Birdsell DT, Rajaram H, Dempsey D, Viswanathan HS (2015) Hydraulic fracturing fluid migration in the subsurface: a review and expanded modeling results. Water Resour Res 51(9):7159–7188

British Columbia Oil and Gas Commission (BCOGC) (2015) August seismic event determination. Industry Bulletin 2015–32. https://www.bcogc.ca/node/12951/download. Accessed 11 Oct 2017

British Geological Survey (BGS) (2017) Earthquakes induced by hydraulic fracturing operations near Blackpool, UK. http://www.earthquakes.bgs.ac.uk/research/BlackpoolEarthquakes.html. Accessed 11 Oct 2017

Clarke H, Eisner L, Styles P, Turner P (2014) Felt seismicity associated with shale gas hydraulic fracturing: the first documented example in Europe. Geophys Res Lett 41(23):8308–8314

Davies RJ, Mathias SA, Moss J, Hustoft S, Newport L (2012) Hydraulic fractures: how far can they go? Mar Pet Geol 37(1):1–6

Davies RJ, Foulger GR, Mathias S, Moss J, Hustoft S, Newport L et al (2013a) Reply: Davies et al. (2012), Hydraulic fractures: How far can they go? Mar Pet Geol 43:519–521

Davies R, Foulger G, Bindley A, Styles P (2013b) Induced seismicity and hydraulic fracturing for the recovery of hydrocarbons. Mar Pet Geol 45:171–185

Gale JF, Reed RM, Holder J (2007) Natural fractures in the Barnett Shale and their importance for hydraulic fracture treatments. AAPG Bull 91(4):603–622

Infrastructure Act (2015) Chapter 7, PART 6 Energy, Section 50, Onshore hydraulic fracturing: safeguards

Johnston R, Shrallow J (2011) Ambiguity in microseismic monitoring. In: 2011 SEG annual meeting. Society of Exploration Geophysicists

Kilpatrick JE, Eisner L, Williams-Stroud S, Cornette B, Hall M (2010) Natural fracture characterization from microseismic source mechanisms: a comparison with FMI data. In: 2010 SEG annual meeting. Society of Exploration Geophysicists

Kissinger A, Helmig R, Ebigbo A, Class H, Lange T, Sauter M, Heitfeld M, Klünker J, Jahnke W (2013) Hydraulic fracturing in unconventional gas reservoirs: risks in the geological system, part 2. Environ Earth Sci 70(8):3855–3873

Kratz M, Hill A, Wessels S (2012) Identifying fault activation in unconventional reservoirs in real time using microseismic monitoring. In: SPE/EAGE European unconventional resources conference & exhibition—from potential to production

Lacazette A, Geiser P (2013) Comment on Davies et al., 2012—Hydraulic fractures: how far can they go? Mar Pet Geol 43:516–518

Mayerhofer MJ, Lolon E, Warpinski NR, Cipolla CL, Walser DW, Rightmire CM (2010) What is stimulated reservoir volume? In: SPE shale gas production conference. Society of Petroleum Engineers

Skoumal RJ, Brudzinski MR, Currie BS (2015) Earthquakes induced by hydraulic fracturing in Poland Township, Ohio. Bull Seismol Soc Am 105(1):189–197

Warpinski NR (2014) A review of hydraulic-fracture induced microseismicity. In: 48th US rock mechanics/geomechanics symposium. American Rock Mechanics Association

Westwood RF, Toon SM, Styles P, Cassidy NJ (2017) Horizontal respect distance for hydraulic fracturing in the vicinity of existing faults in deep geological reservoirs: a review and modelling study. In: Geomechanics and geophysics for geo-energy and geo-resources, pp 1–13

Wilson MP, Foulger GR, Gluyas JG, Davies RJ, Julian BR (2017) HiQuake: the human-induced earthquake database. Seismol Res Lett 88(6):1560–1565

Acknowledgements

Miles Wilson is funded by a Durham Doctoral Studentship and this research was also carried out as part of the ReFINE (Researching Fracking) consortium led by Newcastle and Durham Universities. ReFINE has been funded by the Natural Environment Research Council (UK), Total, Shell, Chevron, GDF Suez, Centrica and Ineos. The results are solely those of the authors. We thank the ReFINE Independent Science Board for spending time prioritising the research and advice on effective governance. We thank two anonymous reviewers who helped improve the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Wilson, M.P., Worrall, F., Davies, R.J. et al. Fracking: How far from faults?. Geomech. Geophys. Geo-energ. Geo-resour. 4, 193–199 (2018). https://doi.org/10.1007/s40948-018-0081-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40948-018-0081-y