Abstract

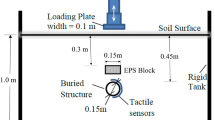

This paper examines the ring deflection of flexible high-density polyethylene pipe caused by repetitive cyclic plate loading under various burial conditions and relative densities. It also looks at possible mitigation strategies, such as using geosynthetic materials like geofoam to lessen the effects of cyclic vehicular wheel load. Geofoam has a new post-beam arrangement where the post is the vertical support for the beam, and the horizontal capping is the beam. The influence of soil cover thickness, relative density, pipe diameter, geofoam post widths, and beam thicknesses (h) on pipe deflection was compared with the unimproved sand fill scenario. Increasing relative density and cover depth improved the pipe's ring deflection and eliminated the excessive surface settling. Further reduction of more than 60% was achieved with the protective layer of geofoam and brought the over-deflection of the pipe to an acceptable limit. An extensive parametric analysis determined the optimum burial depth and precise location of the geofoam to negate the ring deflection subjected to cyclic loading. Using commercially available finite element software (PLAXIS 3D), a new model was created and validated using experimental results and mathematical solutions derived from the modified Iowa formula. The experimental findings corroborated sufficiently with the numerical and analytical solutions.

Similar content being viewed by others

Availability of data and materials

Not applicable.

Code Availability

Not applicable.

References

Koenig RA, Taylor JP (1988) Protection of pipelines through highway roadbeds. National Corporative Highway Research Program, Wilbur Smith Associates Falls Church, Virginia

Moghaddas Tafreshi SN, Khalaj O (2008) Laboratory tests of small-diameter HDPE pipes buried in reinforced sand under repeated load. Geotext Geomembr 26:145–163. https://doi.org/10.1016/j.geotexmem.2007.06.002

Tafreshi SNM, Mehrjardi GT, Dawson AR (2012) Buried pipes in rubber-soil back filled trenches under cyclic loading. J Geotech Geoenvironmental Eng. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000710

Cao Z, Han J, Xu C et al (2016) Road surface permanent deformations with a shallowly buried steel-reinforced high-density polyethylene pipe under cyclic loading. Geotext Geomembr 44:28–38. https://doi.org/10.1016/j.geotexmem.2015.06.009

Elshesheny A, Mohamed M, Sheehan T (2019) Buried flexible pipes behavior in unreinforced and reinforced soils under cyclic loading. Geosynth Int 26:184–205. https://doi.org/10.1680/jgein.18.00046

Elshesheny A, Mohamed M, Sheehan T (2019) Performance of buried rigid pipes under the application of incrementally increasing cyclic loading. Soil Dyn Earthq Eng 125:105729. https://doi.org/10.1016/j.soildyn.2019.105729

Elshesheny A, Mohamed M, Sheehan T (2020) Protection of buried rigid pipes using geogrid-reinforced soil systems subjected to cyclic loading. Soil Dyn Earthq Eng 135:106210. https://doi.org/10.1016/j.soildyn.2020.106210

Siabil SMAG, Tafreshi SNM, Dawson AR, Omran MP (2019) Behavior of expanded polystyrene (EPS) blocks under cyclic pavement foundation loading. Geosynth Int 26:1–25. https://doi.org/10.1680/jgein.18.00033

Al-Naddaf M, Han J, Xu C et al (2019) Experimental investigation of soil arching mobilization and degradation under localized surface loading. J Geotech Geoenviron Eng 145:04019114. https://doi.org/10.1061/(ASCE)gt.1943-5606.0002190

Han J, Ph D, Asce F et al (2017) Progressive development of two-dimensional soil arching with displacement. Int J Geomech 17:1–12. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001025

Abolmaali A, Asce M, Kararam A (2010) Nonlinear finite-element-based investigation of the effect of bedding thickness on buried concrete pipe. J Transp Eng 136:793–799. https://doi.org/10.1061/(ASCE)TE.1943-5436.0000135

Abolmaali A, Asce M, Kararam A (2013) Nonlinear finite-element modeling analysis of soil-pipe interaction. Int J Geomech. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000196

Ezzeldin I, El Naggar H (2021) Three-dimensional finite element modeling of corrugated metal pipes. Transp Geotech 27:100467. https://doi.org/10.1016/j.trgeo.2020.100467

Zhou M, Du YJ, Wang F et al (2017) Earth pressures on the trenched HDPE pipes in fine-grained soils during the construction phase: full-scale field trial and finite element modeling. Transp Geotech 12:56–69. https://doi.org/10.1016/j.trgeo.2017.08.002

Kim H, Choi B, Kim J (2010) Reduction of earth pressure on buried pipes by EPS geofoam inclusions reduction of earth pressure on buried pipes by EPS geofoam inclusions. Geotech Test J 33(4):1–9. https://doi.org/10.1520/GTJ102315

Kantar E (2015) Improving the impact behavior of pipes using geofoam layer for protection. Int J Press Vessel 133:52–64. https://doi.org/10.1016/j.ijpvp.2015.05.007

Keller GR (2016) Application of geosynthetics on low-volume roads. Transp Geotech 8:119–131. https://doi.org/10.1016/j.trgeo.2016.04.002

Mandal YZBJN (2017) Combined use of jute geotextile-EPS geofoam to protect flexible buried pipes: experimental and numerical studies. Int J Geosynth Gr Eng. https://doi.org/10.1007/s40891-017-0107-5

Khan MI, Meguid MA (2018) Experimental investigation of the shear behavior of EPS geofoam. Int J Geosynth Gr Eng. https://doi.org/10.1007/s40891-018-0129-7

Kim K, Yoo CH (2005) Design loading on deeply buried box culverts. J Geotech Geoenviron Eng 131:20–27. https://doi.org/10.1061/(ASCE)1090-0241(2005)131:1(20)

Kang J, Parker F, Yoo CH (2007) Soil-structure interaction and imperfect trench installations for deeply buried corrugated polyvinyl chloride pipes. Transp Res Rec 192:192–202. https://doi.org/10.3141/2028-21

Meguid MA, Hussein MG (2017) A numerical procedure for the assessment of contact pressures on buried structures overlain by EPS geofoam inclusion. Int J Geosynth Gr Eng 3:1–14. https://doi.org/10.1007/s40891-016-0078-y

Qin X, Ni P, Zhou M (2017) Improved analytical solution of vertical pressure on top of induced trench rigid culverts. Geosynth Int 24:615–624. https://doi.org/10.1680/jgein.17.00028

Meguid MA, Hussein MG, Ahmed MR, Whalen J (2017) Investigation of soil-geosynthetic-structure interaction associated with induced trench installation. Geotext Geomembranes. https://doi.org/10.1016/j.geotexmem.2017.04.004

Plácido R, Portelinha FHM (2019) Evaluation of geocomposite compressible layer as induced trench method applied to shallow buried pipelines. Geotext Geomembr. https://doi.org/10.1016/j.geotexmem.2019.103471

Mahgoub A, El Naggar H (2019) Using TDA as an engineered stress-reduction fill over preexisting buried pipes. J Pipeline Syst Eng Pract. https://doi.org/10.1061/(ASCE)ps.1949-1204.0000362

Bildik S, Laman M (2020) Effect of geogrid reinforcement on soil - structure – pipe interaction in terms of bearing capacity, settlement and stress distribution. Geotext Geomembr 48:844–853. https://doi.org/10.1016/j.geotexmem.2020.07.004

Al-Naddaf M, Han J, Xu C, Rahmaninezhad SM (2019) Effect of geofoam on vertical stress distribution on buried structures subjected to static and cyclic footing loads. J Pipeline Syst Eng 10:1–12. https://doi.org/10.1061/(ASCE)PS.1949-1204.0000355

Bartlett SF, Lingwall BN, Vaslestad J (2015) Methods of protecting buried pipelines and culverts in transportation infrastructure using EPS geofoam. Geotext Geomembr 43:450–461. https://doi.org/10.1016/j.geotexmem.2015.04.019

Abdollahi M, Moghaddas Tafreshi SN, Leshchinsky B (2021) Protection of buried utilities against repeated loading: application of geogrid-EPS geofoam system. Int J Geomech 21:04021158. https://doi.org/10.1061/(ASCE)gm.1943-5622.0002120

ASTM D2321-00 (2000) Standard Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications. 04:3-12, ASTM International, West Conshohocken.

MoRTH (2013) Specifications for Road and Bridge Work. Indian Roads Congr. 1–883, Govt. of India, New Delhi.

Meguid MA, Ahmed MR, Hussein MG, Omeman Z (2017) Earth pressure distribution on a rigid box covered with U-shaped geofoam wrap. Int J Geosynth Gr Eng. https://doi.org/10.1007/s40891-017-0088-4

ASTM (2021) ASTM D2412 standard test method for determination of external loading characteristics of plastic pipe by parallel-plate loading. ASTM International, West Conshohocken, pp 1–7. https://doi.org/10.1520/D2412-21.2

ASTM (1991) Standard test method for compressive properties of rigid cellular plastics. ASTM Stand D:1621–1673. https://doi.org/10.1520/D1621-16.2, ASTM International, West Conshohocken.

Brachman RWI, Moore ID, Munro SM (2008) Compaction effects on strains within profiled thermoplastic pipes. Geosynth Int. https://doi.org/10.1680/gein.2008.15.2.72

Kraus E, Oh J, Fernando EG (2014) Impact of repeat overweight truck traffic on buried utility facilities. J Perform Constr Facil. https://doi.org/10.1061/(ASCE)CF.1943-5509.0000454

Hegde AM, Sitharam TG (2015) Experimental and numerical studies on protection of buried pipelines and underground utilities using geocells. Geotext Geomembr 43:372–381. https://doi.org/10.1016/j.geotexmem.2015.04.010

Pires ACG, Palmeira EM (2017) Geosynthetic protection for buried pipes subjected to surface surcharge loads. Int J Geosynth Gr Eng. https://doi.org/10.1007/s40891-017-0109-3

Meguid MA, Youssef TA (2018) Transportation geotechnics experimental investigation of the earth pressure distribution on buried pipes backfilled with tire-derived aggregate Surface loading Pipe. Transp Geotech 14:117–125. https://doi.org/10.1016/j.trgeo.2017.11.007

Kou Y, Shukla SK, Mohyeddin A (2018) Experimental investigation for pressure distribution on flexible conduit covered with sandy soil reinforced with geotextile reinforcement of varying widths. Tunn Undergr Sp Technol 80:151–163. https://doi.org/10.1016/j.tust.2018.06.012

Randeniya C, Robert DJ, Li C, Kodikara J (2020) Large-scale experimental evaluation of soil saturation effect on the behaviour of buried pipes under operational loads. Can Geotech J 220:205–220. https://doi.org/10.1139/cgj-2018-0544

Weissman SL (1999) Influence of tire-pavement contact stress distribution on development of distress mechanisms in pavements. Transp Res Rec 99:161–167. https://doi.org/10.3141/1655-21

Deng Y, Luo X, Zhang Y, Lytton RL (2021) Evaluation of flexible pavement deterioration conditions using deflection profiles under moving loads. Transp Geotech 26:100434. https://doi.org/10.1016/j.trgeo.2020.100434

Siddharthan RV, Sebaaly P (1999) Investigation of asphalt con-crete layer strains from wide-base tires. Transp Res Rec 1655:168–174. https://doi.org/10.3141/1655-22

AASHTO (2012) LRFD bridge design specifications, 6th edn. American Association of State Highway and Transportation Officials, Washington

Abu-Farsakh M, Hanandeh S, Mohammad L, Chen Q (2016) Performance of geosynthetic reinforced/stabilized paved roads built over soft soil under cyclic plate loads. Geotext Geomembranes 44:845–853. https://doi.org/10.1016/j.geotexmem.2016.06.009

ASTM Standard D3034 (2021) Standard test method for determination of external loading characteristics of plastic pipe by parallel-plate loading test. ASTM International, West Conshohocken

Masada T (2001) Modified Iowa formula for vertical deflection of buried flexible pipe. J Transp Eng 126:440–446. https://doi.org/10.1061/(ASCE)0733-947X(2000)126:5(440)

Author information

Authors and Affiliations

Contributions

K. Kiran Prakash: Conceptualization, methodology, validation, data collecting and analysis, and writing the original draft. Deendayal Rathod: Methodology, supervision, writing, reviewing, and editing.

Corresponding author

Ethics declarations

Conflicts of Interest

We declare that this manuscript is original, has not been published before, and is not currently being considered for publication elsewhere. If accepted, it will not be published elsewhere. We know of no conflicts of interest associated with this publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Prakash, K.K., Rathod, D. The Behavior of a Buried Pipe Overlain by Geofoam Due to Cyclic Loading. Int. J. of Geosynth. and Ground Eng. 10, 49 (2024). https://doi.org/10.1007/s40891-024-00561-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-024-00561-3