Abstract

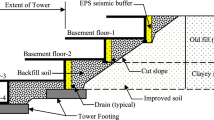

Extruded Polystyrene (EPS) geofoam is a light weight material used in a wide range of geotechnical engineering applications including embankment construction and bridge approaches to reduce earth loads imposed on the adjacent or underlying soils and structures. EPS is also used as a compressible material above deeply buried culverts to promote positive arching and reduce the load transferred to the walls of the structure. An important step towards understanding the soil-geofoam-structure interaction and accurately model the load transfer mechanism is choosing a suitable material model for the EPS geofoam that is capable of simulating the material response to compressive loading for various ranges of strains. In this study, a material model that is able to capture the response of EPS geofoam is first established and validated using index test results for three different geofoam materials. To examine the performance of the model in analyzing complex interaction problems, a laboratory experiment that involves a rigid structure buried in granular material with EPS geofoam inclusion is simulated. The contact pressures acting on the walls of the structure are calculated and compared with measured data for three different geofoam materials. The developed numerical model is then used to study the role of geofoam density on the earth loads acting on the buried structure. Significant pressure reduction is achieved using EPS15 with a pressure ratio of 0.28 of the theoretical overburden pressure at the upper wall. The proposed FE modeling approach is found to be efficient in capturing the behavior of EPS geofoam material under complex interaction soil-structure condition.

Similar content being viewed by others

References

Canadian Standards Association (CSA) (2006) Canadian highway bridge design code, Canadian Standards Association (CSA), Mississauga

AASHTO (2012) LRFD bridge design specifications, 6th edn. American Association of State Highway and Transportation Officials, Washington, D.C.

McAffee RP, Valsangkar AJ (2008) Field performance, centrifuge testing, and numerical modelling of an induced trench installation. Can Geotech J 45:85–101

Sladen JA, Oswell JM (1988) The induced trench method—a critical review and case history. Can Geotech J 25:541–549

Vaslestad J, Johansen TH, Holm W (1993) Load reduction on rigid culverts beneath high fills: long-term behavior. Transp Res Rec 1415:58–68

Liedberg NSD (1997) Load reduction on a rigid pipe: pilot study of a soft cushion installation. Transp Res Record

Sun L, Hopkins T, Beckham T (2011) Long-term monitoring of culvert load reduction using an imperfect ditch backfilled with Geofoam. Transp Res Record 2212:56–64

Oshati OS, Valsangkar AJ, Schriver AB (2012) Earth pressures exerted on an induced trench cast-in-place double-cell rectangular box culvert. Can Geotech J 49:1267–1284

Kim K, Yoo CH (2002) Design Loading for deeply buried box culverts. Highway Research Center, Auburn University, Report No. IR-02-03., Alabama, USA, p 215

Kang J, Parker F, Kang YJ, Yoo CH (2008) Effects of frictional forces acting on sidewalls of buried box culverts. Int J Numer Anal Methods Geomech 32:289–306

Sun L, Hopkins TC, Beckham TL (2009) Reduction of stresses on buried rigid highway structures using the imperfect ditch method and expanded polysterene (geofoam) Kentucky Transportaion Center, University of Kentucky, Report No. KTC-07-14-SPR-228-01-1F, Kentucky, USA, p 49

McGuigan BL, Valsangkar AJ (2010) Centrifuge testing and numerical analysis of box culverts installed in induced trenches. Can Geotech J 47:147–163

McGuigan BL, Valsangkar AJ (2011) Earth pressures on twin positive projecting and induced trench box culverts under high embankments. Can Geotech J 48:173–185

Horvath JS (2001) Concepts for cellular geosynthetics standards with example for EPS-block geofoam as lightweight fill for roads. Manhattan College Research Report No. CGT-2001–4, USA

Takahara T, Miura K (1998) Mechanical characteristics of EPS block fill and its simulation by DEM and FEM. Soils Found 38(1):97–110

Hazarika H (2006) Stress–Strain modeling of EPS Geofoam for large-strain applications. Geotext Geomembr 24(2):79–90

Chun BS, Lim HS, Sagong M, Kim K (2004) Development of a hyperbolic constitutive model for expanded polystyrene (EPS) geofoam under triaxial compression test. Geotext Geomembr 22(4):223–237

Leo CJ, Kumruzzaman M, Wong H, Yin JH (2008) Behavior of EPS geofoam in true triaxial compression tests. Geotext Geomembr 26(2):175–180

Ekanayake SD, Liyanapathirana DS, Leo CJ (2015) Numerical simulation of EPS geofoam behaviour in triaxial tests. Eng Comput 32(5):1372–1390

ASTM D16210-10—Standard Test Method for Compressive Properties of Rigid Celleular Plastics

ABAQUS (2013) ABAQUS User’s Manuals, Version 6.13, Dassault Systems Simulia Corp., Providence, RI, USA

Negussey D (2007) Design parameters for EPS geofoam. Soils Found 47(1):161–170

Ahmed M, Tran V, Meguid MA (2015) On the role of geogrid reinforcement in reducing earth pressures on buried pipes. Soils Found 5(33):588–599

Ahmed MR, Meguid MA, Whalen J (2013) Laboratory Measurement of the Load Reduction on Buried Structures overlain by EPS Geofoam, The 66th Canadian Geotechnical Conference, Montreal, Canada, Paper No. 217 p 8

Hussein MG, Meguid MA (2015) Numerical modeling of soil-structure interaction with applications to geosynthetics. International Conference on Structural and Geotechnical Engineering, Ain Shams University, December, Cairo, Egypt, p 12

Hussein MG, Meguid MA, Whalen J (2015) On the numerical modeling of buried structures with compressible inclusion, GeoQuebec, September, Quebec City, p 8

Ahmed MR (2016) Experimental investigations into the role of geosynthetic inclusions on the earth pressure acting on buried structures. PhD. Thesis, Civil Engineering and Applied Mechanics. McGill University, Canada

Bolton MD (1986) The strength and dilatancy of sands. Géotech 36(1):65–78

Acknowledgements

This research is supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) CRD project No. 452760-13. The generous support of Plasti-Fab Ltd. throughout this study is appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meguid, M.A., Hussein, M.G. A Numerical Procedure for the Assessment of Contact Pressures on Buried Structures Overlain by EPS Geofoam Inclusion. Int. J. of Geosynth. and Ground Eng. 3, 2 (2017). https://doi.org/10.1007/s40891-016-0078-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-016-0078-y