Abstract

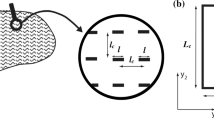

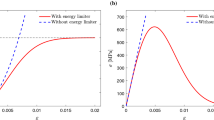

A damage model for dynamic tensile failure of nominally brittle solids is constructed using a two-scale approach. The asymptotic homogenization method is applied to microstructures with penny-shaped microcracks evolving dynamically in order to obtain the new damage law. A microstructural length is present in the deduced evolution equation for which a strain-rate dependent fragment-size type expression is proposed. The ability of the new approach to predict the rate sensitivity of the tensile strength observed in experiments is illustrated for concrete and ceramic materials.

Similar content being viewed by others

References

Erzar B, Forquin P (2011) Experiments and mesoscopic modelling of dynamic testing of concrete. Mech Mater 43:505–527

Gálvez Díaz-Rubio F, Rodríguez Pérez J, Sánchez Gálvez V (2002) The spalling of long bars as a reliable method of measuring the dynamic tensile strength of ceramics. Int J Impact Eng 27:161–177

Zinszner JL, Erzar B, Forquin P, Buzaud E (2015) Dynamic fragmentation of an alumina ceramic subjected to shockless spalling: an experimental and numerical study. J Mech Phys Solids 85:112–127

Ravichandran G, Subhash G (1995) A micromechanical model for high strain rate behavior of ceramics. Int J Solids Struct 32:2627–2646

Huang C, Subhash G, Vitton SJ (2002) A dynamic damage growth model for uniaxial compressive response of rock aggregates. Mech Mater 34:267–277

Paliwal B, Ramesh KT (2008) An interacting micro-crack damage model for failure of brittle materials under compression. J Mech Phys Solids 56(3):896–923

Bhatt H, Rosakis A, Sammis G (2012) A micro-mechanics based constitutive model for brittle failure at high strain rates. J Appl Mech 79:1016–1028

Daphalapurkar NP, Ramesh KT, Graham-Brady L, Molinari J-F (2011) Predicting variability in the dynamic failure strength of brittle materials considering pre-existing flaws. J Mech Phys Solids 59:297–319

Drugan WJ (2001) Dynamic fragmentation of brittle materials: analytical mechanics-based models. J Mech Phys Solids 49:1181–1208

Forquin P, Hild F (2010) A probabilistic damage model of the dynamic fragmentation process in brittle materials. Adv Appl Mech 44:1–72

Hu G, Liu J, Graham-Brady L, Ramesh KT (2015) A 3D mechanistic model for brittle materials containing evolving flaw distributions under dynamic multiaxial loading. J Mech Phys Solids 78:269–297

Grady DE (1982) Local inertial effects in dynamic fragmentation. J Appl Phys 53:322–325

Glenn LA, Chudnovsky A (1986) Strain-energy effects on dynamic fragmentation. J Appl Phys 59:1379–1380

Zhou F, Molinari JF, Ramesh KT (2006) Effects of material properties on the fragmentation of brittle materials. Int J Fract 139:169–196

Levy S, Molinari J-F (2010) Dynamic fragmentation of ceramics, signature of defects and scaling of fragment sizes. J Mech Phys Solids 58:12–26

Bazant Z, Caner F (2014) Impact comminution of solids due to local kinetic energy of high shear strain rate: I. Continuum theory and turbulence analogy. J Mech Phys Solids 64:223–235

Dascalu C, Bilbie G, Agiasofitou E (2008) Damage and size effect in elastic solids: a homogenization approach. Int J Solids Struct 45:409–430

Dascalu C, François B, Keita O (2010) A two-scale model for subcritical damage propagation. Int J Solids Struct 47:493–502

François B, Dascalu C (2010) A two-scale time-dependent damage model based on non-planar growth of micro-cracks. J Mech Phys Solids 58:1928–1946

Markenscoff X, Dascalu C (2012) Asymptotic homogenization analysis for damage amplification due to singular interaction of microcracks. J Mech Phys Solids 60:1478–1485

Atiezo MK, Dascalu C (2017) Antiplane two-scale model for dynamic failure. Int J Fract 206:195–214

Atiezo MK, Gbetchi K, Dascalu C (2020) Dynamic shear damage with frictional sliding on microcracks. Eng Fract Mech 236:107188

Dascalu C (2018) Multiscale modeling of rapid failure in brittle solids: branching instabilities. Mech Mater 199:2765–2778

Keita O, Dascalu C, François B (2014) A two-scale model for dynamic damage evolution. J Mech Phys Solids 64:170–183

Fish J (2013) Practical multiscaling. Wiley, New York

Sanchez-Palencia E (1980) Non-Homogeneous Media and Vibration Theory, vol 127. Lecture Notes in Physics. Springer, Berlin

Atiezo MK, Chen W, Dascalu C (2019) Loading rate effects on dynamic failure of quasi-brittle solids: simulations with a two-scale damage model. Theor Appl Fract Mech 100:269–280

Dascalu C, Gbetchi K (2019) Dynamic evolution of damage by microcracking with heat dissipation. Int J Solids Struct 174–175:128–144

Dascalu C (2021) Dynamic damage law with fragmentation length: strain-rate sensitivity of the tensile response. J Dyn Behav Mater 7:156–160

Budiansky B, Rice JR (1973) Conservation laws and energy-release rates. J Appl Mech 40:201–203

Knowles JK, Sternberg E (1972) On a class of conservation laws in linearized and finite elastostatics. Arch Rat Mech Anal 44:187–211

Moran B, Shih CF (1987) Crac tip and associated domain integrals from momentum and energy balance. Eng Fract Mech 27:615–642

Kostrov BV (1964) The axi-symmetric problem of propagation of a tensile crack. Appl Math Mech 28:793–803

Bergkvist H (1977) An investigation of axisymmetric crack propagation. Fast Fracture and Crack Arrest, ASTM STP 627, G.T. Hahn and M.F. Kanninen eds. 321–335

Broberg KB (1999) Cracks and fracture. Academic Press, San Diego

Freund LB (1990) Dynamic fracture mechanics. Cambridge University Press, Cambridge

Dascalu C (2017) Dynamic localization of damage and microstructural length influence. Int J Damage Mech 28:1190–1218

Pham K, Marigo JJ (2013) From the onset of damage to rupture: construction of responses with damage localization for a general class of gradient damage models. Continuum Mech Thermodyn 25:147–171

Erzar B(2010) Spalling, cratering and dynamic tensile behavior of concrete under impact : experimental and modeling approaches, PhD thesis, University of Lorraine, Metz, France

Gabet T (2016) Comportement triaxial du béton sous fortes contraintes: influence du trajet de chargement. Ph.D. Thesis, Grenoble, France

Najar J (1994) Dynamic tensile fracture phenomena at wave propagation in ceramic bars. J Phys IV 4(C8):647–652

Swanson GD (1972) Fracture energies of ceramics. J Am Ceram Soc 55:48–49

Gálvez F, Rodríguez J, Sánchez Gálvez V (2000) Influence of the strain rate on the tensile strength in aluminas of different purity, J. Phys. IV France, 10 PR9 323-328

Zinszner JL (2010) Identification of the material parameters governing the performances of armor ceramics, PhD Thesis, University of Lorraine, Metz, France

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author has no competing interests to declare that are relevant to the content of this article.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dascalu, C. A Damage Law for Dynamic Failure in Brittle Solids with Penny-Shaped Microcracks. J. dynamic behavior mater. (2023). https://doi.org/10.1007/s40870-023-00395-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40870-023-00395-6