Abstract

Three-dimensional model of closed cell foam based on idealized geometry is developed and used to study its response under quasi-static compression, impact and shock loading. Foams with a wide range of densities and corresponding cell morphologies are modeled. Geometry of the unit cells used to construct the 3-D model is based on experimentally measured cell sizes and cell wall thicknesses. The numerical model is validated against experimentally determined stress vs. strain relationship, depth of indentation, indentation force, total deformation under shock loading etc. A comprehensive insight is obtained about local deformation and failure mechanisms such as cell edge bending, buckling and cell wall tearing. This knowledge can provide critical inputs in the design of foam-based shock absorbers.

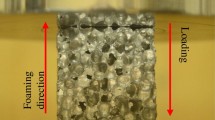

reproduced from reference 36

reproduced from reference 36

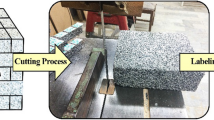

reproduced from reference 35

Similar content being viewed by others

References

Pang X, Du H (2017) Dynamic crushing of aluminium foams under impact crushing. Composites B. https://doi.org/10.1016/j.compositesb.2016.12.044

Peroni M, Solomos G, Pizzinato V (2013) Impact behaviour testing of aluminium foam. Int J Impact Eng. https://doi.org/10.1016/j.ijimpeng.2012.07.002

Kader MA, Islam MA, Hazell PJ, Escobedo JP, Sadatfar M, Brown AD, Appleby-Thomas GJ (2016) Modelling and characterization of cell collapse in aluminium foams during dynamic loading. Int J Impact Eng. https://doi.org/10.1016/j.ijimpeng.2016.05.020

Lu G, Shen J, Hou W, Ruan D, Ong LS (2008) Dynamic indentation and penetration of aluminium foams. Int J Mech Sci. https://doi.org/10.1016/j.ijmecsci.2007.09.006

Islam MA, Kader MA, Hazell PJ, Escobedo JP, Brown AD, Sadatfar M (2020) Effects of impactor shape on the deformation and energy absorption of closed cell aluminium foams under low velocity impact. Mater Des. https://doi.org/10.1016/j.matdes.2020.108599

Jang W-Y, Kyriakides S (2009) On the crushing of aluminum open-cell foams: part II analysis. Int J Solids Struct. https://doi.org/10.1016/j.ijsolstr.2008.10.016

Karagiozova D, Langdon GS, Nurick GN (2012) Propagation of compaction waves in metal foams exhibiting strain hardening. Int J Solids Struct. https://doi.org/10.1016/j.ijsolstr.2012.03.012

Li L, Xue P, Luo G (2016) A numerical study on deformation mode and strength enhancement of metal foam under dynamic loading. Mater Des. https://doi.org/10.1016/j.matdes.2016.07.123

Zhao Z, Jing L (2018) The response of clamped sandwich panels with layered-gradient aluminium foam cores to foam projectile impact. Mech Adv Mater Struct. https://doi.org/10.1080/15376494.2018.1495790

Wang E, Gardner N, Shukla A (2009) The blast resistance of sandwich composites with stepwise graded cores. Int J Solids Struct. https://doi.org/10.1016/j.ijsolstr.2009.06.004

Zhang L, Hebert R, Wright JT, Shukla A, Kim J-H (2014) Dynamic response of corrugated sandwich steel plates with graded cores. Int J Impact Eng. https://doi.org/10.1016/j.ijimpeng.2013.11.011

Yazici M, Wright J, Bertin D, Shukla A (2014) Experimental and numerical study of foam filed corrugated core steel sandwich structures subjected to blast loading. Compos Struct. https://doi.org/10.1016/j.compstruct.2013.11.016

Gardner N, Wang E, Shukla A (2012) Performance of functionally graded sandwich composite beams under shock wave loading. Compos Struct. https://doi.org/10.1016/j.compstruct.2011.12.006

Goel MD, Altenhofer P, Matsagar VA, Gupta AK, Mundt C, Marburg S (2015) Interaction of a shock wave with a closed cell aluminium metal foam. Combust Explos Shock Waves. https://doi.org/10.1134/S0010508215030144

Wahab MMA, Mazek S, Abada MA, Atta MHA (2017) Effect of blast wave on lightweight structure performance. J Eng Sci Mil Technol. https://doi.org/10.21608/ejmtc.2017.429.1010

Liu H, Cao ZK, Yao GC, Luo HJ, Zu GY (2013) Performance of aluminium foam-steel panel sandwich composites subjected to blast loading. Mater Des. https://doi.org/10.1016/j.matdes.2012.12.003

Merrett RP, Langdon GS, Theobald MD (2013) The blast and impact loading of aluminium foam. Mater Des. https://doi.org/10.1016/j.matdes.2012.08.016

Karagiozova D, Nurick GN, Langdon GS (2009) Behaviour of sandwich panels subject to intense air blasts—part 2: numerical simulation. Compos Struct. https://doi.org/10.1016/j.compstruct.2009.04.010

Karigiozova D, Nurick GN, Langdon GS, Chung Kim Yuen S, Chi Y, Bartle S (2009) Response of flexible sandwich-type panels to blast loading. Compos Sci Technol. https://doi.org/10.1016/j.compscitech.2007.12.005

Yang L, Li X, Zi F, Yang S, Zhang Z, Qu J, Dong Y, Wu L (2021) Dynamic response of graded PVC foam sandwich panel under air blast loads. Mech Adv Mater Struct. https://doi.org/10.1080/15376494.2021.1909190

Bahei-EI-Din YA, Dvorak GJ (2007) Wave propagation and dispersion in sandwich plates subjected to blast loads. Mech Adv Mater Struct. https://doi.org/10.1080/15376490701298975

Deshpande VS, Fleck NA (2000) Isotropic constitutive models for metallic foams. J Mech Phys Solids. https://doi.org/10.1016/S0022-5096(99)00082-4

Radford DD, McShane GJ, Deshpande VS, Fleck NA (2006) The response of clamped sandwich plates with metallic foam cores to simulated blast loading. Int J Solids Struct. https://doi.org/10.1016/j.ijsolstr.2005.07.006

Qi C, Yang S, Yang L-J, Wei Z-Y, Zhen-Hua Lu (2013) Blast resistance and multi-objective optimization of aluminium foam-cored sandwich panels. Compos Struct. https://doi.org/10.1016/j.compstruct.2013.04.043

Chen Y, Das R, Battley M (2017) Finite element analysis of the compressive and shear responses of structural foams using computed tomography. Compos Struct. https://doi.org/10.1016/j.compstruct.2016.09.091

Tekoglu C, Gibson LJ, Pardoen T, Onck PR (2011) Size effects in foams: experiments and modeling. Prog Mater Sci. https://doi.org/10.1016/j.pmatsci.2010.06.001

Jigh BHG, Toudeshky HH, Farsi MA (2017) Experimental and multi-scale analyses of open-celled aluminum foam with hole under compressive quasi-static loading. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2016.10.129

Gibson L, Ashby M (1997) Cellular solids: structure and properties. Cambridge university Press, Cambridge. https://doi.org/10.1017/CBO9781139878326

Mills NJ, Stämpfli R, Marone F, Brühwiler P (2008) Finite element micromechanics model of impact compression of closed-cell polymer foams. Int J Solids Struct. https://doi.org/10.1016/j.ijsolstr.2008.09.012

Mills NJ (2007) The high strain mechanical response of the wet Kelvin model for open-cell foams. Int J Solids Struct. https://doi.org/10.1016/j.ijsolstr.2006.04.014

Santosa S, Wierzbicki T (1998) On the modeling of crush behavior of a closed-cell aluminium foam structure. J Mech Phys Solids. https://doi.org/10.1016/S0022-5096(97)00082-3

Meguid SA, Cheon SS, El-Abbasi N (2000) A modified unit cell model for metallic foams. Internal report. EMDL2000-054

Meguid SA, Cheon SS, El-Abbasi N (2002) FE modelling of deformation localization in metallic foams. Finite Elem Anal Des. https://doi.org/10.1016/S0168-874X(01)00096-8

Hasan MA (2010) An improved model for FE modeling and simulation of closed cell al-alloy foams. Adv Mater Sci Eng. https://doi.org/10.1155/2010/567390

Dey C, Thorat M, Sahu SN, Akella K, Gokhale AA (2020) Evaluation of optimum foam density for effective design of blast absorbers. Mech Adv Mater Struct. https://doi.org/10.1080/15376494.2020.1772416

Sahu SN, Sreekantha Reddy T, Reddy GJ, Gokhale AA (2020) Low-velocity impact indentation rate sensitivity of aluminium foams. Mater Today Commun. https://doi.org/10.1016/j.mtcomm.2020.101351

Gokhale AA, Sahu SN, Kulkarni VKWR, Sudhakar B, Rao NR, Rao AA, Ramamurthy U (2007) Aluminium foams through liquid metallurgy: processing and properties. Met Mater Process 19:181–188

Santosa S, Wierzbicki T, Hanssen AG, Langseth M (2000) Experimental and numerical studies of foam-filled sections. Int J Impact Eng 24:509–534. https://doi.org/10.1016/S0734-743X(99)00036-6

Shen J, Guoxing L, Ruan D (2010) Compressive behaviour of closed-cell aluminium foams at high strain rates. Composites B 41:678–685. https://doi.org/10.1016/j.compositesb.2010.07.005

Beals JT, Thompson MS (1997) Density gradient effects on aluminium foam compression behavior. J Mater Sci 32:3595–36001. https://doi.org/10.1023/A:1018670111305

Yang B, Cao Z, Chang Z, Zheng G (2021) The effect of the reflected shock wave on the foam material. Int J Impact Eng. https://doi.org/10.1016/j.ijimpeng.2020.103773

Skews BW (1991) The reflected pressure field in the interaction of weak shock waves with a compressible foam. Shock Waves I:205–211. https://doi.org/10.1007/BF01413795

Mazor G, Ben-Dor G, Igra O, Sorek S (1994) Shock wave interaction with cellular materials: part I: analytical investigation and governing equations. Shock Waves 3:159–165. https://doi.org/10.1007/BF01414710

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dey, C., Sahu, S.N., Akella, K. et al. Numerical Prediction of Quasi-Static Compression, Indentation Impact and Shock Loading Behaviour of Aluminium Foam Using Idealized Cell Geometry. J. dynamic behavior mater. 8, 324–339 (2022). https://doi.org/10.1007/s40870-022-00336-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-022-00336-9