Abstract

The rate dependent tensile response of a bimodal amine epoxy was experimentally evaluated and compared to the response of a single amine. This dual amine epoxy resin was formulated to provide a broadened glass transition temperature. An enhanced ballistic performance is therefore possible within a widened range of operational conditions. To further investigate what contributes to this increase in ballistic performance, the tensile response of the two cured epoxy resins was compared across strain rates of 0.001–1800 s−1. Tensile experiments utilized a novel miniature specimen geometry in tandem with direct localized measurements. This small specimen alleviated issues that commonly arise at elevated strain rates like oscillatory loadings or premature specimen failure, while encouraging dynamic equilibrium. While tensile toughness was not seen to be largely effected, the additional amine promoted rate dependence; yield behavior and overall flow stress increased with increasing strain rates. This effort may be regarded as a first step in understanding the underlying mechanisms of impact conditions on these transparent epoxy resins.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Epoxy systems have seen use in a broad range of contexts as a coating, adhesive, composite matrix, or as materials to withstand impact. These thermosets are traditionally designed in a certain fashion; a glass transition temperature (Tg) must comfortably exceed an expected operational temperature range. Other mechanical, chemical, and physical properties are then dependent on these original Tg requirements. This method can yield well performing materials in a multitude of applications. However, military and aerospace applications give large fluctuations in temperature and pressure over a wide range of time scales. Polymer chemistry must therefore be specifically tailored for these demanding environments.

Polymer designs can be tailored for properties such as morphology and structure, and for thermal, chemical, and mechanical qualities. Cross-linked polymer epoxy systems can often provide solutions that require high stiffness and failure strength, even at elevated temperatures. While adequate for many uses, under more extreme conditions a cured and highly brittle thermoset will show limitations in performance. For example, cross-linked polymer epoxies typically have a low overall fracture toughness and have often been candidates for toughness enhancement. Some toughening methods employed rubber additives [1], thermoplastics [2, 3], or even nanosilicates [4] or nanoclays [5].

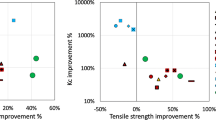

In impact applications, a thermoset’s fracture toughness is also enhanced when the temperature of a high strain rate ballistic event coincides with the Tg of the material [6, 7]. Previous work performed by Knorr et al. [7] included in Fig. 1 elucidates this phenomena for DGEBA and some DGEBF epoxy resin systems, and greatly contributed to the selection of the dual amine PACM/D2000 mixture examined here. Single amine epoxies are able to achieve this heightened impact resistance but only under a narrow breadth of temperature close to the Tg. With these considerations in mind, we compared an epoxy system cured with a single amine to one cured with a blend of two amines. The blend is intended to relax the strict Tg requirement to give enhanced ballistic performance over an increased extent of operational conditions [8].

Ballistic response versus temperature difference with Tg for various epoxy formulations [7]

The mechanics of ballistic response is known to be inherently complicated and highly dependent on individual material behavior [9–11]. In an attempt to characterize material properties relevant to ballistics and impact, many prior researchers have examined the strain rate dependent response of polymers, but primarily in compression [7, 12–14]. While facilitated by comparatively simpler Kolsky bar techniques for dynamic rate experiments, the influence of friction and radial inertia often complicates or even invalidates results [6, 15, 16]. Prior work by Whittie et al. [17] used a novel wing-type geometry to measure certain rate dependent fracture properties of a DGEBA/PACM mixture, but strain gage recordings were not included, load equilibrium was not verified, and the mode of fracture was not specifically determined. Here we attempt to alleviate or avoid these known experimental complications by using a tensile method that is applicable to a wide range of strain rates, and has been shown to give analogous results to those of quasi-static ASTM D638 polymer experiments [18].

The tensile properties of polymers are classically examined using either ASTM D638 or ISO 527 [19, 20]. While able to ensure that reliable data is acquired, these standards do not describe plasticity nor do they accommodate strain rates exceeding 1.0 s−1. Many researchers have investigated alternative methods to apply high strain rate tensile loading however, with the majority implementing variations on threaded rod specimen configurations [21–24]. These threaded designs are effective at lower strain rates but can cause problems when tested at higher loading rates. Complexities of machining consistent thread tolerances in plastics and strain softening behaviors present in some polymers create load oscillations at dynamic strain rates [18]. Others achieved limited success using miniature dogbone epoxy resin specimens but premature failure outside of the gage region was prevalent, and obtaining direct strain measurements was not trivial [25, 26]. Little et al. achieved success with cylindrical epoxy resin specimens in tension, but had reached strain rates of at most 0.1 s−1 [27]. Despite this development regarding polymers under tension at elevated strain rates, individual mechanisms and the extent to which they are related is still not well understood.

Experiment

A mixture of diglycidyl ether of bisphenol A (DGEBA) was crosslinked with PACM, a cyclic diamine curing agent. This formulation was compared to a formulation of DGEBA cured with a blend of amines, PACM and the propylene oxide based Jeffamine D2000 with a total amine volume fraction of 0.5 (PACM volume fraction = 0.14, D2000 volume fraction = 0.36). Figure 2 shows the structures of these constituents. Samples were cast into silicone molds that were originally formed using machined thermoplastic poly-methyl methacrylate (PMMA) positives and allowed to degas under vacuum. Initial inspection showed the specimen manufacturing process to be successful. No specimen post machining was necessary after removal, and specimens showed both a lack of visible defects and identical dimensions to the original PMMA mold positives. Refer to Masser et al. [8] for other formulation and mixing parameters specific to these thermosets.

The polymer tension specimen geometry was designed with a few key requirements. The gripping surface area should be maximized, and the majority of specimen deformation needs to be localized to the gage section. A miniaturized specimen is well-suited for studies on rate dependence as a variety of strain rates can be achieved at lower overall displacement rates. Less time is required to reach dynamic equilibrium at high strain rates as well [28]. Further, in order to reduce fracture initiation points at corners and therefore maximize possible strain to failure, a cylindrical cross section was maintained in the gage length. Thread type grips or the application of glues were necessarily eliminated. Essentially, friction in the conical surface was instead used to fix the specimen to the grips which also reduces the probability of premature failure seen by other researchers [25, 26]. Finally, simple insertion and removal from the grips would promote operator efficiency and allow for more complex supplemental measurements. These design requirements were the driving factors behind the specimen geometry used in this work and shown in Fig. 3. The accompanying conical grips were also necessarily simple; a hole is drilled with a conical taper on the bottom to match that of the specimen ends, and a side slot allows for each specimen to be inserted, rotated 90°, and locked into position by the mating conical taper. Any preload was able to be examined by observation of the load cell signal as the specimen is inserted.

The tensile response of these epoxies were studied at rates of 0.001, 1.0, 100, and approximately 1800 s−1. Experiments were performed on a servohydraulic Instron 1331 for quasi-static and intermediate rates, leaving only the highest strain rate experiments for a modified Kolsky tensile bar. Figure 4 contains a diagram of this Kolsky tensile bar, which has been modified for soft materials. All experiments were performed at room temperature.

Traditional Kolsky or Hopkinson bar experiments were performed on metals, with a mechanical impedance closely matching that of the incident and transmitted bars [29, 30]. However, many researchers have found that modifications are required when testing softer materials such as polymers [15]. In this case, the tensile system used previously for amorphous polymers [18] was implemented again where a 7075-T6 aluminum bar was added to the end of the existing M300 steel incident bar in order to decrease the amount of impact energy at higher reliable striker velocities. While somewhat similar impedances exist in these two materials, the reduction in cross sectional area in the aluminum bar reduces the amount of incident energy placed on the specimen. In addition a technique originally implemented for the tensile testing of single fibers was also used here; the transmitted bar was replaced by a Kistler 9712B load cell and accompanying Kistler 5010B dynamic amplifier to increase measurement sensitivity [31].

3D digital image correlation (DIC) was implemented to measure surface strain distributions on the specimen gage lengths for all strain rates. Table 1 clarifies camera types and other specifications. Each specimen was first speckled with a high contrast black and white pattern using a white basecoat and fine tipped marker. Then once images were obtained during the loading, each was analyzed using an optimization algorithm to obtain displacements and corresponding strains. Data was extracted from the gage length of each specimen using a single point measurement from where the failure was seen to occur. Of particular interest is the camera system utilized at high strain rates; an innovative dual setup consisting of two Kirana cameras in a custom frame was utilized here for strain measurement at these high shutter speeds. Both camera systems at quasi-static and intermediate rates used a maximum exposure time for the framerate, whereas the Kirana system used an exposure time of 500 ns coupled with an adjustable Photogenic DR1000 studio moonlight. This allowed for fine tuning exposure levels with this incredibly sensitive camera system at dynamic rates. Images of all camera setups are included in Fig. 5, and Fig. 6 contains a sample raw image and processed 3D DIC measurement information extracted from such images.

Results and Discussion

Figure 7 shows a typical result from a quasi-static experiment for the single amine DGEBA/PACM mixture, and Fig. 8 contains similar results for the formulation with the added D2000 amine. All data reduction was performed on fully failed specimens that showed no failure in the gripping region. Extraction of all measurements were in the gage length. There is a clear disagreement in Figs. 7 and 8 when the traditional strain measured from machine displacement and that recorded using the DIC method are compared. For a given experiment, the strain in the specimen gage length is much less than that measured with grip separation. This is a similar result to that of Gilat [26], where elastic deformation outside of the gage section creates a large difference between traditional strain measurements based on displacement and those made with local strain gages or other methods.

These preliminary results showed no slipping in the gripping region with the majority of deformation confined to the specimen gage length. The additional amine was seen to provide a nearly bilinear stress–strain response, with a much more pronounced yielding and hardening behavior than the single amine DGEBA/PACM epoxy. Interestingly, the ultimate tensile strength was reduced by over 50 % while the ductility of the DGEBA/PACM/D2000 more than doubled over that of the DGEBA/PACM.

Results from high strain rate experiments are shown in Figs. 9 and 10 for DGEBA/PACM and DGEBA/PACM/D2000 specimens respectively. Each shows that no loading pulse overlap occurred in the Kolsky bar strain gage signals, and that dynamic equilibrium is achieved over the majority of the test duration. Therefore, the traditional data reduction first developed by Kolsky [29] is applicable. However, this simple data reduction may be inaccurate when applied to more complex specimen designs such as the one utilized here. For example, the strains recorded from bar end displacement and calculated from the bar strain gages again drastically overestimates the strain experienced by the specimen. This disagreement persisted regardless of epoxy formulation and at all strain rates. While the stress–strain response may appear noisy, it is found to be well within acceptable levels considering the high rate of loading and the low overall strain level.

The formulation with the additional D2000 amine again showed to give much more strain to failure than the single amine epoxy; a result similar to experiments at the lower strain rate regimes. Dynamic equilibrium was again maintained, and the stress–strain response was seen to have a much more pronounced yield. Strain levels recorded on the specimen by DIC were once again much lower than that calculated using input bar end displacement.

In Fig. 11 a nearly constant relationship with strain rate shows that the disagreement in strain measurements is essentially independent of strain rate. Each strain rate has a vertical line with an average bar along with measured maximum and minimum values as the top and bottom horizontal bars. Therefore, these extreme points include outliers and any total variation in measurements, and does not represent a standard deviation. An increase in relative strain between DIC and machine displacement in the DGEBA/PACM/D2000 mixture could indicate that at higher overall strains the DIC may measure values more similar to engineering strain calculated from displacement. This disparity is likely due to deformations occurring in the entire specimen, including the lower level strains in the gripping regions. A contrast between these two measurements emphasizes the necessity of DIC and local measurements when using nontraditional experimental methods like the novel technique in this study.

The single amine DGEBA/PACM mixture showed brittle behavior across all strain rates. No appreciable yielding occurred, and stress levels remained relatively consistent throughout the changes in strain rate. However, as seen in Fig. 12, when the strain rate was further increased to 1800 s−1 this single amine material gave a clearly increased true stress.

When compared to the single amine mixture, the dual amine combination in the DGEBA/PACM/D2000 formulation drastically increased the strain to failure across all strain rates, with specimens exhibiting a more well defined yield stress followed by strain hardening behavior. Figure 13 shows this stress–strain response of the dual amine material at each strain rate. Of other interest is the similarity in hardening behavior between each strain rate, in addition to the clear increase in yield stress as the strain rate increases. This could indicate that the bimodal amine originally examined by Masser et al. [8] provides a stronger rate dependence and a post-yield hardening which could potentially correlate to an increased ballistic performance.

Any experimental errors associated with the dynamic rate were seen to be well within acceptable bounds, as the error bars for maximum and minimum values shown in Fig. 12 are similar to those at the lower strain rates. While the dual amine mixture gave increased variability at dynamic rate in Fig. 13 perhaps due to variations in yielding and thermal behaviors amongst specimens, the relatively low error levels reinforce the measurement precision of the load and strain extraction techniques at the dynamic rate. In addition, the typical measurement errors associated with Kolsky bar strain gage measurements are avoided when DIC is used along with the output load cell. Experimental errors in the load cell measurement may be attributed to the inherent performance of the load cell and associated amplifier and data acquisition system. Otherwise, a systematic assessment of errors in DIC measurements is nontrivial, and is both entirely dependent on the stereo camera calibration as well as the assumptions used in the correlation algorithms. This primarily places it outside the scope of the work performed here. Instead, it is more beneficial to refer to the existing literature for in depth investigations of DIC errors [32–34].

The tensile toughness of a material is related to the amount of energy a unit volume of a material can withstand before catastrophic failure. In order to further investigate how the inclusion of an additional amine could increase ballistic response, tensile toughness was evaluated and is included in Fig. 14. The vertical lines again describe the average as well as absolute maximum and minimum; these are not given as a standard of deviation. As previously, little difference is shown between the different mixtures in this case. Only at the intermediate strain rate of 100 s−1 does a considerable difference appear, which may in this case simply be due to an outlier. This could indicate other factors contribute to the increase in ballistic performance, not necessarily tensile toughness itself. This is unsurprising, since the tensile toughness is highly dependent on sample quality, and is readily affected by defects. Figure 15 shows that when the initial moduli of the two formulations are compared, the single amine mixture gives higher values at all strain rates. However, the decreasing trend in modulus seen at the moderate rates for DGEBA/PACM may not be fully representative, especially if tensile modulus values here are compared to the storage moduli reported by Masser et al. [8] despite the agreement with the quasi-static tensile modulus published by Knorr et al. [7]. This decrease cannot be attributed to thermal softening because the tensile modulus does not include plastic behavior by definition. Otherwise, a more significant increase in modulus is seen at the dynamic rate for both materials, and does agree with previous data by Masser et al. performed using time temperature superposition in dynamic mechanical analysis (DMA) experiments [8].

Conclusions

A bimodal mixture of DGEBA/PACM/D2000 was compared to a single amine mixture of DGEBA/PACM under uniaxial tension across a wide range of strain rates. It is hoped this effort will begin to elucidate the underlying mechanisms of the increased ballistic response with the added D2000 mixture. A newly developed tensile specimen geometry was used to extend the range of possible strain rates beyond those of traditional standard test methods. This miniaturized tensile method allowed for experiments at rates from 0.001 to about 1800 s−1. While tensile toughness may not have increased with the additional amine, strain to failure was drastically enhanced and post-yield hardening manifested at all strain rates. A significant rate sensitivity favorable for impact resistance also was introduced, as yield stress and modulus were seen to increase with strain rate.

References

Wu H (2013) Tensile properties and fracture toughness of three-rubber modified epoxies. Appl Mech Mater 392:46–50. doi:10.1016/0032-3861(95)93590-I

Pearson RA, Yee AF (1993) Toughening mechanisms in thermoplastic-modified epoxies: 1. Modification using poly(phenylene oxide). Polymer 34(17):3658–3670. doi:10.1007/BF01174528

Francis B, Rao VL, Jose S, Catherine BK, Ramaswamy R, Jose J, Thomas S (2006) Poly(ether ether ketone with pendent methyl groups as a toughening agent for amine cured DGEBA epoxy resin. J Mater Sci 41:5467–5479. doi:10.1007/s10853-006-0294-2

Hsieh TH, Kinloch AJ, Masania K, Taylor AC, Sprenger S (2010) The mechanisms and mechanics of the toughening of epoxy polymers modified with silica nanoparticles. Polymer 51:6284–6294. doi:10.1016/j.polymer.2010.10.048

Qi B, Zhang QX, Bannister M, Mai YW (2006) Investigation of the mechanical properties of DGEBA-based epoxy resin with nanoclay additives. Compos Struct 75:514–519. doi:10.1016/j.compstruct.2006.04.032

D’Almeida JRM, Cella N (2002) Correlation between the impact energy and the glass transition temperature of DGEBA based epoxy systems. J Mater Sci Lett 21:1917–1919. doi:10.1023/A:1021648328117

Knorr DB Jr, Yu JH, Richardson AD, Hindenlang MD, McAninch IM, LaScala JJ, Lenhart JL (2012) Glass transition dependence of ultrahigh strain rate response in amine cured resins. Polymer 53:5917–5923. doi:10.1016/j.polymer.2012.09.058

Masser KA, Knorr DB Jr, Hindenlang MD, Yu JH, Richardson AD, Strawhecker KE, Beyer FL, Lenhart JL (2015) Relating structure and chain dynamics to ballistic performance in transparent epoxy networks exhibiting nanometer scale heterogeneity. Polymer 58:96–106. doi:10.1016/j.polymer.2014.12.027

Backman ME, Goldsmith W (1978) The mechanics of penetration of projectiles into targets. Int J Eng Sci 16:1–99. doi:10.1016/0020-7225(78)90002-2

Patel PJ, Gilde GA, Dehmer PG, McCauley PW (2000) Transparent armor. Adv Mater Process Technol Newslett 4(3):1–13

McCauley JW, Strassburger E, Patel P, Paliwal B, Ramesh KT (2013) Experimental observations on dynamic response of selected armor materials. Exp Mech 53:3–29. doi:10.1007/s11340-012-9658-5

Mulliken AD, Boyce MC (2006) Mechanics of the rate dependent elastic-plastic deformation of glassy polymers from low to high strain rates. Int J Solids Struct 43:1331–1356. doi:10.1016/j.ijsolstr.2005.04.016

Richeton J, Ahzi S, Vecchio KS, Jiang FC, Adharapurapu RR (2006) Influence of temperature and strain rate on the mechanical behavior of three amorphous polymers: characterization and modeling of the yield stress. Int J Solids Struct 43:2318–2335. doi:10.1016/j.ijsolstr.2005.06.040

Moy P, Gunnarsson CA, Weerasooriya T, Chen W (2011) Stress-strain response of PMMA as a function of strain rate and temperature. Dynamic behavior of materials. Proceedings of 2011 annual conference on experimental and applied mechanics, vol 1. Springer, New York, pp 125–133. doi:10.1007/978-1-4614-0216-9_18

Chen W, Lu F, Frew DJ, Forrestal MJ (2002) Dynamic compression testing of soft materials. J Appl Mech 69:214–223. doi:10.1115/1.1464871

Song B, Ge Y, Chen WW, Weerasooriya T (2007) Radial inertia effects in kolsky bar testing of extra-soft specimens. Exp Mech 47:659–670. doi:10.1007/s11340-006-9017-5

Whittie S, Moy P, Gunnarsson CA, Knorr D, Weerasooriya T, Lenhart J (2013) Fracture response of cross-linked epoxy resins as a function of loading rate. Dynamic behavior of materials. Proceedings of 2012 annual conference on experimental and applied mechanics, vol 1. Springer, New York, pp 7–15. doi:10.1007/978-1-4614-0216-9_8

Foster M, Love B, Kaste R, Moy P (2015) The rate dependent tensile response of polycarbonate and poly-methylmethacrylate. J Dyn Behav Mater 1(2):162–175. doi:10.1007/s40870-015-0020-8

ASTM D638–14 (2014) Standard test method for tensile properties of plastics. ASTM Int. doi:10.1520/D0638-10

ISO 527-1. Plastics-determination of tensile properties—Part 1: General principles. Int. Org for Standardization. (E)

Chen W, Lu F, Cheng M (2002) Tension and compression tests of two polymers under quasi-static and dynamic loading. Polym Test 21:113–121. doi:10.1016/S0142-9418(01)00055-1

Rae PJ, Brown EN (2005) The properties of poly(tetrafluoroethylene) (PTFE) in tension. Polymer 46:8128–8140. doi:10.1016/j.polymer.2005.06.120

Sarva SS, Boyce MC (2007) Mechanics of polycarbonate during high-rate tension. J Mech Mater Struct 2(10):1853–1880. doi:10.2140/jomms.2007.2.1853

Fu S, Wang Y, Wang Y (2009) Tension testing of polycarbonate at high strain rates. Polym Test 28:724–729. doi:10.1016/j.polymertesting.2009.06.002

Buckley CP, Harding J, Hou JP, Ruiz C, Trojanowski A (2001) Deformation of thermosetting resins at impact rates of strain. Part I: experimental study. J Mech Phys Solids 49:1517–1538. doi:10.1016/S0022-5096(00)00085-5

Gilat A, Goldberg RK, Roberts GD. (2005) Strain rate sensitivity of epoxy resin in tensile and shear loading. National Aeronautics and Space Administration. NASA/TM- 2005-213595. doi:10.1061/(ASCE)0893-1321(2007)20:2(75)

Littel JD, Ruggeri CR, Goldberg RK, Roberts GD, Arnold WA, Binienda WK (2008) Measurement of epoxy resin tension, compression, and shear stress-strain curves over a wide range of strain rates using small test specimens. J Aerospace Eng 21(3):162–173. doi:10.1061/(ASCE)0893-1321(2008)21:3(162)

Song B, Chen W (2004) Dynamic stress equilibration in split Hopkinson pressure bar tests on soft materials. Exp Mech 44(3):300–312. doi:10.1177/0014485104041543

Kolsky H (1949) An investigation of the mechanical properties of materials at very high rates of strain. Proc R Phys Soc B62:676–700. doi:10.1088/0370-1301/62/11/302

Davies EDH, Hunter SC (1963) The dynamic compression testing of solids by the method of the split Hopkinson pressure bar. J Mech Phys Solids 11(3):155–179. doi:10.1016/0022-5096(63)90050-4

Cheng M, Chen W, Weerasooriya T (2005) Mechanical properties of kevlar KM2 single fiber. J Eng Mater Trans ASME 127:197–203. doi:10.1115/1.1857937

Siebert T, Becker T, Spiltthof K, Neumann I, Krupka R (2007) High speed digital image correlation: error estimations and applications. Opt Eng 46(5):051004. doi:10.1117/1.2741217

Bornert M, Bremand F et al (2009) Assessment of digital image correlation errors: methodology and results. Exp Mech 49:353–370. doi:10.1007/s11340-008-9204-7

Sutton MA, Orteu JJ, Schreier HW (2009) Image correlation for shape, motion and deformation measurements. Springer, New York. doi:10.1007/978-0-387-78747-3

Acknowledgments

The research reported in this document was performed in connection with contract/instrument W911QX-14-C-0016 with the U.S. Army Research Laboratory. The research reported in this document was performed in connection with contract/instrument W911QX-14-C-0016 with the U.S. Army Research Laboratory. The views and conclusions contained in this document are those of TKC Global and the U.S. Army Research Laboratory. Citation of manufacturer’s or trade names does not constitute an official endorsement or approval of the use thereof. The U.S. Government is authorized to reproduce and distribute reprints for Government purposes notwithstanding any copyright notation hereon.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Foster, M., Masser, K.A. & Lenhart, J.L. Tensile Properties and Rate Dependence of a Dual Amine Epoxy Network. J. dynamic behavior mater. 2, 112–121 (2016). https://doi.org/10.1007/s40870-016-0054-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-016-0054-6