Abstract

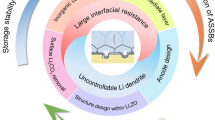

Solid-state lithium metal batteries (SSLMBs) have attracted a lot of interest owing to their high safety and high energy density potential. However, the growth of lithium dendrite in solid electrolytes still hinders practical applications of SSLMBs. In this study, we develop a simple heat treatment method for reviving and recycling garnet oxide electrolytes with Li dendrite penetration. Interestingly, the recovered garnet electrolyte exhibits higher relative density, enhanced ionic conductivity and improved critical current density compared with the pristine one. The thermal healing is due to the products of the reaction between dendritic Li metal and air that contribute to the further densification of garnet electrolytes during heat treatment. This work demonstrates a new way to recycle garnet electrolytes, which may further extend to other various solid electrolytes.

摘要

固态锂金属电池(SSLMBs)因其高安全性和潜在的高能量密度引起了广泛的兴趣. 然而, 锂枝晶在固态电解质中的生长严重阻碍了SSLMBs的实际应用. 在本文中, 我们开发了一种简单的方法, 通过热处理修复和回收被锂枝晶刺穿的石榴石氧化物电解质. 与初始对照样相比, 回收后的石榴石电解质表现出更高的相对密度、离子电导率和临界电流密度. 热愈合是基于树突状锂枝晶和空气间的反应产物, 其有助于在热处理过程中石榴石电解质的进一步致密化. 这项工作为石榴石型固态电解质的回收利用开辟了一条新的途径.

Similar content being viewed by others

References

Lin D, Liu Y, Cui Y. Reviving the lithium metal anode for high-energy batteries. Nat Nanotech, 2017, 12: 194–206

Guo Y, Li H, Zhai T. Reviving lithium-metal anodes for next-generation high-energy batteries. Adv Mater, 2017, 29: 1700007

Ji X, Zhang Y, Cao M, et al. Advanced inorganic/polymer hybrid electrolytes for all-solid-state lithium batteries. J Adv Ceram, 2022, 11: 835–861

Liu H, Cheng X, Zhang R, et al. Mesoporous graphene hosts for dendrite-free lithium metal anode in working rechargeable batteries. Trans Tianjin Univ, 2020, 26: 127–134

Hu Q, Sun Z, Nie L, et al. High-safety composite solid electrolyte based on inorganic matrix for solid-state lithium-metal batteries. Mater Today Energy, 2022, 27: 101052

Zheng J, Zhang W, Huang C, et al. In-situ polymerization with dual-function electrolyte additive toward future lithium metal batteries. Mater Today Energy, 2022, 26: 100984

Zhao N, Khokhar W, Bi Z, et al. Solid garnet batteries. Joule, 2019, 3: 1190–1199

Chen S, Zhang J, Nie L, et al. All-solid-state batteries with a limited lithium metal anode at room temperature using a garnet-based electrolyte. Adv Mater, 2021, 33: 2002325

Jia K, Wang J, Ma J, et al. Suppressed lattice oxygen release via Ni/Mn doping from spent LiNi0.5Mn0.3Co0.2O2 toward high-energy layered-oxide cathodes. Nano Lett, 2022, 22: 8372–8380

Jiao M, Zhang Q, Ye C, et al. Isolating contiguous Fe atoms by forming a Co−Fe intermetallic catalyst from spent lithium-ion batteries to regulate activity for zinc-air batteries. ACS Nano, 2022, 16: 13223–13231

Jiao M, Zhang Q, Ye C, et al. Recycling spent LiNi1−x−yMnxCoyO2 cathodes to bifunctional NiMnCo catalysts for zinc-air batteries. Proc Natl Acad Sci USA, 2022, 119: e2202202119

Ma J, Wang J, Jia K, et al. Adaptable eutectic salt for the direct recycling of highly degraded layer cathodes. J Am Chem Soc, 2022, 144: 20306–20314

Wang J, Ma J, Jia K, et al. Efficient extraction of lithium from anode for direct regeneration of cathode materials of spent Li-ion batteries. ACS Energy Lett, 2022, 7: 2816–2824

Wang J, Zhang Q, Sheng J, et al. Direct and green repairing of degraded LiCoO2 for reuse in lithium-ion batteries. Natl Sci Rev, 2022, 9: nwac097

Azhari L, Bong S, Ma X, et al. Recycling for all solid-state lithium-ion batteries. Matter, 2020, 3: 1845–1861

Schwich L, Küpers M, Finsterbusch M, et al. Recycling strategies for ceramic all-solid-state batteries—Part I: Study on possible treatments in contrast to Li-ion battery recycling. Metals, 2020, 10: 1523

Tan DHS, Chen Z. Sustainable design of fully recyclable all solid-state batteries. MRS Bull, 2020, 45: 990–991

Yuan K, Tu T, Shen C, et al. Self-ball milling strategy to construct high-entropy oxide coated LiNi0.8Co0.1Mn0.1O2 with enhanced electrochemical performance. J Adv Ceram, 2022, 11: 882–892

Sun M, Zeng Z, Peng L, et al. Ultrathin polymer electrolyte film prepared by in situ polymerization for lithium metal batteries. Mater Today Energy, 2021, 21: 100785

Gonzalez Puente PM, Song S, Cao S, et al. Garnet-type solid electrolyte: Advances of ionic transport performance and its application in all-solid-state batteries. J Adv Ceram, 2021, 10: 933–972

Zheng C, Su J, Song Z, et al. Improvement of density and electrochemical performance of garnet-type Li7La3Zr2O12 for solid-state lithium metal batteries enabled by W and Ta co-doping strategy. Mater Today Energy, 2022, 27: 101034

Chen S, Nie L, Hu X, et al. Ultrafast sintering for ceramic-based all-solid-state lithium-metal batteries. Adv Mater, 2022, 34: 2200430

Chen S, Hu X, Bao W, et al. Low-sintering-temperature garnet oxides by conformal sintering-aid coating. Cell Rep Phys Sci, 2021, 2: 100569

Wu W, Song Z, Dai Y, et al. Magnetic actuation enables programmable lithium metal engineering. Adv Energy Mater, 2022, 12: 2200999

Monroe C, Newman J. The impact of elastic deformation on deposition kinetics at lithium/polymer interfaces. J Electrochem Soc, 2005, 152: A396

Chen R, Li Q, Yu X, et al. Approaching practically accessible solid-state batteries: Stability issues related to solid electrolytes and interfaces. Chem Rev, 2020, 120: 6820–6877

Krauskopf T, Dippel R, Hartmann H, et al. Lithium-metal growth kinetics on LLZO garnet-type solid electrolytes. Joule, 2019, 3: 2030–2049

Mo F, Ruan J, Sun S, et al. Inside or outside: Origin of lithium dendrite formation of all solid-state electrolytes. Adv Energy Mater, 2019, 9: 1902123

Chen S, Nie Z, Tian F, et al. The influence of surface chemistry on critical current density for garnet electrolyte. Adv Funct Mater, 2022, 32: 2113318

Cheng EJ, Sharafi A, Sakamoto J. Intergranular Li metal propagation through polycrystalline Li6.25Al0.25La3Zr2O12 ceramic electrolyte. Electrochim Acta, 2017, 223: 85–91

Han F, Westover AS, Yue J, et al. High electronic conductivity as the origin of lithium dendrite formation within solid electrolytes. Nat Energy, 2019, 4: 187–196

Song Y, Yang L, Zhao W, et al. Revealing the short-circuiting mechanism of garnet-based solid-state electrolyte. Adv Energy Mater, 2019, 9: 1900671

Kazyak E, Garcia-Mendez R, LePage WS, et al. Li penetration in ceramic solid electrolytes: Operando microscopy analysis of morphology, propagation, and reversibility. Matter, 2020, 2: 1025–1048

Porz L, Swamy T, Sheldon BW, et al. Mechanism of lithium metal penetration through inorganic solid electrolytes. Adv Energy Mater, 2017, 7: 1701003

Liu X, Garcia-Mendez R, Lupini AR, et al. Local electronic structure variation resulting in Li ‘filament’ formation within solid electrolytes. Nat Mater, 2021, 20: 1485–1490

Fu KK, Gong Y, Liu B, et al. Toward garnet electrolyte-based Li metal batteries: An ultrathin, highly effective, artificial solid-state electrolyte/metallic Li interface. Sci Adv, 2017, 3: e1601659

Liang JY, Zeng XX, Zhang XD, et al. Engineering janus interfaces of ceramic electrolyte via distinct functional polymers for stable high-voltage Li-metal batteries. J Am Chem Soc, 2019, 141: 9165–9169

Luo W, Gong Y, Zhu Y, et al. Reducing interfacial resistance between garnet-structured solid-state electrolyte and Li-metal anode by a germanium layer. Adv Mater, 2017, 29: 1606042

Wu B, Wang S, Lochala J, et al. The role of the solid electrolyte interphase layer in preventing Li dendrite growth in solid-state batteries. Energy Environ Sci, 2018, 11: 1803–1810

Zhou W, Wang S, Li Y, et al. Plating a dendrite-free lithium anode with a polymer/ceramic/polymer sandwich electrolyte. J Am Chem Soc, 2016, 138: 9385–9388

He M, Cui Z, Chen C, et al. Formation of self-limited, stable and conductive interfaces between garnet electrolytes and lithium anodes for reversible lithium cycling in solid-state batteries. J Mater Chem A, 2018, 6: 11463–11470

Li Y, Xu B, Xu H, et al. Hybrid polymer/garnet electrolyte with a small interfacial resistance for lithium-ion batteries. Angew Chem Int Ed, 2017, 56: 753–756

Fu J, Yu P, Zhang N, et al. In situ formation of a bifunctional interlayer enabled by a conversion reaction to initiatively prevent lithium dendrites in a garnet solid electrolyte. Energy Environ Sci, 2019, 12: 1404–1412

Han X, Gong Y, Fu KK, et al. Negating interfacial impedance in garnet-based solid-state Li metal batteries. Nat Mater, 2017, 16: 572–579

Shao Y, Wang H, Gong Z, et al. Drawing a soft interface: An effective interfacial modification strategy for garnet-type solid-state Li batteries. ACS Energy Lett, 2018, 3: 1212–1218

Parejiya A, Amin R, Essehli R, et al. Electrochemical healing of dendrites in garnet-based solid electrolytes. ACS Energy Lett, 2020, 5: 3368–3373

Qin Z, Xie Y, Meng X, et al. Recycling garnet-type electrolyte toward superior cycling performance for solid-state lithium batteries. Energy Storage Mater, 2022, 49: 360–369

Nowroozi MA, Waidha AI, Jacob M, et al. Towards recycling of LLZO solid electrolyte exemplarily performed on LFP/LLZO/LTO cells. ChemistryOpen, 2022, 11: e202100274

Wang T, Song Z, Zhang Y, et al. Direct recycling of shorted solid-state electrolytes enabled by targeted recovery. Energy Storage Mater, 2022, 52: 365–370

Li Y, Cao Y, Guo X. Influence of lithium oxide additives on densification and ionic conductivity of garnet-type Li6.75La3Zr1.75Ta0.25O12 solid electrolytes. Solid State Ion, 2013, 253: 76–80

Acknowledgements

This work was partially supported by Shanghai Rising-Star Program (20QA1406600). We also acknowledge the Centre for High-resolution Electron Microscopy (CℏEM), School of Physical Science and Technology, ShanghaiTech University (EM02161943), Shanghai Science and Technology Plan (21DZ2260400) and Double-Class Initiative Fund of ShanghaiTech University for support.

Author information

Authors and Affiliations

Contributions

Chen S and Hu X contributed to the experiments and editing; Nie L contributed to the discussion; Yu Y and Liu W were in charge of the scientific research project. All authors contributed to the general discussion.

Corresponding author

Additional information

Conflict of interest

The authors declare that they have no conflict of interest.

Supplementary information

Supporting data are available in the online version of the paper.

Shaojie Chen received his BS degree in materials science and engineering from Zhejiang Sci-Tech University in 2018. He then joined the School of Physical Science and Technology at ShanghaiTech University under the supervision of Prof. Wei Liu. His research interests focus on solid-state lithium metal batteries and lithium-sulfur batteries.

Xiangchen Hu received his BE degree in materials science and engineering from Shanghaitech University in 2018. He then joined the School of Physical Science and Technology at Shanghaitech University under the supervision of Prof. Yi Yu. His research focuses on the aberration-corrected TEM characterization on beam-sensitive materials (halide perovskite and lithium batteries).

Wei Liu received her BS degree in materials physics from Beijing Normal University in 2008 and her PhD degree in materials science and engineering from Tsinghua University in 2013. She visited the University of Tokyo during 2010–2011. From 2013 to 2017, she was a postdoctoral scholar at Stanford University. She joined ShanghaiTech University as an assistant professor in 2017. Her research interests cover the area of solid-state ionics and nanotechnology, with a focus on the studies of lithium batteries.

Supporting information for

Rights and permissions

About this article

Cite this article

Chen, S., Hu, X., Nie, L. et al. Recycling of garnet solid electrolytes with lithium-dendrite penetration by thermal healing. Sci. China Mater. 66, 2192–2198 (2023). https://doi.org/10.1007/s40843-022-2371-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-022-2371-9