Abstract

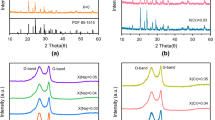

Li3VO4 shows great potential as an intercalation/de-intercalation type anode material for energy-storage devices. Morphology tailoring and surface modification are effective to enhance its lithium storage performance. In this work, we fabricate carbon coated Li3VO4 (C@LVO) rods by a facile morphology inheritance route. The as-prepared C@LVO rods are 400–800 nm in length and 200–400 nm in diameter, and orthorhombic phase with V5+. The unique core-shell rods structure greatly improves the transport ability of electrons and Li+. Such C@LVO submicron-rods as anode materials exhibit excellent rate capability (a reversible capability of 460, 438, 416, 359 and 310 mA h g−1 at 0.2, 1, 2, 5 and 10 C, respectively) and a high stable capacity of 440 and 313 mA h g−1 up to 300 cycles at 0.2 and 5 C, respectively.

摘要

Li3VO4作为一种能够应用到储能装置上的脱嵌型负极材料 展现了巨大的应用潜力.形貌调控和表面修饰是提升Li3VO4电化学 性能非常有效的方法.本文通过一种形貌遗传法制备了碳包覆的 棒状Li3VO4, SEM和TEM结果表明这种碳包覆棒状Li3VO4材料的 长度约为400–800 nm, 直径约为200–400 nm. XRD和XPS结果证明 碳包覆棒状Li3VO4仍然是正交相, 其中V的价态为+5. 由于其独特 的核壳结构, 它的电子和锂离子的传输能力都有较大的提升. 因此, 碳包覆棒状Li3VO4展现出优异的电化学性能, 在0.2, 1, 2, 5和10 C 的电流密度下分别有460, 438, 416, 359 和310 mA h g−1 的可逆容量, 在0.2和5 C的电流密度下循环300圈后仍然具有440和313 mA h g−1 的可逆容量.

Similar content being viewed by others

References

Tarascon JM, Armand M. Issues and challenges facing rechargeable lithium batteries. Nature, 2001, 414: 359–367

Armand M, Tarascon JM. Building better batteries. Nature, 2008, 451: 652–657

Dunn B, Kamath H, Tarascon JM. Electrical energy storage for the grid: A battery of choices. Science, 2011, 334: 928–935

Assat G, Tarascon JM. Fundamental understanding and practical challenges of anionic redox activity in Li-ion batteries. Nat Energy, 2018, 3: 373–386

Kaskhedikar NA, Maier J. Lithium storage in carbon nanostructures. Adv Mater, 2009, 21: 2664–2680

Kim HK, Bak SM, Kim KB. Li4Ti5O12/reduced graphite oxide nano-hybrid material for high rate lithium-ion batteries. Electrochem Commun, 2010, 12: 1768–1771

Park H, Wu HB, Song T, et al. Porosity-controlled TiNb2O7 microspheres with partial nitridation as a practical negative electrode for high-power lithium-ion batteries. Adv Energy Mater, 2015, 5: 1401945

Agyeman DA, Song K, Lee GH, et al. Carbon-coated Si nano-particles anchored between reduced graphene oxides as an extremely reversible anode material for high energy-density Li-ion battery. Adv Energy Mater, 2016, 6: 1600904

Zhu Y, Cao T, Li Z, et al. Two-dimensional SnO2/graphene heterostructures for highly reversible electrochemical lithium storage. Sci China Mater, 2018, 61: 1527–1535

Geng Z, Li B, Liu H, et al. Oxygen-doped carbon host with enhanced bonding and electron attraction abilities for efficient and stable SnO2/carbon composite battery anode. Sci China Mater, 2018, 61: 1067–1077

Zhou L, Yi Z, Lyu F, et al. Facile one-pot fabrication of α-Fe2O3 nano-coffee beans by etching along [001] direction for high lithium storage. Sci China Mater, 2017, 60: 1187–1195

An C, Liu X, Gao Z, et al. Filling and unfilling carbon capsules with transition metal oxide nanoparticles for Li-ion hybrid super-capacitors: Towards hundred grade energy density. Sci China Mater, 2017, 60: 217–227

Li H, Liu X, Zhai T, et al. Li3VO4: A promising insertion anode material for lithium-ion batteries. Adv Energy Mater, 2013, 3: 428–432

Choi NS, Chen Z, Freunberger SA, et al. Challenges facing lithium batteries and electrical double-layer capacitors. Angew Chem Int Ed, 2012, 51: 9994–10024

Zhu GN, Liu HJ, Zhuang JH, et al. Carbon-coated nano-sized Li4Ti5O12 nanoporous micro-sphere as anode material for high-rate lithium-ion batteries. Energy Environ Sci, 2011, 4: 4016–4022

Sha Y, Zhao B, Ran R, et al. Synthesis of well-crystallized Li4Ti5O12 nanoplates for lithium-ion batteries with outstanding rate capability and cycling stability. J Mater Chem A, 2013, 1: 13233–13243

Zhang C, Song H, Liu C, et al. Fast and reversible Li ion insertion in carbon-encapsulated Li3VO4 as anode for lithium-ion battery. Adv Funct Mater, 2015, 25: 3497–3504

Ni S, Lv X, Zhang J, et al. The electrochemical performance of lithium vanadate/natural graphite composite material as anode for lithium ion batteries. Electrochim Acta, 2014, 145: 327–334

Shen L, Chen S, Maier J, et al. Carbon-coated Li3VO4 spheres as constituents of an advanced anode material for high-rate long-life lithium-ion batteries. Adv Mater, 2017, 29: 1701571

Yang G, Zhang B, Feng J, et al. Morphology controlled lithium storage in Li3VO4 anodes. J Mater Chem A, 2018, 6: 456–463

Ni S, Zhang J, Ma J, et al. Superior electrochemical performance of Li3VO4/N-doped C as an anode for Li-ion batteries. J Mater Chem A, 2015, 3: 17951–17955

Yang Y, Li J, He X, et al. A facile spray drying route for mesoporous Li3VO4/C hollow spheres as an anode for long life lithium ion batteries. J Mater Chem A, 2016, 4: 7165–7168

Mu C, Lei K, Li H, et al. Enhanced conductivity and structure stability of Ti4+ doped Li3VO4 as anodes for lithium-ion batteries. J Phys Chem C, 2017, 121: 26196–26201

Zhang C, Liu C, Nan X, et al. Hollow-cuboid Li3VO4/C as high-performance anodes for lithium-ion batteries. ACS Appl Mater Interfaces, 2016, 8: 680–688

Shen L, Lv H, Chen S, et al. Peapod-like Li3VO4/N-doped carbon nanowires with pseudocapacitive properties as advanced materials for high-energy lithium-ion capacitors. Adv Mater, 2017, 29: 1700142

Zheng YZ, Ding H, Uchaker E, et al. Nickel-mediated polyol synthesis of hierarchical V2O5 hollow microspheres with enhanced lithium storage properties. J Mater Chem A, 2015, 3: 1979–1985

Ragupathy P, Shivakumara S, Vasan HN, et al. Preparation of nanostrip V2O5 by the polyol method and its electrochemical characterization as cathode material for rechargeable lithium batteries. J Phys Chem C, 2008, 112: 16700–16707

Zeng L, Pan A, Liang S, et al. Novel synthesis of V2O5 hollow microspheres for lithium ion batteries. Sci China Mater, 2016, 59: 567–573

Wang H, Ma D, Huang Y, et al. Electrospun V2O5 nanostructures with controllable morphology as high-performance cathode materials for lithium-ion batteries. Chem Eur J, 2012, 18: 8987–8993

Yue Y, Liang H. Micro- and nano-structured vanadium pentoxide (V2O5) for electrodes of lithium-ion batteries. Adv Energy Mater, 2017, 7: 1602545

Deng Z, Tang F, Chen D, et al. A simple solution route to single-crystalline Sb2O3 nanowires with rectangular cross sections. J Phys Chem B, 2006, 110: 18225–18230

Deng Z, Chen D, Tang F, et al. Orientated attachment assisted self-assembly of Sb2O3 nanorods and nanowires: end-to-end versus side-by-side. J Phys Chem C, 2007, 111: 5325–5330

Uchaker E, Zhou N, Li Y, et al. Polyol-mediated solvothermal synthesis and electrochemical performance of nanostructured V2O5 hollow microspheres. J Phys Chem C, 2013, 117: 1621–1626

Liu Y, Uchaker E, Zhou N, et al. Facile synthesis of nanostructured vanadium oxide as cathode materials for efficient Li-ion batteries. J Mater Chem, 2012, 22: 24439–24445

Liu J, Lu PJ, Liang S, et al. Ultrathin Li3VO4 nanoribbon/graphene sandwich-like nanostructures with ultrahigh lithium ion storage properties. Nano Energy, 2015, 12: 709–724

Li Q, Wei Q, Sheng J, et al. Mesoporous Li3VO4/C submicron-ellipsoids supported on reduced graphene oxide as practical anode for high-power lithium-ion batteries. Adv Sci, 2015, 2: 1500284

Li S, Wang T, Zhu W, et al. Controllable synthesis of uniform mesoporous H-Nb2O5/rGO nanocomposites for advanced lithium ion hybrid supercapacitors. J Mater Chem A, 2019, 7: 693–703

Di Noto V, Negro E, Polizzi S, et al. Synthesis, studies and fuel cell performance of “core-shell” electrocatalysts for oxygen reduction reaction based on a PtNix carbon nitride “shell” and a pyrolyzed polyketone nanoball “core”. Int J Hydrogen Energy, 2014, 39: 2812–2827

Sathiya M, Prakash AS, Ramesha K, et al. V2O5-anchored carbon nanotubes for enhanced electrochemical energy storage. J Am Chem Soc, 2011, 133: 16291–16299

Cai Z, Xu L, Yan M, et al. Manganese oxide/carbon yolk-shell nanorod anodes for high capacity lithium batteries. Nano Lett, 2015, 15: 738–744

Qin R, Shao G, Hou J, et al. One-pot synthesis of Li3VO4@C nanofibers by electrospinning with enhanced electrochemical performance for lithium-ion batteries. Sci Bull, 2017, 62: 1081–1088

Glushenkov AM, Stukachev VI, Hassan MF, et al. A novel approach for real mass transformation from V2O5 particles to na-norods. Cryst Growth Des, 2008, 8: 3661–3665

Zhang LL, Li Y, Peng G, et al. High-performance Li3V2(PO4)3/C cathode materials prepared via a sol–gel route with double carbon sources. J Alloys Compd, 2012, 513: 414–419

Tartaj P, Amarilla JM, Vazquez-Santos MB. Aerosol-assisted synthesis of colloidal aggregates with different morphology: Toward the electrochemical optimization of Li3VO4 battery anodes using scalable routes. Chem Mater, 2016, 28: 986–993

Hu S, Song Y, Yuan S, et al. A hierarchical structure of carbon-coated Li3VO4 nanoparticles embedded in expanded graphite for high performance lithium ion battery. J Power Sources, 2016, 303: 333–339

Liu H, Hu P, Yu Q, et al. Boosting the deep discharging/charging lithium storage performances of Li3VO4 through double-carbon decoration. ACS Appl Mater Interfaces, 2018, 10: 23938–23944

Xia L, Wang S, Liu G, et al. Flexible SnO2/N-doped carbon nanofiber films as integrated electrodes for lithium-ion batteries with superior rate capacity and long cycle life. Small, 2016, 12: 853–859

Wang G, Xie J, Wu C, et al. Submicron lithium nickel manganese oxide spinel with long cycling stability and high rate performance prepared by a facile route. J Power Sources, 2014, 265: 118–124

Cheng F, Wang H, Zhu Z, et al. Porous LiMn2O4 nanorods with durable high-rate capability for rechargeable Li-ion batteries. Energy Environ Sci, 2011, 4: 3668–3675

Lou XW, Li CM, Archer LA. Designed synthesis of coaxial SnO2@carbon hollow nanospheres for highly reversible lithium storage. Adv Mater, 2009, 21: 2536–2539

Ko JS, Doan-Nguyen VVT, Kim HS, et al. High-rate capability of Na2FePO4F nanoparticles by enhancing surface carbon functionality for Na-ion batteries. J Mater Chem A, 2017, 5: 18707–18715

Yang C, Tang Y, Tian Y, et al. Achieving of flexible, free-standing, ultracompact delaminated titanium carbide films for high volumetric performance and heat-resistant symmetric supercapacitors. Adv Funct Mater, 2018, 28: 1705487

Brezesinski T, Wang J, Tolbert SH, et al. Ordered mesoporous α-MoO3 with iso-oriented nanocrystalline walls for thin-film pseudocapacitors. Nat Mater, 2010, 9: 146–151

Lou S, Cheng X, Wang L, et al. High-rate capability of three-dimensionally ordered macroporous t-Nb2O5 through Li+ intercalation pseudocapacitance. J Power Sources, 2017, 361: 80–86

Lou S, Cheng X, Gao J, et al. Pseudocapacitive Li+ intercalation in porous Ti2Nb10O29 nanospheres enables ultra-fast lithium storage. Energy Storage Mater, 2018, 11: 57–66

Lou S, Cheng X, Zhao Y, et al. Superior performance of ordered macroporous TiNb2O7 anodes for lithium ion batteries: Understanding from the structural and pseudocapacitive insights on achieving high rate capability. Nano Energy, 2017, 34: 15–25

Zhao C, Yu C, Zhang M, et al. Ultrafine MoO2-carbon microstructures enable ultralong-life power-type sodium ion storage by enhanced pseudocapacitance. Adv Energy Mater, 2017, 7: 1602880

Fan X, Tang X, Ma D, et al. Novel hollow Sn-Cu composite nanoparticles anodes for Li-ion batteries prepared by galvanic replacement reaction. J Solid State Electrochem, 2014, 18: 1137–1145

Acknowledgements

This work was supported by the National Natural Science Foundation of China (21476019 and 21676017).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Author contributions

Qin P, Zheng YZ and Tao X conceived the idea of the project. Qin P conducted the material synthesis, structural characterizations and electrochemical test. Lv X and Li C helped to discuss partial experimental data. Qin P wrote the paper with support from Zheng YZ. All authors contributed to the general discussion.

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Qin, P., Lv, X., Li, C. et al. Morphology inheritance synthesis of carbon-coated Li3VO4 rods as anode for lithium-ion battery. Sci. China Mater. 62, 1105–1114 (2019). https://doi.org/10.1007/s40843-019-9424-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-019-9424-9