Abstract

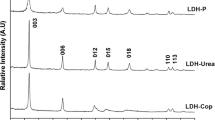

Lithium aluminum layered double hydroxide chlorides (LADH-Cl) are the only industrial-level lithium sorbents. However, as an applied material, the composition-structure-property-performance relation is far from well constrained, leaving the manufacture and application of LADH-Cl lithium sorbents empirical rather than rational. Herein, we studied the phase evolution of gibbsite phase Al(OH)3 in concentrated LiOH aqueous solution, suggesting the formation of lithiated lithium aluminum layered double hydroxide (LADH-OH) with Al:Li molar ratio 2. However, LADH-OH is not an active ingredient as a lithium sorbent. The neutralization of LADH-OH with a dilute HCl aqueous solution resulted in the formation of the active LADH-Cl phase. Unlike the traditional LADH-Cl phase (g-LADH-Cl) generated from direct LiCl intercalation of gibbsite, LADH-OH derived LADH-Cl (b-LADH-Cl) has a topological parent of bayerite instead of gibbsite. This is one of the most important roots for different performances. Another source for the different performance is very likely from variations of the particle size and morphology when the raw gibbsite reacted with LiCl or LiOH aqueous solution. Nevertheless, we found that the limiting-delithiation of b-LADH-Cl is still the same as g-LADH-Cl, that is only maximum 1/3 lithium can be delithiated from the LADH-Cl phase without any decomposition into gibbsite or bayerite. This concluded that b-LADH-Cl and g-LADH-Cl have the same reversible lithium “sorption–desorption” capacity, even through different lithium affinity and sorption kinetics. Also, notably, the “sorption–desorption” performance of the optimal sorbent is very sensitive to the properties of service brines. These results substantially enlarged our knowledge of the LADH-Cl phase and provided a demo of the rational manufacture of lithium sorbent.

Graphical Abstract

Similar content being viewed by others

References

Goldberg V, Dashti A, Egert R, Benny B, Kohl T, Nitschke FV (2023) Challenges and opportunities for lithium extraction from geothermal systems in Germany—part 3: the return of the extraction brine. Energies 16(16):5899

Bae H, Kim Y (2021) Technologies of lithium recycling from waste lithium ion batteries: a review. Mater Adv 2:3234–3250

Alessia A, Alessandro B, Maria VG, Carlos VA, Francesca B (2021) Challenges for sustainable lithium supply: a critical review. J Clean Prod 300:126954

Greim P, Solomon AA, Breyer C (2020) Assessment of lithium criticality in the global energy transition and addressing policy gaps in transportation. Nat Commun 11:4570

Kumar A, Fukuda H, Hatton TA, Lienhard JH (2019) Lithium recovery from oil and gas produced water: a need for a growing energy industry. ACS Energy Lett 4(6):1471–1474

Xu S, Song J, Bi Q, Chen Q, Zhang WM, Qian Z, Zhang L, Xu S, Tang N, He T (2021) Extraction of lithium from Chinese salt-lake brines by membranes: design and practice. J Membr Sci 635:119441

Sanjuan B, Gourcerol B, Millot R, Rettenmaier D, Jeandel E, Rombaut A (2022) Lithium-rich geothermal brines in Europe: an up-date about geochemical characteristics and implications for potential Li resources. Geothermics 101:102385

Kotsupalo N, Ryabtsev A, Poroshina I, Kurakov A, Mamylova E, Menzheres L, Korchagin M (2013) Effect of structure on the sorption properties of chlorine-containing form of double aluminum lithium hydroxide. Russ J Appl Chem 86:482–487

Menzheres L, Ryabtsev A, Mamylova E (2019) Synthesis of selective sorbent LiCl·2Al(OH)3·nH2O. Theor Found Chem Eng 53:821–826

Paranthaman MP, Li L, Luo J, Hoke T, Ucar H, Moyer BA, Harrison S (2017) Recovery of lithium from geothermal brine with lithium−aluminum layered double hydroxide chloride sorbents. Environ Sci Technol 51:13481–13486

Jiang H, Yang Y, Sun S, Yu J (2020) Adsorption of lithium ions on lithium-aluminum hydroxides: equilibrium and kinetics. Can J Chem Eng 98(2):544–555

Zhong J, Lin S, Yu J (2021) Li+ adsorption performance and mechanism using lithium/aluminum layered double hydroxides in low grade brines. Desalination 505:114983

Isupov V, Kotsupalo N, Nemudry A, Menzeres L (1999) Aluminium hydroxide as selective sorbent of lithium salts from brines and technical solutions. Stud Surf Sci Catal 120:621–652

Sheng B, Su H, Yu J, Lin S (2023) Lithium extraction process from low grade Na+/K+ brines dependent on high layer charge layered double hydroxides. Desalination 565:116856

Li J, Luo Q, Dong M, Nie G, Liu Z, Wu Z (2022) Synthesis of granulated Li/Al-LDHs adsorbent and application for recovery of Li from synthetic and real salt lake brines. Hydrometallurgy 209:105828

Britto S, Kamath PS (2009) Structure of bayerite-based lithium-aluminum layered double hydroxides (LDHs): observation of monoclinic symmetry. Inorg Chem 48(24):11646–11654

Li D, Zhang N, Gao D, Zhuang Z, Zeng D (2024) Phase chemistry for hydration sensitive (de)intercalation of lithium aluminum layered double hydroxide chlorides. ACS Mater Au 4(1):45–54

Li Y, Tang N, Zhang L, Li J (2023) Fabrication of Fe-doped Lithium-aluminum-layered hydroxide chloride with enhanced reusable stability inspired by computational theory and its application in lithium extraction. Colloids Surf A 658:130641

Jayanthi K, Lamichhane TN, Roy V, Zhao F, Navrotsky A, Moyer BA, Paranthaman MP (2023) Integrated circular economy model system for direct lithium extraction: from minerals to batteries utilizing aluminum hydroxide. ACS Appl Mater Interfaces 15(50):58984–58993

Wang T, Luo H, Bai Y, Belharouak I, Jayanthi K, Paranthaman MP, Manard BT, Wang ET-H, Dogan F, Son S-B, Ingram BJ, Dai Q, Dai S (2024) Direct recycling of spent nickel-rich cathodes in reciprocal ternary molten salts. J Power Sources 593:233798

Paranthaman MP, Bhave RR, Moyer BA, Harrison S (2019) Composition for recovery of lithium from brines, and process of using said composition. US Patent 10266915

Wu L, Li L, Evans SF, Eskander TA, Moyer BA, Hu Z, Antonick PJ, Harrison S, Paranthaman MP, Riman R et al (2019) Lithium aluminum-layered double hydroxide chlorides (LDH): formation enthalpies and energetics for lithium ion capture. J Am Ceram Soc 102:2398–2404

Wu L, Evans SF, Cheng Y, Navrotsky A, Moyer BA, Harrison S, Paranthaman MP (2019) Neutron spectroscopic and thermochemical characterization of lithium−aluminum−layered double hydroxide chloride: implications for lithium recovery. J Phys Chem C 123:20723–20729

Jayanthi K, Neilsen G, Rosen PF, Andersen CI, Dickson MS, Evans SF, Paranthaman MP, Woodfield BF, Navrotsky A (2022) Cryogenic heat capacity measurements and thermodynamic analysis of lithium aluminum layered double hydroxides (LDHs) with intercalated chloride. Am Mineral 107:709–715

Jayanthi K, Paranthaman MP, Manard BT, Navrotsky A (2023) Effect of anions on the delithiation of [Li-Al] layered double hydroxides: thermodynamic insights. J Phys Chem C 127(49):23879–23886

Graham TR, Hu J-Z, Zhang X, Dembowski M, Jaegers NR, Wan C, Bowden M, Lipton AS, Felmy AR, Clark SB, Rosso KM, Pearce CI (2019) Unraveling gibbsite transformation pathways into LiAl-LDH in concentrated lithium hydroxide. Inorg Chem 58(18):12385–12394

Acknowledgements

D.L. thanks the West Light Foundation of Chinese Academy of Sciences (No. 292022000019), Young Scientist Project of National Key Research and Development Program (No. 2022YFC2906200), and 2023 Kunlun Talents Plan of Qinghai Province for financial support. D.G thanks the Basic Research Project in Qinghai Province (No. 2021-ZJ-747). L.H thanks the 2021 Kunlun Talents Plan of Qinghai Province. We are grateful to Li-Zhi Hong from Shanghai Jiaotong University for ssNMR characterization, and Xiuping Ding from Qinghai Institute of Salt Lakes, CAS for SEM and TEM characterizations.

Funding

This work was financially supported by the West Light Foundation of the Chinese Academy of Sciences (No. 292022000019), Young Scientist Project of the National Key Research and Development Program (No. 2022YFC2906200), 2023 Kunlun Talents Plan of Qinghai Province grant to D. Li, the Basic Research Project in Qinghai Province (No. 2021-ZJ-747) Grant to D. Gao, and 2021 Kunlun Talents Plan of Qinghai Province grant to L. Han.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was Hiromichi Takebe.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

You, C., Li, D., Fan, Y. et al. Rationalize the High Performance of Lithium Sorbents Derived from Gibbsite Guided by Phase Chemistry. J. Sustain. Metall. (2024). https://doi.org/10.1007/s40831-024-00839-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40831-024-00839-w