Abstract

An efficient separation method is crucial for recovering low-value iron from the spent pickling solutions as valuable materials. In this study, selective separation of Fe(III) from the spent pickling effluent was achieved through anti-synergistic solvent extraction, where Cyanex923 and TBP were used as the extractants. The extraction of both Fe(III) and Zn(II) was depressed owing to the molecular interaction between TBP and Cyanex923, but this anti-synergistic role is more evident for zinc. The separation coefficient of Fe(III)/Zn(II) can be improved from 125 to 525 when 0.2 mol/L TBP was mixed with 0.1 mol/L Cyanex923. The structures of the organic phase before and after extraction were disclosed by UV–vis, FT-IR, and SAXS spectroscopies. The addition of TBP can boost Fe(III) stripping because the molecular interaction impairs the combining capacity between Fe(III) and Cyanex923. Moreover, the loaded Fe(III) was recovered as the ferric phosphate precipitates. Therefore, the interaction between Cyanex923 and TBP enhances the separation of Fe(III)/Zn(II) and promotes Fe(III) stripping, thus realizing its efficient recovery and utilization. These results will contribute to the efficient treatment and recycling of spent pickling liquors.

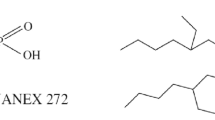

Graphical Abstract

Similar content being viewed by others

References

Regel M, Sastre AM, Szymanowski J (2001) Recovery of zinc(II) from HCI spent pickling solutions by solvent extraction. Environ Sci Technol 35:630. https://doi.org/10.1021/es001470w

Hu S, Xu C, Srinivasakannan C, Tan X, Ni S, Zhang J, Li X, Zhang H, Li S (2022) Recovery of zinc and iron from hot-dip galvanizing spent pickle liquor using solvent extraction. J Mol Liq 362:119741. https://doi.org/10.1016/j.molliq.2022.119741

Arguillarena A, Margallo M, Irabien Á, Urtiaga A (2022) Life cycle assessment of zinc and iron recovery from spent pickling acids by membrane-based solvent extraction and electrowinning. J Environ Manage 318:115567. https://doi.org/10.1016/j.jenvman.2022.115567

Randazzo S, La Corte D, Gueccia R, Cipollina A, Micale G (2021) Metals recovery from waste pickling solutions by reactive precipitation. Chem Eng Trans 86:1045. https://doi.org/10.3303/CET2186175

Wang X, Wang D, Xu J, Fu J, Zheng G, Zhou L (2022) Modified chemical mineralization-alkali neutralization technology: Mineralization behavior at high iron concentrations and its application in sulfur acid spent pickling solution. Water Res 218:118513. https://doi.org/10.1016/j.watres.2022.118513

Wang Y, He Y, Yin S, Long H, Li S (2020) Research on extraction of zinc from spent pickling solution using Aliquat 336. Hydrometallurgy 193:105322. https://doi.org/10.1016/j.hydromet.2020.105322

Zueva SB, Ferella F, Innocenzi V, De Michelis I, Corradini V, Ippolito NM, Vegliò F (2021) Recovery of zinc from treatment of spent acid solutions from the pickling stage of galvanizing plants. Sustainability 13:407. https://doi.org/10.3390/su13010407

Pietrelli L, Ferro S, Vocciante M (2018) Raw materials recovery from spent hydrochloric acid-based galvanizing wastewater. Chem Eng J 341:539. https://doi.org/10.1016/j.cej.2018.02.041

Xu C, Zhou J, Yin S, Wang Y, Zhang L, Hu S, Li X, Li S (2021) Solvent extraction and separation of zinc-iron from spent pickling solution with tri-n-octylamine. Sep Purif Technol 278:119579. https://doi.org/10.1016/j.seppur.2021.119579

Regel M, Sastre AM, Szymanowski J (2001) Recovery of Zinc(II) from HCl spent pickling solutions by solvent extraction. Environ Sci Technol 35:630. https://doi.org/10.1021/es001470w

Mishra RK, Rout PC, Sarangi K, Nathsarma KC (2010) A comparative study on extraction of Fe(III) from chloride leach liquor using TBP, Cyanex 921 and Cyanex 923. Hydrometallurgy 104:298. https://doi.org/10.1016/j.hydromet.2010.07.003

Zhang Y, Tang J, Liu S, Hu F, Liu M, Jin W, Hu J (2020) Extraction separation of copper and cobalt dependent on intermolecular interaction between Cyanex302 and Cyphos IL101. Sep Purif Technol 240:116625. https://doi.org/10.1016/j.seppur.2020.116625

El Dessouky SI, El-Nadi YA, Ahmed IM, Saad EA, Daoud JA (2008) Solvent extraction separation of Zn(II), Fe(II), Fe(III) and Cd(II) using tributylphosphate and CYANEX 921 in kerosene from chloride medium. Chem Eng Process 47:177. https://doi.org/10.1016/j.cep.2007.03.002

Zhang G, Chen D, Wei G, Zhao H, Wang L, Qi T, Meng F, Meng L (2015) Extraction of iron (III) from chloride leaching liquor with high acidity using tri-n-butyl phosphate and synergistic extraction combined with methyl isobutyl ketone. Sep Purif Technol 150:132. https://doi.org/10.1016/j.seppur.2015.07.001

Liu H, Zhang Y-M, Huang J, Liu T, Wang Y-P (2022) Coordination extraction for separating vanadium and impurities from black shale HCl leachate at low pH using D2EHPA and EHEHPA mixture. Sep Purif Technol 302:122088. https://doi.org/10.1016/j.seppur.2022.122088

Sinha MK, Sahu SK, Meshram P, Pandey BD (2014) Solvent extraction and separation of zinc and iron from spent pickle liquor. Hydrometallurgy 147–148:103. https://doi.org/10.1016/j.hydromet.2014.05.006

Xiong Y, Kuang W, Zhao J, Liu H (2017) Ionic liquid-based synergistic extraction of rare earths nitrates without diluent: typical ion-association mechanism. Sep Purif Technol 179:349. https://doi.org/10.1016/j.seppur.2017.02.026

Azizitorghabeh A, Rashchi F, Babakhani A (2016) Stoichiometry and structural studies of Fe(III) and Zn(II) solvent extraction using D2EHPA/TBP. Sep Purif Technol 171:197. https://doi.org/10.1016/j.seppur.2016.07.037

Cui L, Cheng F, Zhou J (2015) Behaviors and mechanism of iron extraction from chloride solutions using undiluted cyphos IL 101. Ind Eng Chem Res 54:7534. https://doi.org/10.1021/acs.iecr.5b01546

Fritz G, Glatter O (2006) Structure and interaction in dense colloidal systems: evaluation of scattering data by the generalized indirect Fourier transformation method. J Phys: Condens Matter 18:S2403. https://doi.org/10.1088/0953-8984/18/36/s14

Erlinger C, Belloni L, Zemb T, Madic C (1999) Attractive interactions between reverse aggregates and phase separation in concentrated malonamide extractant solutions. Langmuir 15:2290. https://doi.org/10.1021/la980313w

Ellis RJ (2014) Critical exponents for solvent extraction resolved using SAXS. J Phys Chem B 118:315. https://doi.org/10.1021/jp408078v

Ellis RJ, Anderson TL, Antonio MR, Braatz A, Nilsson M (2013) A SAXS study of aggregation in the synergistic TBP-HDBP solvent extraction system. J Phys Chem B 117:5916. https://doi.org/10.1021/jp401025e

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (No. 2019YFC1907801), National Natural Science Foundation of China (No. 52174286), and Natural Science Foundation of Hunan Province in China (2023JJ10068).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was Zhongwei Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lei, X., Tang, J., Zhu, P. et al. Fe Separation as Ferric Phosphate from Spent Pickling Liquors Through Anti-synergistic Solvent Extraction. J. Sustain. Metall. 10, 311–319 (2024). https://doi.org/10.1007/s40831-024-00797-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-024-00797-3