Abstract

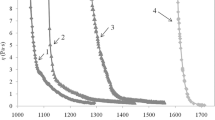

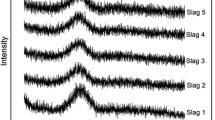

The viscosity measurement of FeO–SiO2–Al2O3–CaO–MgO synthesized slag via inner cylinder-rotation method revealed the effects of Al2O3, CaO, and MgO on the viscosity of FeOx–SiO2 (x = 1.0–1.5) slag melt under the oxygen partial pressure of 4.0 × 10−8 atm at 1200 °C–1300 °C. The spindle and crucible material were Pt–30%Rh, which has high corrosion resistance and maintains sufficient strength in high-temperature melts. The thermodynamic calculation using FactSage predicted the slag components, solid-phase crystallization conditions, and abundance ratio of FeO and Fe2O3 in the slag samples under the melt conditions. The predictions were based on the measured oxygen partial pressure in the slag melt using a self-made zirconia oxygen sensor and analyzed components of the quenched slag samples after viscosity measurement. The viscosity of the slag increased with increasing Al2O3 content (4.0–12.0 mass%) and decreased with increasing CaO and MgO contents (0.0–8.0 and 0.0–6.0 mass%, respectively). A multiregression analysis based on the slag composition and their experimental viscosity was used in deriving the viscosity prediction equation for FeO–SiO2–Al2O3–CaO–MgO slag.

Graphical Abstract

Similar content being viewed by others

References

IEA (2021) Committed mine production and primary demand for copper. 2020–2030. IEA, Paris. IEA Publishing. https://www.iea.org/data-and-statistics/charts/committed-mine-production-and-primary-demand-for-copper-2020-2030. Accessed 3 Mar 2023

Schlesinger ME, King MJ, Sole KC, Davenport WG (2011) Extractive metallurgy of copper, 5th edn. Elsevier, Oxford, pp 73–89

Obe RKD, Brito DJ, Mangabhai R, Lye CQ (2016) Sustainable construction materials: copper slag, 1st edn. Woodhead Publishing, Cambridge, pp 30–34

Bellemans I, Wilde ED, Moelans N, Verbeken K (2018) Metal losses in pyrometallurgical operations—a review. Adv Colloid Interface Sci 255:47–63. https://doi.org/10.1016/j.cis.2017.08.001

Mackey PJ (1982) The physical chemistry of copper smelting slags—a review. Can Metall Q 21:221–260. https://doi.org/10.1179/cmq.1982.21.3.221

Klaffenbach E, Mostaghel S, Guo M, Blanpain B (2021) Thermodynamic analysis of copper smelting, considering the impact of minor elements behavior on slag application options and Cu-recovery. J Sustain Metall 7:664–683. https://doi.org/10.1007/s40831-021-00354-2

Northey S, Haque N, Mudd G (2013) Using sustainability reporting to assess the environmental footprint of copper mining. J Clean Prod 40:118–128. https://doi.org/10.1016/j.jclepro.2012.09.027

Flores GA, Risopatron C, Pease J (2020) Processing of complex materials in the copper industry: Challenges and opportunities ahead. JOM 72:3447–3461. https://doi.org/10.1007/s11837-020-04255-9

Poggi D, Minto R, Davenport WG (1969) Mechanisms of metal entrapment in slags. JOM 21:40–45. https://doi.org/10.1007/BF03378796

Ji F-Z, Sichen D, Seetharaman S (1997) Experimental studies of the viscosities in the CaO-Fen O-SiO2 slags. Metall Trans B 28B:827–834. https://doi.org/10.1007/s11663-997-0010-x

Chen M, Zhao B (2015) Viscosity measurements of SiO2-“FeO”-CaO system in equilibrium with metallic Fe. Metall Trans B 46B:577–584. https://doi.org/10.1007/s11663-014-0241-6

Viswanathan NN, Ji F-Z, Sichen D, Seetharaman S (2001) Viscosity measurements on some fayalite slags. ISIJ Int 41:722–727. https://doi.org/10.2355/isijinternational.41.722

Park H-S, Park SS, Sohn I (2011) The viscous behavior of FeOt-Al2O3-SiO2 copper smelting slags. Metall Trans B 42B:577–584. https://doi.org/10.1007/s11663-011-9512-7

Sukenaga S, Gonda Y, Yoshimura S, Saito N, Nakashima K (2010) Viscosity measurement of calcium ferrite based slags during structural relaxation process. ISIJ Int 50:195–199. https://doi.org/10.2355/isijinternational.50.195

Lee YS, Kim JR, Yi SH, Min DJ (2004) Viscous behaviour of CaO-SiO2-Al2O3-MgO-FeO slag. Proceedings of VII International Conference on Molten Slags 225–230. https://www.pyro.co.za/MoltenSlags2004/225-Lee.pdf. Accessed 28 May 2023

Kuzumaki S, Nishioka N, Fujishiro F, Takebe H (2021) Viscosity measurements of FeO-Fe2O3-SiO2-Al2O3 slag melt under suppression of magnetite formation. J MMIJ (Japan) 137:110–115. https://doi.org/10.2473/journalofmmij.137.110

https://www.factsage.com/. Accessed 3 Mar 2023

Arman TA, Arma LH, Takebe H (2017) Viscosity measurement and prediction of gasified and synthesized coal slag melts. Fuel 200:521–528. https://doi.org/10.1016/j.fuel.2017.03.094

Kemori N, Denholm WT, Kurokawa H (1989) Reaction mechanism in a copper flash smelting furnace. Metall Trans B 20B:327–336. https://doi.org/10.1007/BF02696985

Sack RO, Carmichael ISE, Rivers M, Ghiorso MS (1980) Ferric-ferrous equilibria in natural silicate liquids at 1 bar. Contrib Miner Pet 75:369–376. https://doi.org/10.1007/BF00374720

Shi C, Alderman OLG, Tamalonis A, Weber R, You J, Benmore CJ (2020) Redox-structure dependence of molten iron oxides. Commun Mater 1:1–7. https://doi.org/10.1038/s43246-020-00080-4

Larson HR, Chipman J (1954) Activity of iron in iron-platinum solid solutions. Acta MET 2:1–2. https://doi.org/10.1016/0001-6160(54)90085-1

Vargas S, Frandsen FJ, Dam-Johansen K (2001) Rheological properties of high-temperature melts of coal ashes and other silicates. Prog Energy Combust Sci 27:237–429. https://doi.org/10.1016/S0360-1285(00)00023-X

Alexander MN, Onorato PIK, Struck CW, Rozen JR, Tasker GW, Uhlmann DR (1986) Structure of alkali(alumino)silicate glasses: I. Tl+ luminescence and the non-bridging oxygen issue. J Non-Cryst Solid 79:137–154. https://doi.org/10.1016/0022-3093(86)90042-6

Zhao B, Jak E, Hayes P (2009) Viscosity and electric conductivity of copper slag at controlled oxygen potential. Proceedings of the VIII international conference on molten slags 225–235. https://pyro.co.za/MoltenSlags2009/0225-Zhao.pdf. Accessed 3 Mar 2023

Diaz C (1974) The thermodynamic properties of copper-slag systems. The International Copper Research Assoc Inc, New York, pp 24–59

Acknowledgements

This study was funded by the Mining and Materials Processing Institute of Japan under a Grant-in-Aid.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was M. Akbar Rhamdhani.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Eguchi, T., Nishioka, N. & Takebe, H. Additive Effect of Al2O3, CaO, and MgO on the Viscosity of FeOx–SiO2 Slag Melt (x = 1.0–1.5). J. Sustain. Metall. 9, 1487–1498 (2023). https://doi.org/10.1007/s40831-023-00741-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00741-x