Abstract

Fluorite is widely employed as a fluxing agent in metallurgical processes, inevitably leading to severe pollution. In this study, to promote the development of sustainable metallurgy, B2O3 is used as a fluxing agent of CaO–SiO2–MgO–Al2O3–TiO2–Cr2O3 slag, acting as a replacement for CaF2. The effect of B2O3 on the melting temperature and viscosity of CaO–SiO2–MgO–Al2O3–TiO2–Cr2O3 slag was investigated using a melting-point and melting-rate measurement instrument and a melting physical property comprehensive measurement instrument. Scanning electron microscopy was used to observe the microstructure of the precipitated phase, and X-ray diffraction was used to identify its phase composition. The results indicated that both the melting temperature and viscosity decreased with increasing B2O3 content. Moreover, B2O3 had a significant influence on the morphology of the precipitated phase, particularly for the shape and size of the precipitated particles. Accordingly, with the increase in the B2O3 content, the composition of the precipitated phase and the corresponding diffraction peak intensities changed. The results of this study provide a theoretical and technical basis for the comprehensive utilization of Cr-containing high-titanium melting slag.

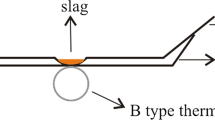

Graphical Abstract

Similar content being viewed by others

References

Hu T, Lv XW, Bai CG, Lun ZG, Qiu GB (2013) Carbothermic reduction of titanomagnetite concentrates with ferrosilicon addition. ISIJ Int 53:557–563

Lv XW, Lun ZG, Yin JQ, Bai CG (2013) Carbothermic reduction of vanadium titanomagnetite by microwave irradiation and smelting behavior. ISIJ Int 53:1115–1119

Shi LY, Zhen YL, Chen DS, Wang LN, Qi T (2018) Carbothermic reduction of vanadium-titanium magnetite in molten NaOH. ISIJ Int 58:627–632

Long HM, Chun TJ, Wang P, Meng QM, Di ZX, Li JX (2016) Grinding kinetics of vanadium-titanium magnetite concentrate in a damp mill and its properties. Metall Mater Trans B 47:1765–1772

Wang YZ, Zhang JL, Liu ZJ, Du CB (2017) Carbothermic reduction reactions at the metal-slag interface in Ti-bearing slag from a blast furnace. JOM 69:2397–2403

Li W, Fu GQ, Chu MS, Zhu MY (2017) Gas-based direct reduction of Hongge vanadium titanomagnetite-oxidized pellet and melting separation of the reduced pellet. Steel Res Int 88:1–10

Samal S, Mohapatra BK, Mukherjee PS (2010) The effect of heat treatment on titania slag. J Min Met Charact Eng 9:795–809

Chen G, Chen J, Song ZK, Srinivasakannan C, Peng JH (2014) A new highly efficient method for the synthesis of rutile TiO2. J Alloys Compd 585:75–77

Fox AB, Mills KC, Lever D, Bezerra C, Valadares C, Unamuno I, Laraudogoitia JJ, Gisby J (2005) Development of fluoride-free fluxes for billet casting. ISIJ Int 45:1051–1058

Klug JL, Silva DR, Freitas SL, Pereira MMSM, Heck NC, Vilela ACF, Jung D (2012) Fluorine-free mould powders for billet casting-technological parameters and industrial tests. Steel Res Int 83:791–799

Mills KC, Fox AB, Li Z, Thackray RP (2005) Performance and properties of mould fluxes. Ironmak Steelmak 32:26–34

Zhou LJ, Wang WL, Wei J, Lu BX (2013) Effect of Na2O and B2O3 on heat transfer behavior of low fluorine mold flux for casting medium carbon steels. ISIJ Int 53:665–672

Qi X, Wen G, Tang P (2008) Investigation on heat transfer performance of fluoride-free and titanium-bearing mold fluxes. J Non-Cryst Solids 354:5444–5452

Viswanathan NN, Ji FZ, Sichen D, Seetharaman S (2001) Viscosity measurements on some fayalite slags. ISIJ Int 41:722–727

Wang HM, Yang LL, Zhu H, Yan YQ (2011) Comparison of effects of B2O3 and CaF2 on metallurgical properties of high basicity CaO-based flux. Adv Mater Res 311:966–969

Qi X, Wen GH, Tang P (2010) Viscosity and viscosity estimate model of fluoride-free and titanium-bearing mold fluxes. J Iron Steel Res 17:6–10

Na XZ, Xue M, Zhang XZ, Gan Y (2007) Numerical simulation of heat transfer and deformation of initial shell in soft contact continuous casting mold under high frequency electromagnetic field. J Iron Steel Res Int 14:14–21

Li GR, Wang HM, Dai QX, Zhao YT, Li JS (2007) Effect of additives on melting point of last refining ladle slag. J Iron Steel Res Int 14:25–29

Gao YH, Bian LT, Liang ZY (2015) Influence of B2O3 and TiO2 on viscosity of titanium-bearing blast furnace slag . Steel Res Int 86:386–390

Wang HM, Zhang TW, Zhu H, Li GR, Yan YQ, Wang JH (2011) Effect of B2O3 on melting temperature, viscosity and desulfurization capacity of CaO-based refining flux. ISIJ Int 51:702–706

Ren S, Zhang JL, Wu LS, Liu WJ, Bai YN, Xing XD, Su BX, Kong DW (2012) Influence of B2O3 on viscosity of high Ti-bearing blast furnace slag. ISIJ Int 52:984–991

He SP (2010) Research of low fluorine and fluorine free mold fluxes. Chongqing University, Chongqing, pp 45–60

Li QH, Yang SF, Zhang YL, An ZQ, Guo ZC (2017) Effects of MgO, Na2O, and B2O3 on the viscosity and structure of Cr2O3-bearing CaO–SiO2–Al2O3 slags. ISIJ Int 57:689–696

Kim GH, Sohn I (2014) Role of B2O3 on the viscosity and structure in the CaO–Al2O3–Na2O-based system. Metall Mater Trans B 45:86–95

Wang HM, Li GR, Dai QX, Li B, Zhang XJ, Shi GM (2013) CAS-OB refining: slag modification with B2O3–CaO and CaF2–CaO. Ironmak Steelmak 34:350–353

Chen M, Raghunath S, Zhao BJ (2013) Viscosity measurements of “FeO”-SiO2 slag in equilibrium with metallic Fe. Metall Mater Trans B 44:506–515

Xu RZ, Zhang JL, Wang ZY, Jiao KX (2017) Influence of Cr2O3 and B2O3 on viscosity and structure of high alumina slag. Steel Res Int 88:1–7

Kim JR, Lee YS, Min DJ, Jung SM, Yi SH (2004) Influence of MgO and Al2O3 contents on viscosity of blast furnace type slags containing FeO. ISIJ Int 44:1291–1297

Wang Q, Chi J (1991) Study on the physical and chemical properties of E2 steel continuous casting mold slag. Sichuan Metall. 3:40–46

Wang Z, Shu QF, Chou KC (2013) Viscosity of fluoride-free mold fluxes containing B2O3 and TiO2. Steel Res Int 84:766–776

Suito HK, Inoue R (2002) Dissolution behavior and stabilization of fluorine in secondary refining slags. ISIJ Int 42:921–929

Lai FF, Yao W, Li JL (2020) Effect of B2O3 on structure of CaO–Al2O3–SiO2–TiO2–B2O3 glassy systems. ISIJ Int 60:1596–1601

Park JY, Kim GH, Kim JB, Park S, Sohn I (2016) Thermo-physical properties of B2O3-containing mold flux for high carbon steels in thin slab continuous casters: structure, viscosity, crystallization, and wettability. Metall Mater Trans B 47:2582–2594

Kline J, Tangstad M, Tranell G (2015) A Raman spectroscopic study of the structural modifications associated with the addition of calcium oxide and boron oxide to silica. Metall Mater Trans B 46:62–73

Kim Y, Morita K (2014) Relationship between molten oxide structure and thermal conductivity in the CaO–SiO2–B2O3 system. ISIJ Int 54:2077–2083

Yang J, Zhang J, Sasaki Y, Ostrovski O, Zhang C, Cai D, Kashiwaya Y (2017) Effect of B2O3 on crystallization behavior, structure, and heat transfer of CaO–SiO2–B2O3–Na2O–TiO2–Al2O3–MgO–Li2O mold fluxes. Metall Mater Trans B 48:2077–2091

Wang Z, Shu QF, Chou KC (2011) Structure of CaO–B2O3–SiO2–TiO2 glasses: a Raman spectral study. ISIJ Int 51:1021–1027

Sun YG, Zhang ZT (2015) Structural roles of boron and silicon in the CaO–SiO2–B2O3 glasses using FTIR, Raman, and NMR spectroscopy. Metall Mater Trans B 46:1549–1554

Li LX, Jia R (2010) Physical chemistry of silicate. Metallurgical Industry Press, Beijing, pp 133–144

Qi CL, Zhang JL, Shao JG, Lu WJ, Zhao ZX, Zhang XS (2011) Study of boronizing mechanism of high-alumina slag. Steel Res Int 82:1319–1324

Wang G, Wang JS, Xue QG (2018) Properties of boron-rich slag separated from boron-bearing iron concentrate. J Cent South Univ 25:783–794

Wang L, Cui YR, Yang J, Zhang C, Cai DX, Zhang JQ, Sasaki Y, Ostrovski O (2015) Melting properties and viscosity of SiO2–CaO–Al2O3–B2O3 system. Steel Res Int 86:670–677

Huang XH, Liao JL, Zheng K, Hu HH, Wang FM, Zhang ZT (2014) Effect of B2O3 addition on viscosity of mould slag containing low silica content. Ironmak Steelmak 41:67–74

Padmaja G, Kistaiah P (2009) Infrared and Raman spectroscopic studies on alkali borate glasses: evidence of mixed alkali effect. J Phys Chem A 113:2397–2404

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (Grant No. 51904066), Liaoning Revitalization Talents Program (Grant No. XLYC1802032), Fundamental Research Funds for the Central Universities (Grant No. N182503032), Postdoctoral Foundation of Northeastern University (Grant No. 20190201), and Postdoctoral International Exchange Program (Dispatch Project, 20190075).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was Mansoor Barati.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, J., Li, W., Fu, G. et al. Effect of B2O3 on the Melting Temperature and Viscosity of CaO–SiO2–MgO–Al2O3–TiO2–Cr2O3 Slag. J. Sustain. Metall. 7, 1190–1199 (2021). https://doi.org/10.1007/s40831-021-00413-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-021-00413-8