Abstract

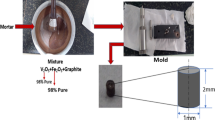

The vanadium industry has experienced significant change over the last two decades with the emergence of vanadium redox flow batteries for grid-level energy storage, the growing demand for high-strength steel, and the selection of vanadium as a critical material in multiple countries. This review presents the status of the vanadium industry examining production processes and detailing facilities. The available information for each producer is presented including vanadium products and capacity. The production of pure vanadium is identified as a potential vulnerability for some nations where vanadium metal is needed in small, yet strategic, applications and globally only two producers of pure V were identified. One potential method to produce pure V is electron beam melt refining. Exploratory electron beam melt refining trials were performed on kilogram quantities of master (V–Al) alloys from the aerospace industry to explore the use of commercially available vanadium alloys to produce pure vanadium metal with minimal processing, as a means to mitigate potential risks.

Graphical Abstract

Similar content being viewed by others

References

Moskalyk RR, Alfantazi AM (2003) Processing of vanadium: a review. Miner Eng 16:793–805. https://doi.org/10.1016/S0892-6875(03)00213-9

Nicholas L (2018) China’s new vanadium-steel rebar standards take effect, what’s next for vanadium market? In: VanadiumCorp Resource Inc. https://www.vanadiumcorp.com/news/industry/chinas-new-vanadium-steel-rebar-standards-take-effect-whats-next-for-vanadium-market/. Accessed 30 Apr 2020

Hilbert J (2018) Vanitec applauds new stricter Chinese Rebar Standards. In: Vanitec. http://vanitec.org/latest-from-vanitec/article/vanitec-applauds-new-stricter-chinese-rebar-standard. Accessed 30 Apr 2020

Roskill (2018) Vanadium: new Chinese rebar standards positive for ferrovanadium demand. https://roskill.com/news/vanadium-new-chinese-rebar-standards-positive-ferrovanadium-demand/. Accessed 30 Apr 2020

Lourenssen K, Williams J, Ahmadpour F et al (2019) Vanadium redox flow batteries: a comprehensive review. J Energy Storage 25:100844. https://doi.org/10.1016/j.est.2019.100844

U.S. Department of Energy (2020) Global Energy Storage Database | Energy Storage Systems. https://www.sandia.gov/ess-ssl/global-energy-storage-database-home/. Accessed 30 Apr 2020

Kotze C (2020) Shining a light on VRFBs for energy storage applications. In: Mining review Africa. https://www.miningreview.com/energy/shining-a-light-on-vrfb-for-energy-storage-applications/. Accessed 30 Apr 2020

U.S. Department of the Interior (2018) Final list of critical minerals 2018. Fed Reg 83:23295–23296

European Commission (2017) The 2017 list of critical raw materials for the EU. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52017DC0490. Accessed 30 Apr 2020

European Commission (2017) Study on the review of the list of critical raw materials: critical raw materials factsheets. In: Publications Office of the European Union. http://op.europa.eu/en/publication-detail/-/publication/7345e3e8-98fc-11e7-b92d-01aa75ed71a1. Accessed 24 Mar 2021

Hayes SM, McCullough EA (2018) Critical minerals: a review of elemental trends in comprehensive criticality studies. Resour Policy 59:192–199. https://doi.org/10.1016/j.resourpol.2018.06.015

Petranikova M, Tkaczyk AH, Bartl A et al (2020) Vanadium sustainability in the context of innovative recycling and sourcing development. Waste Manag 113:521–544. https://doi.org/10.1016/j.wasman.2020.04.007

Thomason J, Johannes E, Last H et al (2019) Estimating supply, demand, and base case shortfalls for high purity chromium and high purity vanadium for U.S. Defense and Essential Civilian Applications in Support of the Strategic and Critical Materials 2019 Report on Stockpile Requirements. Institute of Defense Analysis, Alexandria

Gupta CK (2004) Pyrometallurgy. In: Gupta CK (ed) Chemical metallurgy. John Wiley & Sons, Ltd, pp 343–457

Bakish R (1998) The substance of a technology: electron-beam melting and refining. JOM 50:28

Choudhury A, Hengsberger E (1992) Electron-beam melting and refining of metals and alloys. ISIJ Int 32:673–681. https://doi.org/10.2355/isijinternational.32.673

Sasaki H, Kobashi Y, Nagai T, Maeda M (2013) Application of electron beam melting to the removal of phosphorus from silicon: toward production of solar-grade silicon by metallurgical processes. Adv Mater Sci Eng 2013:857196. https://doi.org/10.1155/2013/857196

Murr LE, Gaytan SM, Ramirez DA et al (2012) Metal fabrication by additive manufacturing using laser and electron beam melting technologies. J Mater Sci Technol 28:1–14. https://doi.org/10.1016/S1005-0302(12)60016-4

Bauer G, Güther V, Hess H, et al (2017) Vanadium and vanadium compounds. In: Ley C, Elvers B (eds) Ullmann’s encyclopedia of industrial chemistry. Wiley‐VCH Verlag GmbH & Co., pp 1–22

Hilliard HE (1994) The materials flow of vanadium in the United States: U.S. Bureau of Mines Information Circular 9409. US Geological Survey

Goonan TG (2011) Vanadium recycling in the United States in 2004. In: Sibley SF (ed) Flow studies for recycling metal commodities. US Geological Survey, pp S1–S17

Marafi M, Stanislaus A (2008) Spent hydroprocessing catalyst management: a review: part II. Advances in metal recovery and safe disposal methods. Resour Conserv Recycl 53:1–26. https://doi.org/10.1016/j.resconrec.2008.08.005

Bushveld Minerals (2019) The vertically integrated primary vanadium producer. In: Bushveld Minerals. http://www.bushveldminerals.com/wp-content/uploads/2019/04/March-2019-Corporate-Presentation.pdf. Accessed 4 May 2020

Equities O (2011) Vanadium sector review. Ocean Equities Ltd, London

Kelley KD, Scott C, Polyak DE, Kimball BE (2017) Vanadium. U.S. Geological Survey, Reston

Taylor PR, Shuey SA, Vidal EE, Gomez JC (2006) Extractive metallurgy of vanadium-containing titaniferous magnetite ores: a review. Min Metall Explor 23:80–86. https://doi.org/10.1007/BF03403340

GE21 Ltda (2017) An updated mine plan, mineral reserve and preliminary economic assessment of the inferred resources. In: Largo Resources Ltd. https://s22.q4cdn.com/197308373/files/doc_downloads/maracas/NI43-101TechRpt(MaracasMen)-Nov8.pdf. Accessed 1 May 2020

Mukherjee TK, Gupta CK (1993) Extraction of vanadium from an industrial waste. High Temp Mater Process 11:189–206. https://doi.org/10.1515/HTMP.1993.11.1-4.189

Trypuć M, Kiełkowska U (1996) Solubility in the NH4HCO3 + NH4VO3 + H2O system. J Chem Eng Data 41:1005–1007. https://doi.org/10.1021/je950290c

International Atomic Energy Agency (1993) Uranium extraction technology. IAEA, Vienna

Energy Fuels Inc. (2019) Energy fuels provides update on vanadium production. In: Energy fuels. https://www.energyfuels.com/2019-04-01-Energy-Fuels-Provides-Update-on-Vanadium-Production. Accessed 30 Apr 2020

Brewer L, Searcy AW (1951) The gaseous species of the Al-Al2O3 system 1,2,3. J Am Chem Soc 73:5308–5314. https://doi.org/10.1021/ja01155a090

Porter RF, Schissel P, Inghram MG (1955) A mass spectrometric study of gaseous species in the Al–Al2O3 system. J Chem Phys 23:339–342. https://doi.org/10.1063/1.1741963

Banchorndhevakul W, Matsui T, Naito K (1986) Vaporization study on vanadium-oxygen solid solution by mass spectrometric method. J Nucl Sci Technol 23:873–882. https://doi.org/10.1080/18811248.1986.9735071

Powell A, Pal U, van den Avyle J et al (1997) Analysis of multicomponent evaporation in electron beam melting and refining of titanium alloys. Metall Mater Trans B 28:1227–1239. https://doi.org/10.1007/s11663-997-0078-3

Safarian J, Engh TA (2013) Vacuum evaporation of pure metals. Metall Mater Trans A 44:747–753. https://doi.org/10.1007/s11661-012-1464-2

Stull D (1972) Vapor pressure. In: Gray DE (ed) American institute of physics handbook, 3rd edn. McGraw Hill, New York

Polyak D (2016) 2015 Mineral yearbook: vanadium. U.S. Geological Survey, Reston

Summerfield D (2019) Australian resource reviews: vanadium 2018. Geoscience Australia, Canberra

Mojapelo F, Nikomarov M (2018) Vanadium 101. In: Bushveld Minerals. http://www.bushveldminerals.com/wp-content/uploads/2018/05/Bushveld-Minerals-Vanadium-101_Final.pdf. Accessed 6 May 2020

Chengde Tianda Vanadium Industry Co., Ltd. (2020) About us. In: Chengde Tianda Vanadium Industry Co. http://www.cdtdfy.com/cn/about.php. Accessed 6 May 2020

EVRAZ plc (2015) EVRAZ annual report 2015. https://www.ar2015.evraz.com/AR2015_EVRAZ.pdf. Accessed 6 May 2020

AMG Titanium Alloys and Coatings GfE (2020) Product overview A-Z. In: GfE Gesellschaft für Elektrometallurgie mbH. http://www.gfe.com/en/products-and-solutions/product-overview-a-z. Accessed 6 May 2020

Rubamin (2020) Zinc & catalyst recycling. In: Rubamin Limited. https://rubamin.com/sourcing/. Accessed 6 May 2020

Shirahase T (1993) Recycling of metals from spent hydrodesulfurizing catalysts. Shigen-to-Sozai 109:1133–1135. https://doi.org/10.2473/shigentosozai.109.1133

Taiyo Koko Co., Ltd. (2015) Vanadium. In: Taiyo Koko Co., Ltd. http://www.taiyokoko.co.jp/en/product/prod02.html. Accessed 6 May 2020

Moxba Metrex (2019) Spent catalyst recycling process and flow. In: Moxba Metrex. https://moxba.com/wp-content/uploads/2019/05/Moxba_Process_Flow_Brochure.pdf. Accessed 6 May 2020

Bushveld Minerals (2020) Vanchem. In: Bushveld Minerals. https://www.bushveldminerals.com/vanchem-vanadium-project/. Accessed 6 May 2020

Glencore (2019) Full year 2018 production report. In: Glencore. https://www.glencore.com/dam/jcr:3c1bb66d-e4f6-43f8-9664-b4541396c297/GLEN-2018-Q4-Production-Report.pdf. Accessed 6 May 2020

Glencore (2020) Ferroalloys. In: Glencore. https://www.glencore.com/what-we-do/metals-and-minerals/ferroalloys. Accessed 6 May 2020

GS Caltex (2012) 2012 sustainability report. In: GS Caltex. https://www.gscaltex.com/download/363. Accessed 6 May 2020

Hong Jing Environment Company (2007) Factory profile. In: Hong Jing Environment Company. http://www.hjec.com.tw/en/Profile02.html. Accessed 7 May 2020

AMG Advanced Metallurgical Group N.V. (2019) Enabling the circular economy—annual report 2019. In: AMG Advanced Metallurgical Group N.V. https://ig9we1q348z124x3t10meupc-wpengine.netdna-ssl.com/wp-content/uploads/AMG-Annual-Report-Web-FINAL.pdf. Accessed 7 May 2020

AMG Advanced Metallurgical Group N.V. (2019) AMG Advanced Metallurgical Group N.V. completes acquisition of international specialty alloys. In: GfE Gesellschaft für Elektrometallurgie mbH. http://www.gfe.com/en/news/news-press-review/amg-advanced-metallurgical-group-n-v-completes-acquisiton-of-international-specialty-alloys-n858.html. Accessed 27 Apr 2020

EVRAZ Stratcor (2015) Product specification: 85% vanadium-aluminum. In: EVRAZ. http://vanadium.evraz.com/upload/Van-Al%202.pdf. Accessed 7 May 2020

Hilliard H (1994) 1994 Mineral yearbook: vanadium. U.S. Geological Survey, Reston

Llanos ZR, Deering WG (2013) Evolution of GCMC’s spent catalyst operations. In: Stewart DL, Daley JC, Stephens RL (eds) Recycling of metals and engineered materials. John Wiley & Sons, Ltd, pp 759–771

Silver Elephant Mining Corp. (2021) Gibellini (Vanadium). In: Silver Elephant Mining Corp. https://www.silverelef.com/projects/gibellini-vanadium/. Accessed 19 Mar 2021

Polyak D (2020) 2017 Mineral yearbook: vanadium. U.S. Geological Survey, Reston

Laney K (2015) Ferrovanadium from China and South Africa. U.S. International Trade Commission, Washington, DC

VanadiumPrice.com (2020) V2O5 vanadium pentoxide flake 98% price. In: LIVE Vanadium Price, News and Articles. https://www.vanadiumprice.com/#. Accessed 7 May 2020

Smith JF (1985) The Si–V (silicon–vanadium) system: addendum. Bull Alloy Phase Diagr 6:266–271. https://doi.org/10.1007/BF02880413

Acknowledgements

This work was performed under the auspices of the US Department of Energy by Lawrence Livermore National Laboratory under Contract DE-AC52-07NA27344. The authors also wish to acknowledge the assistance of Matthew Duncan and Robin Lampson in operating the electron beam furnace.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was Christina Meskers.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rappleye, D., Haun, R. Production of Pure Vanadium: Industry Review and Feasibility Study of Electron Beam Melt Refining of V–Al Alloys. J. Sustain. Metall. 7, 755–766 (2021). https://doi.org/10.1007/s40831-021-00407-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-021-00407-6